good question, if your not experianced

Ive got lots of those software dyno programs and cam sellection software ETC., AND HAVE COMPARED REAL WORLD DYNOS WITH THOSE PRODICTIONS MANY TIMES

(1) SOFTWARE TENDS TO BE overly OPTOMISTIC, TAKE THAT INTO ACCOUNT

(2) ONLY THE RPM RANGE YOUR CARS ENGINE COMBO AND DRIVE TRAIN OPPERATES IN COUNTS,

EXAMPLE, IF ITS A TPI EVERYTHING BELOW ABOUT 1400 RPM OR ABOVE ABOUT 6000RPM IS WORTHLESS AS ITS RARELY IF EVER REACHED WHILE DRIVING

(3) HP PEAK SHOULD ALWAYS EQUAL OR SLIGHTLY EXCEED THE TQ PEAK, AND IDEALLY BE ABOUT 1000RPM-1500RPM HIGHER

(4)THE HP PEAK SHOULD FALL UNDER YOUR MAX RPM AND THE TQ PEAK SHOULD BE AS LOW IN THE RPM AS YOU CAN GET IT

(5) MAXIMIZE THE AREA UNDER THE TQ CURVE, ITS MAXIMUM AVERAGE TQ NOT PEAK POWER THAT MATTERS

(6) MATCHING YOUR DRIVE TRAINS OPPERATIONAL RANGE TO THE CAM SELLECTED IS CRITICAL

(7) IF YOUR AUTO TRANS SHIFTS AT 5500RPM, AND YOUR INTAKE EFFECTIVELY STARTS STRANGLING POWER AT 4500RPM ITS STUPID TO CAM FOR 6500RPM

(8) ANYTHING IN POWER PREDICTED THATS MUCH ABOVE 6300RPM WITH A HYDRAULIC LIFTER IS WISHFUL THINKING

http://garage.grumpysperformance.com/index.php?threads/dyno-software.784/

http://www.chevytalk.org/fusionbb/showtopic.php?tid/92966/

http://www.chevytalk.org/fusionbb/showtopic.php?tid/131229/

http://www.chevytalk.org/fusionbb/showtopic.php?tid/56243/

while factors like your

displacement,

bore dia.

compression ratio

intake port cross section and length

exhaust design/flow/primary and collector dia. and length

your cams LCA and durration and lift

your rear gear ratio

stall speed

type of transmission

tire dia.

will change the ideal combo

youll generally find max power available IN a

SBC TPI engine from a cam having a durration at .050 lift of between 225-240 intake durration

and max power in the 3000rpm-6500rpm range with that modified TPI style engine and that will require a cpr between 10:1-11:1 and

a rear gear ratio between 3.73:1-4.11:1

that will require a port in the 190cc-210cc range and a matched intake design

port flow rates and cams exceeding 240cfm at .500 lift have a distinct advantageIF the correct matching components are used.

example

if you cam max lift is at .550, great flowing ports at .700 are meaningless

if your cams durration and LCA is designed for an rpm range of 4500rpm-7000rpm, but your gearing keeps you in the 2500rpm-5500rpm range youll find its going to run badly most of the time, read the previous links and sub-links

naturally a big block with its larger ports,valves and displacement may require a larger cam(more lift and durration)

cam install info

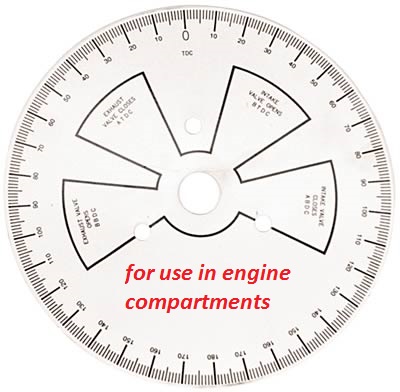

I think most experienced guys have two or three degree wheels for that very reason,

(that the larger size is tough to fit in an engine compartment on an installed engine)

I bought these

http://www.summitracing.com/parts/mor-62191/overview/

http://www.summitracing.com/parts/pro-66791/overview/

http://www.summitracing.com/parts/pro-66830/overview/

http://www.summitracing.com/parts/cca-4927/overview/

JUST TRYING TO FIND TDC??

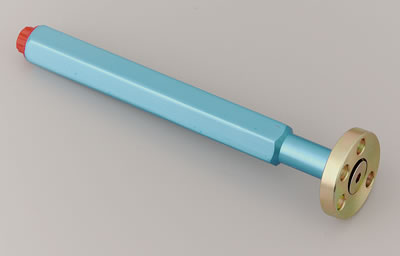

you FIRST disconnect the battery and use a ratchet to spin the engine slowly by hand , useing the damper bolt and a 5/8 socket after removing the spark plugs, chalking the wheels and putting the cars trans in neutral

ways to turn over the engine WITHOUT the starter

theres large bolts for your ballancer

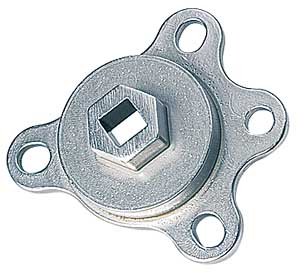

theres crank sockets

Crankshaft Socket Tool For turning AND MOUNTING Degree Wheels

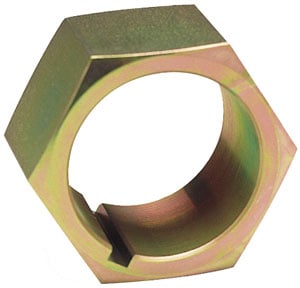

CRANK NUTS

crank rotaters

flywheel turning tools

http://www.jegs.com/i/JEGS/555/80743/10002/-1

finding TDC

youll need a piston stop and degree wheel to be

exact

but thats not 100% required unless you want it to work correctly???

http://store.summitracing.com/partdetail.asp?autofilter=1&part=CRN-99412-1&N=700+115&autoview=sku

use of a camshaft install handle generally reduces the chances of damaged cam bearings

read

http://www.2quicknovas.com/happyTDC.html

btw you might want to verify this next time you degree in a cam, so that next time you use dyno simulation software you enter the data correctly,

theres a hugely popular myth that simply is wrong, if your using a dyno simulation software program, ...,

no you don,t reduce or subtract the lift of the cam lobe by the lash, clearance,

when calculating the valve lift of a solid lifter cam,

and you don,t subtract the lifter seat movement on a hydraulic cam,

as that change in lift rate is ALL absorbed or removed on the cam lobes feed ramp

the lifter still lift,s the valve to the full lift.

measure the difference the edge of the lifter moves from the time the lifter is on the cams base circle to peak lift than set the lifter back on the base circle again and set the dial indicator to zero with a .0024 feeler gauge between the lifter and dial indicator, and re- measure total lift.

nothing changes on that peak lift , its change is absorbed by the cam lobes feed ramp, the rate of lift per degree of rotation is very slightly delayed , not reduced

http://www.summitracing.com/parts/mor-62191/overview/

http://www.summitracing.com/parts/pro-66791/overview/

http://www.summitracing.com/parts/pro-66830/overview/

http://www.summitracing.com/parts/cca-4927/overview/