Before I can assemble my heads, I need to make a decision about Valve Stem Seals. Not wanting to take anything for granted, I wanted to know more about possible different designs and materials available.

A few things I learned about seals are:

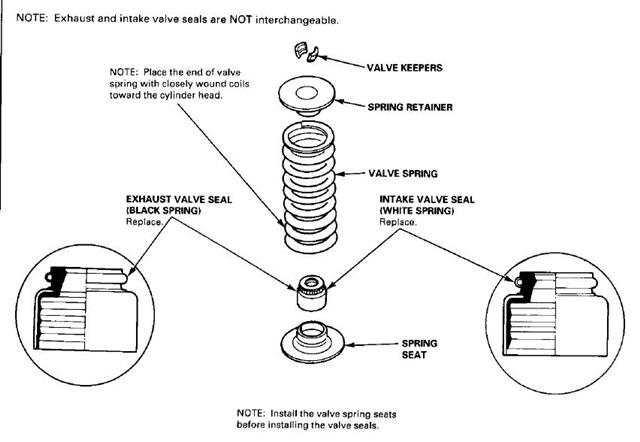

1) There are basically two general designs, Oil Deflectors and Positive type seals. The umbrella or o-ring seal is a type of oil deflector and move with the valve stem, where a positive seal is stationary.

2) They are OIL METERING devices ! They precisely meter the amount of oil passing by the seal and therefore into the the valve guide. Although the requirements for each engine differ according to the design parameters and operating conditions, the oil metering rate is generally within the range 0.1 - 1.0 mg per valve per hour.They are not installed to completely stop the oil, since it's required for valve stem to valve guide lubrication.

3) They operate on the same principle as the main and rod bearings, the hydrodynamic lubrication principle. When conditions are right, there is no metal-to-metal contact. The seal, valve stem and valve guide are riding on a thin film of oil just like main bearings.

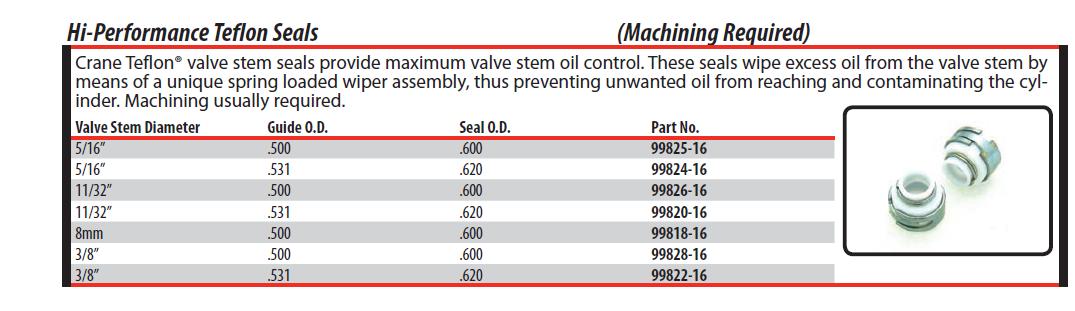

4) Depending on the application and the design of the seal, the material used may be nitrile, polyacrylate, fluoroelastomer (Viton), silicone, nylon or Teflon.

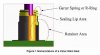

The component parts, that make up a seal are:

These links can it explain it much better than I can.

http://www.enginebuildermag.com/Article ... signs.aspx

http://www.hastingsmfg.com/ServiceTips/valve_seals.htm

http://www.skf.com/files/004641.pdf

A very technical article if you are interested.

http://file.seekpart.com/keywordpdf/201 ... 516501.pdf

A few things I learned about seals are:

1) There are basically two general designs, Oil Deflectors and Positive type seals. The umbrella or o-ring seal is a type of oil deflector and move with the valve stem, where a positive seal is stationary.

2) They are OIL METERING devices ! They precisely meter the amount of oil passing by the seal and therefore into the the valve guide. Although the requirements for each engine differ according to the design parameters and operating conditions, the oil metering rate is generally within the range 0.1 - 1.0 mg per valve per hour.They are not installed to completely stop the oil, since it's required for valve stem to valve guide lubrication.

3) They operate on the same principle as the main and rod bearings, the hydrodynamic lubrication principle. When conditions are right, there is no metal-to-metal contact. The seal, valve stem and valve guide are riding on a thin film of oil just like main bearings.

4) Depending on the application and the design of the seal, the material used may be nitrile, polyacrylate, fluoroelastomer (Viton), silicone, nylon or Teflon.

The component parts, that make up a seal are:

These links can it explain it much better than I can.

http://www.enginebuildermag.com/Article ... signs.aspx

http://www.hastingsmfg.com/ServiceTips/valve_seals.htm

http://www.skf.com/files/004641.pdf

A very technical article if you are interested.

http://file.seekpart.com/keywordpdf/201 ... 516501.pdf