bytor

Well-Known Member

Came across this info while doing some research and thought I'd share.

https://www.rockauto.com/en/catalog...,exhaust+&+emission,mass+air+flow+sensor,5128

http://www.hobracing.com/tech/tpi_flow.asp

www.motortrend.com

www.motortrend.com

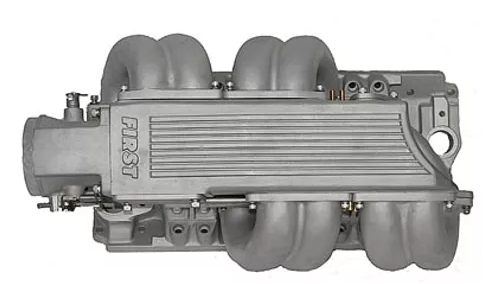

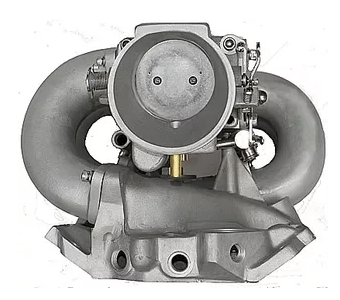

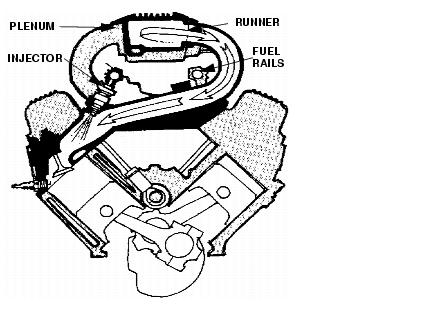

TPI Intakes and runners

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

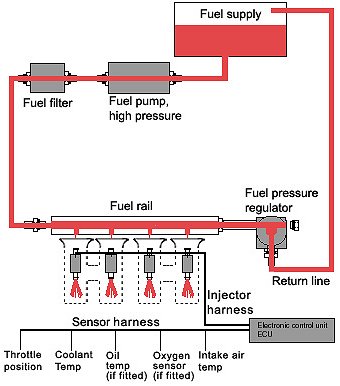

increasing power is in large part the result of increasing the amount of air/fuel mix you can efficiently pack into and burn in the cylinders and the number of power strokes per second that the engine can produce in its effective power range.

http://www.jegs.com/webapp/wcs/stores/servlet/topcategory_10001_10002_-1

https://www.ebay.com/itm/Weiand-908...For-Use-With-144-174-Blower-Kits/400669303867

https://www.ebay.com/itm/Weiand-622...r-Small-Block-and-Big-Block-Chev/112273744933

Have one to sell? Sell now

Weiand 6221 Offset Thermostat Housing Adapter For Small Block and Big Block Chev

your problem is VERY COMMON, if the throttle body and thermostat housing has a clearance issue on some modified EFI intakes, heres the usual cure

BTW theres two common vortec intake manifold gaskets, these vortec heads have taller ports than the standard 23 degree first gen SBC heads

The Fel Pro 1255 is .120 thick

The GM 89017465 is .060 thick

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

NOTICE THE MAF SENSOR, IN THE TPI , NOT THE THROTTLE BODY IS THE MAJOR FLOW RESTRICTION

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max........ NA HP

Stock ............668 .............300

Stock w/airfoil 710........... 350

52MM w/airfoil .835 ........400

54MM (AS&M) 900.......... 450

58MM 1050...................... 500

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

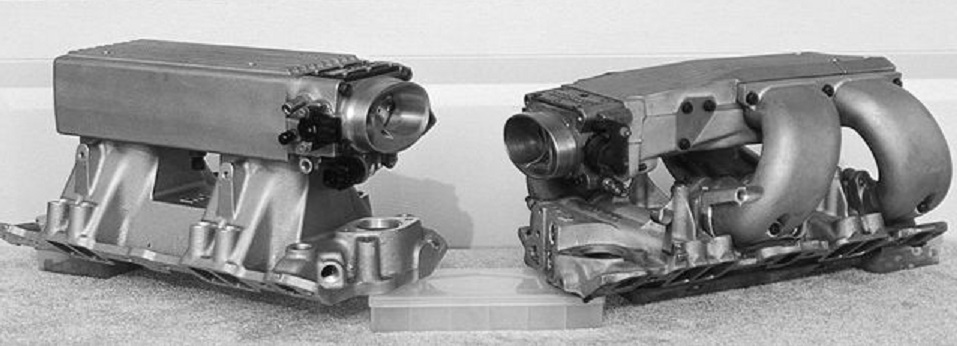

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm (after recommended runner clean-up)

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

Also interesting TPI mods. Not so sure I agree with the one on bumping up the initial timing.

http://www.hobracing.com/tech/tpi_mods.asp

Basic TPI modifications

Friday, May 23, 2014

http://garage.grumpysperformance.co...g-the-edelbrock-pro-flow-xt-7137.14248/page-4

http://garage.grumpysperformance.co...otal-panic-over-an-easy-fix.12177/#post-58940

Basic TPI Mods: by DEBBIES87

There are a few basic mods that should be done to any TPI car, I call these "entry-level" modifications.

1) Cut the air box open without letting air in the engine without going through the air filter & remove the additional plastic piece below the air box to get more air into the engine.

2) Modify the mass air sensor; remove the screens, & and if your brave cut down the fins.

3) Port the plenum (upper intake). There are two small ridges sticking up in the entry-behind the throttle body, remove these. The throttle body openings are already 52mm, so don't go crazy when porting.

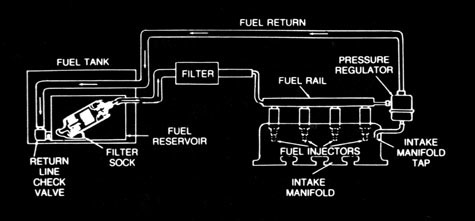

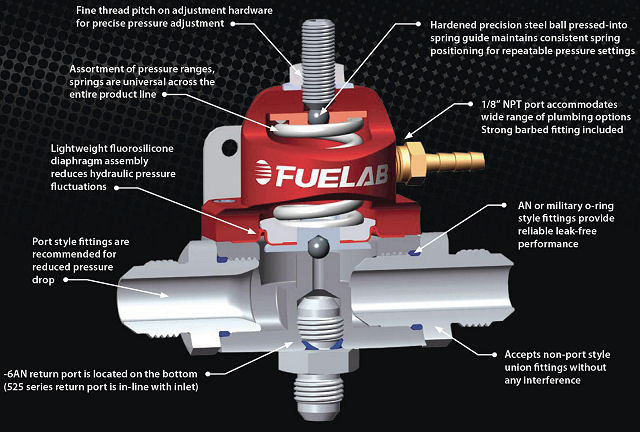

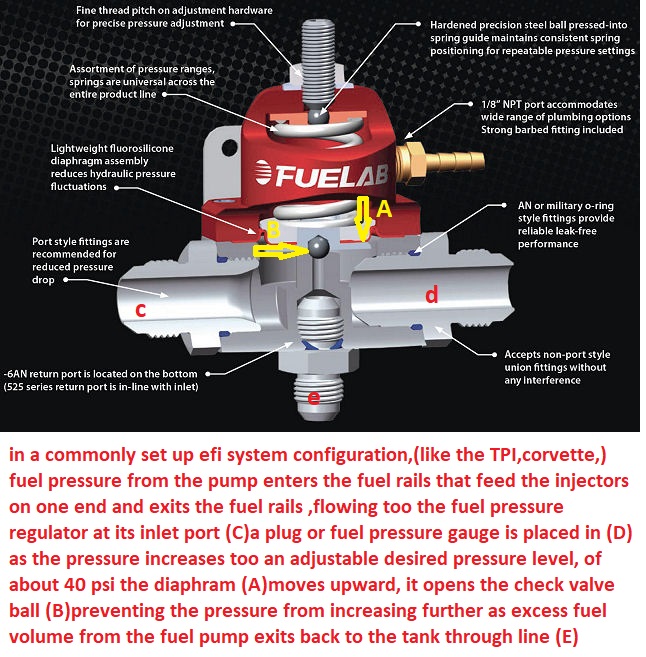

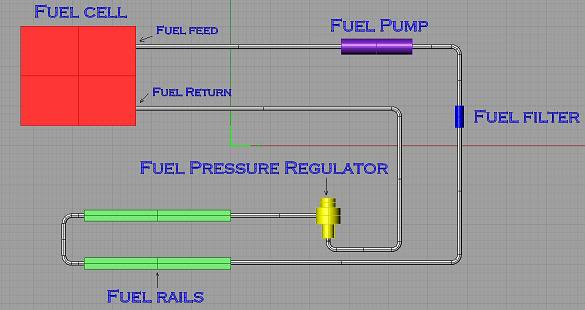

4) While the plenum is off for porting, it is now a good time to get a adjustable fuel pressure regulator & a MAT sensor relocater kit. The Adj. FPR will aid in tuning, and the new MAT sensor will improve throttle response as well. The new LT1 style MAT sensor is placed in the air box instead of the plenum, this allows it to read cooler air and advance the timing accordingly.

5) Advance the base timing to 12-13 degrees. Note: the harmonic balancers on these cars tend to drift with age, adjust timing to where the car still starts good and doesn't detonate.

6) If legal in your area, gut the catalytic converter and remove the smog pump belt (85-87), or run a shorter serpentine belt to bypass the pump (88-92); you will need to remove the smog pump on the 88-92's to reroute the belt properly. Check local smog laws first.

7) On automatic cars, adjust T.V. cable (throttle valve cable), so that the car shifts out between 4200-4500 RPM under wide open throttle. TPI motor power drops off drastically after 4500-4700 RPM, they peak at about 4200-4400 RPM. No need to over-rev these motors.

8) Bypass fan relay to make fans come on manually, or install aftermarket relay to turn on fans sooner.

All together these mods should make the car perform like it should have from the factory, gains should be between .6-.9 tenths of a second from these modifications.

T.V

https://www.rockauto.com/en/catalog...,exhaust+&+emission,mass+air+flow+sensor,5128

http://www.hobracing.com/tech/tpi_flow.asp

Stealth TPI Induction - L98 Stroker Installation - Super Chevy Magazine

This Chevrolet L98 TPI engine has its displacement stroked to 383 cubic inches and has stealth mods installed including a new cam and an extrude honed tuned port injection system to make 458 HP - Super Chevy Magazine

TPI Intakes and runners

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

increasing power is in large part the result of increasing the amount of air/fuel mix you can efficiently pack into and burn in the cylinders and the number of power strokes per second that the engine can produce in its effective power range.

http://www.jegs.com/webapp/wcs/stores/servlet/topcategory_10001_10002_-1

https://www.ebay.com/itm/Weiand-908...For-Use-With-144-174-Blower-Kits/400669303867

https://www.ebay.com/itm/Weiand-622...r-Small-Block-and-Big-Block-Chev/112273744933

Have one to sell? Sell now

Weiand 6221 Offset Thermostat Housing Adapter For Small Block and Big Block Chev

your problem is VERY COMMON, if the throttle body and thermostat housing has a clearance issue on some modified EFI intakes, heres the usual cure

BTW theres two common vortec intake manifold gaskets, these vortec heads have taller ports than the standard 23 degree first gen SBC heads

The Fel Pro 1255 is .120 thick

The GM 89017465 is .060 thick

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

NOTICE THE MAF SENSOR, IN THE TPI , NOT THE THROTTLE BODY IS THE MAJOR FLOW RESTRICTION

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max........ NA HP

Stock ............668 .............300

Stock w/airfoil 710........... 350

52MM w/airfoil .835 ........400

54MM (AS&M) 900.......... 450

58MM 1050...................... 500

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm (after recommended runner clean-up)

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

Also interesting TPI mods. Not so sure I agree with the one on bumping up the initial timing.

http://www.hobracing.com/tech/tpi_mods.asp

Basic TPI modifications

Friday, May 23, 2014

http://garage.grumpysperformance.co...g-the-edelbrock-pro-flow-xt-7137.14248/page-4

http://garage.grumpysperformance.co...otal-panic-over-an-easy-fix.12177/#post-58940

Basic TPI Mods: by DEBBIES87

There are a few basic mods that should be done to any TPI car, I call these "entry-level" modifications.

1) Cut the air box open without letting air in the engine without going through the air filter & remove the additional plastic piece below the air box to get more air into the engine.

2) Modify the mass air sensor; remove the screens, & and if your brave cut down the fins.

3) Port the plenum (upper intake). There are two small ridges sticking up in the entry-behind the throttle body, remove these. The throttle body openings are already 52mm, so don't go crazy when porting.

4) While the plenum is off for porting, it is now a good time to get a adjustable fuel pressure regulator & a MAT sensor relocater kit. The Adj. FPR will aid in tuning, and the new MAT sensor will improve throttle response as well. The new LT1 style MAT sensor is placed in the air box instead of the plenum, this allows it to read cooler air and advance the timing accordingly.

5) Advance the base timing to 12-13 degrees. Note: the harmonic balancers on these cars tend to drift with age, adjust timing to where the car still starts good and doesn't detonate.

6) If legal in your area, gut the catalytic converter and remove the smog pump belt (85-87), or run a shorter serpentine belt to bypass the pump (88-92); you will need to remove the smog pump on the 88-92's to reroute the belt properly. Check local smog laws first.

7) On automatic cars, adjust T.V. cable (throttle valve cable), so that the car shifts out between 4200-4500 RPM under wide open throttle. TPI motor power drops off drastically after 4500-4700 RPM, they peak at about 4200-4400 RPM. No need to over-rev these motors.

8) Bypass fan relay to make fans come on manually, or install aftermarket relay to turn on fans sooner.

All together these mods should make the car perform like it should have from the factory, gains should be between .6-.9 tenths of a second from these modifications.

T.V

Last edited by a moderator: