Ive heard several theory's ,it supposedly has several potential benefits, theres no real debate that its worth an extra 5-15 hp depending on the application, the debates on why the change in the firing order of the cylinders works

the changed firing order tends to spread out the pulse stress on the crankshaft, reducing torsion & induced friction, and it spreads the intake draw into the intake runners from the plenum area making the fuel air ratio distribution a bit more uniform, and it supposedly reduces harmonic vibrations, I'm not sure whats the true reasons but it has usually resulted in a horsepower gain in the 5-7hp range so it obviously doesn,t hurt to go that route, its also suppose to equalize cylinder cooling a bit

READ THIS THREAD ALSO

viewtopic.php?f=52&t=1925

BOGIE POSTED THIS INFO

"Yes it's often good for about 10, 15 horsepower, claims of 30 is telling me that the engine has other problems such as detonation that this is fixing. For the most part all this firing order re-sequencing does is recover otherwise lost power as it corrects to some extent number 7's problems and moves them someplace more tolerant.

The reasons for this improvement are several.

7 and 8 tend to run hot as they see coolant that's passed over 3 cylinders before getting to them, unless you install external plumbing to take coolant off the pump and put in into the block often at the soft plugs. However, some guys drill and tap the block for fittings. The flow from the back of the heads isn’t the best either, 7 and 8 tend to suffer from flow stacking or stalling above the combustion chamber where steam pockets form, more on that in a bit.

Number 7 has the additional problem of exhausting into number 5's slightly earlier event, as a result, has some pressure and temperature problems. It also, tends to get the short end of the mixture stick, especially with a 2 plane manifold and carb. Injection gets around this problem, as do ram designs with 2-4's typical of drag engines. But with a circle track configuration of one carb, there's lots of mixture issues, especially with 7. Attempts to solve this have included cross jetting to richen that side, twisting the carb to move the left rear barrel closer or further from the valve, or the Duntov/Holley "Z" that connects 7 and 8 with a balance pipe have been tried with varying successes. Two plane manifolds have problems on the lower plane, those cylinders see anywhere from 20 to 50 cfm less at WOT and full valve lift than their cousin's feeding off the upper plane. Of these on the lower plane number 7 is by far the worst. This is not a problem unique to Chevy, considering Ford's numbering scheme of 1 thru 4 on the right side and 5 thru 8 on the left, they've always had problems with 7 and 8 which are in the same place on the firing order as Chevy's 5 and 7. From my days at Ford when I was a smoker, I have this really neat collection of melted and busted #8 pistons I used as ash trays once upon a time.

Chevy's tried to deal with the exhaust interference problem a bit with a left side manifold that exits between 5 and 7. But this makes problems for 1 and 3. The Ram horn manifold probably does as good a job as any manifold at getting 5's exhaust out of the way, but all these factory designs allow too much interference as the blasting gases from 5 will happily go back toward 7 then surge back toward the head pipe as much as going promptly out. So 7 is always seeing some additional backpressure and heat that it has to work against. As a fix, headers tend to reduce the 5 to 7 exhaust issues but if you're stuck with factory manifolds you’ve got a problem that really doesn’t have any sort of a solution so far as exhaust interference goes.

Cooling is another large issue both at the cylinder and combustion chamber and getting some control on the back of the engine will result in improved reliability as well as some power not lost to preigniiton or detonation. Coolant flow off the back of the engine is poor having been preheated by the preceding cylinders causing 8 and especially 7 to run hot. A cheapo/weepo cooling solution for the average guy with a street/strip machine, who isn't running air conditioning but just has an old fashion heater, is to put a return fitting on both sides at the rear of the intake where the heater sources hot coolant. Remember to remove any plugs from the manifold to head gasket so the cooling passages are open. Then "Y" or "T" the two sides together and run them into the heater core and back to the pump or radiator connection, which ever return configuration your vehicle has. This provides an extra flow path off the back of the heads and helps eliminate "pressure stacking" and steam pockets within the back of the heads that lead to 7 and 8 running too hot. Lots of racers tap the head temp sender port for a return, while this works pretty well for the right side, on the left the head is flipped around and this tap ends up between 1 and 3 where it isn't needed. So use the heater hose trick off the intake. If your intake isn't set up for a fitting on both sides drill and tap it. You can also do this without the heater core and just run back to the intake side of the cooling system. The problem with air-conditioning is that these systems usually have a shut off valve for the heater, so unless you’re running the heater there’s no coolant flow present.

So the big advantage in changing 7 and 4 around is that 4 is running cooler being only 1 cylinder behind the pump's inlet to the block. But now you've got a 2 to 4 exhaust interference but it has less of an effect because of 4's lower operating temps.

Another trick used in years gone by was to "retard" 7's timing by filing off the leading edge of the contact inside the distributor cap, resulting in the rotor having to move a few degrees further before sparking that cylinder resulting in a little retarded timing right there. That seems self defeating, but if you're loosing power to pre-ignition or detonation, that technique can help squelch it thus increasing power.

I'm going to stop here a moment and say something about the differences between preigniiton and detonation. Somebody wrote in one of these boards I frequent and intimated that pre-ignition and detonation were the same thing. They are not; each has its own cause and very different result. When you have to replace the piston you can see the different failure modes. Pre-ignition is when the mixture commences burning before the spark initiates it. This is usually caused by a piece of carbon, an overheated spark plug, a metal burr or sharp edge that is glowing hot. The failure mode on the piston will be melt, usually down a side thru the ring pack. Detonation happens after the spark has occurred. It's like watching video of a room fire flash over where the temperature and pressure are so high the gasses spontaniously ignite. In the cylinder temperature and pressure ahead of the flame from goes out of control and the unburnt mixture explodes. The failure mode on the piston is a jagged broken hole, like somebody hit it with a sledge hammer. Often you also get a rod bearing failure as the wallop is so heavy it blows the oil film out of the bearing. You may find you're having bearing problems on a cylinder or it may actually blow the rod out of the block, you might be seeing the effect of detonation before the piston has a chance to cave in. Both modes make a pinging sound and until a piston lets go it can be hard to tell which is going on. Both modes respond to getting the cylinder temperature down by whatever technique.

I have to say that of all the books out there on performance engine building, not many say much about cooling. It's like a big racers secret. But the fact is that there are no competitive racers that depend upon water going into the block in front of 1 and 2 flowing to the back of the engine then into the head and returning thru a passage of the intake manifold. Certainly the LT-1 an LT-4 were something of a belated attempt by the factory to deal with temp problems if only those of the head. I'm left to scratch where ever you think my brains are at the Jack Evans law suit against GM regarding utilization of "his" reverse cooling process. Backwards cooling had been done by many race teams for many years by drilling and tapping the water pump arms for AN fittings. Then plugging the water intake to the block thus forcing coolant into the hoses which then fed coolant into the heads, then into the block to be returned from hoses attached to the soft plug locations. This requires a vent line back to the pump from the front and rear of the heads as is done on the LT-1/4. Or a similar set up fed the conventional flow direction by routing into the soft plug locations of the block, flowing internally up to the heads with return fittings drilled and tapped into the ends of the heads, or other options. These techniques establish that no cylinder is more than one away from a fresh coolant source. But they're messy looking and certainly don't fit into the modern look of hiding the engine under plastic covers, Yuk! One might consider that for a street engine that all these hoses reduce cooling system reliability, plus when you bring your drilled and tapped water pump to the parts store as a core for a replacement pump, they probably won't take it."

BOB posted this info

Here's the best information we have at this time.

1)The advantage is in the fuel distribution onto cylinder #2. In the conventional firing order 5 and 7 pull fuel to the back of the engine and then 2 pulls to the front at the opposite end. This became a problem in BBC because the number 2 and 7 cylinder ports are long. 5 helps 7 pull to the back then 2 tries to pull forward and gets lean. You do not see this on 1 and 8 because they are short runners. By revising order (swap 7 and 4), 8 helps 7 and 4 helps 2. Thus, your fuel distribution is more balanced between cylinders.

2)Helps equalize EGT across the board.

3)Works best with 500+cid/7000rpm+ packages. +/- 1% on the dyno.

4)Reduces crankshaft deflection (jurys out on that one)

5)Has been used in Cup/Busch/Craftsman but unconfirmed information has it that it has been outlawed, stock firing order only now. Don, perhaps your contacts can shed some light on that.

6)I have information that some restricted intake class builders have had very good success with the 4/7 cams. That seems to go against the grain but I have heard it from more than one source.

7) Flatter torque curve.

A few points for discussion. Fire away.

heres dyno results from LUNATI

http://www.hotrod.com/techfaq/113_0701_ ... ewall.html

|

|

We just knew it wasn't gonna work. Over the past few years, nearly every cam manufacturer has introduced 4/7-swap cams for big and small Chevys, all claiming that the change in firing order makes power. Lunati was the only cam grinder to actually ask us to test a pair of cams to learn for ourselves what the big deal was. So we did.

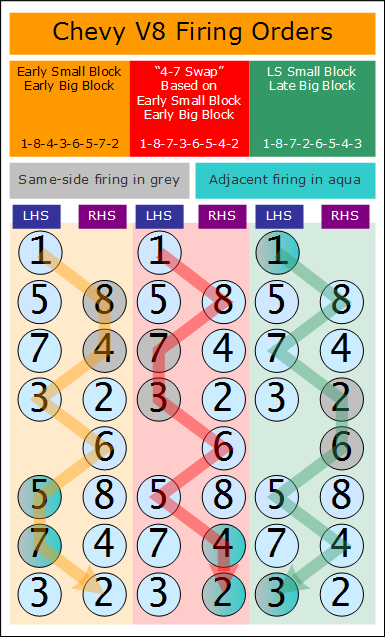

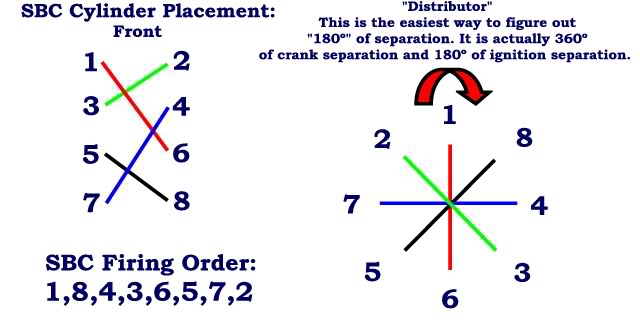

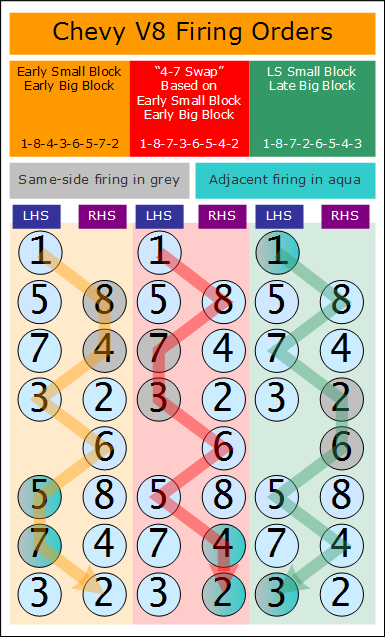

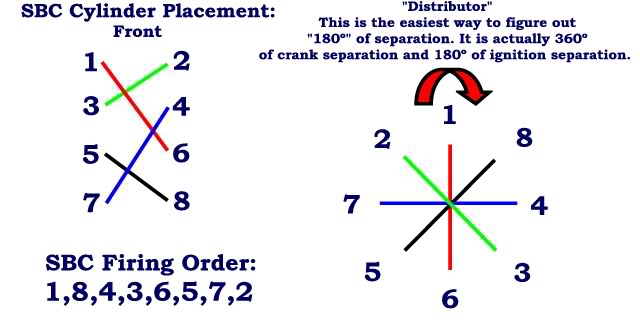

Firing Order Basics

First, let's give you a clue what we're talking about. A 4/7-swap cam changes the engine's firing order, moving the power stroke for cylinder 4 to where 7 used to be, and vice versa. Therefore, a stock Chevy firing order of 1-8-4-3-6-5-7-2 becomes 1-8-7-3-6-5-4-2. To understand how this is done, you need to know about companion cylinders, which are the pairs of cylinders that reach top dead center (TDC) and bottom dead center (BDC) at the same time. On a four-stroke V-8 that fires every 90 degrees (that's any production V-8 you're working on), you can find the companion cylinders by comparing the first half of the firing order to the second half like this:

1-8-4-3

6-5-7-2

Cylinders 1 and 6, 8 and 5, 4 and 7, and 3 and 2 are companions: One in the pair is at TDC of the compression stroke at the exact same time that its companion is at TDC on the exhaust stroke. (When an engine such as the new 5.7L/6.1L Hemi has one coil feeding spark to two cylinders simultaneously, the cylinders that share the same coil are always companions.) Because the piston position in each pair of companion cylinders is identical, it's only the camshaft's timing of the valve opening and closing events that determines which cylinder is on the compression stroke and which one is on the exhaust stroke. In other words, the cam decides the firing order. Therefore, any pair of companion cylinders can swap places in the firing order; all it takes is an altered camshaft, plus moving the location of the spark-plug wires on the distributor cap.

Something You Didn't Know About Fords And Gen IIIsFord figured this out a long time ago. The original firing order for small V-8s, FEs, and 385-series big-blocks is 1-5-4-2-6-3-7-8, so the companion cylinders look like this:

1-5-4-2

6-3-7-8

All 351s and later 5.0L V-8s use 1-3-7-2-6-5-4-8, with these cylinder pairings:

1-3-7-2

6-5-4-8

Lunati 4 7 Swap Cam Test Cams

Here's a standard cam in the...

read full caption

Lunati 4 7 Swap Cam Test Cam Swap

Our cam-swap testing was done...

read full caption

Lunati 4 7 Swap Cam Test Firing Order

This diagram might help you...

read full caption

As you can see, all Ford did was swap the order of cylinders 5 and 3 and cylinders 4 and 7 to get the new firing order. Also, don't forget that Ford numbers its cylinders differently than Chevy. A Ford has 1-2-3-4 on the right (passenger) bank and 5-6-7-8 on the left (driver) side. Chevy is 1-3-5-7 on the left and 2-4-6-8 on the right (see the diagram on the next page). If you simply renumber cylinder locations of the older Ford engines as if they were Chevys, you'll discover that the firing order is, in fact, identical to GM style. Further, if you take the 351 and late-5.0L Ford firing order and renumber the cylinders like a Chevy, the firing order is 1-8-7-2-6-5-4-3. That's the same as the Chevy Gen III and IV (LS-series) V-8s.

In the realm of OE production engines, the altered firing order is said to increase engine smoothness. In fact, when we questioned Gen III valvetrain engineer Steve Pass, he said the firing order was dictated by the crank guy. That was Bill Compton, who had this to say via e-mail: "Since the G3 engine was a clean-slate project, each group looked at things that they could change to optimize the performance of the small-block. Although we did not have an issue with crankshaft loading on the older V-8s, there was room for improvement in the area of distributing the peak firing loads among the five crankshaft journals. Analysis showed that main 4 had peak loads significantly higher than main 2. By changing the firing order, the peak loading on main 4 was reduced and the peak loading on main 2 went up. Overall, the loading through the mains was much better balanced. By improving the load balance across the crank, we created a better balanced oil film interface across the crank. The valvetrain group simply changed the cam lobe timing to work with the new crank firing order."

Which Brings Us To Our Test

So the OEs may have aspirations of smooth reliability, but what about the power benefits? James Humphreys of Lunati thinks it was probably NHRA Pro Stock racer Steve Schmidt who first had success making added horsepower with the firing-order switcharoo, resulting in today's aftermarket offerings of 4/7 swaps. It's also common to see juggling of cylinders 3 and 2, usually in conjunction with the 4 and 7 switch, and that results in an order often called Corvette style, or just "C," and it's the same as a new LS1 (1-8-7-2-6-5-4-3). However, our test was of two Lunati solid-roller cams that were identical other than the 4/7 swap.

The engine is the same 492ci big-block Chevy long-block you last saw in our story, "The Great Bore vs. Stroke Shootout," (June '05). It uses a bore and stroke of 4.560x3.766 with a compression ratio of 10.87:1. Airflow Research 335 CNC heads are sealed with Cometic gaskets, and the induction this time is a Holley 1,050-cfm Dominator atop a port-matched Edelbrock 454-R manifold. We ran MSD ignition and Hooker 2-inch headers with 18-inch extensions and Dynomax 311/42-inch Bullet mufflers. All our testing was done with Lucas synthetic 10W30 oil and Rockett Brand 91-octane gasoline.

Lunati 4 7 Swap Cam Test Test Fit

Prior to testing, we test-fit...

read full caption

Lunati 4 7 Swap Cam Test Dyno

On the dyno, the engine used...

read full caption

Lunati 4 7 Swap Cam Test Cylinder Heads

Lunati cam designers felt...

read full caption

Lunati 4 7 Swap Cam Test Head Gasket

For our past few dyno tests...

read full caption

The Lunati solid-roller cams both had the same lobes: 272/276 duration at 0.050 tappet lift, 0.712/0.712 lift with 1.7:1 rocker arms, and a lobe separation angle of 110 degrees. Once the engine was tuned up with the standard cam, nothing else was changed when we installed the 4/7 swap. We tried total ignition timing settings of 38 , 40 , and 42 degrees with both cams, though 40 degrees proved optimal either way. During testing, we made certain to execute the dyno pulls at exactly the same water and oil temperature.

Guess what? It worked. The 4/7 cam swap gave our pump-gas Rat a little extra midrange power by as much as 12 numbers and added a repeatable 2-3 hp to the top end. Lunati tells us that, cam for cam, the 4/7-swap versions cost $30 more than a standard cam. If we were building a street/strip engine from scratch, it seems like that's $30 we'd choose to spend.

But why?

"No one knows why." That was Reher-Morrison Racing Engines' Darrin Morgan when we asked him why 4/7 swaps make power, and sure enough, we ran into a lot of differing opinions from the experts we spoke with. Morgan told us that every Reher-Morrison crate engine above 555 ci uses a 4/7 cam, and that he's used them to prove gains of 4-6 hp on single-four-barrel engines and 6-8 on tunnel-rams, and the gains are everywhere in the curve. The bigger the displacement, the greater the gain of up to 10 hp. He says he has no hard-core evidence as to why the firing order makes power, as he's seen conflicting information from test to test, but he did comment that, "The Corvette firing order has been proven to be more dynamically stable in the crank, but it's not what made the most power for us. The 4/7 is the only one that makes power on every engine we tested, and it's even better with a properly tuned intake."

On the other end of the opinion scale is Tony Bischoff of BES Racing Engines, a winning NMCA and street-car-racing builder. He told us of three separate back-to-back tests with regular cams and 4/7 cams in small-blocks operating above 6,000 rpm. "You're not going to like the answer," he told us, "because I didn't find any power anywhere." After we bench-raced all the theories, he allowed that, "Some people say the power is due to reduced crank bending, so maybe I don't see anything because I always use the best billet cranks. Others say it's in the intake, but any off-the-shelf intake is symmetrical on both ends."

That comment leads to James Humphreys at Lunati, who's adamant that the power gains are in the intake manifold. Many believe that the point of the 4/7 swap is to prevent cylinders 5 and 7 from firing next to each other and drawing too much from the same area of the intake and carb. However, a 4/7 swap puts cylinders 4 and 2 firing next to each other at the right front of the engine instead of 5 and 7 at the left rear, so what's the difference? Further, if you swap the order of cylinders 3 and 2 in addition to 4 and 7 to get the LS1 firing order, then it's 1 and 3 that fire next to each other. There's no way around it with an even-fire V-8. So the issue is not consecutive firing. According to Humphreys, it's the sequence and location of the pulses in the intake that change locations when you alter the firing order, and which cuts down on reversion.

Finally, Charles Jenckes, in engine development for Dale Earnhardt Inc., puts merit on the theories that the added power is through both intake and crankshaft dynamics, but stresses that overall engine harmonics, and especially those in the valvetrain, also add up in the effect of firing orders. Don't forget this is a guy who's a hero if he can make 1 hp here and there. He was also cautionary about how firing order can affect intake manifold design, stating that, the more highly specialized the intake-including tuned EFI intakes-the more trouble you might cause with cylinder starving if you change the firing order without altering the intake to match. He didn't even want us to make the statement that a 4/7 swap is probably beneficial with nearly any off-the-shelf single-plane, telling us that in our test, "You just got lucky that more cylinders seemed happier for more of the time."

Is it right for you?

Clearly, the 4/7 swap has benefits, but whether you'll see them or not in your engine depends on its purpose. Lunati's Humphreys explains, "It really has to do with good heads and intake. With stock castings, I wouldn't expect to see any difference." In fact, he went so far as to say he'd actually lost a little power once when testing the 4/7 swap on a stock 350 Chevy.

Some claim that the firing-order swap should not be used with a dual-plane intake, as the split-plenum arrangement is tuned for the conventional firing order. And while we have not tested that theory, consider this: Ford did not change the intake design when it changed the firing order. Also, Edelbrock's carbureted dual-plane for GM Gen III engines uses the same exact runner configuration as the old small-blocks.

Weighing all the evidence and even the conflicting opinions, here's our conclusion. If you've got a stock daily driver under 5,000 rpm, the 4/7 swap probably isn't worth messing with. If you're into technology and love messing with EFI and want a new toy to play with to justify individual cylinder tuning, by all means get a 4/7 swap and you might find some power.And if you're building a street/strip or maximum effort engine with a single-plane or a tunnel-ram, spend the extra $30 and find yourself a little power and smoothness.

We knew it would work.

CAM-SWAP POWER

STANDARD

CAMSHAFT

4/7 SWAP

CAMSHAFT CHANGE

RPM LB-FT HP LB-FT HP LB-FT HP

4,400 608.7 510.0 611.8 512.6 +3.1 +2.6

4,500 611.4 523.9 612.0 524.4 +0.6 +0.5

4,600 616.2 539.7 616.0 539.5 -0.2 -0.2

4,700 617.3 552.4 619.4 554.3 +2.1 +1.9

4,800 619.5 566.2 621.0 567.6 +1.5 +1.4

4,900 620.3 578.7 625.5 583.6 +5.2 +4.9

5,000 622.3 592.4 628.9 598.7 +6.6 +6.3

5,100 622.7 604.7 628.4 610.2 +5.7 +5.5

5,200 622.4 616.2 626.7 620.5 +4.3 +4.3

5,300 622.5 628.2 626.0 631.7 +3.5 +3.5

5,400 620.4 637.9 625.2 642.8 +4.8 +4.9

5,500 621.9 651.3 624.9 654.4 +3.0 +3.1

5,600 620.3 661.4 624.3 664.7 +4.0 +3.3

5,700 617.9 670.6 625.9 679.3 +8.0 +8.7

5,800 614.9 679.0 626.5 691.9 +11.6 +12.9

5,900 613.5 689.2 623.7 700.7 +10.2 +11.5

6,000 612.0 699.2 619.7 708.0 +7.7 +8.8

6,100 611.9 710.7 615.0 714.3 +3.1 +3.6

6,200 608.9 718.8 609.6 719.6 +0.7 +0.8

6,300 606.4 727.4 607.3 728.5 +0.9 +1.1

6,400 601.2 732.6 602.0 733.6 +0.8 +1.0

6,500 595.4 736.9 596.7 738.5 +1.3 +1.6

6,600 588.4 739.4 590.3 741.8 +1.9 +2.4

6,700 579.0 738.6 582.3 742.8 +3.3 +4.2

6,800 570.8 739.0 572.3 741.0 +1.5 +2.0

6,900 557.9 733.0 563.4 740.2 +5.5 +7.2

7,000 549.4 732.3 553.5 737.7 +4.1 +5.4

Read more: http://www.hotrod.com/techfaq/113_0701_ ... z1Z0RESmL8

the changed firing order tends to spread out the pulse stress on the crankshaft, reducing torsion & induced friction, and it spreads the intake draw into the intake runners from the plenum area making the fuel air ratio distribution a bit more uniform, and it supposedly reduces harmonic vibrations, I'm not sure whats the true reasons but it has usually resulted in a horsepower gain in the 5-7hp range so it obviously doesn,t hurt to go that route, its also suppose to equalize cylinder cooling a bit

READ THIS THREAD ALSO

viewtopic.php?f=52&t=1925

BOGIE POSTED THIS INFO

"Yes it's often good for about 10, 15 horsepower, claims of 30 is telling me that the engine has other problems such as detonation that this is fixing. For the most part all this firing order re-sequencing does is recover otherwise lost power as it corrects to some extent number 7's problems and moves them someplace more tolerant.

The reasons for this improvement are several.

7 and 8 tend to run hot as they see coolant that's passed over 3 cylinders before getting to them, unless you install external plumbing to take coolant off the pump and put in into the block often at the soft plugs. However, some guys drill and tap the block for fittings. The flow from the back of the heads isn’t the best either, 7 and 8 tend to suffer from flow stacking or stalling above the combustion chamber where steam pockets form, more on that in a bit.

Number 7 has the additional problem of exhausting into number 5's slightly earlier event, as a result, has some pressure and temperature problems. It also, tends to get the short end of the mixture stick, especially with a 2 plane manifold and carb. Injection gets around this problem, as do ram designs with 2-4's typical of drag engines. But with a circle track configuration of one carb, there's lots of mixture issues, especially with 7. Attempts to solve this have included cross jetting to richen that side, twisting the carb to move the left rear barrel closer or further from the valve, or the Duntov/Holley "Z" that connects 7 and 8 with a balance pipe have been tried with varying successes. Two plane manifolds have problems on the lower plane, those cylinders see anywhere from 20 to 50 cfm less at WOT and full valve lift than their cousin's feeding off the upper plane. Of these on the lower plane number 7 is by far the worst. This is not a problem unique to Chevy, considering Ford's numbering scheme of 1 thru 4 on the right side and 5 thru 8 on the left, they've always had problems with 7 and 8 which are in the same place on the firing order as Chevy's 5 and 7. From my days at Ford when I was a smoker, I have this really neat collection of melted and busted #8 pistons I used as ash trays once upon a time.

Chevy's tried to deal with the exhaust interference problem a bit with a left side manifold that exits between 5 and 7. But this makes problems for 1 and 3. The Ram horn manifold probably does as good a job as any manifold at getting 5's exhaust out of the way, but all these factory designs allow too much interference as the blasting gases from 5 will happily go back toward 7 then surge back toward the head pipe as much as going promptly out. So 7 is always seeing some additional backpressure and heat that it has to work against. As a fix, headers tend to reduce the 5 to 7 exhaust issues but if you're stuck with factory manifolds you’ve got a problem that really doesn’t have any sort of a solution so far as exhaust interference goes.

Cooling is another large issue both at the cylinder and combustion chamber and getting some control on the back of the engine will result in improved reliability as well as some power not lost to preigniiton or detonation. Coolant flow off the back of the engine is poor having been preheated by the preceding cylinders causing 8 and especially 7 to run hot. A cheapo/weepo cooling solution for the average guy with a street/strip machine, who isn't running air conditioning but just has an old fashion heater, is to put a return fitting on both sides at the rear of the intake where the heater sources hot coolant. Remember to remove any plugs from the manifold to head gasket so the cooling passages are open. Then "Y" or "T" the two sides together and run them into the heater core and back to the pump or radiator connection, which ever return configuration your vehicle has. This provides an extra flow path off the back of the heads and helps eliminate "pressure stacking" and steam pockets within the back of the heads that lead to 7 and 8 running too hot. Lots of racers tap the head temp sender port for a return, while this works pretty well for the right side, on the left the head is flipped around and this tap ends up between 1 and 3 where it isn't needed. So use the heater hose trick off the intake. If your intake isn't set up for a fitting on both sides drill and tap it. You can also do this without the heater core and just run back to the intake side of the cooling system. The problem with air-conditioning is that these systems usually have a shut off valve for the heater, so unless you’re running the heater there’s no coolant flow present.

So the big advantage in changing 7 and 4 around is that 4 is running cooler being only 1 cylinder behind the pump's inlet to the block. But now you've got a 2 to 4 exhaust interference but it has less of an effect because of 4's lower operating temps.

Another trick used in years gone by was to "retard" 7's timing by filing off the leading edge of the contact inside the distributor cap, resulting in the rotor having to move a few degrees further before sparking that cylinder resulting in a little retarded timing right there. That seems self defeating, but if you're loosing power to pre-ignition or detonation, that technique can help squelch it thus increasing power.

I'm going to stop here a moment and say something about the differences between preigniiton and detonation. Somebody wrote in one of these boards I frequent and intimated that pre-ignition and detonation were the same thing. They are not; each has its own cause and very different result. When you have to replace the piston you can see the different failure modes. Pre-ignition is when the mixture commences burning before the spark initiates it. This is usually caused by a piece of carbon, an overheated spark plug, a metal burr or sharp edge that is glowing hot. The failure mode on the piston will be melt, usually down a side thru the ring pack. Detonation happens after the spark has occurred. It's like watching video of a room fire flash over where the temperature and pressure are so high the gasses spontaniously ignite. In the cylinder temperature and pressure ahead of the flame from goes out of control and the unburnt mixture explodes. The failure mode on the piston is a jagged broken hole, like somebody hit it with a sledge hammer. Often you also get a rod bearing failure as the wallop is so heavy it blows the oil film out of the bearing. You may find you're having bearing problems on a cylinder or it may actually blow the rod out of the block, you might be seeing the effect of detonation before the piston has a chance to cave in. Both modes make a pinging sound and until a piston lets go it can be hard to tell which is going on. Both modes respond to getting the cylinder temperature down by whatever technique.

I have to say that of all the books out there on performance engine building, not many say much about cooling. It's like a big racers secret. But the fact is that there are no competitive racers that depend upon water going into the block in front of 1 and 2 flowing to the back of the engine then into the head and returning thru a passage of the intake manifold. Certainly the LT-1 an LT-4 were something of a belated attempt by the factory to deal with temp problems if only those of the head. I'm left to scratch where ever you think my brains are at the Jack Evans law suit against GM regarding utilization of "his" reverse cooling process. Backwards cooling had been done by many race teams for many years by drilling and tapping the water pump arms for AN fittings. Then plugging the water intake to the block thus forcing coolant into the hoses which then fed coolant into the heads, then into the block to be returned from hoses attached to the soft plug locations. This requires a vent line back to the pump from the front and rear of the heads as is done on the LT-1/4. Or a similar set up fed the conventional flow direction by routing into the soft plug locations of the block, flowing internally up to the heads with return fittings drilled and tapped into the ends of the heads, or other options. These techniques establish that no cylinder is more than one away from a fresh coolant source. But they're messy looking and certainly don't fit into the modern look of hiding the engine under plastic covers, Yuk! One might consider that for a street engine that all these hoses reduce cooling system reliability, plus when you bring your drilled and tapped water pump to the parts store as a core for a replacement pump, they probably won't take it."

BOB posted this info

Here's the best information we have at this time.

1)The advantage is in the fuel distribution onto cylinder #2. In the conventional firing order 5 and 7 pull fuel to the back of the engine and then 2 pulls to the front at the opposite end. This became a problem in BBC because the number 2 and 7 cylinder ports are long. 5 helps 7 pull to the back then 2 tries to pull forward and gets lean. You do not see this on 1 and 8 because they are short runners. By revising order (swap 7 and 4), 8 helps 7 and 4 helps 2. Thus, your fuel distribution is more balanced between cylinders.

2)Helps equalize EGT across the board.

3)Works best with 500+cid/7000rpm+ packages. +/- 1% on the dyno.

4)Reduces crankshaft deflection (jurys out on that one)

5)Has been used in Cup/Busch/Craftsman but unconfirmed information has it that it has been outlawed, stock firing order only now. Don, perhaps your contacts can shed some light on that.

6)I have information that some restricted intake class builders have had very good success with the 4/7 cams. That seems to go against the grain but I have heard it from more than one source.

7) Flatter torque curve.

A few points for discussion. Fire away.

heres dyno results from LUNATI

http://www.hotrod.com/techfaq/113_0701_ ... ewall.html

|

|

We just knew it wasn't gonna work. Over the past few years, nearly every cam manufacturer has introduced 4/7-swap cams for big and small Chevys, all claiming that the change in firing order makes power. Lunati was the only cam grinder to actually ask us to test a pair of cams to learn for ourselves what the big deal was. So we did.

Firing Order Basics

First, let's give you a clue what we're talking about. A 4/7-swap cam changes the engine's firing order, moving the power stroke for cylinder 4 to where 7 used to be, and vice versa. Therefore, a stock Chevy firing order of 1-8-4-3-6-5-7-2 becomes 1-8-7-3-6-5-4-2. To understand how this is done, you need to know about companion cylinders, which are the pairs of cylinders that reach top dead center (TDC) and bottom dead center (BDC) at the same time. On a four-stroke V-8 that fires every 90 degrees (that's any production V-8 you're working on), you can find the companion cylinders by comparing the first half of the firing order to the second half like this:

1-8-4-3

6-5-7-2

Cylinders 1 and 6, 8 and 5, 4 and 7, and 3 and 2 are companions: One in the pair is at TDC of the compression stroke at the exact same time that its companion is at TDC on the exhaust stroke. (When an engine such as the new 5.7L/6.1L Hemi has one coil feeding spark to two cylinders simultaneously, the cylinders that share the same coil are always companions.) Because the piston position in each pair of companion cylinders is identical, it's only the camshaft's timing of the valve opening and closing events that determines which cylinder is on the compression stroke and which one is on the exhaust stroke. In other words, the cam decides the firing order. Therefore, any pair of companion cylinders can swap places in the firing order; all it takes is an altered camshaft, plus moving the location of the spark-plug wires on the distributor cap.

Something You Didn't Know About Fords And Gen IIIsFord figured this out a long time ago. The original firing order for small V-8s, FEs, and 385-series big-blocks is 1-5-4-2-6-3-7-8, so the companion cylinders look like this:

1-5-4-2

6-3-7-8

All 351s and later 5.0L V-8s use 1-3-7-2-6-5-4-8, with these cylinder pairings:

1-3-7-2

6-5-4-8

Lunati 4 7 Swap Cam Test Cams

Here's a standard cam in the...

read full caption

Lunati 4 7 Swap Cam Test Cam Swap

Our cam-swap testing was done...

read full caption

Lunati 4 7 Swap Cam Test Firing Order

This diagram might help you...

read full caption

As you can see, all Ford did was swap the order of cylinders 5 and 3 and cylinders 4 and 7 to get the new firing order. Also, don't forget that Ford numbers its cylinders differently than Chevy. A Ford has 1-2-3-4 on the right (passenger) bank and 5-6-7-8 on the left (driver) side. Chevy is 1-3-5-7 on the left and 2-4-6-8 on the right (see the diagram on the next page). If you simply renumber cylinder locations of the older Ford engines as if they were Chevys, you'll discover that the firing order is, in fact, identical to GM style. Further, if you take the 351 and late-5.0L Ford firing order and renumber the cylinders like a Chevy, the firing order is 1-8-7-2-6-5-4-3. That's the same as the Chevy Gen III and IV (LS-series) V-8s.

In the realm of OE production engines, the altered firing order is said to increase engine smoothness. In fact, when we questioned Gen III valvetrain engineer Steve Pass, he said the firing order was dictated by the crank guy. That was Bill Compton, who had this to say via e-mail: "Since the G3 engine was a clean-slate project, each group looked at things that they could change to optimize the performance of the small-block. Although we did not have an issue with crankshaft loading on the older V-8s, there was room for improvement in the area of distributing the peak firing loads among the five crankshaft journals. Analysis showed that main 4 had peak loads significantly higher than main 2. By changing the firing order, the peak loading on main 4 was reduced and the peak loading on main 2 went up. Overall, the loading through the mains was much better balanced. By improving the load balance across the crank, we created a better balanced oil film interface across the crank. The valvetrain group simply changed the cam lobe timing to work with the new crank firing order."

Which Brings Us To Our Test

So the OEs may have aspirations of smooth reliability, but what about the power benefits? James Humphreys of Lunati thinks it was probably NHRA Pro Stock racer Steve Schmidt who first had success making added horsepower with the firing-order switcharoo, resulting in today's aftermarket offerings of 4/7 swaps. It's also common to see juggling of cylinders 3 and 2, usually in conjunction with the 4 and 7 switch, and that results in an order often called Corvette style, or just "C," and it's the same as a new LS1 (1-8-7-2-6-5-4-3). However, our test was of two Lunati solid-roller cams that were identical other than the 4/7 swap.

The engine is the same 492ci big-block Chevy long-block you last saw in our story, "The Great Bore vs. Stroke Shootout," (June '05). It uses a bore and stroke of 4.560x3.766 with a compression ratio of 10.87:1. Airflow Research 335 CNC heads are sealed with Cometic gaskets, and the induction this time is a Holley 1,050-cfm Dominator atop a port-matched Edelbrock 454-R manifold. We ran MSD ignition and Hooker 2-inch headers with 18-inch extensions and Dynomax 311/42-inch Bullet mufflers. All our testing was done with Lucas synthetic 10W30 oil and Rockett Brand 91-octane gasoline.

Lunati 4 7 Swap Cam Test Test Fit

Prior to testing, we test-fit...

read full caption

Lunati 4 7 Swap Cam Test Dyno

On the dyno, the engine used...

read full caption

Lunati 4 7 Swap Cam Test Cylinder Heads

Lunati cam designers felt...

read full caption

Lunati 4 7 Swap Cam Test Head Gasket

For our past few dyno tests...

read full caption

The Lunati solid-roller cams both had the same lobes: 272/276 duration at 0.050 tappet lift, 0.712/0.712 lift with 1.7:1 rocker arms, and a lobe separation angle of 110 degrees. Once the engine was tuned up with the standard cam, nothing else was changed when we installed the 4/7 swap. We tried total ignition timing settings of 38 , 40 , and 42 degrees with both cams, though 40 degrees proved optimal either way. During testing, we made certain to execute the dyno pulls at exactly the same water and oil temperature.

Guess what? It worked. The 4/7 cam swap gave our pump-gas Rat a little extra midrange power by as much as 12 numbers and added a repeatable 2-3 hp to the top end. Lunati tells us that, cam for cam, the 4/7-swap versions cost $30 more than a standard cam. If we were building a street/strip engine from scratch, it seems like that's $30 we'd choose to spend.

But why?

"No one knows why." That was Reher-Morrison Racing Engines' Darrin Morgan when we asked him why 4/7 swaps make power, and sure enough, we ran into a lot of differing opinions from the experts we spoke with. Morgan told us that every Reher-Morrison crate engine above 555 ci uses a 4/7 cam, and that he's used them to prove gains of 4-6 hp on single-four-barrel engines and 6-8 on tunnel-rams, and the gains are everywhere in the curve. The bigger the displacement, the greater the gain of up to 10 hp. He says he has no hard-core evidence as to why the firing order makes power, as he's seen conflicting information from test to test, but he did comment that, "The Corvette firing order has been proven to be more dynamically stable in the crank, but it's not what made the most power for us. The 4/7 is the only one that makes power on every engine we tested, and it's even better with a properly tuned intake."

On the other end of the opinion scale is Tony Bischoff of BES Racing Engines, a winning NMCA and street-car-racing builder. He told us of three separate back-to-back tests with regular cams and 4/7 cams in small-blocks operating above 6,000 rpm. "You're not going to like the answer," he told us, "because I didn't find any power anywhere." After we bench-raced all the theories, he allowed that, "Some people say the power is due to reduced crank bending, so maybe I don't see anything because I always use the best billet cranks. Others say it's in the intake, but any off-the-shelf intake is symmetrical on both ends."

That comment leads to James Humphreys at Lunati, who's adamant that the power gains are in the intake manifold. Many believe that the point of the 4/7 swap is to prevent cylinders 5 and 7 from firing next to each other and drawing too much from the same area of the intake and carb. However, a 4/7 swap puts cylinders 4 and 2 firing next to each other at the right front of the engine instead of 5 and 7 at the left rear, so what's the difference? Further, if you swap the order of cylinders 3 and 2 in addition to 4 and 7 to get the LS1 firing order, then it's 1 and 3 that fire next to each other. There's no way around it with an even-fire V-8. So the issue is not consecutive firing. According to Humphreys, it's the sequence and location of the pulses in the intake that change locations when you alter the firing order, and which cuts down on reversion.

Finally, Charles Jenckes, in engine development for Dale Earnhardt Inc., puts merit on the theories that the added power is through both intake and crankshaft dynamics, but stresses that overall engine harmonics, and especially those in the valvetrain, also add up in the effect of firing orders. Don't forget this is a guy who's a hero if he can make 1 hp here and there. He was also cautionary about how firing order can affect intake manifold design, stating that, the more highly specialized the intake-including tuned EFI intakes-the more trouble you might cause with cylinder starving if you change the firing order without altering the intake to match. He didn't even want us to make the statement that a 4/7 swap is probably beneficial with nearly any off-the-shelf single-plane, telling us that in our test, "You just got lucky that more cylinders seemed happier for more of the time."

Is it right for you?

Clearly, the 4/7 swap has benefits, but whether you'll see them or not in your engine depends on its purpose. Lunati's Humphreys explains, "It really has to do with good heads and intake. With stock castings, I wouldn't expect to see any difference." In fact, he went so far as to say he'd actually lost a little power once when testing the 4/7 swap on a stock 350 Chevy.

Some claim that the firing-order swap should not be used with a dual-plane intake, as the split-plenum arrangement is tuned for the conventional firing order. And while we have not tested that theory, consider this: Ford did not change the intake design when it changed the firing order. Also, Edelbrock's carbureted dual-plane for GM Gen III engines uses the same exact runner configuration as the old small-blocks.

Weighing all the evidence and even the conflicting opinions, here's our conclusion. If you've got a stock daily driver under 5,000 rpm, the 4/7 swap probably isn't worth messing with. If you're into technology and love messing with EFI and want a new toy to play with to justify individual cylinder tuning, by all means get a 4/7 swap and you might find some power.And if you're building a street/strip or maximum effort engine with a single-plane or a tunnel-ram, spend the extra $30 and find yourself a little power and smoothness.

We knew it would work.

CAM-SWAP POWER

STANDARD

CAMSHAFT

4/7 SWAP

CAMSHAFT CHANGE

RPM LB-FT HP LB-FT HP LB-FT HP

4,400 608.7 510.0 611.8 512.6 +3.1 +2.6

4,500 611.4 523.9 612.0 524.4 +0.6 +0.5

4,600 616.2 539.7 616.0 539.5 -0.2 -0.2

4,700 617.3 552.4 619.4 554.3 +2.1 +1.9

4,800 619.5 566.2 621.0 567.6 +1.5 +1.4

4,900 620.3 578.7 625.5 583.6 +5.2 +4.9

5,000 622.3 592.4 628.9 598.7 +6.6 +6.3

5,100 622.7 604.7 628.4 610.2 +5.7 +5.5

5,200 622.4 616.2 626.7 620.5 +4.3 +4.3

5,300 622.5 628.2 626.0 631.7 +3.5 +3.5

5,400 620.4 637.9 625.2 642.8 +4.8 +4.9

5,500 621.9 651.3 624.9 654.4 +3.0 +3.1

5,600 620.3 661.4 624.3 664.7 +4.0 +3.3

5,700 617.9 670.6 625.9 679.3 +8.0 +8.7

5,800 614.9 679.0 626.5 691.9 +11.6 +12.9

5,900 613.5 689.2 623.7 700.7 +10.2 +11.5

6,000 612.0 699.2 619.7 708.0 +7.7 +8.8

6,100 611.9 710.7 615.0 714.3 +3.1 +3.6

6,200 608.9 718.8 609.6 719.6 +0.7 +0.8

6,300 606.4 727.4 607.3 728.5 +0.9 +1.1

6,400 601.2 732.6 602.0 733.6 +0.8 +1.0

6,500 595.4 736.9 596.7 738.5 +1.3 +1.6

6,600 588.4 739.4 590.3 741.8 +1.9 +2.4

6,700 579.0 738.6 582.3 742.8 +3.3 +4.2

6,800 570.8 739.0 572.3 741.0 +1.5 +2.0

6,900 557.9 733.0 563.4 740.2 +5.5 +7.2

7,000 549.4 732.3 553.5 737.7 +4.1 +5.4

Read more: http://www.hotrod.com/techfaq/113_0701_ ... z1Z0RESmL8