Hey GRUMPY?

I purchased an aftermarket large port and runner performance intake and now find the edge of the stamped sheet metal cover contacts the upper runner surface just enough to prevent the valve cover from sealing on the heads gasket surface, NOW WHAT?

thats not all that rare with some intake and some stamped valve cover combos, the lip on the stamped valve covers are designed to help locate the valve cover gaskets and prevent them from easily squeezing out of place and leaking.

theres several ways to go about curing this

(1) using thicker valve cover gaskets is the most common route taken. most valve cover gaskets are between .090-.200 thick, but they are made up to .375" thick

http://www.summitracing.com/parts/edl-7549

Valve Cover Gaskets, Composite, Core-Reinforced, 0.313 in. Thick, Chevy, Small Block, Pair

http://www.jegs.com/i/Mr.+Gasket/720/5863/10002/-1

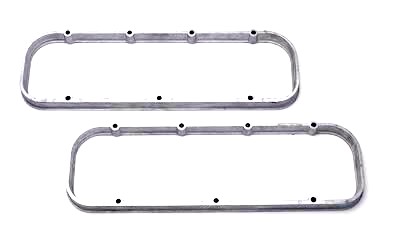

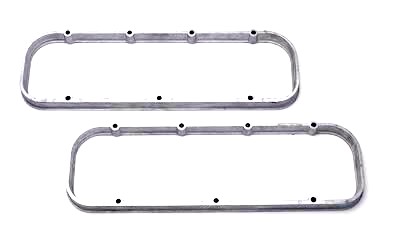

stamped steel valve covers are notorious for bending and leaking so , if you have a set of those common chrome plated valve covers, these drop over load spreading rings are a huge help, in keeping the valve cover gaskets sealed

(2) THERE ARE VALVE COVER SPACERS MADE

(3)cast aluminum valve covers rarely have a lip that extends downward nearly as far as stamped steel covers because they are significantly stiffer

RELATED THREAD

[1] synthetic oil desolves that yellow 3m weatherstrip gasket adhesive than many guys use over a few months time so you cant use it to glue valve cover gaskets

[2]you must use a o2 safe gasket cement like the BLACK RTV silicone cement and you must clean and degrease the cover with acetone or a similar solvent before glueing on the gasket to get the best retention

[3]you need to allow at least a few hours to over night, depends mostly on temp. for that black silicone gasket cement to set up before installing the valve covers, and placing them gasket side down on a table with a sheet of wax paper under them and a 20lb weight on top of each valve cover while the cement sets up is the best way to insure the gaskets stay correctly aligned on the valve covers perimeter

[4]a light coat of (PAM) cooking spray on the lower gasket surface keeps them from sticking to the cylinder heads after installation

[5] these gasket retaining rings add a great deal to the valve covers ability to firmly hold the gasket WITHOUT bending SHEET METAL VALVE COVERS OR CRACKING CAST ALUMINUM VALVE COVERS AND ARE WELL WORTH THE MINIMAL COST

[6]doing it correctly the first time saves time and money

I purchased an aftermarket large port and runner performance intake and now find the edge of the stamped sheet metal cover contacts the upper runner surface just enough to prevent the valve cover from sealing on the heads gasket surface, NOW WHAT?

thats not all that rare with some intake and some stamped valve cover combos, the lip on the stamped valve covers are designed to help locate the valve cover gaskets and prevent them from easily squeezing out of place and leaking.

theres several ways to go about curing this

(1) using thicker valve cover gaskets is the most common route taken. most valve cover gaskets are between .090-.200 thick, but they are made up to .375" thick

http://www.summitracing.com/parts/edl-7549

Valve Cover Gaskets, Composite, Core-Reinforced, 0.313 in. Thick, Chevy, Small Block, Pair

http://www.jegs.com/i/Mr.+Gasket/720/5863/10002/-1

stamped steel valve covers are notorious for bending and leaking so , if you have a set of those common chrome plated valve covers, these drop over load spreading rings are a huge help, in keeping the valve cover gaskets sealed

(2) THERE ARE VALVE COVER SPACERS MADE

(3)cast aluminum valve covers rarely have a lip that extends downward nearly as far as stamped steel covers because they are significantly stiffer

RELATED THREAD

[1] synthetic oil desolves that yellow 3m weatherstrip gasket adhesive than many guys use over a few months time so you cant use it to glue valve cover gaskets

[2]you must use a o2 safe gasket cement like the BLACK RTV silicone cement and you must clean and degrease the cover with acetone or a similar solvent before glueing on the gasket to get the best retention

[3]you need to allow at least a few hours to over night, depends mostly on temp. for that black silicone gasket cement to set up before installing the valve covers, and placing them gasket side down on a table with a sheet of wax paper under them and a 20lb weight on top of each valve cover while the cement sets up is the best way to insure the gaskets stay correctly aligned on the valve covers perimeter

[4]a light coat of (PAM) cooking spray on the lower gasket surface keeps them from sticking to the cylinder heads after installation

[5] these gasket retaining rings add a great deal to the valve covers ability to firmly hold the gasket WITHOUT bending SHEET METAL VALVE COVERS OR CRACKING CAST ALUMINUM VALVE COVERS AND ARE WELL WORTH THE MINIMAL COST

[6]doing it correctly the first time saves time and money

Last edited by a moderator: