Stick the Corners

Active Member

I wish I had something more fun to talk about, but need some information about tracking down a wiring glitch. The weird problem my 84 C4 has consists of failure of my left front sided turn signal lights including the signal side light and the emergency front left flashers. But when the parking light switch is turned on, that left same parking bulb, used for the flashers also, does go on. Only when the headlights are turned on, does the left side white cornering lamp go on WHEN THE LEFT TURN SIGNAL LEVER ON THE COLUMN IS PULLED DOWN. Other interesting features include the lack of fog lamp on left side only ( when rocker switch turned on in conjunction with headlight switch going on), and the horn constantly blasting steady after replacing the bad horn relay( which for sanity I disconnected.I guess I could reinstall that relay and button up my dash if I remove the wire to each horn.)The rear brake, turn signal,and emergency flashers seem to work normally, except the rear signal bulb on the left does not flash, unsurprisingly, like there was a blown bulb filament on the left front. All the bulbs have unbroken filaments and test positive for continuity. The craziness of it all suggests that I’m dealing with a dead ground and aberrant current flow looking for a good ground, but am open to suggestions.

I have replaced the emergency flasher module in the dash, to no avail, and am trying not to disassemble the dash further to replace the turn signal flasher module hidden on the right.

Just to help get me on the right path, I have the following questions:

1)Since the right turn signal works perfectly, does that rule out a problem with the the dash turn signal module affecting the left side?

2)Since the left turn signal lever turns on the left side cornering lamp (when headlights on) in conjunction with the rear lamp, even if it does not flash, does that prove the steering column signal lever switch is not defective?

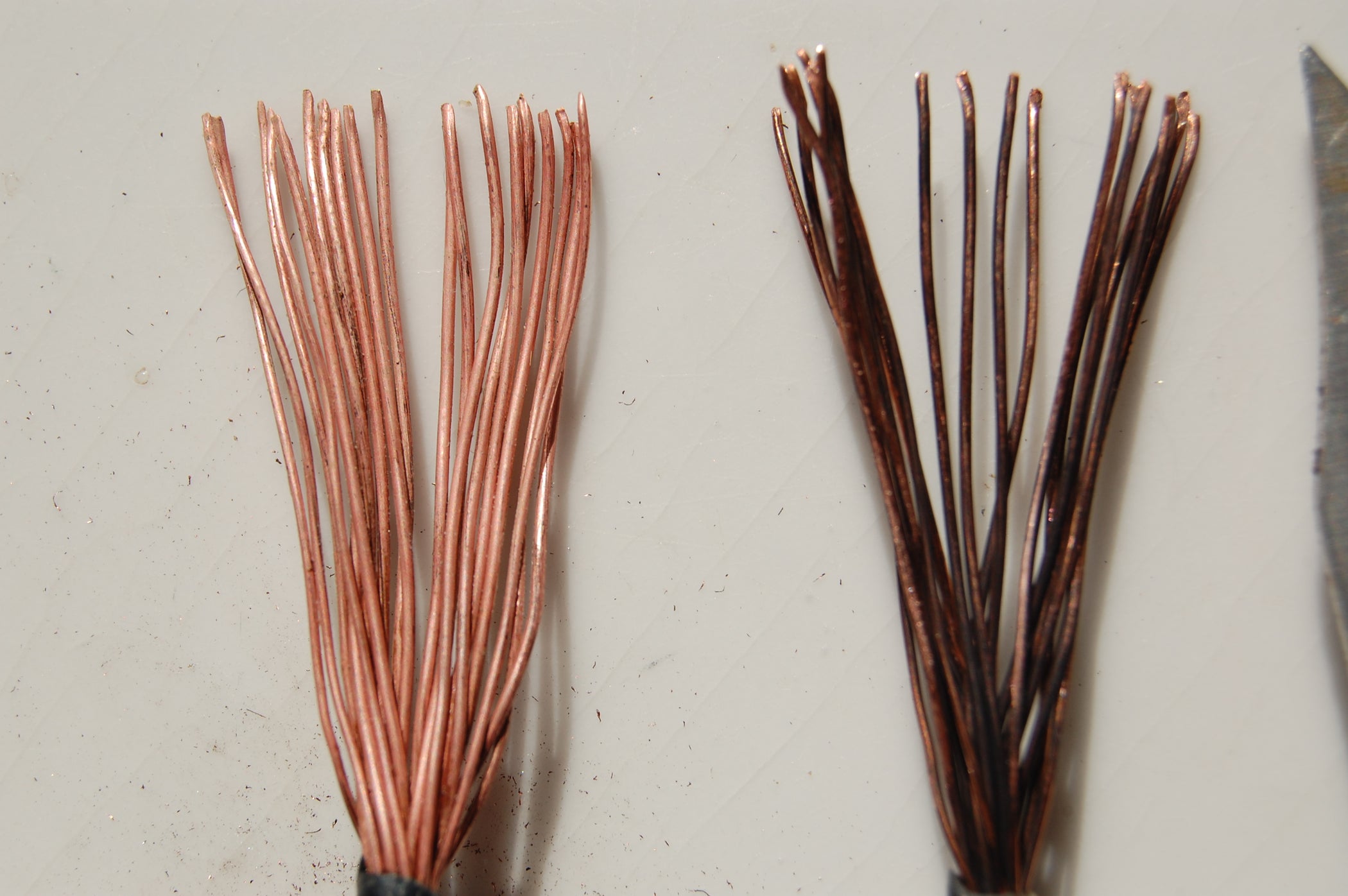

I thought I found a possible grounding short as I noted a lot of corrosion on a female connector( which had been left unconnected for years to keep the under hood lights from coming on.( see photos 1,2 and 3). If one looks at the ground diagram, it would seem that a short there could cause many problems with most of the issues cited above. However, when I pulled the connector apart, no improvement in the issues occurred. Unfortunately, I did not realize you had a link about pulling the leads out properly, so I just pulled the wires out sans leads. Hopefully, will do better on install.

I now either need a new female( not sure what to look for on the internet that will exactly fit the male connector from the hood) or the parts to disassemble the old and replace with new hardware to rewire after trying to clean all the corrosion.

3) Can anyone help with suggestions here?

Note: I do see Grumpy’s link here https://ceautoelectricsupply.com/product/2-position-weatherpack-connector-kit/

,but is this the correct connector for my 84 C4?

Again, after looking at the ground diagram, G107 is on the left radiator support.

4)Is that the ground in my photo?(5th photo)

I cleaned up that one and noted no extraneous voltage there (nor to the engine exhaust manifold)when checking with the HF cheap multimeter, and attached a direct negative from battery ground to that, but no change in symptoms.

Next, after following that ground up, there is what appears to to be a connector (not on the ground diagram) that I was trying to pull apart to see if the short was higher up in the harness, but it is unclear whether that should be separable by squeezing the plastic leg, or separating it further, and then pulling apart. (See photo 4th and 6th)

5)Guidance on this point is requested.

6)I wonder if using a signal generator ( the cheap one from harbor freight) connected to fuse box on this circuit, can help me track down where the circuit is discontinuous with the ground in the front engine bay. I’m trying not to put pin holes in the wiring to test trying to find a voltage drop(although I see your link for Permatex liquid copper)

Here are some voltages at the various receptacles.

I tested the voltage at each pole of parking light/turn signal/emergency flasher receptacle on left and right sides under different “power on configurations.”

Emerg flasher powered on:

Left

.4v one pole

.37 other pole

0-.01v spring side leg

Right

8v

.4v

0-.01v

Turn signal

Left

.15v

.11v

.01-.02v

Right

10.63v

.23v

.01-02v

Parking lights alone

Left

10.75v

11.93v

0

Right

10.82v

11.93v

0

Fog lamp receptacle with bulb in place

Left (not lit)

11.57v

.02v

Right (lit)

11.49v

.05v

Thanks again for your help. I’ll apologize in advance for not finding one of your many links that answer questions.

I have replaced the emergency flasher module in the dash, to no avail, and am trying not to disassemble the dash further to replace the turn signal flasher module hidden on the right.

Just to help get me on the right path, I have the following questions:

1)Since the right turn signal works perfectly, does that rule out a problem with the the dash turn signal module affecting the left side?

2)Since the left turn signal lever turns on the left side cornering lamp (when headlights on) in conjunction with the rear lamp, even if it does not flash, does that prove the steering column signal lever switch is not defective?

I thought I found a possible grounding short as I noted a lot of corrosion on a female connector( which had been left unconnected for years to keep the under hood lights from coming on.( see photos 1,2 and 3). If one looks at the ground diagram, it would seem that a short there could cause many problems with most of the issues cited above. However, when I pulled the connector apart, no improvement in the issues occurred. Unfortunately, I did not realize you had a link about pulling the leads out properly, so I just pulled the wires out sans leads. Hopefully, will do better on install.

I now either need a new female( not sure what to look for on the internet that will exactly fit the male connector from the hood) or the parts to disassemble the old and replace with new hardware to rewire after trying to clean all the corrosion.

3) Can anyone help with suggestions here?

Note: I do see Grumpy’s link here https://ceautoelectricsupply.com/product/2-position-weatherpack-connector-kit/

,but is this the correct connector for my 84 C4?

Again, after looking at the ground diagram, G107 is on the left radiator support.

4)Is that the ground in my photo?(5th photo)

I cleaned up that one and noted no extraneous voltage there (nor to the engine exhaust manifold)when checking with the HF cheap multimeter, and attached a direct negative from battery ground to that, but no change in symptoms.

Next, after following that ground up, there is what appears to to be a connector (not on the ground diagram) that I was trying to pull apart to see if the short was higher up in the harness, but it is unclear whether that should be separable by squeezing the plastic leg, or separating it further, and then pulling apart. (See photo 4th and 6th)

5)Guidance on this point is requested.

6)I wonder if using a signal generator ( the cheap one from harbor freight) connected to fuse box on this circuit, can help me track down where the circuit is discontinuous with the ground in the front engine bay. I’m trying not to put pin holes in the wiring to test trying to find a voltage drop(although I see your link for Permatex liquid copper)

Here are some voltages at the various receptacles.

I tested the voltage at each pole of parking light/turn signal/emergency flasher receptacle on left and right sides under different “power on configurations.”

Emerg flasher powered on:

Left

.4v one pole

.37 other pole

0-.01v spring side leg

Right

8v

.4v

0-.01v

Turn signal

Left

.15v

.11v

.01-.02v

Right

10.63v

.23v

.01-02v

Parking lights alone

Left

10.75v

11.93v

0

Right

10.82v

11.93v

0

Fog lamp receptacle with bulb in place

Left (not lit)

11.57v

.02v

Right (lit)

11.49v

.05v

Thanks again for your help. I’ll apologize in advance for not finding one of your many links that answer questions.

Attachments

-

5ED9D8D5-93EA-4FC8-A7DC-44133ECDD09C.jpeg80.6 KB · Views: 1

5ED9D8D5-93EA-4FC8-A7DC-44133ECDD09C.jpeg80.6 KB · Views: 1 -

D5CC41F1-7FE7-49CA-8205-CE036B53CB8B.jpeg82.9 KB · Views: 1

D5CC41F1-7FE7-49CA-8205-CE036B53CB8B.jpeg82.9 KB · Views: 1 -

E22F5CFF-4726-414C-9958-7F40737CA7BF.jpeg79 KB · Views: 1

E22F5CFF-4726-414C-9958-7F40737CA7BF.jpeg79 KB · Views: 1 -

86283D88-4079-4498-A6A5-8B74C80DB883.jpeg196.1 KB · Views: 1

86283D88-4079-4498-A6A5-8B74C80DB883.jpeg196.1 KB · Views: 1 -

B442BA6A-2FCC-462C-84D7-00F63A623210.jpeg177.1 KB · Views: 1

B442BA6A-2FCC-462C-84D7-00F63A623210.jpeg177.1 KB · Views: 1 -

52C09849-2355-413F-A89B-C963994CFCEC.jpeg220.8 KB · Views: 1

52C09849-2355-413F-A89B-C963994CFCEC.jpeg220.8 KB · Views: 1