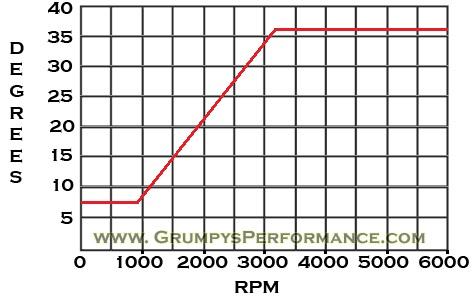

basically a electronic microphone designed to recognize a specific frequency, that the cars computer uses to retard the ignition timing to reduce potential damage that could destroy your engine from DETONATION in the cylinders caused by low octane fuel, excessive temperatures or an ignition advance curve thats too aggressive, the sensors DO GO BAD, but the most common cause of related trouble codes Ive seen relates to broken or melted electrical connections and shorted or loose wires

READ THIS THREAD

viewtopic.php?f=80&t=728&p=9217&hilit=trouble+codes#p9217

http://www.engineblox.com/?p=65

http://www.wellsve.com/sft503/counterp_v4_i4_2000.pdf

http://www.ehow.com/how-does_5491841_kn ... -work.html

http://forums.nicoclub.com/how-do-knock ... 25199.html

http://www.cartechautoparts.com/engine-knock-sensor/

http://www.megamanual.com/ms2/knock.htm

think you may have a blown head gasket or cracked heads ETC??

have you tested for a cracked head or block with the reactive dye in the coolant that shows exhaust gasses contamination?

watch this link

http://www.youtube.com/watch?v=QA7KVQq9vKA

http://www.freeengineinfo.com/knock-sensor.htm

A knock sensor is generally used on turbocharged or high compression performance engines. The knock sensor is generally screwed into the engine block for all cars. To test the knock sensor, generally you can tap a wrench on it as it runs. The engine should change idle speed as the timing retards. If the idle speed doesn’t change, try again at a slightly higher rpm. If the speed once again dosen’t change the knock sensor probably doesn’t work. High performance engines are alot more prone to detonating when they are under boost. The timing on a turbocharged engine should retard when the boost comes on. If the boost would go too high the timing will be too advanced for the higher boost and will detonate. If the engine detonates it builds very high pressure waves. This can damage the engine’s pistons, bearings and crankshaft. The knock sensor senses the very high frequency pressure waves ocurring inside the cylinder. If the knock sensor is tightened too tight or is too loose it can effect the measurable frequency band. The tightening torque depends on the knock sensor specification for that engine. If it is incorrectly tightened it will sense other vibrations in the engine and incorrectly believe that there is a problem. The knock sensor works by simply retarding the timing until the detonaton quits. The driver should feel the significant decrease in power as it retards. It saves the engine from detonation which will break pistons and burn up head gaskets.

http://www.ehow.com/how_8003993_check-k ... nuity.html

The knock sensor within your vehicle is a component designed to listen for engine detonation, or knocking. The knock sensor is a crucial part of the engine, as detonation is harmful to the engine; detonation is the result of fuel and air mixture exploding quickly instead of burning evenly. It's important that your engine knock sensor work properly to detect the detonation of the engine. The knock sensor should have continuity, which is a current electrical path between the wire and sensor. If continuity does not exist, the sensor cannot function properly; the sensor can be tested for continuity with a multimeter.

Instructions

Things You'll Need

Multimeter

1

Park the vehicle on a level surface. Turn the engine off and engage the emergency brake. Open the hood of the vehicle and then turn the engine back on. It's best to engage the emergency brake and open the hood with the engine off to prevent possible injury.

2

Locate the knock sensor. The component is found on the engine manifold, mounted beneath the intake manifold in the middle of the engine. The knock sensor is connected with a wire harness coming out of the top. The location will vary slightly by manufacturer; refer to your repair manual for an exact diagram.

3

Disconnect the wire harness from the knock sensor. Pull on the base of the harness where it meets the sensor.

4

Clip the multimeter lead to the knock sensor; connect the negative multimeter lead to a ground point, such as the negative battery terminal. Continuity should exist, and the multimeter should read more than 10 ohms. If there is no continuity, the sensor should be replaced.

http://www.ecklerscorvette.com/corvette ... -1996.html

Corvette Knock Sensor Test Tool, 1985-1996

Test Accuracy Of Sensors

For Use With Digital Voltmeter

GMP'S Sensor Test Tools help you maintain a smooth, efficient running vehicle. Each tool plugs directly into the appropriate sensors. Use voltmeter (not included) to determine whether or not a signal is being exchanged between the sensor and computer. The tool helps read the accuracy of that signal.

RELATED INFO

http://www.highperformancepontiac.com/t ... index.html

viewtopic.php?f=52&t=2630&p=15954&hilit=detonation#p15954

viewtopic.php?f=52&t=2630&p=13145&hilit=detonation#p13145

viewtopic.php?f=57&t=4701&p=15021&hilit=detonation#p15021

viewtopic.php?f=86&t=5034&p=14207&hilit=detonation#p14207

viewtopic.php?f=52&t=4081&p=13147&hilit=detonation#p13147

viewtopic.php?f=52&t=727&p=12783&hilit=detonation#p12783

viewtopic.php?f=55&t=613&p=12677&hilit=detonation#p12677

viewtopic.php?f=53&t=3443&p=9118&hilit=detonation#p9118

READ THIS THREAD

viewtopic.php?f=80&t=728&p=9217&hilit=trouble+codes#p9217

http://www.engineblox.com/?p=65

http://www.wellsve.com/sft503/counterp_v4_i4_2000.pdf

http://www.ehow.com/how-does_5491841_kn ... -work.html

http://forums.nicoclub.com/how-do-knock ... 25199.html

http://www.cartechautoparts.com/engine-knock-sensor/

http://www.megamanual.com/ms2/knock.htm

think you may have a blown head gasket or cracked heads ETC??

have you tested for a cracked head or block with the reactive dye in the coolant that shows exhaust gasses contamination?

watch this link

http://www.youtube.com/watch?v=QA7KVQq9vKA

http://www.freeengineinfo.com/knock-sensor.htm

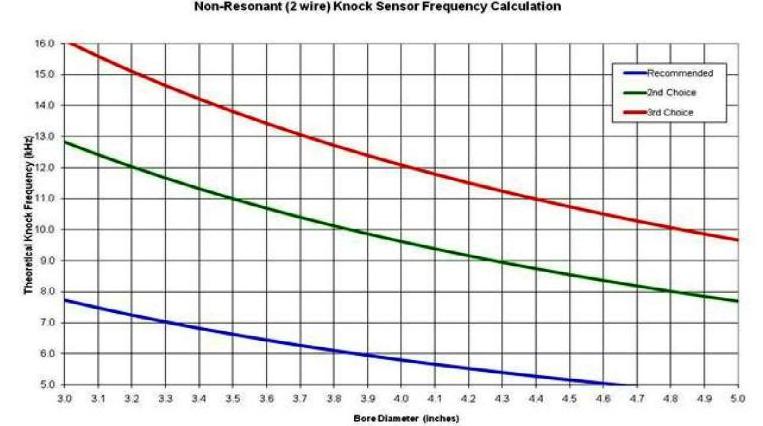

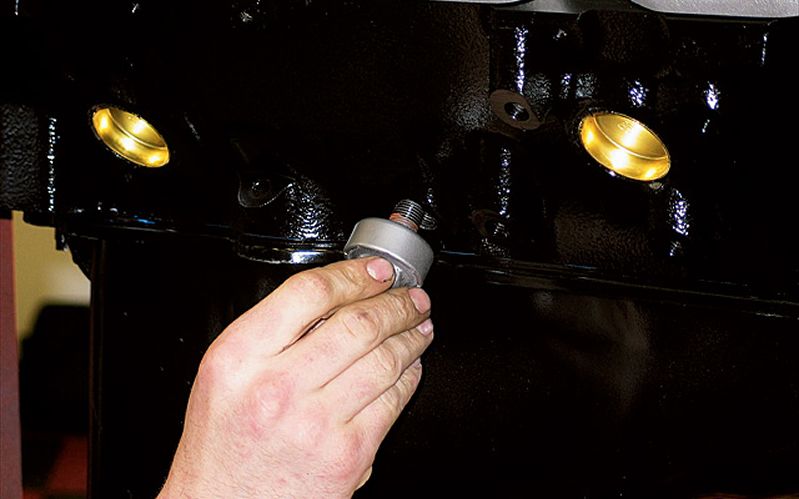

A knock sensor is generally used on turbocharged or high compression performance engines. The knock sensor is generally screwed into the engine block for all cars. To test the knock sensor, generally you can tap a wrench on it as it runs. The engine should change idle speed as the timing retards. If the idle speed doesn’t change, try again at a slightly higher rpm. If the speed once again dosen’t change the knock sensor probably doesn’t work. High performance engines are alot more prone to detonating when they are under boost. The timing on a turbocharged engine should retard when the boost comes on. If the boost would go too high the timing will be too advanced for the higher boost and will detonate. If the engine detonates it builds very high pressure waves. This can damage the engine’s pistons, bearings and crankshaft. The knock sensor senses the very high frequency pressure waves ocurring inside the cylinder. If the knock sensor is tightened too tight or is too loose it can effect the measurable frequency band. The tightening torque depends on the knock sensor specification for that engine. If it is incorrectly tightened it will sense other vibrations in the engine and incorrectly believe that there is a problem. The knock sensor works by simply retarding the timing until the detonaton quits. The driver should feel the significant decrease in power as it retards. It saves the engine from detonation which will break pistons and burn up head gaskets.

http://www.ehow.com/how_8003993_check-k ... nuity.html

The knock sensor within your vehicle is a component designed to listen for engine detonation, or knocking. The knock sensor is a crucial part of the engine, as detonation is harmful to the engine; detonation is the result of fuel and air mixture exploding quickly instead of burning evenly. It's important that your engine knock sensor work properly to detect the detonation of the engine. The knock sensor should have continuity, which is a current electrical path between the wire and sensor. If continuity does not exist, the sensor cannot function properly; the sensor can be tested for continuity with a multimeter.

Instructions

Things You'll Need

Multimeter

1

Park the vehicle on a level surface. Turn the engine off and engage the emergency brake. Open the hood of the vehicle and then turn the engine back on. It's best to engage the emergency brake and open the hood with the engine off to prevent possible injury.

2

Locate the knock sensor. The component is found on the engine manifold, mounted beneath the intake manifold in the middle of the engine. The knock sensor is connected with a wire harness coming out of the top. The location will vary slightly by manufacturer; refer to your repair manual for an exact diagram.

3

Disconnect the wire harness from the knock sensor. Pull on the base of the harness where it meets the sensor.

4

Clip the multimeter lead to the knock sensor; connect the negative multimeter lead to a ground point, such as the negative battery terminal. Continuity should exist, and the multimeter should read more than 10 ohms. If there is no continuity, the sensor should be replaced.

http://www.ecklerscorvette.com/corvette ... -1996.html

Corvette Knock Sensor Test Tool, 1985-1996

Test Accuracy Of Sensors

For Use With Digital Voltmeter

GMP'S Sensor Test Tools help you maintain a smooth, efficient running vehicle. Each tool plugs directly into the appropriate sensors. Use voltmeter (not included) to determine whether or not a signal is being exchanged between the sensor and computer. The tool helps read the accuracy of that signal.

RELATED INFO

http://www.highperformancepontiac.com/t ... index.html

viewtopic.php?f=52&t=2630&p=15954&hilit=detonation#p15954

viewtopic.php?f=52&t=2630&p=13145&hilit=detonation#p13145

viewtopic.php?f=57&t=4701&p=15021&hilit=detonation#p15021

viewtopic.php?f=86&t=5034&p=14207&hilit=detonation#p14207

viewtopic.php?f=52&t=4081&p=13147&hilit=detonation#p13147

viewtopic.php?f=52&t=727&p=12783&hilit=detonation#p12783

viewtopic.php?f=55&t=613&p=12677&hilit=detonation#p12677

viewtopic.php?f=53&t=3443&p=9118&hilit=detonation#p9118