occasionally I get asked questions ,concerning terms or concepts that I assumed were common knowledge.

ok lets start with the basics,

oil flowing over the moving surfaces in any engine is used too,

absorb and transfer heat away from, and separate

and prevent physical contact between moving surfaces,

AND as the oil passes over and between the two surfaces,

pressurized oil flow, absorbs and transports the heat from combustion and friction away from the parts.

oil does almost all initial cooling, oil flow over the block transfers heat to the coolant, coolant transfers that heat to the outside air flow.

every choice you make is a compromise in several areas.

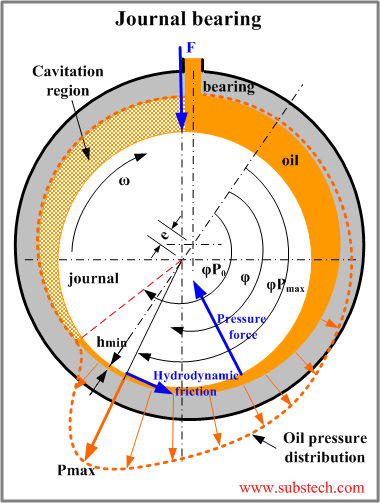

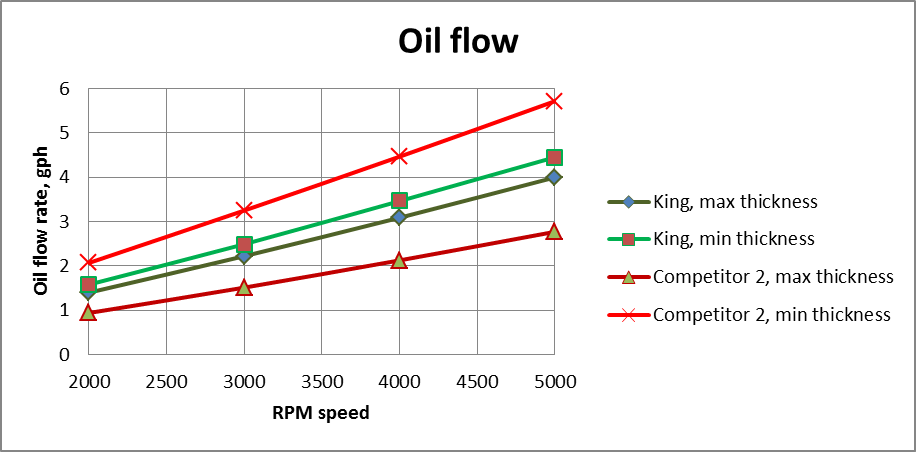

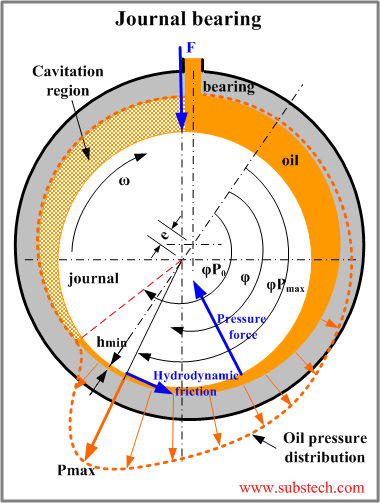

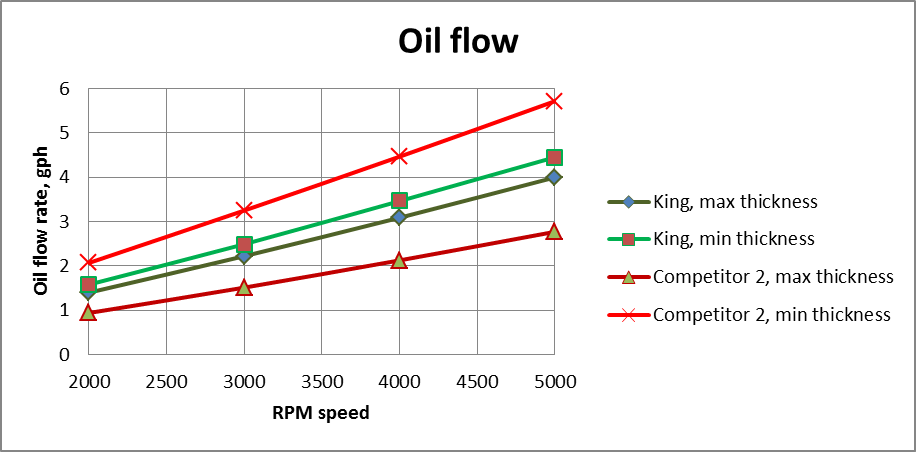

keep in mind that your oil pressure gauge measures the resistance to flow the oil sees as it flows thru the bearing clearances, larger clearances will require higher flow rates or a higher viscosity oil, higher flow rates can be supplied with a high volume oil pump but that also requires a larger baffled oil pan and windage screen to control the higher oil flow rates

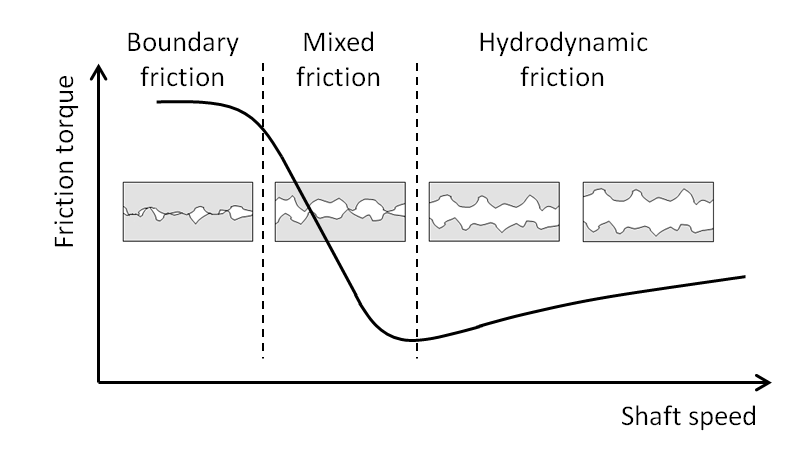

thicker or higher viscosity oils flow slower, at lower temps, this means a minor delay in how fast oil reaches the bearings surfaces in colder temps but it almost always results in a bit more volume or distance between the supported surfaces, of oil on/between the bearing surfaces , that pressurized oil between the bearing and both moving surfaces ,the oil flow provides is preventing from direct physical contact between the bearing and the moving parts in a running engine

keep in mind oil temperature and the viscosity at that temperature will effect how rapidly,

the oil can flow into and through the clearances between the moving surfaces.

thinner oils flow faster and in most case.s absorb and transfer trapped heat away from surfaces more rapidly,

this is one reason the newer engine designs with tighter tolerances use thinner viscosity oils.

different oils penetrate into and fill clearances between moving surfaces at a significantly different flow rates,

doing some research on the oil you select, vs your options never hurts.

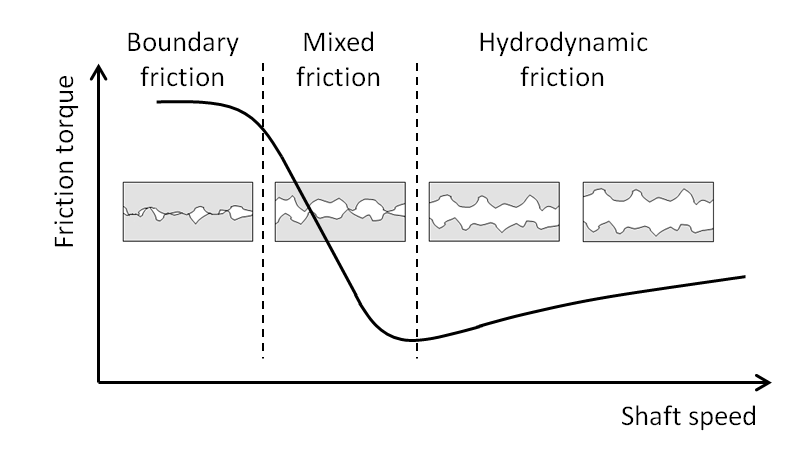

and most engine wear occurs at start-up while lubricants are cooler and the areas between moving surfaces may not have yet been supported by a pressurized film of hot flowing oil keeping the two adjacent surfaces separated, thinner viscosity tends to fill hydraulic lifters and bearing clearances far more rapidly.

this is also why use of a moly based assembly lube that fills the micro surfaces is beneficial.

Oil additives are chemical compounds that improve the performance of an oil's base stock. They are included by the oil manufacturer to enhance lubrication, modify viscosity, clean engine deposits that can lead to sludge, and prevent corrosion.

The centistoke is a unit of measurement of kinematic viscosity. A centistoke (cSt) is the derived centimeter-gram-second (CGS) unit of kinematic viscosity.

(think of this (centistoke )as the metric definition of how rapidly clearances between bearings and moving surfaces like rockers,

and how fast hydraulic lifters get filled and pressurized,

so they don,t click )(thinner (lower numbers) tends to be faster too, flow into and fill voids/ clearances) obviously as oil heats up the viscosity drops and it much more easily flows into restrictive clearances, but on initial start-up the thinner oils reach and lubriicate parts significantly faster

What is viscosity?

This question is often best answered by example. Imagine a styrofoam cup with a hole in the bottom. If I then pour honey into the cup I will find that the cup drains very slowly. That is because honey's viscosity is large compared to other liquids' viscositie's. If I fill the same cup with water, for example, the cup will drain much more quickly.

Viscosity is a measure of a fluid's resistance to flow. It describes the internal friction of a moving fluid. A fluidwith large viscosity resists motion because its molecular makeup gives it a lot of internal friction. A fluid with low viscosity flows easily because its molecular makeup results in very little friction when it is in motion.

engine oil operates at about 180F-240F in most cases.

, its required to allow the bearings, valve train.pistons and rings to function and remain cool.

oil temps under about 180F will not flow and lube well, and oil temps over about 240f tend to degrade and loose the ability to lubricate, the higher the temp the faster this tends to happen, most oils degrade very rapidly at temps exceeding 275f.

30-50 years ago thicker oil viscosity was required as the technology was not then common too manufacture consistently or maintain precise clearances and oils were of far lower quality, with todays better synthetic oil blends clearances that were virtually impossible too machine or maintain are now common.

back in the 1960s-1980s 10w30 was about the standard suggested oil viscosity, now its more like 5w30

oil changes were suggested at about 4000 mile intervals,in the 1960s-1990s,

now oil and filter changes at 7000-10K miles are very common.

https://www.translatorscafe.com/unit-converter/en/viscosity-kinematic/18-1/

Centistoke @

25° C 40° C 100° C

Driven BR30 5W-30 63 11

Driven FR20 5W-20 613 162 9

Driven FR50 5W-50 203 104 17.3

Driven DT40 5W-40 152 77 13

Driven DT50 15W-50 203 104 17.3

Driven LS30 5W-30 126 64 11

Driven HR Syn 10W-30 126 64 11

Driven HR Syn 10W-40 126 64 11

Driven HR Syn 15W-50 203 104 17.3

Driven HR Con 10W-30 135 64 10.3

Driven HR Con 10W-40

Driven HR Con 15W-50 139

Valvoline VR-1 10W-30 77 11.5

Valvoline VR-1 20W-50 181.8 20.5

Valvoline VR-1 Syn 10W-30 64 11.5

Valvoline VR-1 Syn 20W-50 147 20

Valvoline Syn SAE 0W-16 34.4 6.8

Valvoline Syn SAE 0W-20 42.2 8.1

Valvoline Syn SAE 5W-20 46.5 8.1

Valvoline Syn SAE 5W-30 60.1 10.2

Valvoline Syn SAE 10W-30 66.8 10.8

Valvoline Syn MST 5W-30 70.6 12.2

Valvoline Syn MST 5W-40 79 13.1

Valvoline Syn HST 5W-40 82 13.5

Valvoline Syn XL-III 5W-30 68.1 11.7

Valvoline Syn 0W-40 77 13.5

Valvoline Syn 20W-50 139 19

Valvoline Syn HM 0W-20 42.8 8.1

Valvoline Syn HM 5W-20 46.1 8.1

Valvoline Syn HM 5W-30 59 10.1

Valvoline Syn HM 10W-30 67.2 10.8

Valvoline Con 5W-20 50 8.5

Valvoline Con 5W-30 63 11

Valvoline Con 10W-30 69.7 10.5

Valvoline Con 10W-40 104 15.1

Valvoline Con 20W-50 170.9 18.5

Valvoline Con 30 82 10.3

Valvoline Con 40 127 13.5

Valvoline Con 50 223 20

Mobil 1 Syn EP 5W-20 49.6 8.9

Mobil 1 Syn EP 0W-20 44.9 8.6

Mobil 1 Syn EP 5W-30 59.8 10.6

Mobil 1 Syn EP 10W-30 63.7 10.2

Mobil 1 Syn HM 0W-20 9

Mobil 1 Syn HM 5W-20 50 8.6

Mobil 1 Syn HM 5W-30 72 12.1

Mobil 1 Syn HM 10W-30 78 12.1

Mobil 1 Syn HM 10W-40 107 16

Mobil 1 Syn FS 0W40 70.8 12.9

Mobil 1 Syn 5W-20 49.8 8.9

Mobil 1 Syn 5W-30 61.7 11

Mobil 1 Syn 10W-30 63.2 10.1

Mobil 1 Syn FS X2 5W-50 104.3 17.1

Mobil 1 Syn 15W-50 125 18

Motul 300V Syn 0W-20 42 8

Motul 300V Syn 5W-30 64 11

Motul 300V Syn 0W-40 75.7 13.6

Motul 300V Syn 5W-40 81.8 13.6

Motul 300V Syn 15W-50 122.9 18.1

Motul 300V Syn 20W-60 168.3 23.8

Motul 300V Syn 0W-15 23.3 5.1

Castrol EDGE 5W-30 62.64 10.7

Castrol EDGE 5W-40 84.2 14.1

Castrol EDGE 5W-50 114.36 18.4

Castrol EDGE 10W-30 71.5 11.3

Castrol EDGE 10W-40 91.89 14.6

Castrol EDGE 10W-60 160 22.7

Castrol EDGE HM 5W-30 67.2 11.3

Castrol EDGE HM 10W-30 71.5 11.5

Castrol EDGE HM 10W-40 91.89 14.78

Castrol GTX 10W-30 70.1 10.85

Castrol GTX 10W-40 108.8 14.3

Castrol GTX 15W-40 107.7 13.8

Castrol GTX 20W-50 158.7 18.1

Castrol GTX 5W-20 52.98 9.1

Castrol GTX HM 10W-30 73.23 11.7

Castrol GTX HM 10W-40 104.2 15.6

Castrol GTX HM 20W-50 187.7 20.3

Castrol GTX HM 25W-60 215.1 23.4

Castrol GTX HM 5W-20 51.6 8.9

Castrol GTX HM 5W-30 68.6 11.7

keep in mind that your oil pressure gauge measures the resistance to flow the oil sees as it flows thru the bearing clearances, larger clearances will require higher flow rates or a higher viscosity oil, higher flow rates can be supplied with a high volume oil pump but that also requires a larger baffled oil pan and windage screen to control the higher oil flow rates

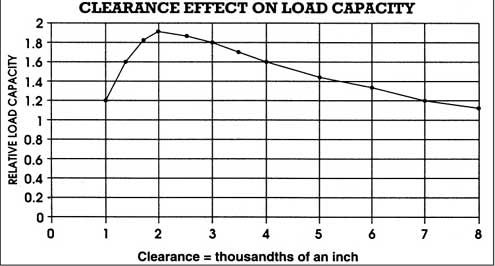

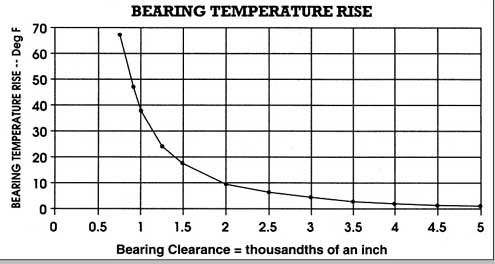

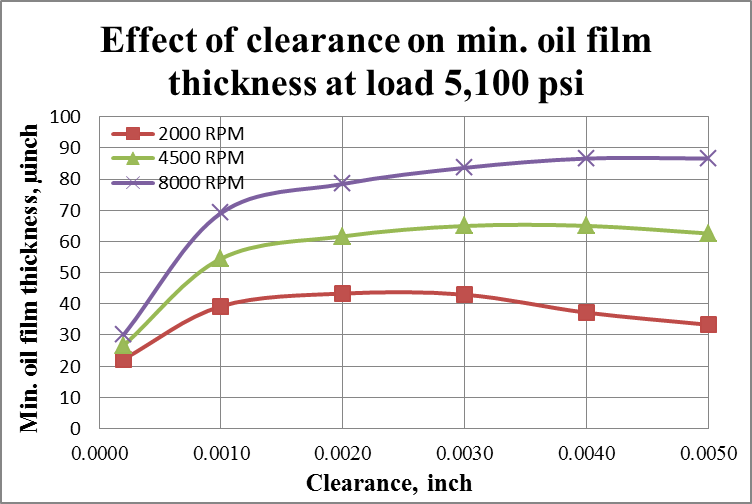

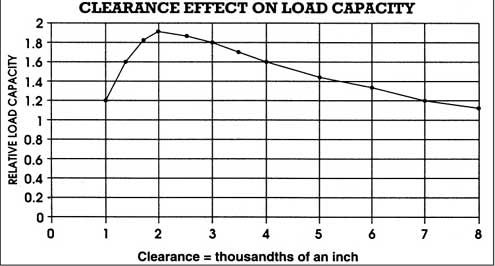

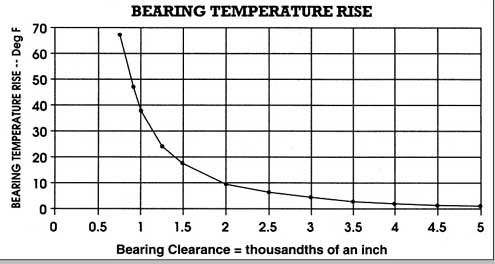

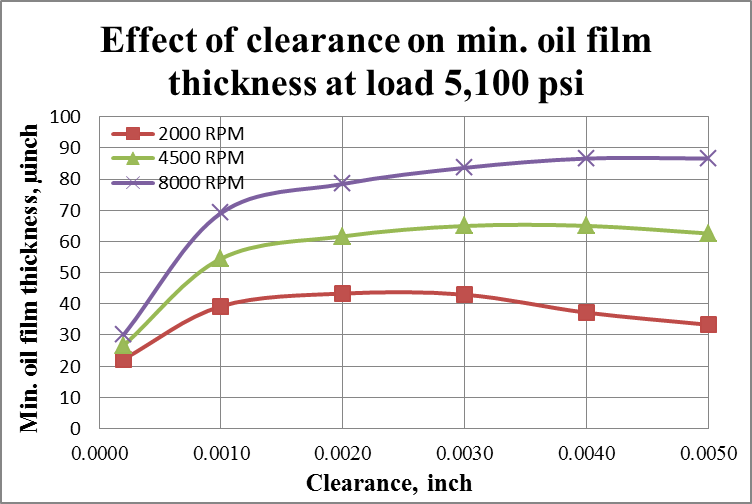

look at the charts, it should be rather obvious that bearing clearances in the 2-2.5 thousands range,

provide a good balance between bearing support, capacity, heat heat absorption, bearing cooling and oil flow rates required

Molybdenum is a very hard metal with a number of industrial uses.

It is combined with chromium in steel to make the steel harder and more resistant to bending. Most of the bicycle frames produced today use chromium and molybdenum steel. Because the steel is so much harder, the manufacturers can use less, thereby making the frame lighter.

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts.

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out.

Eventually, there is metal to metal contact, which damages these moving parts and creates large amounts of heat. Fortunately, this is not the case with some lubricants.The layer of moly that forms on these moving surfaces can withstand pressures of 500,000 psi, without being squeezed out.

READ THE RELATED LINKED INFO

http://garage.grumpysperformance.com/index.php?threads/which-oil-what-viscosity.1334/

http://garage.grumpysperformance.com/index.php?threads/magnets.120/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://kingbearings.com/wp-content/uploads/2014/10/optimization-of-clearance-engine-professional.pdf

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/assembly-lube-summary.6352/#post-56615

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

ok lets start with the basics,

oil flowing over the moving surfaces in any engine is used too,

absorb and transfer heat away from, and separate

and prevent physical contact between moving surfaces,

AND as the oil passes over and between the two surfaces,

pressurized oil flow, absorbs and transports the heat from combustion and friction away from the parts.

oil does almost all initial cooling, oil flow over the block transfers heat to the coolant, coolant transfers that heat to the outside air flow.

every choice you make is a compromise in several areas.

keep in mind that your oil pressure gauge measures the resistance to flow the oil sees as it flows thru the bearing clearances, larger clearances will require higher flow rates or a higher viscosity oil, higher flow rates can be supplied with a high volume oil pump but that also requires a larger baffled oil pan and windage screen to control the higher oil flow rates

thicker or higher viscosity oils flow slower, at lower temps, this means a minor delay in how fast oil reaches the bearings surfaces in colder temps but it almost always results in a bit more volume or distance between the supported surfaces, of oil on/between the bearing surfaces , that pressurized oil between the bearing and both moving surfaces ,the oil flow provides is preventing from direct physical contact between the bearing and the moving parts in a running engine

keep in mind oil temperature and the viscosity at that temperature will effect how rapidly,

the oil can flow into and through the clearances between the moving surfaces.

thinner oils flow faster and in most case.s absorb and transfer trapped heat away from surfaces more rapidly,

this is one reason the newer engine designs with tighter tolerances use thinner viscosity oils.

different oils penetrate into and fill clearances between moving surfaces at a significantly different flow rates,

doing some research on the oil you select, vs your options never hurts.

and most engine wear occurs at start-up while lubricants are cooler and the areas between moving surfaces may not have yet been supported by a pressurized film of hot flowing oil keeping the two adjacent surfaces separated, thinner viscosity tends to fill hydraulic lifters and bearing clearances far more rapidly.

this is also why use of a moly based assembly lube that fills the micro surfaces is beneficial.

Oil additives are chemical compounds that improve the performance of an oil's base stock. They are included by the oil manufacturer to enhance lubrication, modify viscosity, clean engine deposits that can lead to sludge, and prevent corrosion.

The centistoke is a unit of measurement of kinematic viscosity. A centistoke (cSt) is the derived centimeter-gram-second (CGS) unit of kinematic viscosity.

(think of this (centistoke )as the metric definition of how rapidly clearances between bearings and moving surfaces like rockers,

and how fast hydraulic lifters get filled and pressurized,

so they don,t click )(thinner (lower numbers) tends to be faster too, flow into and fill voids/ clearances) obviously as oil heats up the viscosity drops and it much more easily flows into restrictive clearances, but on initial start-up the thinner oils reach and lubriicate parts significantly faster

What is viscosity?

This question is often best answered by example. Imagine a styrofoam cup with a hole in the bottom. If I then pour honey into the cup I will find that the cup drains very slowly. That is because honey's viscosity is large compared to other liquids' viscositie's. If I fill the same cup with water, for example, the cup will drain much more quickly.

Viscosity is a measure of a fluid's resistance to flow. It describes the internal friction of a moving fluid. A fluidwith large viscosity resists motion because its molecular makeup gives it a lot of internal friction. A fluid with low viscosity flows easily because its molecular makeup results in very little friction when it is in motion.

engine oil operates at about 180F-240F in most cases.

, its required to allow the bearings, valve train.pistons and rings to function and remain cool.

oil temps under about 180F will not flow and lube well, and oil temps over about 240f tend to degrade and loose the ability to lubricate, the higher the temp the faster this tends to happen, most oils degrade very rapidly at temps exceeding 275f.

30-50 years ago thicker oil viscosity was required as the technology was not then common too manufacture consistently or maintain precise clearances and oils were of far lower quality, with todays better synthetic oil blends clearances that were virtually impossible too machine or maintain are now common.

back in the 1960s-1980s 10w30 was about the standard suggested oil viscosity, now its more like 5w30

oil changes were suggested at about 4000 mile intervals,in the 1960s-1990s,

now oil and filter changes at 7000-10K miles are very common.

https://www.translatorscafe.com/unit-converter/en/viscosity-kinematic/18-1/

Centistoke @

25° C 40° C 100° C

Driven BR30 5W-30 63 11

Driven FR20 5W-20 613 162 9

Driven FR50 5W-50 203 104 17.3

Driven DT40 5W-40 152 77 13

Driven DT50 15W-50 203 104 17.3

Driven LS30 5W-30 126 64 11

Driven HR Syn 10W-30 126 64 11

Driven HR Syn 10W-40 126 64 11

Driven HR Syn 15W-50 203 104 17.3

Driven HR Con 10W-30 135 64 10.3

Driven HR Con 10W-40

Driven HR Con 15W-50 139

Valvoline VR-1 10W-30 77 11.5

Valvoline VR-1 20W-50 181.8 20.5

Valvoline VR-1 Syn 10W-30 64 11.5

Valvoline VR-1 Syn 20W-50 147 20

Valvoline Syn SAE 0W-16 34.4 6.8

Valvoline Syn SAE 0W-20 42.2 8.1

Valvoline Syn SAE 5W-20 46.5 8.1

Valvoline Syn SAE 5W-30 60.1 10.2

Valvoline Syn SAE 10W-30 66.8 10.8

Valvoline Syn MST 5W-30 70.6 12.2

Valvoline Syn MST 5W-40 79 13.1

Valvoline Syn HST 5W-40 82 13.5

Valvoline Syn XL-III 5W-30 68.1 11.7

Valvoline Syn 0W-40 77 13.5

Valvoline Syn 20W-50 139 19

Valvoline Syn HM 0W-20 42.8 8.1

Valvoline Syn HM 5W-20 46.1 8.1

Valvoline Syn HM 5W-30 59 10.1

Valvoline Syn HM 10W-30 67.2 10.8

Valvoline Con 5W-20 50 8.5

Valvoline Con 5W-30 63 11

Valvoline Con 10W-30 69.7 10.5

Valvoline Con 10W-40 104 15.1

Valvoline Con 20W-50 170.9 18.5

Valvoline Con 30 82 10.3

Valvoline Con 40 127 13.5

Valvoline Con 50 223 20

Mobil 1 Syn EP 5W-20 49.6 8.9

Mobil 1 Syn EP 0W-20 44.9 8.6

Mobil 1 Syn EP 5W-30 59.8 10.6

Mobil 1 Syn EP 10W-30 63.7 10.2

Mobil 1 Syn HM 0W-20 9

Mobil 1 Syn HM 5W-20 50 8.6

Mobil 1 Syn HM 5W-30 72 12.1

Mobil 1 Syn HM 10W-30 78 12.1

Mobil 1 Syn HM 10W-40 107 16

Mobil 1 Syn FS 0W40 70.8 12.9

Mobil 1 Syn 5W-20 49.8 8.9

Mobil 1 Syn 5W-30 61.7 11

Mobil 1 Syn 10W-30 63.2 10.1

Mobil 1 Syn FS X2 5W-50 104.3 17.1

Mobil 1 Syn 15W-50 125 18

Motul 300V Syn 0W-20 42 8

Motul 300V Syn 5W-30 64 11

Motul 300V Syn 0W-40 75.7 13.6

Motul 300V Syn 5W-40 81.8 13.6

Motul 300V Syn 15W-50 122.9 18.1

Motul 300V Syn 20W-60 168.3 23.8

Motul 300V Syn 0W-15 23.3 5.1

Castrol EDGE 5W-30 62.64 10.7

Castrol EDGE 5W-40 84.2 14.1

Castrol EDGE 5W-50 114.36 18.4

Castrol EDGE 10W-30 71.5 11.3

Castrol EDGE 10W-40 91.89 14.6

Castrol EDGE 10W-60 160 22.7

Castrol EDGE HM 5W-30 67.2 11.3

Castrol EDGE HM 10W-30 71.5 11.5

Castrol EDGE HM 10W-40 91.89 14.78

Castrol GTX 10W-30 70.1 10.85

Castrol GTX 10W-40 108.8 14.3

Castrol GTX 15W-40 107.7 13.8

Castrol GTX 20W-50 158.7 18.1

Castrol GTX 5W-20 52.98 9.1

Castrol GTX HM 10W-30 73.23 11.7

Castrol GTX HM 10W-40 104.2 15.6

Castrol GTX HM 20W-50 187.7 20.3

Castrol GTX HM 25W-60 215.1 23.4

Castrol GTX HM 5W-20 51.6 8.9

Castrol GTX HM 5W-30 68.6 11.7

keep in mind that your oil pressure gauge measures the resistance to flow the oil sees as it flows thru the bearing clearances, larger clearances will require higher flow rates or a higher viscosity oil, higher flow rates can be supplied with a high volume oil pump but that also requires a larger baffled oil pan and windage screen to control the higher oil flow rates

look at the charts, it should be rather obvious that bearing clearances in the 2-2.5 thousands range,

provide a good balance between bearing support, capacity, heat heat absorption, bearing cooling and oil flow rates required

Molybdenum is a very hard metal with a number of industrial uses.

It is combined with chromium in steel to make the steel harder and more resistant to bending. Most of the bicycle frames produced today use chromium and molybdenum steel. Because the steel is so much harder, the manufacturers can use less, thereby making the frame lighter.

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts.

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out.

Eventually, there is metal to metal contact, which damages these moving parts and creates large amounts of heat. Fortunately, this is not the case with some lubricants.The layer of moly that forms on these moving surfaces can withstand pressures of 500,000 psi, without being squeezed out.

READ THE RELATED LINKED INFO

http://garage.grumpysperformance.com/index.php?threads/which-oil-what-viscosity.1334/

http://garage.grumpysperformance.com/index.php?threads/magnets.120/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://kingbearings.com/wp-content/uploads/2014/10/optimization-of-clearance-engine-professional.pdf

http://garage.grumpysperformance.com/index.php?threads/cam-wear-articles-you-need-to-read.282/

http://garage.grumpysperformance.com/index.php?threads/assembly-lube-summary.6352/#post-56615

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

Last edited: