Most guys with corvettes stay with the stock valve covers unless forced into swapping , due too clearance issues caused by the need to use roller rockers, stud girdles or other aftermarket valve train accessories. On some corvettes theres serious clearance issues with the windshield wiper motor housing and valve cover or accessory brackets that make using tall valve covers difficult, or nearly impossible

viewtopic.php?f=44&t=849.

http://garage.grumpysperformance.co...er-rockers-and-stud-girdles.12208/#post-59297

http://garage.grumpysperformance.com/index.php?threads/small-block-best-valve-cover-gasket.16186/

but one thing that has not yet been pointed out is that the taller valve covers do have some slight advantage other that just additional clearance on the rocker assembly, and that slight advantage is they have increased surface area that's exposed to the relatively cool air of the engine compartment,compared to the oil temp, altho the air temp in the engine compartment may reach 170-190 degs its still much cooler than the oil that can reach 210-260 degrees or more while the rpms are high, while racing, that larger surface area allows the constant sheets of oil thrown from the rocker assembly onto the inner surface too cool a bit as it has the heat absorbed as the oil runs over the inner surface on its return to the sump. in effect the taller valve covers greater surface area tends to act like a marginally effective oil cooler that helps cool oil that flows over the valve springs very slightly. now it may only be a few degrees but each little advantage adds to the efficiency of the total lubrication system.

I try to use those tall cast aluminum valve covers just for that reason even if they are not mandatory, but even the tall chrome steel valve covers work here.. another advantage is that the oil separator baffles tend to be positioned further from the flowing oil in the cylinder heads making it less likely that the breathers allow oil film to blow onto the outer engine or the PVC valve to suck oil into the intake on older engines with worn rings

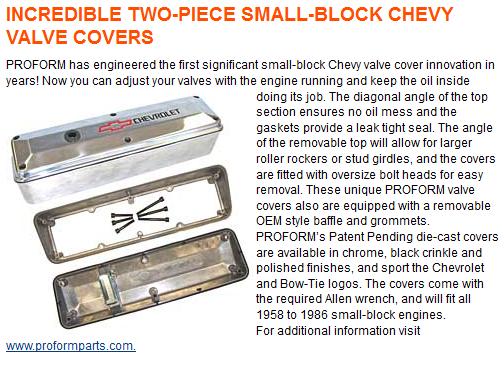

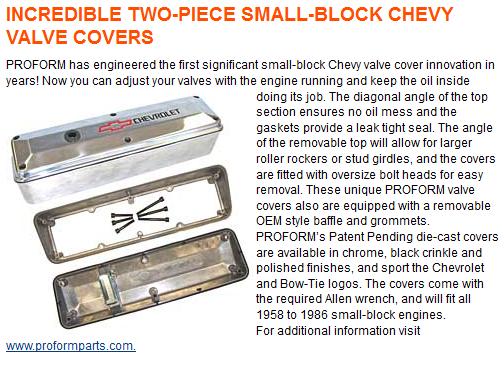

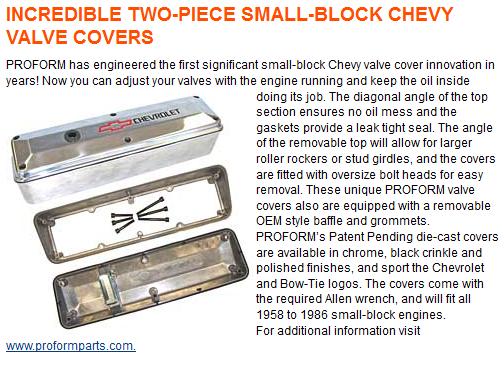

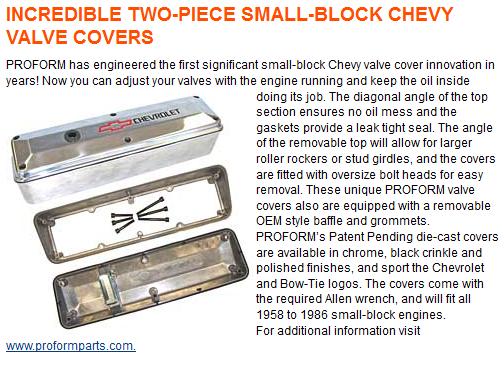

WHILE THESE ARE RATHER EXPENSIVE VALVE COVERS THEY HAVE ADVANTAGES THAT I THINK MAKE THEM WORTH THE COST

http://www.summitracing.com/parts/pro-141-913

READ THE LINKS AND SUB LINKS

viewtopic.php?f=52&t=126&p=1193&hilit=ratio+rockers+louis#p1193

viewtopic.php?f=52&t=181

http://garage.grumpysperformance.co...s-and-valve-cover-install-info.946/#post-1615

http://garage.grumpysperformance.co...g-rocker-ratios-and-the-effects.126/#post-156

BTW if they are sbc perimeter valve covers

JEGS sells these that help a great deal

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=2207&prmenbr=361

a few things you should know

http://www.speedwaymotors.com/Valve-Cover-Adapter-for-Center-Bolt-Heads,1890.html

there are adapters that allow you to run standard , early perimeter bolt valve covers on the later center bolt heads

WHILE THESE ARE RATHER EXPENSIVE VALVE COVERS THEY HAVE ADVANTAGES THAT I THINK MAKE THEM WORTH THE COST

http://www.summitracing.com/parts/pro-141-913

http://www.speedwaymotors.com/Valve-Cover-Adapter-for-Center-Bolt-Heads,1890.html

there are adapters that allow you to run standard , early perimeter bolt valve covers on the later center bolt heads

THE LT1 uses different recessed synthetic valve cover gaskets , than the standard first gen SBC cylinder heads

[1] synthetic oil dissolves that yellow 3m weatherstrip gasket adhesive than many guys use over a few months time so you cant use it to glue valve cover gaskets

[2]you must use a o2 safe gasket cement like the BLACK RTV silicone cement and you must clean and degrease the cover with acetone or a similar solvent before gluing on the gasket to get the best retention

[3]you need to allow at least a few hours to over night,depends mostly on temp. for that black silicone gasket cement to set up before installing the valve covers, and placing them gasket side down on a table with a sheet of wax paper under them and a 20lb weight on top of each valve cover while the cement sets up is the best way to insure the gaskets stay correctly aligned on the valve covers perimeter

[4]a light coat of (PAM) cooking spray on the lower gasket surface keeps them from sticking to the cylinder heads after installation

[5] these gasket retaining rings add a great deal to the valve covers ability to firmly hold the gasket WITHOUT bending SHEET METAL VALVE COVERS OR CRACKING CAST ALUMINUM VALVE COVERS AND ARE WELL WORTH THE MINIMAL COST

[6]doing it correctly the first time saves time and money

viewtopic.php?f=44&t=849.

http://garage.grumpysperformance.co...er-rockers-and-stud-girdles.12208/#post-59297

http://garage.grumpysperformance.com/index.php?threads/small-block-best-valve-cover-gasket.16186/

but one thing that has not yet been pointed out is that the taller valve covers do have some slight advantage other that just additional clearance on the rocker assembly, and that slight advantage is they have increased surface area that's exposed to the relatively cool air of the engine compartment,compared to the oil temp, altho the air temp in the engine compartment may reach 170-190 degs its still much cooler than the oil that can reach 210-260 degrees or more while the rpms are high, while racing, that larger surface area allows the constant sheets of oil thrown from the rocker assembly onto the inner surface too cool a bit as it has the heat absorbed as the oil runs over the inner surface on its return to the sump. in effect the taller valve covers greater surface area tends to act like a marginally effective oil cooler that helps cool oil that flows over the valve springs very slightly. now it may only be a few degrees but each little advantage adds to the efficiency of the total lubrication system.

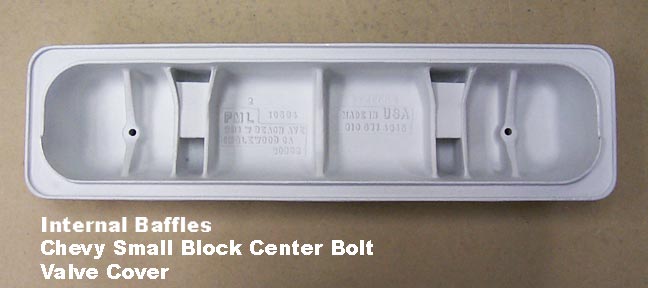

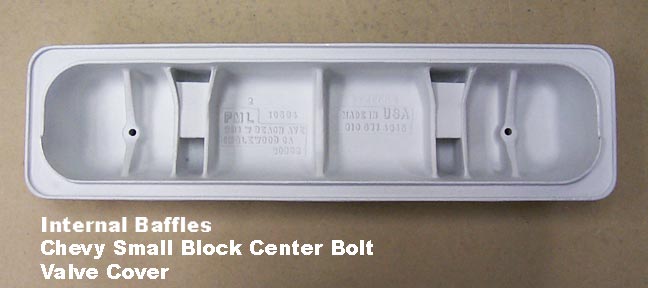

I try to use those tall cast aluminum valve covers just for that reason even if they are not mandatory, but even the tall chrome steel valve covers work here.. another advantage is that the oil separator baffles tend to be positioned further from the flowing oil in the cylinder heads making it less likely that the breathers allow oil film to blow onto the outer engine or the PVC valve to suck oil into the intake on older engines with worn rings

WHILE THESE ARE RATHER EXPENSIVE VALVE COVERS THEY HAVE ADVANTAGES THAT I THINK MAKE THEM WORTH THE COST

http://www.summitracing.com/parts/pro-141-913

READ THE LINKS AND SUB LINKS

viewtopic.php?f=52&t=126&p=1193&hilit=ratio+rockers+louis#p1193

viewtopic.php?f=52&t=181

http://garage.grumpysperformance.co...s-and-valve-cover-install-info.946/#post-1615

http://garage.grumpysperformance.co...g-rocker-ratios-and-the-effects.126/#post-156

BTW if they are sbc perimeter valve covers

JEGS sells these that help a great deal

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=2207&prmenbr=361

a few things you should know

http://www.speedwaymotors.com/Valve-Cover-Adapter-for-Center-Bolt-Heads,1890.html

there are adapters that allow you to run standard , early perimeter bolt valve covers on the later center bolt heads

WHILE THESE ARE RATHER EXPENSIVE VALVE COVERS THEY HAVE ADVANTAGES THAT I THINK MAKE THEM WORTH THE COST

http://www.summitracing.com/parts/pro-141-913

http://www.speedwaymotors.com/Valve-Cover-Adapter-for-Center-Bolt-Heads,1890.html

there are adapters that allow you to run standard , early perimeter bolt valve covers on the later center bolt heads

THE LT1 uses different recessed synthetic valve cover gaskets , than the standard first gen SBC cylinder heads

[1] synthetic oil dissolves that yellow 3m weatherstrip gasket adhesive than many guys use over a few months time so you cant use it to glue valve cover gaskets

[2]you must use a o2 safe gasket cement like the BLACK RTV silicone cement and you must clean and degrease the cover with acetone or a similar solvent before gluing on the gasket to get the best retention

[3]you need to allow at least a few hours to over night,depends mostly on temp. for that black silicone gasket cement to set up before installing the valve covers, and placing them gasket side down on a table with a sheet of wax paper under them and a 20lb weight on top of each valve cover while the cement sets up is the best way to insure the gaskets stay correctly aligned on the valve covers perimeter

[4]a light coat of (PAM) cooking spray on the lower gasket surface keeps them from sticking to the cylinder heads after installation

[5] these gasket retaining rings add a great deal to the valve covers ability to firmly hold the gasket WITHOUT bending SHEET METAL VALVE COVERS OR CRACKING CAST ALUMINUM VALVE COVERS AND ARE WELL WORTH THE MINIMAL COST

[6]doing it correctly the first time saves time and money

Last edited by a moderator: