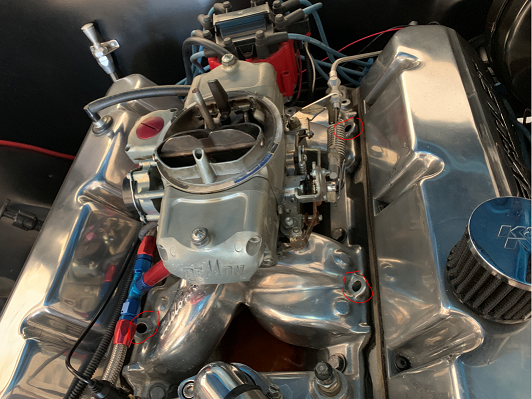

while tuning up my electric choke i noticed a sucking noise on the intake manifold. Its coming from four holes. Put you finger on them and its sucking, all four hole. Quick google and these are the four bolt holes on a edelbrock performer RPM 2 intake #75621. Heads are patriot 320CC both have rectangular intake ports. These four bolts are specified in manual as hand tighten only.

Mine have no bolts and you can see the gasket covering the holes between block and manifold. Never was a bolt in any of these four holes.

The question is this, is there any reason this would have been done intentionally? The car runs great, its dyno'd at 638 hp 652 torque. When i plug all four holes the idle drops way down and car barely wants to keep idling.

yes you need to replace the intake gasket and install the correct length 3/8"/16 tpi intake hold down bolts in the 4 holes circled in the picture

then re-adjust the carb to get the engine idle correct

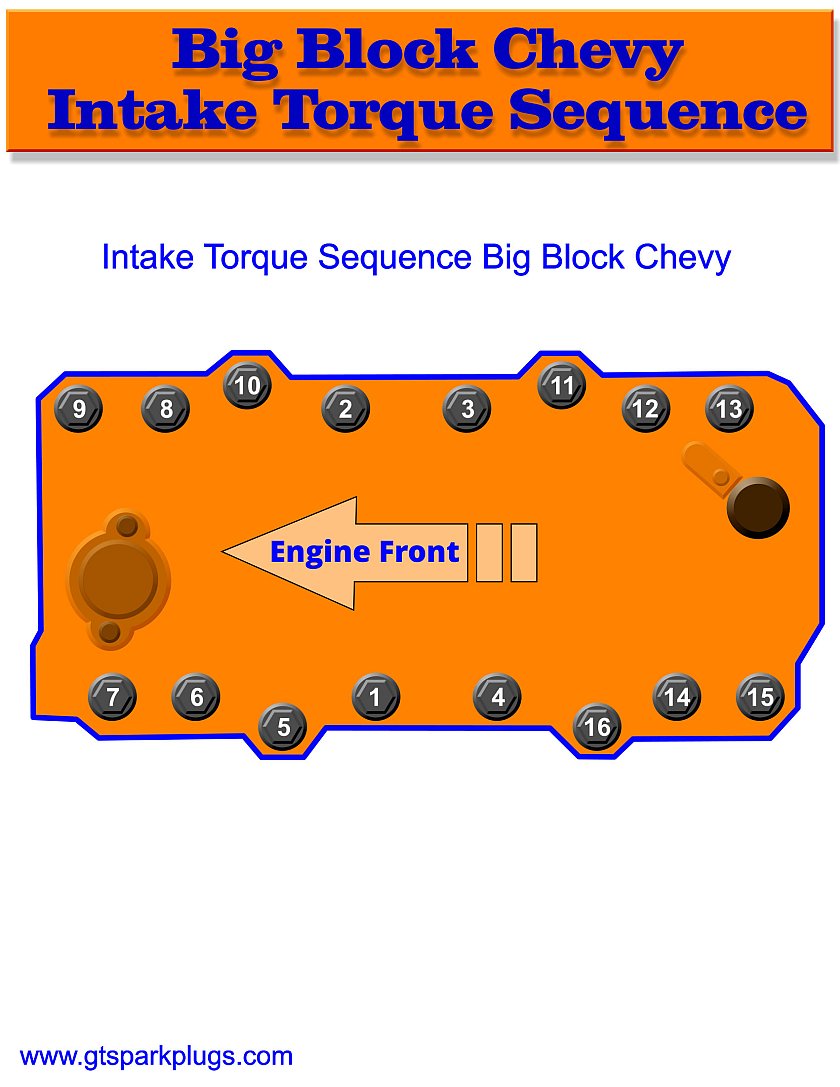

http://www.gtsparkplugs.com/BBC-Intake-Torque-Sequence.html

Big Block Chevrolet Intake Torque Sequence

So we got that cool new dual quad tunnel ram and you are going to need to figure out how to get it on and torqued

properly. Make sure you follow the manufactures instructions (Edelbrock, Holley, Weiand, etc) for the proper

procedures. You will need a few things including the "Nuts, Bolts and Gaskets" as they say. Don't forget the gasket

sealer(s) torque wrench and this page. My preferences for gasket sealers on the race cars are Hylomar (Permatex

Version) for intake ports and a light coat of High temp RTV sealer for the water jackets and end seals. It's also a

good idea to coat bolts that enter the water jacket with some Permatex or similar bolt sealer.

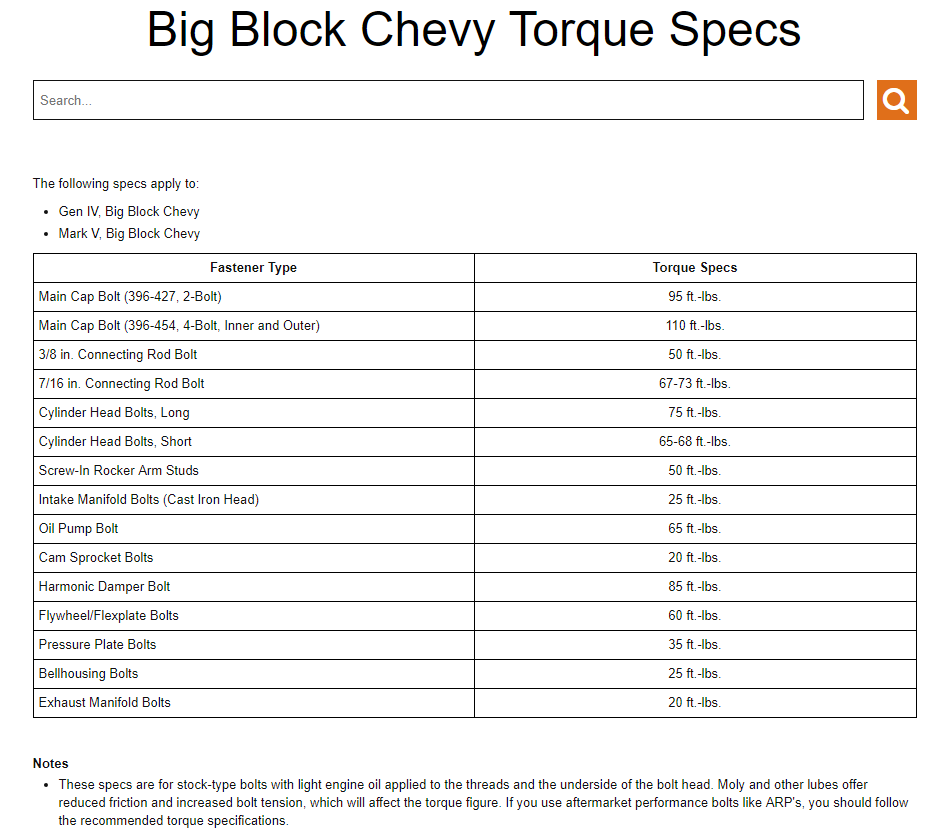

Big Block Chevy Intake Bolt Torque Specifications

25 Ft/Lbs - Aluminum Heads

35 Ft/Lbs - Iron Heads

The torque spec can be anywhere from 25-35 on Iron heads, but for aluminum I tend to go towards the lower side.

IF you do have a spec from the manufacturer follow that. Make sure threads in the head are clean and in good

shape.

Make sure you follow the sequence in a couple of steps, worry about this more on old and aluminum manifolds.

Cast Iron is much more forgiving if you are unfortunate to have to use a boat anchor of an intake. They are HEAVY

on the BBC.

Some Common Intake Manifold Tips

If you have an old used manifold, before installing it, check for cracks, leaks and the threads in the thermostat

housing (often a problem area) and the threads in the bolt for the distributor clamp. You don't want to find out you

have to toss in a Helicoil or other insert while it's on the car. For the T-Stat housing and Distributor claps it's nice to

use studs.

Test fit your manifold with gaskets (no sealer). Make sure it looks like it will align. Milling heads and decking blocks

can make things not align properly and cause leaks.

Use good sealers, do not use silicon around intake ports, just the water ports. Some folks like to use the end seals,

I typically toss them and use a bead of silicon on the front and rear seals of the manifold. Do it in the way you are

most comfortable with. If tossing the end seals make sure things are totally clean an oil free.

Last thing is to be careful of the 5, 9, 10, 11, 16. These are often on weak parts of the manifold. Some manifold do

not have bolts 5, 10, 11, 16 as the ports are way too big to have a bolt hole smack in the middle. I don't know what

the 'Proper' technique is but I just skip to the next one in the sequence.

Copyright (C) 2013 - 2019 Sandy Ganz, GTSparkplugs. All Rights Reserved. Content May NOT be used without written permission. Use at your own risk

Last edited: