hey every one its been a minute since I been around parked my truck for 5 years after the cam gear eat the dizzy gear but I got it back together and got it tuned and dyno'd

engine spec's with the last cam

Comp Cams XR269HR-12

@ .050 218 int./224 exh, 0.495 int./0.503 exh. lift, Lobe Separation 112

engine specs

350 over .030, 3.75 stroke, -16cc pistons, H beam rods & splayed caps 9.8 to 1 comp.

Dart Aluminum Pro 1, 200cc int, 64cc chambers, 2.02 int/1.60exh valves, int 264cfm @ .500" lift/28", exh 180cfm @ .600 lift/ 28" beehive springs install to new cam specs

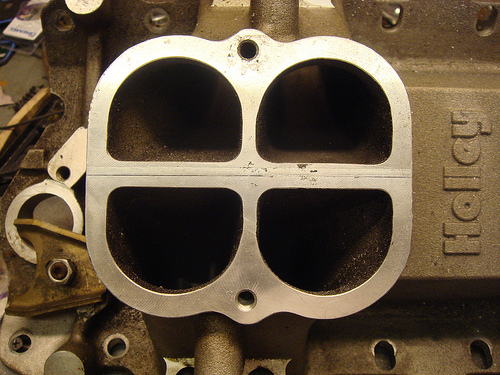

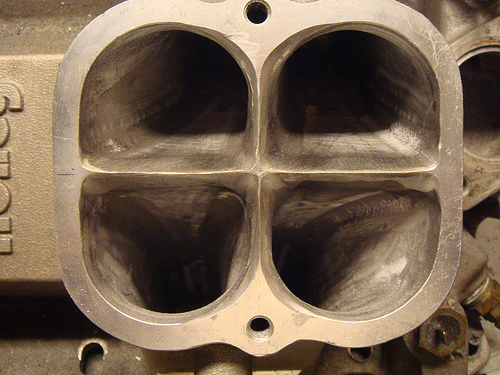

Holley Stealth Ram fuel injection system/ 950c ecu, 36lb injectors 1000cfm

700r4, edge 3k stall 12 bolt 3.73 and 29" tire

best dyno was 293rwhp (no torque numbers since they was not able to get a tech signal)

the new set up was porting the stealth ram intake polishing the combustion chambers and mild port on the heads new cam

Lunati 54799lun

@ .050 int 231/ exh 239, .535 int. / .550 exh

the new numbers are 342rwhp again no torque numbers

I dont feel its 100% dialed in, the tuner did not like the 950 commander pro software and was annoyed by it (not enough tunablity for him) he had it at 320rwhp I pushed him some and he messed with it found another 23rwhp and said thats all he can get, I think there might be "some" HP left on the table but it cant be much? similar engine have made well over 370rwhp at this point I feel a "little" cheated / disappointed since i dont feel it has the missing 30 or so HP in it maybe 10 or so if the tune is dead on.......

Grumpy I'm interested to read your thoughts? you gave me a bunch of advice along the way and always appreciated it :mrgreen:

engine spec's with the last cam

Comp Cams XR269HR-12

@ .050 218 int./224 exh, 0.495 int./0.503 exh. lift, Lobe Separation 112

engine specs

350 over .030, 3.75 stroke, -16cc pistons, H beam rods & splayed caps 9.8 to 1 comp.

Dart Aluminum Pro 1, 200cc int, 64cc chambers, 2.02 int/1.60exh valves, int 264cfm @ .500" lift/28", exh 180cfm @ .600 lift/ 28" beehive springs install to new cam specs

Holley Stealth Ram fuel injection system/ 950c ecu, 36lb injectors 1000cfm

700r4, edge 3k stall 12 bolt 3.73 and 29" tire

best dyno was 293rwhp (no torque numbers since they was not able to get a tech signal)

the new set up was porting the stealth ram intake polishing the combustion chambers and mild port on the heads new cam

Lunati 54799lun

@ .050 int 231/ exh 239, .535 int. / .550 exh

the new numbers are 342rwhp again no torque numbers

I dont feel its 100% dialed in, the tuner did not like the 950 commander pro software and was annoyed by it (not enough tunablity for him) he had it at 320rwhp I pushed him some and he messed with it found another 23rwhp and said thats all he can get, I think there might be "some" HP left on the table but it cant be much? similar engine have made well over 370rwhp at this point I feel a "little" cheated / disappointed since i dont feel it has the missing 30 or so HP in it maybe 10 or so if the tune is dead on.......

Grumpy I'm interested to read your thoughts? you gave me a bunch of advice along the way and always appreciated it :mrgreen: