2Loose

reliable source of info

Tuning A Blown Olds Motor w/ Dual Mighty Demons with an Innovate LM-2 Air/Fuel Logger....

My latest project is an old style 60's era '55 Chevy "gasser" project. Complete with an early Ford F1 truck front axle, a stick shift, a stiff clutch, a built up '67 Olds 425 motor, a 6/71 blower, a heavy duty Ford 9" rear end with a Detroit Locker, and a pair of Mighty Demon 650's.

I built up the 425 Olds motor specifically for a stick shift blown street/strip operation with a 6/71 and dual carbs. Found a used pair of Mighty Demon 650's set up for a roots blower with remote vacuum sensors for the power valves.

My old LM-1 A/F logger went up in smoke before I could get it on this motor for tuning, so sent it in for an upgrade to the LM-2. Using basic tuning techniques I got it running pretty good, but I want to do a better job. Just got my new LM-2 yesterday, got the software in the laptop, and am ready to do some logging and see just where I am at.

Thought I might run a thread here on what I find and how I adjust it. Anybody wants to tune in with comments, you're more than welcome, as I trip on through this learning event....

At this point the 8:1 pistons and 1:1 blower drive are pulling 15 inches at idle, 900-1000 rpm, and giving me 5 lbs at full boost. I'm running progressive linkage on the secondaries. 72/75 primary/secondary jets. #4 power valves primary only. Idle fuel screws at 3/4 out. Don't know and have not addressed what accel pump cams or squirters are in there yet.

Messed with the timing quite a bit. Using an MSD 6AL with the blower timing retard add-on, and the dash timing control add-on. We found out fairly quickly that this motor seems to like a fair amount of advance in the ignition timing. I'm using heavy springs on the mech. advance with 20 deg advance available, coming in all the way fairly late, about 3000 rpm. Initial setting at idle with no vacuum advance is 18, giving a total of 38 deg at 3000. I am using the vacuum advance at idle, it is 10 deg, so giving 28 at idle, which the motor seems to like. So from idle at 28, it backs off to 18, then advances to 38 full advance at 3000, as long as I am not into boost. Driving it on the street it very seldom gets into boost, is making so much power without the boost that I just never get that far into it on the street.

When going into boost I get detonation, so added 2 deg of retard per lb of boost, making the 5 lb full boost timing at 3000 backed off 10 deg to 28 deg. Not sure that is the best setting for now, but the plugs look pretty good, kind of a dark cola brown, and the exhaust pipe is a light gray color, and I don't think I can hear any detonation. I'm not sure how well adding a detonation sensor would work, as I have heard that the roots blower noise tends to mask that and can give false information.

As I mentioned above, I do have the adjustable timing control mounted on the dash. I have it set at 10 on the dash with the 38 full in at 3000. I have the option to advance timing up to an additional six, or to retard it, up to a max of ten. So far I have only advanced or retarded it a couple of degrees while driving but haven't been able to see much difference. So for now I just leave it at 10, which is the 38 setting on the distributor. I hope that all made sense!

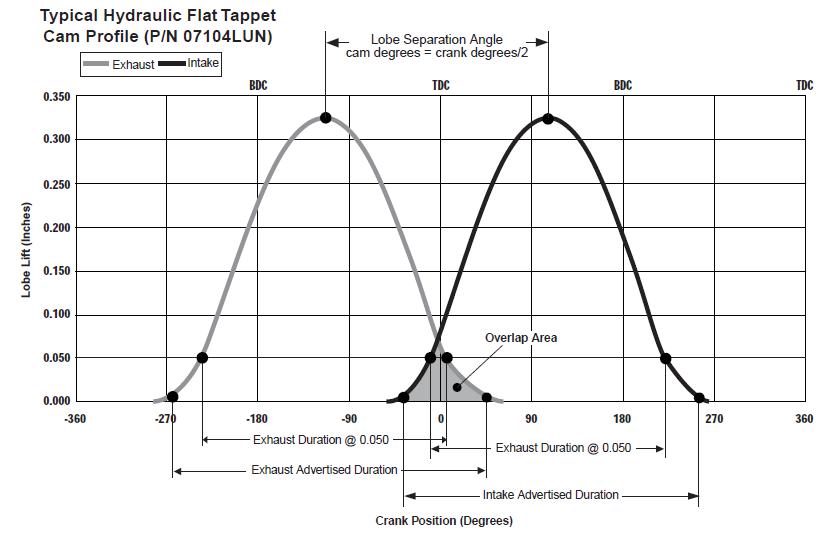

At 1/2 turn out on idle screws it idled more smoothly, but when driving would die off when taking my foot off the gas and hitting the clutch at stop signs. Upping the idle screws to 3/4 turn stopped that, but now it can occasionally get into a surging idle condition that can build until it goes so far down at idle on the low end of the surging that it dies off. I feel I ought to be able to tune out that "typical blower surging" that so many people think is normal for a roots blown motor. It's what I consider a slightly aggressive street cam, hydraulic roller lifters, but fairly tame really when I look at the specs (230/236 duration at .050, .507/.516 lift, with fairly steep ramps due to the roller lifters).

Part of that die off problem is the really light (12 lbs) aluminum flywheel I put in. It revs up and drops back down really, really quickly when I hit the throttle. It's like the carbs can't "catch" it fast enough to recover when it comes back down from a throttle jab, and it slows down too much and dies.

On startup it hits on the first fire, instantaneously, hot or cold.

Am down with a bad cold today, so had time to do research on the LM-2 and carb tuning, and thought I'd post this thread. As I get some logs will post what I find.

Aloha from Maui,

2Loose Willy

viewtopic.php?f=50&t=9250&p=33361#p33361

LINK: If you are interested, I have been running some build pages on this project.

My latest project is an old style 60's era '55 Chevy "gasser" project. Complete with an early Ford F1 truck front axle, a stick shift, a stiff clutch, a built up '67 Olds 425 motor, a 6/71 blower, a heavy duty Ford 9" rear end with a Detroit Locker, and a pair of Mighty Demon 650's.

I built up the 425 Olds motor specifically for a stick shift blown street/strip operation with a 6/71 and dual carbs. Found a used pair of Mighty Demon 650's set up for a roots blower with remote vacuum sensors for the power valves.

My old LM-1 A/F logger went up in smoke before I could get it on this motor for tuning, so sent it in for an upgrade to the LM-2. Using basic tuning techniques I got it running pretty good, but I want to do a better job. Just got my new LM-2 yesterday, got the software in the laptop, and am ready to do some logging and see just where I am at.

Thought I might run a thread here on what I find and how I adjust it. Anybody wants to tune in with comments, you're more than welcome, as I trip on through this learning event....

At this point the 8:1 pistons and 1:1 blower drive are pulling 15 inches at idle, 900-1000 rpm, and giving me 5 lbs at full boost. I'm running progressive linkage on the secondaries. 72/75 primary/secondary jets. #4 power valves primary only. Idle fuel screws at 3/4 out. Don't know and have not addressed what accel pump cams or squirters are in there yet.

Messed with the timing quite a bit. Using an MSD 6AL with the blower timing retard add-on, and the dash timing control add-on. We found out fairly quickly that this motor seems to like a fair amount of advance in the ignition timing. I'm using heavy springs on the mech. advance with 20 deg advance available, coming in all the way fairly late, about 3000 rpm. Initial setting at idle with no vacuum advance is 18, giving a total of 38 deg at 3000. I am using the vacuum advance at idle, it is 10 deg, so giving 28 at idle, which the motor seems to like. So from idle at 28, it backs off to 18, then advances to 38 full advance at 3000, as long as I am not into boost. Driving it on the street it very seldom gets into boost, is making so much power without the boost that I just never get that far into it on the street.

When going into boost I get detonation, so added 2 deg of retard per lb of boost, making the 5 lb full boost timing at 3000 backed off 10 deg to 28 deg. Not sure that is the best setting for now, but the plugs look pretty good, kind of a dark cola brown, and the exhaust pipe is a light gray color, and I don't think I can hear any detonation. I'm not sure how well adding a detonation sensor would work, as I have heard that the roots blower noise tends to mask that and can give false information.

As I mentioned above, I do have the adjustable timing control mounted on the dash. I have it set at 10 on the dash with the 38 full in at 3000. I have the option to advance timing up to an additional six, or to retard it, up to a max of ten. So far I have only advanced or retarded it a couple of degrees while driving but haven't been able to see much difference. So for now I just leave it at 10, which is the 38 setting on the distributor. I hope that all made sense!

At 1/2 turn out on idle screws it idled more smoothly, but when driving would die off when taking my foot off the gas and hitting the clutch at stop signs. Upping the idle screws to 3/4 turn stopped that, but now it can occasionally get into a surging idle condition that can build until it goes so far down at idle on the low end of the surging that it dies off. I feel I ought to be able to tune out that "typical blower surging" that so many people think is normal for a roots blown motor. It's what I consider a slightly aggressive street cam, hydraulic roller lifters, but fairly tame really when I look at the specs (230/236 duration at .050, .507/.516 lift, with fairly steep ramps due to the roller lifters).

Part of that die off problem is the really light (12 lbs) aluminum flywheel I put in. It revs up and drops back down really, really quickly when I hit the throttle. It's like the carbs can't "catch" it fast enough to recover when it comes back down from a throttle jab, and it slows down too much and dies.

On startup it hits on the first fire, instantaneously, hot or cold.

Am down with a bad cold today, so had time to do research on the LM-2 and carb tuning, and thought I'd post this thread. As I get some logs will post what I find.

Aloha from Maui,

2Loose Willy

viewtopic.php?f=50&t=9250&p=33361#p33361

LINK: If you are interested, I have been running some build pages on this project.