2Loose

reliable source of info

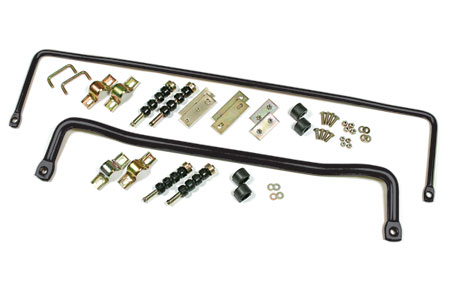

I have quite a collection of sway bars I've pulled off of various rigs over the years.

When setting up a custom build of one sort or another I often can find just the right fit from my "stock pile".....

My latest project is a '55 Chevy "retro" gasser, which I have fitted a '59 Ford F100 front axle under.

It sits 16" off the ground at the rocker panels, and with the blown Olds 425 motor is pretty "top heavy"......

So I figured I better add sway bars to help keep it level on the street. The back is no problem as I have set up parallel ladder bars, and they act like a fairly stiff sway bar. But I thought I better add a sway bar to the front. As I have a front mounted steering box with cross steer, it is in the way of a mount there. The front part of the Moroso pan I'm using allows room where a sway bar could be fitted behind the front axle.

This fit requires a pretty narrow sway bar, and the closest I have been able to come in fitting this up is a sway bar from the rear of a Ranger pickup. I can fit it up under the frame and pan pretty nicely, but the ends angle outward a little too much, and hit my coil-overs that I am running on the front end. So I looked at heating up this sway bar at the bends on each end and bending those front arms on each side inward a couple of inches to get a "perfect" fit (well, at least a fit that will work pretty well....).

The only thing that concerns me is that by heating the sway bar up to "soft" red hot enough to make the bend, I am removing the spring temper from the sway bar!

It's been way too many years since I had my Materials Engineering class in college, but I do remember bits and pieces about annealing, hardening, and tempering carbon steel. Reviewed some sources on the internet recently, and found I was pretty much correct, by heating up that bend, forming it to my specs, and letting it slowly air cool, I am removing the temper or "springiness" at that area. If I water or oil quench it while it is red hot, I "harden" it, which makes it brittle. The correct procedure, as I understand it, is to harden it with a quench, then reheat it to about 700 deg (blue color on polished steel) and oil quench it again to restore the spring temper. The problem is the WHOLE spring or sway bar has to be heat treated in this manner, I can't just do this to the bent area to restore it.

One of my buddies (who really doesn't know what he is doing, but gets away with "murder" sometimes) says to just "heat it, bend it, let it cool, and use it, and quit worrying about it......", which is tempting. It is a 1-1/8" sway bar, plenty stout, by heating and bending just that small area, I might get away with it. But I would hate to render a good sway bar useless by applying heat in this manner without know for sure what I was doing.

Any suggestions?

"2Loose" Willy

When setting up a custom build of one sort or another I often can find just the right fit from my "stock pile".....

My latest project is a '55 Chevy "retro" gasser, which I have fitted a '59 Ford F100 front axle under.

It sits 16" off the ground at the rocker panels, and with the blown Olds 425 motor is pretty "top heavy"......

So I figured I better add sway bars to help keep it level on the street. The back is no problem as I have set up parallel ladder bars, and they act like a fairly stiff sway bar. But I thought I better add a sway bar to the front. As I have a front mounted steering box with cross steer, it is in the way of a mount there. The front part of the Moroso pan I'm using allows room where a sway bar could be fitted behind the front axle.

This fit requires a pretty narrow sway bar, and the closest I have been able to come in fitting this up is a sway bar from the rear of a Ranger pickup. I can fit it up under the frame and pan pretty nicely, but the ends angle outward a little too much, and hit my coil-overs that I am running on the front end. So I looked at heating up this sway bar at the bends on each end and bending those front arms on each side inward a couple of inches to get a "perfect" fit (well, at least a fit that will work pretty well....).

The only thing that concerns me is that by heating the sway bar up to "soft" red hot enough to make the bend, I am removing the spring temper from the sway bar!

It's been way too many years since I had my Materials Engineering class in college, but I do remember bits and pieces about annealing, hardening, and tempering carbon steel. Reviewed some sources on the internet recently, and found I was pretty much correct, by heating up that bend, forming it to my specs, and letting it slowly air cool, I am removing the temper or "springiness" at that area. If I water or oil quench it while it is red hot, I "harden" it, which makes it brittle. The correct procedure, as I understand it, is to harden it with a quench, then reheat it to about 700 deg (blue color on polished steel) and oil quench it again to restore the spring temper. The problem is the WHOLE spring or sway bar has to be heat treated in this manner, I can't just do this to the bent area to restore it.

One of my buddies (who really doesn't know what he is doing, but gets away with "murder" sometimes) says to just "heat it, bend it, let it cool, and use it, and quit worrying about it......", which is tempting. It is a 1-1/8" sway bar, plenty stout, by heating and bending just that small area, I might get away with it. But I would hate to render a good sway bar useless by applying heat in this manner without know for sure what I was doing.

Any suggestions?

"2Loose" Willy