elisalvador

Member

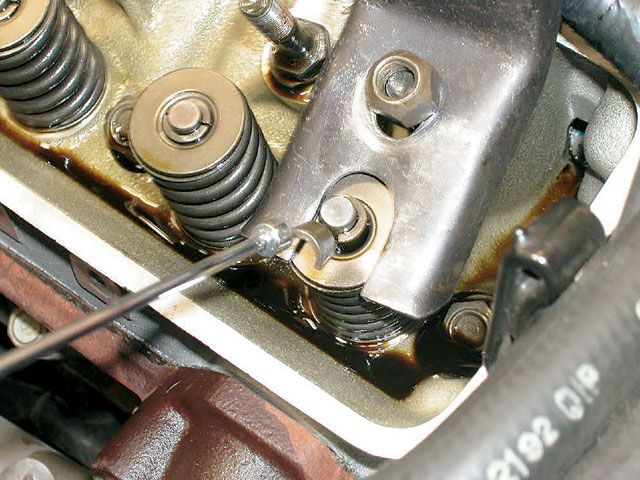

hi grumpy, im rebuilding a 350 , im checking the valve spring for squareness, it seems all the springs that I have checked, are not fully square, I have not done all of them yet, they are used , im taking the heads apart and checking condition of valve ,seats, springs, guides. But the question I have is ,is there any tolerance allowed for spring squareness, they are not fully square all around. there is some gap on top of spring against a square edge? thanks