yes thats usually a good place to set it, but just a side note, I purchased an aftermarket 6-8 quart rated oil pan for my 1985 corvette with its 383, a fabricated an extended sump so if its filled to the counter weight depth it holds almost 11 quarts, I generally run 9-10 quarts, but that includes the volume in the oil cooler.

every one seems mesmerized by the idea of purchasing and installing parts like big lopey cams and intake manifolds, but its a well designed lubrication and cooling system that helps the engine live under stress.

KEEP IN MIND the object is not to have a certain oil level, its to keep the oil pump pick-up covered and maintain consistent pressurized oil flow on all the moving components as oil flow cools and lubricates those surfaces, and in the case of bearings supports and separates the moving surfaces

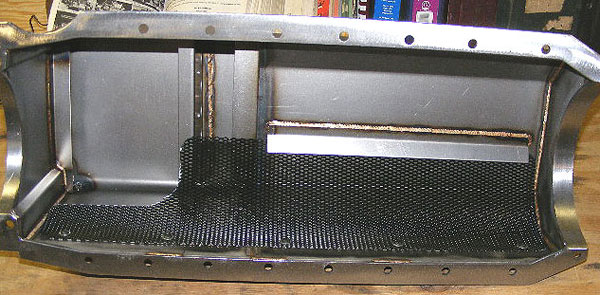

I ran across these first two pictures, on a different site and felt they could be useful as a teaching aid,

the owner obviously has installed a slosh baffle gate in the lower sump and the rear area has what appears to be a partial windage screen, obviously this will function better than if he had not taken any effort and simply installed a open oil pan sump like most cars engines come with, but he stopped well short of the ideal oil control level that could have been reached.

I think the screening must have been having a clearance issue in the forward area of the oil pan under the forward four cylinders from the look of the way the screen was cut, now assuming there was room and no suspension or cross member prevented it a deeper pan or modifying the current oil pan seems like an option, a solid sheet metal horizontal upper sump slosh baffle should have extended back under the windage screen , and over the oil pan sump at the level of the upper oil pan floor ,well past the location of the swinging oil gate , to prevent oil from rushing forward under hard braking, not having the upper plate in place defeats a great deal of the purpose of having the lower slosh gate

(similar to the third picture)

KEEP IN MIND THERES SEVERAL THINGS GOING ON IN A PROPERLY DESIGNED OIL PAN

THE MAIN OBJECT IS TO MAINTAIN A CONSTANT DEPENDABLE SUPPLY OF OIL OVER THE OIL PUMP PICK UP, and REDUCE THE RESISTANCE THE SPINNING CRANK SEES PUSHING RETURNING OIL AROUND IN THE CRANK CASE

(1)the upper full length slosh plate,over the baffles and gates direct oil to the oil pump

(2)the screen allows oil to flow along the upper surface of the slosh plate back to the sump without the spinning crank assembly picking it up and circulating it in the crank case

(3)the screen shears off oil flow passing over its surface and directs oil into protected routes back to the sump

the area behind the screen but over the sump forms a semi-protected path for oil flow forced

by the spinning crank assembly to easily travel back to the sump. yet prevents oil slosh under hard braking

a windage screen like these mounted over the slosh plate adds a good deal more efficiency

HERES A DIFFERENT MANUFACTURERS OIL PAN,the oil pan below LACKS a SLOSH PLATE over the sump area and has very limited windage protection of the oil in the sump as a result, so even though it may look impressive it will likely not prevent oil windage effectively or force oil back into the sump or protect and trap oil under high g-loads during cornering or braking

there are some nice commercially made semi custom oil pans, but if you can weld and fabricate sheet metal you can custom build something thats a perfect fit to your chassis and fits your application exactly, and don,t ignore an oil accumulator, and remote mounted oil filters and remote mount fan equipped oil coolers as an additional option, to add capacity and cooling

http://aviaid.com/shopsite_sc/store/htm ... s_bbc.html

http://aviaid.com/shopsite_sc/store/htm ... s_sbc.html

viewtopic.php?f=32&t=3071&p=8131&hilit=corvette+quart#p8131

viewtopic.php?f=54&t=65

viewtopic.php?f=54&t=64

viewtopic.php?f=80&t=10514&p=44478&hilit=corvette+quart#p44478