Terry S said:I am refreshing a set of heads that have had the guides cut for positive stop seals. My question is, the guides measure .530. Do I need to get seals that are .530 or .531

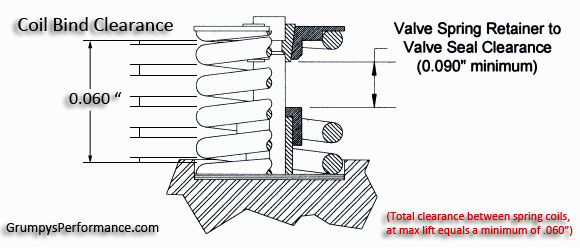

either size seal should fit, Id go with the slightly larger size ,but as always its best to have a local machine shop that machine the heads measure and install the valve seals if your not familiar with the process, theres a spring lock and they are flexible, theres some ability to stretch or clamp as required in the basic design of the seals , if in doubt ask the machine shop that did your heads or bring a head down to a local machine shop and ask them to measure the valve guides and order the correct valve seals, for the application, you might pay a couple bucks more but its well worth it to know its done correctly if your not comfortable with and experienced at installing the valve seals

Many teflon valve guide seal designs are not very flexible and if the valve guides are a bit loose they can leak considerable oil,Switching to the more flexible viton seals can at times help reduce oil consumption issues

http://www.summitracing.com/search/Part ... oelastomer

The O-ring must be accompanied by a tin shield over the outside of the valvespring (left). The tin shield keeps excess oil from splashing on the valve stem and valveguide. The tin shield and O-ring must be used together to be effective. Installing the earlier double-groove valves, an O-ring, and a tin shield will allow the Vortec heads to use camshafts with 0.500 inches of valve lift, without machining the valveguides lower for clearance.

If the valve springs are to be removed with the heads still on the car,

the last thing you want is too remove a valve spring and have the valve to drop into the cylinder,

if you use air the crank tends to want to spin the crank to BDC, youll want to verify TDC ,

and make sure the flywheels temporarily prevented from turning from that the TDC position,

Ive used both methods both work,you can put 6 ft of rope in the cylinder while its in BDC then turn it to TDC, Ive used both with zero issues,

If you use the compressor youll want to keep it at 120 psi and constantly feeding pressurized air to keep the valves held in place,

and theres a small chance the compressor pushes enough moisture to allow water to accumulate in the cylinders,

so be sure you spin the engine with the starter with the spark plugs removed several times before you re-install plugs.

if you use the rope, theres a very low chance that the rope will tangle and form a knot that makes removal difficult,

in either case be sure the pistons locked at tdc,

before removing the valve springs, on each cylinder.

READ THE THREADS AND SUB LINKS

viewtopic.php?f=44&t=1054&p=1990&hilit=valve+seals#p1990

http://www.cylinderheadsupply.com/valve-guide-tools-guide-top-cutters.html

viewtopic.php?f=52&t=1053&p=1989&hilit=valve+seals#p1989

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

viewtopic.php?f=52&t=181

Last edited by a moderator: