I had bob stop by with a friend who had a 1967 corvette that he had installed a really nice 427 big block with a 1/2" stroker kit

making it a 489 cid stroker , the engine looked really great as the owner had done extremely impressive paint and chrome detail work and accents and cleaned up the engine bay to show room condition.

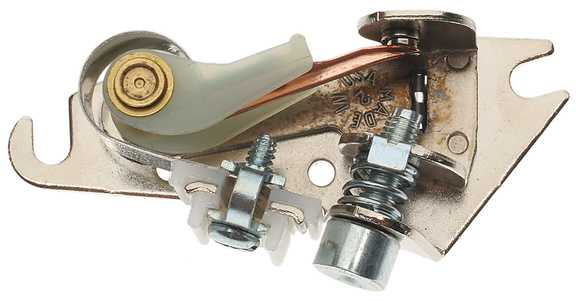

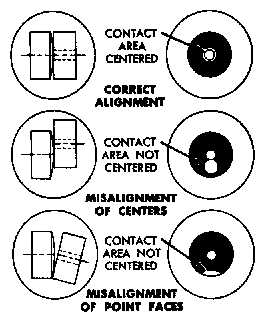

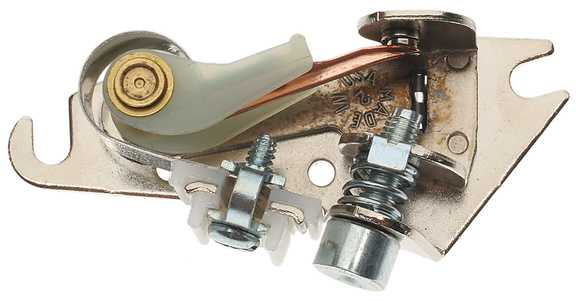

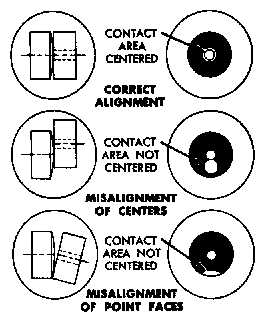

the problem was that it ran like crap once the rpms exceeded about 5000rpm as he still had a points distributor installed, and had well worn points, these points were purchased only 3000-3500 miles ago yet they were well worn,the new replacement points were purchased at NAPA and comparing them side bye side showed obviously stronger construction.

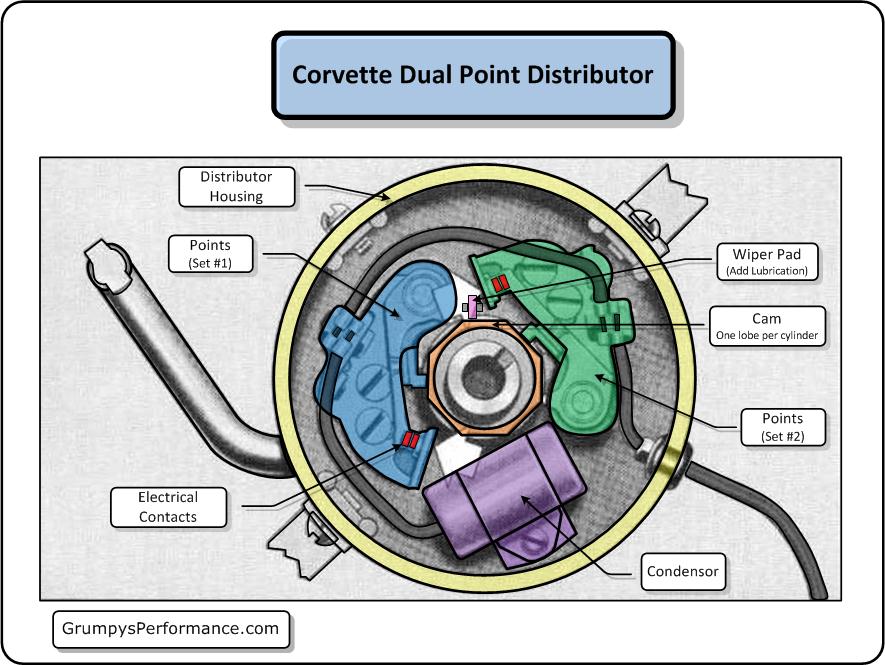

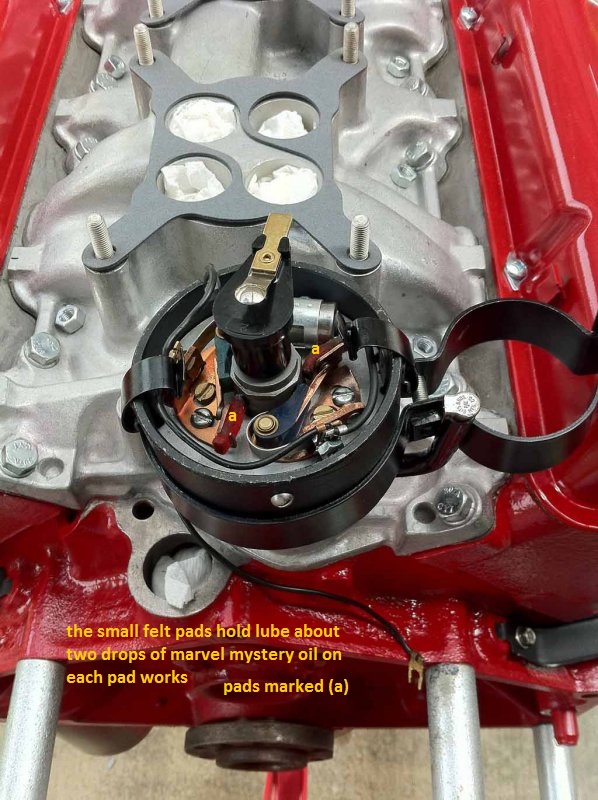

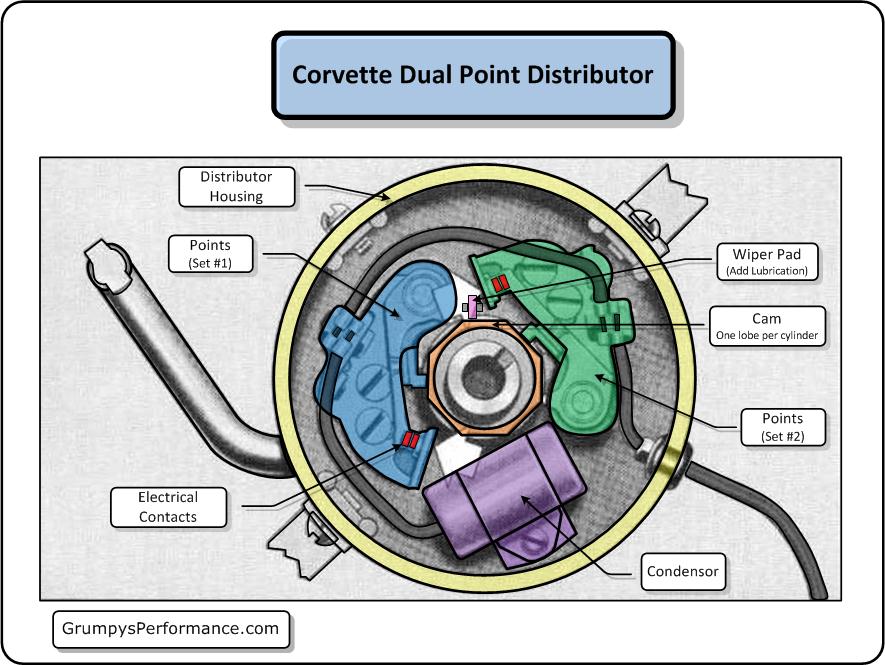

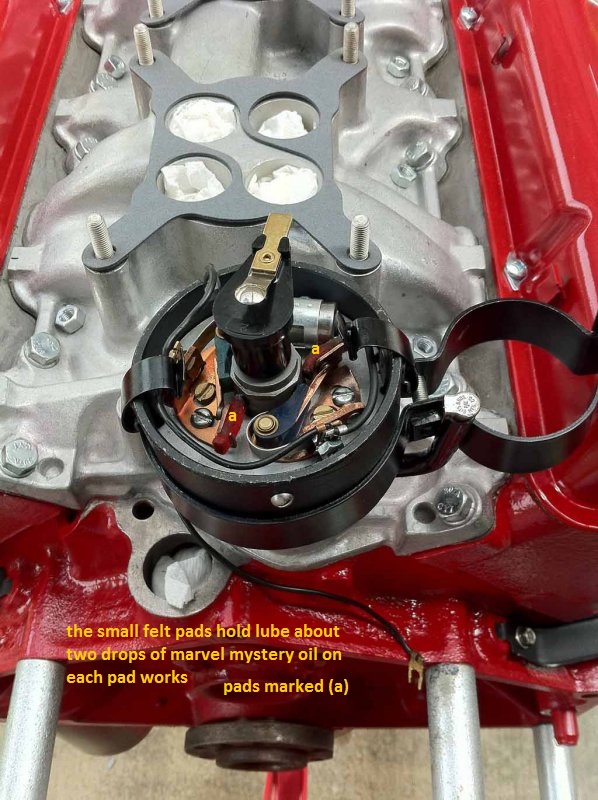

the problem was easily traced to a set of defective ignition points, and it appeared he had never put lube on the distributor lube pad.

those little felt pads on each set of points are generally oiled and a finger tip of MOLY grease on the cam won,t hurt either.

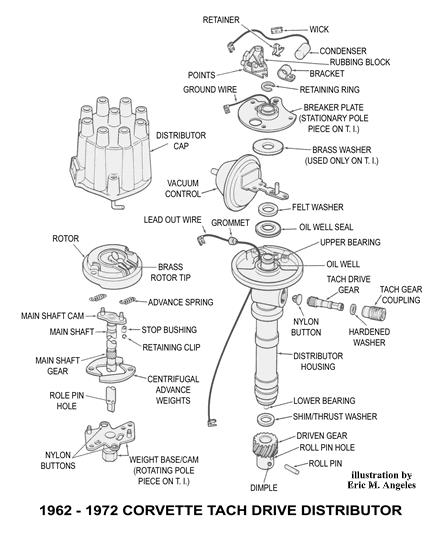

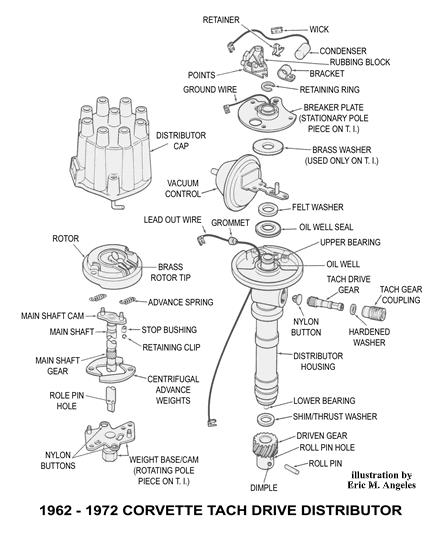

Bob installed, and having never even seen the inside of a dual point distributor, prior to this car, bob has no idea how to install,or set up points, previously.

corvette dual points ,which it seems are very hard to locate at most local auto parts stores.

a dual point distributor is not difficult to work with but it is old school tech, the newer systems are usually more durable and take less maintenance, BTW be sure to lubricate the wiper pad on the distributors cam as a worn distributor cam on a 40-45 year old ignition is a common problem, in this case , installing two new sets of points and the car ran far better

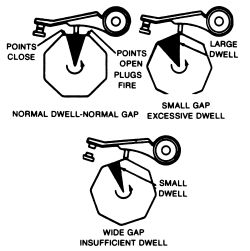

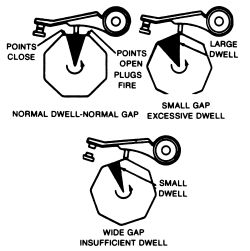

on Corvette (Delco) dual-point distributors, each set of points is adjusted individually to 27-29 degrees dwell (by blocking the other set with a small piece of matchbook cover or business card), and with both sets operating, dwell should be 32-34 degrees.

you might want to watch this video on swapping to low resistance ignition wire

its the AMP load that heats and burns points, getting 20-25 k miles is very common before you notice any need to clean and reset points in my experience, youll want a dwell meter and a points file if your going old school ignitions

http://www.amazon.com/dp/B000N31ZTE/ref ... B000N31ZTE

http://www.amazon.com/Actron-CP7605-Tac ... B00062YUUS

because of easy interchangeability between most SBC and even the BBC engines , the early dual point distributors can be, and frequently were a commonly swapped to ignition, upgrade, but most originally came in...

1957 283 Passenger 245 & 270 HP 2X4

1957 283 Corvette 220, 245, 270 HP 2X4

1958-61 283 Corvette 245, 270 HP 2X4

http://www.mre-books.com/chevy/engines/ ... ition.html

http://www.tispecialty.com/articles/article6.htm

1953 - 1967 Corvette Specification Guide

(1953-1967 Delco-Remy Ignition Distributors)

1953-55

1112314 1953-1955 Six-Cylinder Engines

1110855 1955 V-8 Engines with vacuum advance

1110847 Some later 1955 V-8 Engines with no vacuum advance

1956

1110872 Early Engines

1110879 Late Engines

1957

1110891 220, 245 & 270 Horsepower Engines

1110889 Early 250 & 283 Horsepower Engines (with FI unit 4360)

1110905 Mid-to-End 250 & 283 Horsepower FI Engines with Manual Transmission (with FI units 4360, 4520, 4800 & 4960) Mid-to-Late 250 Horsepower FI Engine with Powerglide

1110906 Late 250 Horsepower FI Engine with Powerglide (with FI units 4520 & 4800)

1110908 Mid-to-End RPO 579E & Some Late 283 Horsepower (with FI unit 4960)

1958-1961

1110890 1958 230 Horsepower Engine

1110946 1959-61 230 Horsepower Engine

1110891 1958-61 245 & 270 Horsepower 2x4BC Engines

1110908 Early 1958 290 Horsepower FI Engine

1110914 Mid-1958 through 1960 290 Horsepower & 1961 315 HP FI Engines

1110915 1958-1960 250 HP & 1961 275 Horsepower FI Engines

1962

1110984 250 & 300 Horsepower Engines

1110985 340 Horsepower Engine

1110990 Early 360 Horsepower FI Engine

1111011 Mid-to-Late 360 Horsepower FI Engine

1963

1111024 250, 300 & 340 Horsepower Engines

1111022 360 Horsepower FI Engine

1964

1111024 250 & 300 Horsepower Engines

1111062 Early 365 Horsepower Engine

1111069 2nd Production 365 Horsepower Engine

1111060 365 Horsepower Engine with K66 Transistor Ignition

1111063 Early 375 Horsepower FI Engine

1111070 2nd Production 375 Horsepower FI Engine

1111064 375 Horsepower FI Engine with K66 Transistor Ignition

1965

1111076 250 & 300 Horsepower 327 Engines

1111087 350 Horsepower 327 Engine

1111088 350 Horsepower 327 Engine with K66 Transistor Ignition

1111069 365 Horsepower 327 Engine

1111060 365 Horsepower 327 Engine with K66 Transistor Ignition

1111070 375 Horsepower 327 Engine

1111064 375 Horsepower 327 Engine with K66 Transistor Ignition

1111093 425 Horsepower 396 Engine with K66 Transistor Ignition

1966

1111153 300 Horsepower 327 Engine

1111156 350 Horsepower 327 Engine

1111157 350 Horsepower 327 Engine with K66 Transistor Ignition

1111141 390 Horsepower 427 Engine

1111142 390 Horsepower 427 Engine with K66 Transistor Ignition

1111093 425 Horsepower 427 Engine with K66 Transistor Ignition

1967

1111194 300 Horsepower 327 Engine

1111117 300 Horsepower 327 Engine with Powerglide & K19 Air Injection Reactor

1111196 350 Horsepower 327 Engine

1111157 350 Horsepower 327 Engine with K66 Transistor Ignition

1111141 Early 390 Horsepower 427 Engine (1966 carryover)

1111247 390 & 400 Horsepower 427 Engines

1111248 Early 390 & 400 Horsepower 427 Engines with K66 Transistor Ignition

1111294 2nd Production 390 & 400 HP 427 Engines with K66 Transistor Ignition

1111240 L88 427 Engine with K66 Transistor Ignition

1111258 435Horsepower 427 Engine with K66 Transistor Ignition

Note: Delco-Remy Ignition coils are embossed with the last three digits of the part numbers listed.

1953 - 1967 Corvette Specification Guide

(1953-1967 Corvette Delco-Remy Ignition Coils)

1953-1955

1115394 1953-55 Six-Cylinder Engines

1115086 1995 V-8 Engines

1956-1962

1115091 All Carbureted Engines

1115107 All Fuel Injected Engines

1963

1115091 Early; All Engines

1115087 Mid-to-Late; All Engines

1964

1115087 250 & 300 Horsepower 327 Engines

1115091 365 & 375 Horsepower 327 Engines

1115196 K66 Transistor Ignition System (early; usage unverified)

1115176 K66 Transistor Ignition System

1965

1115202 327 Engines with Standard Ignition

1115203 Early 350, 365 & 375 HP 327 Engines with K66 Transistor Ignition

1115207 Mid-to-Late 350, 365 & 375 HP with K66 Transistor Ignition

1115210 425 Horsepower 396 Engine with K66 Transistor Ignition

1966

1115202 300 & 350 Horsepower 327 Engines with Standard Ignition

1115232 or 1115262 390 Horsepower 427 Engine with Standard Ignition

1115207 350 Horsepower 327 Engine with K66 Transistor Ignition

1115210 Early 390 HP 427 Engine with Manual Trans. & K66 Trans. Ignition

1115261 390 HP 427 Engine with Powerglide & K66 Transistor Ignition

1115231 or 1115261 Mid-to-Late 390 & 425 HP with Manual Trans. & K66 Trans. Ignition

1967

1115202 300 & 350 Horsepower 327 Engines with Standard Ignition

1115207 350 Horsepower 327 Engine with K66 Transistor Ignition

1115264 390 & 400 Horsepower 427 Engine with Standard Ignition

1115263 390, 400, 435 HP & L88 427 Engines with K66 Transistor Ignition

Note: Delco-Remy ignition coils are embossed with the last three digits of the part numbers listed.

Previous Page Next Page

viewtopic.php?f=70&t=6778&p=21751&hilit=corvette+distributor#p21751

http://www.socalsacc.com/Ignition Timing.htm

http://www.centuryperformance.com/setti ... pg-90.html

viewtopic.php?f=69&t=2165

http://mgaguru.com/mgtech/ignition/ig200.htm

http://www.earlycorvettes.com/corvetteg ... 56to57.pdf

http://www.gofastforless.com/ignition/points.htm

http://www.summitracing.com/parts/ANM-CP7605

viewtopic.php?f=70&t=855

http://www.wernersparts.com/Distributors.htm

http://www.corvettefever.com/techarticl ... ewall.html

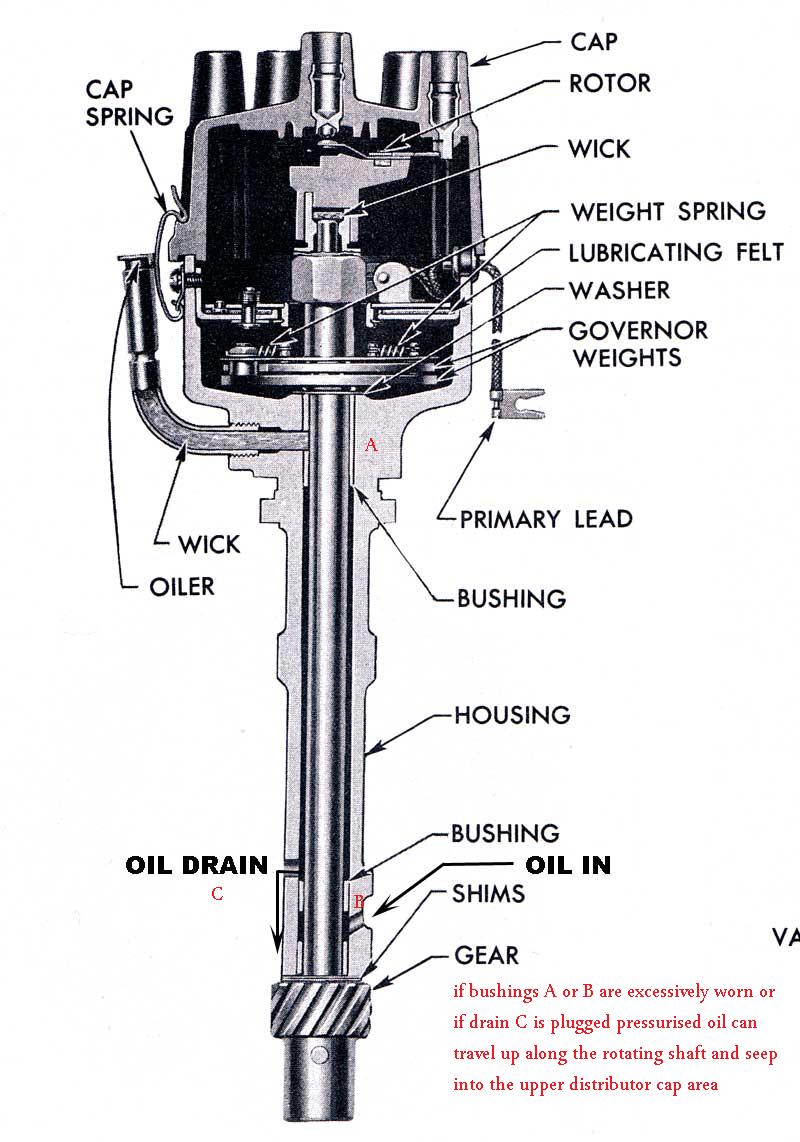

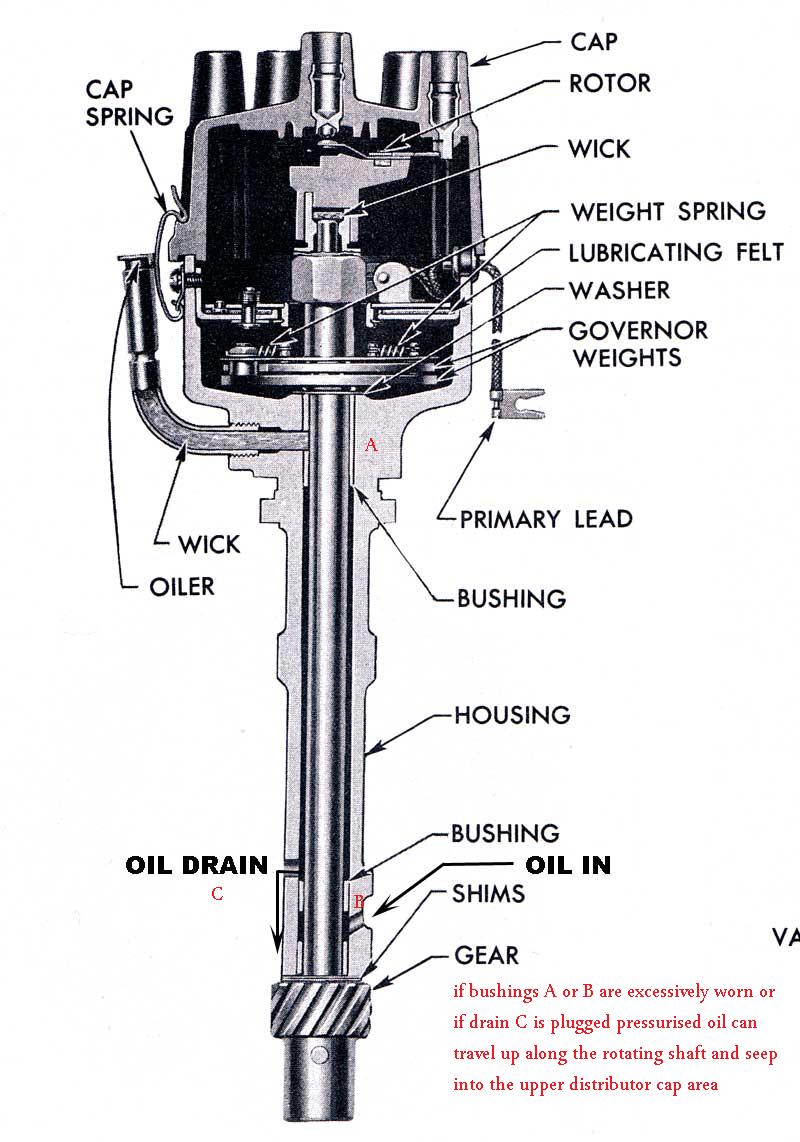

HERES A PICTURE OF A SIMILAR DISTRIBUTOR ON A SBC ENGINE

RELATED THREAD

viewtopic.php?f=70&t=251&p=299#p299

MALLORY SELLS A NEW QUALITY DUAL POINT CORVETTE STYLE DISTRIBUTOR #2664501

these are small base and easy to use with a tunnel ram intake which makes then very useful if you don,t want to spent the cash for a vertex magneto

making it a 489 cid stroker , the engine looked really great as the owner had done extremely impressive paint and chrome detail work and accents and cleaned up the engine bay to show room condition.

the problem was that it ran like crap once the rpms exceeded about 5000rpm as he still had a points distributor installed, and had well worn points, these points were purchased only 3000-3500 miles ago yet they were well worn,the new replacement points were purchased at NAPA and comparing them side bye side showed obviously stronger construction.

the problem was easily traced to a set of defective ignition points, and it appeared he had never put lube on the distributor lube pad.

those little felt pads on each set of points are generally oiled and a finger tip of MOLY grease on the cam won,t hurt either.

Bob installed, and having never even seen the inside of a dual point distributor, prior to this car, bob has no idea how to install,or set up points, previously.

corvette dual points ,which it seems are very hard to locate at most local auto parts stores.

a dual point distributor is not difficult to work with but it is old school tech, the newer systems are usually more durable and take less maintenance, BTW be sure to lubricate the wiper pad on the distributors cam as a worn distributor cam on a 40-45 year old ignition is a common problem, in this case , installing two new sets of points and the car ran far better

on Corvette (Delco) dual-point distributors, each set of points is adjusted individually to 27-29 degrees dwell (by blocking the other set with a small piece of matchbook cover or business card), and with both sets operating, dwell should be 32-34 degrees.

you might want to watch this video on swapping to low resistance ignition wire

its the AMP load that heats and burns points, getting 20-25 k miles is very common before you notice any need to clean and reset points in my experience, youll want a dwell meter and a points file if your going old school ignitions

http://www.amazon.com/dp/B000N31ZTE/ref ... B000N31ZTE

http://www.amazon.com/Actron-CP7605-Tac ... B00062YUUS

because of easy interchangeability between most SBC and even the BBC engines , the early dual point distributors can be, and frequently were a commonly swapped to ignition, upgrade, but most originally came in...

1957 283 Passenger 245 & 270 HP 2X4

1957 283 Corvette 220, 245, 270 HP 2X4

1958-61 283 Corvette 245, 270 HP 2X4

http://www.mre-books.com/chevy/engines/ ... ition.html

For Dual Point distributors there is a bit more effort involved. You can still set the point gap on the "primary" point set in the distributor (see note below), but you might as well forget the secondary point set at this moment.

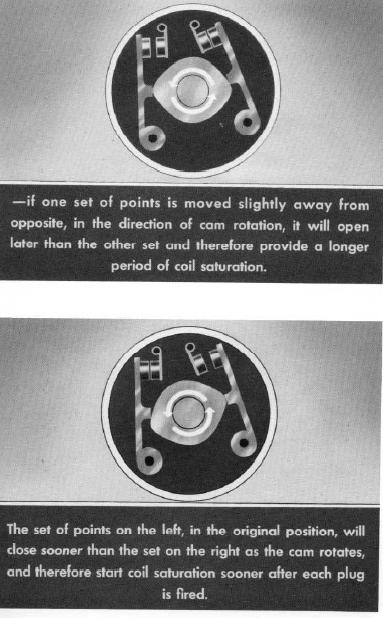

NOTE: Primary vs. Secondary (or trailing) point set. The Primary point set is the "first" point to open in relation to the rotation of the engine and it's placement in the distributor housing. If you look into the distributor from the top, you will notice that the pair of points are nested to one side of the distributor housing. No matter the rotation of your distributor, the first point set that opens is called the primary set. The second one that opens is called the secondary (or trailing) point set. When the primary point opens, watch it ... before it closes, the secondary point will open.

To set dual point ignitions you first block the "secondary" point set. You can block it by either not having it in the distributor, or using a thin piece of cardboard such as a matchbook cover between the contacts of the secondary point set. With the same (Safety Precautions) as above: ignition coil wire removed, the cap and rotor off the distributor, and a dwell meter properly connected to the coil, you can spin the engine. The best way to do this is with a remote starter button. The only other way to do this is with someone assisting you. Crank the engine and watch the reading on the dwell meter. You will be setting ONLY the primary point to the required setting at this time.

After you have set the primary point set to the required dwell, install or unblock the secondary point set. You will now spin the engine again and by adjusting ONLY the secondary point set, adjust the the secondary point so that the dwell reading matches the "combined" dwell specification. You do not have to touch the primary set again.

Example: You have a V8 engine application and your dwell settings are 26° (each point), and a combined setting of 33° ± 2°. You will set the primary point to 26° with the secondary set blocked, then by adjusting ONLY the secondary point set, adjust it so the dwell reads 33° (or between 31° and 35°).

http://www.tispecialty.com/articles/article6.htm

1953 - 1967 Corvette Specification Guide

(1953-1967 Delco-Remy Ignition Distributors)

1953-55

1112314 1953-1955 Six-Cylinder Engines

1110855 1955 V-8 Engines with vacuum advance

1110847 Some later 1955 V-8 Engines with no vacuum advance

1956

1110872 Early Engines

1110879 Late Engines

1957

1110891 220, 245 & 270 Horsepower Engines

1110889 Early 250 & 283 Horsepower Engines (with FI unit 4360)

1110905 Mid-to-End 250 & 283 Horsepower FI Engines with Manual Transmission (with FI units 4360, 4520, 4800 & 4960) Mid-to-Late 250 Horsepower FI Engine with Powerglide

1110906 Late 250 Horsepower FI Engine with Powerglide (with FI units 4520 & 4800)

1110908 Mid-to-End RPO 579E & Some Late 283 Horsepower (with FI unit 4960)

1958-1961

1110890 1958 230 Horsepower Engine

1110946 1959-61 230 Horsepower Engine

1110891 1958-61 245 & 270 Horsepower 2x4BC Engines

1110908 Early 1958 290 Horsepower FI Engine

1110914 Mid-1958 through 1960 290 Horsepower & 1961 315 HP FI Engines

1110915 1958-1960 250 HP & 1961 275 Horsepower FI Engines

1962

1110984 250 & 300 Horsepower Engines

1110985 340 Horsepower Engine

1110990 Early 360 Horsepower FI Engine

1111011 Mid-to-Late 360 Horsepower FI Engine

1963

1111024 250, 300 & 340 Horsepower Engines

1111022 360 Horsepower FI Engine

1964

1111024 250 & 300 Horsepower Engines

1111062 Early 365 Horsepower Engine

1111069 2nd Production 365 Horsepower Engine

1111060 365 Horsepower Engine with K66 Transistor Ignition

1111063 Early 375 Horsepower FI Engine

1111070 2nd Production 375 Horsepower FI Engine

1111064 375 Horsepower FI Engine with K66 Transistor Ignition

1965

1111076 250 & 300 Horsepower 327 Engines

1111087 350 Horsepower 327 Engine

1111088 350 Horsepower 327 Engine with K66 Transistor Ignition

1111069 365 Horsepower 327 Engine

1111060 365 Horsepower 327 Engine with K66 Transistor Ignition

1111070 375 Horsepower 327 Engine

1111064 375 Horsepower 327 Engine with K66 Transistor Ignition

1111093 425 Horsepower 396 Engine with K66 Transistor Ignition

1966

1111153 300 Horsepower 327 Engine

1111156 350 Horsepower 327 Engine

1111157 350 Horsepower 327 Engine with K66 Transistor Ignition

1111141 390 Horsepower 427 Engine

1111142 390 Horsepower 427 Engine with K66 Transistor Ignition

1111093 425 Horsepower 427 Engine with K66 Transistor Ignition

1967

1111194 300 Horsepower 327 Engine

1111117 300 Horsepower 327 Engine with Powerglide & K19 Air Injection Reactor

1111196 350 Horsepower 327 Engine

1111157 350 Horsepower 327 Engine with K66 Transistor Ignition

1111141 Early 390 Horsepower 427 Engine (1966 carryover)

1111247 390 & 400 Horsepower 427 Engines

1111248 Early 390 & 400 Horsepower 427 Engines with K66 Transistor Ignition

1111294 2nd Production 390 & 400 HP 427 Engines with K66 Transistor Ignition

1111240 L88 427 Engine with K66 Transistor Ignition

1111258 435Horsepower 427 Engine with K66 Transistor Ignition

Note: Delco-Remy Ignition coils are embossed with the last three digits of the part numbers listed.

1953 - 1967 Corvette Specification Guide

(1953-1967 Corvette Delco-Remy Ignition Coils)

1953-1955

1115394 1953-55 Six-Cylinder Engines

1115086 1995 V-8 Engines

1956-1962

1115091 All Carbureted Engines

1115107 All Fuel Injected Engines

1963

1115091 Early; All Engines

1115087 Mid-to-Late; All Engines

1964

1115087 250 & 300 Horsepower 327 Engines

1115091 365 & 375 Horsepower 327 Engines

1115196 K66 Transistor Ignition System (early; usage unverified)

1115176 K66 Transistor Ignition System

1965

1115202 327 Engines with Standard Ignition

1115203 Early 350, 365 & 375 HP 327 Engines with K66 Transistor Ignition

1115207 Mid-to-Late 350, 365 & 375 HP with K66 Transistor Ignition

1115210 425 Horsepower 396 Engine with K66 Transistor Ignition

1966

1115202 300 & 350 Horsepower 327 Engines with Standard Ignition

1115232 or 1115262 390 Horsepower 427 Engine with Standard Ignition

1115207 350 Horsepower 327 Engine with K66 Transistor Ignition

1115210 Early 390 HP 427 Engine with Manual Trans. & K66 Trans. Ignition

1115261 390 HP 427 Engine with Powerglide & K66 Transistor Ignition

1115231 or 1115261 Mid-to-Late 390 & 425 HP with Manual Trans. & K66 Trans. Ignition

1967

1115202 300 & 350 Horsepower 327 Engines with Standard Ignition

1115207 350 Horsepower 327 Engine with K66 Transistor Ignition

1115264 390 & 400 Horsepower 427 Engine with Standard Ignition

1115263 390, 400, 435 HP & L88 427 Engines with K66 Transistor Ignition

Note: Delco-Remy ignition coils are embossed with the last three digits of the part numbers listed.

Previous Page Next Page

viewtopic.php?f=70&t=6778&p=21751&hilit=corvette+distributor#p21751

http://www.socalsacc.com/Ignition Timing.htm

http://www.centuryperformance.com/setti ... pg-90.html

viewtopic.php?f=69&t=2165

http://mgaguru.com/mgtech/ignition/ig200.htm

http://www.earlycorvettes.com/corvetteg ... 56to57.pdf

http://www.gofastforless.com/ignition/points.htm

http://www.summitracing.com/parts/ANM-CP7605

viewtopic.php?f=70&t=855

http://www.wernersparts.com/Distributors.htm

http://www.corvettefever.com/techarticl ... ewall.html

HERES A PICTURE OF A SIMILAR DISTRIBUTOR ON A SBC ENGINE

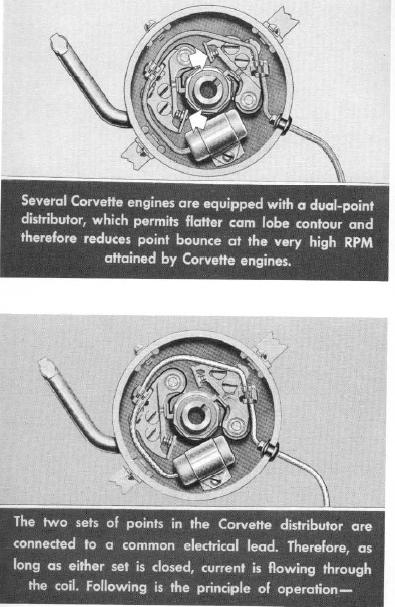

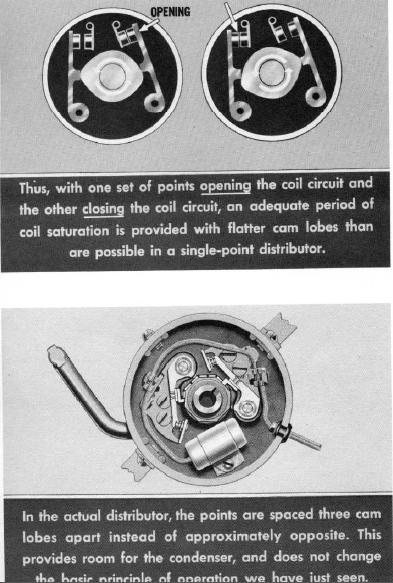

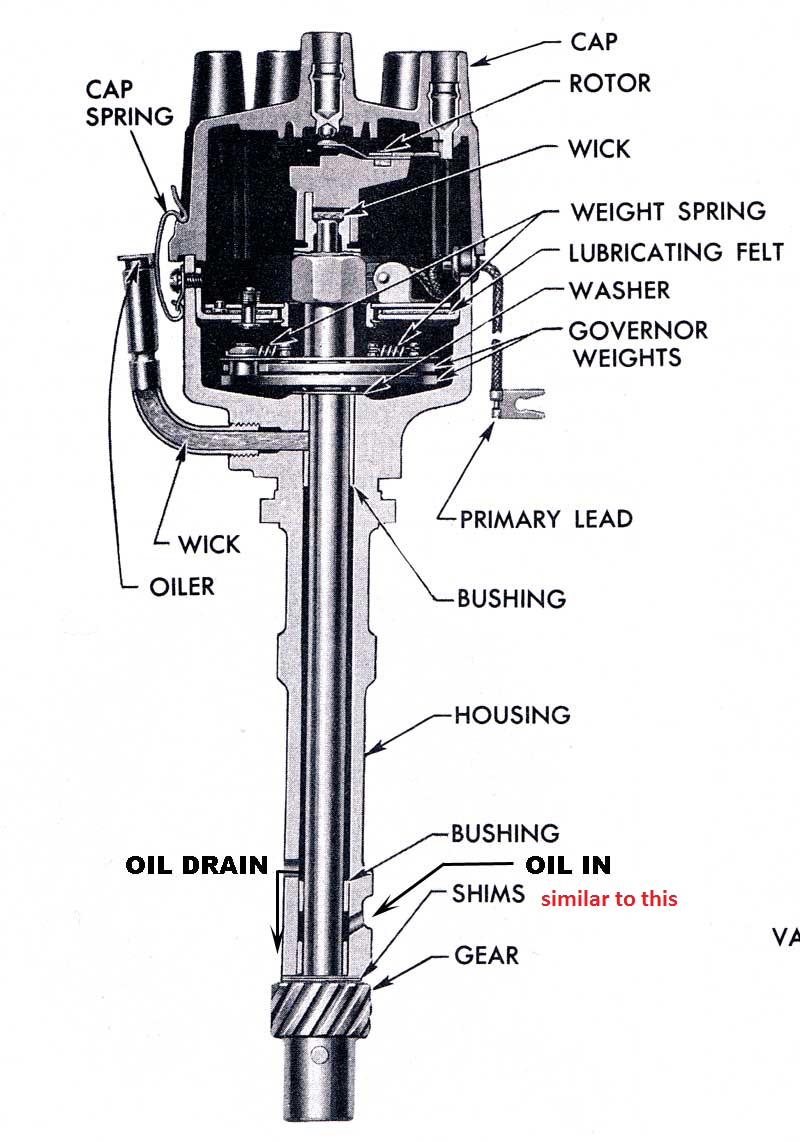

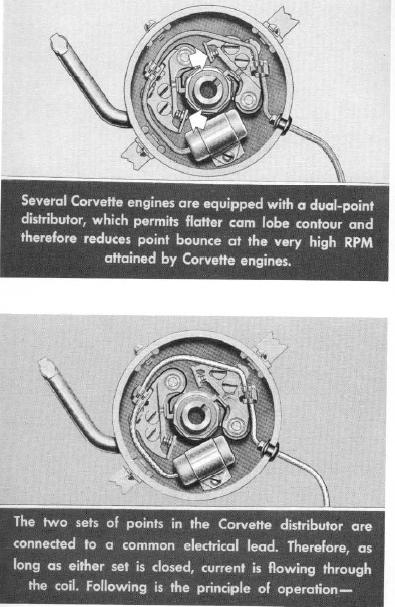

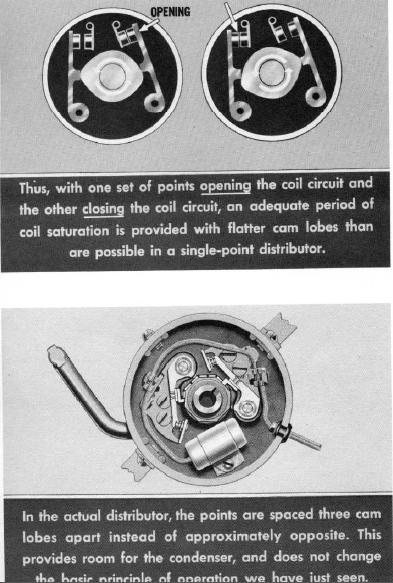

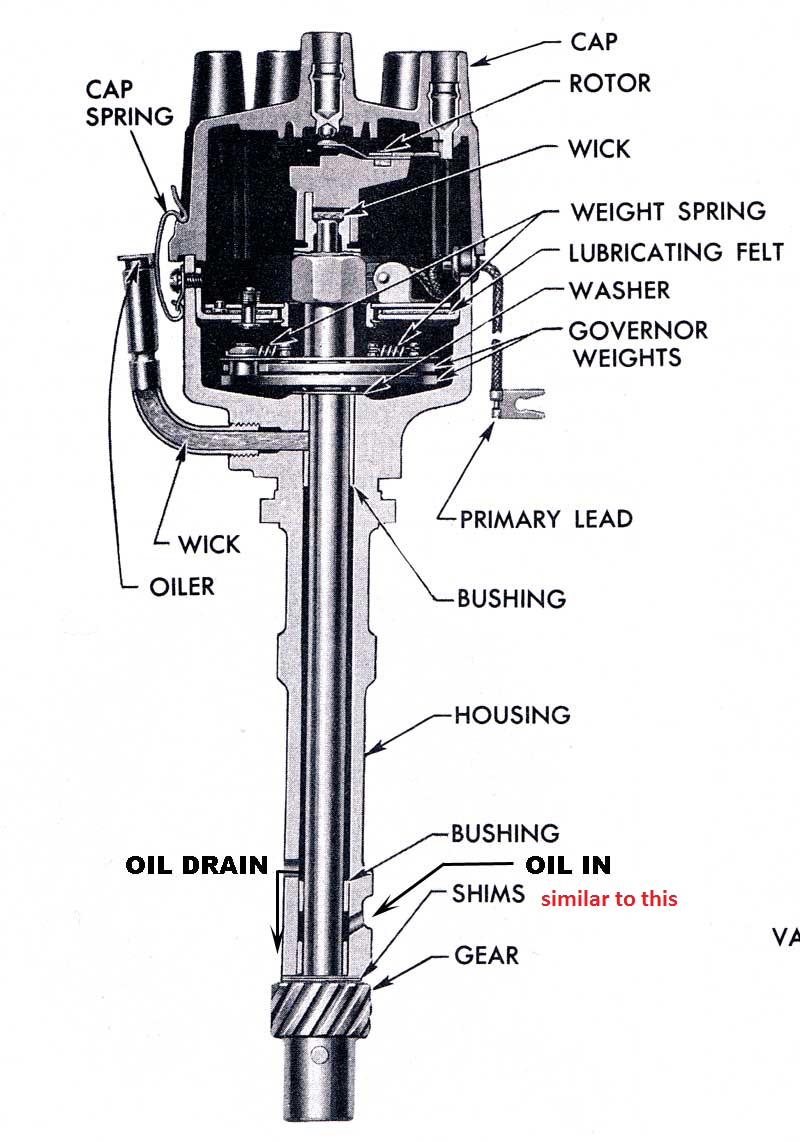

There are two kinds of dual point systems. In one kind each contact set serves four cylinders, which in theory the points will last twice as long before needing replacement. This offers no "performance" gain.

The other kind uses both points in tandem for each cylinder. The points act at nearly but not exactly the same time. There is overlap or a "handoff", meaning that the contact made between the power supply and the coil stays longer, leading to a higher saturation or "charge" in the coil, leading to a higher voltage spark. (by the way, there's no such thing as a "longer" spark, if "longer" means time, but a higher voltage spark can travel a longer distance over a bigger gap).

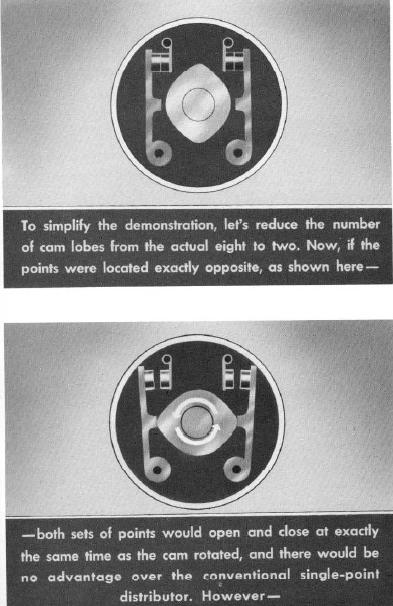

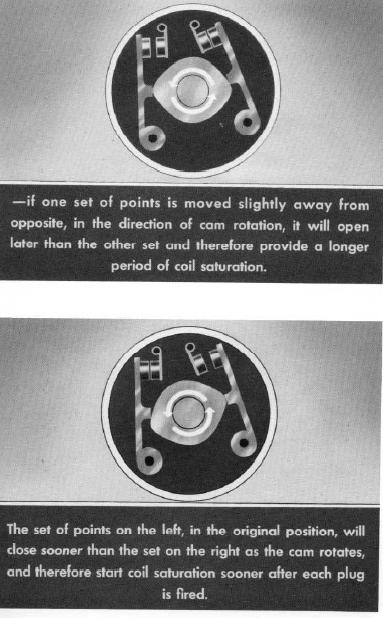

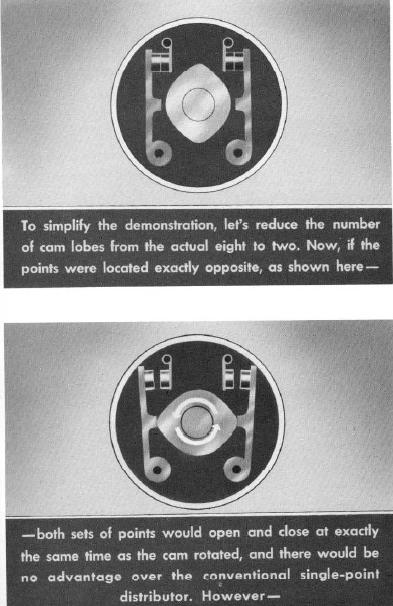

Think of it like this, you have Points A and Points B, as the cam turns, Points A reach the low spot first (they Close) and get charged while on the low spot. B follows and continues the circuit. Turn more and Points A reach the high spot and open, but B isn't there yet so the circuit is still closed. When B reaches the high spot the circuit is opened and the coil fires.

Like this:

AAAAAABBBBBBB FIRE!

RELATED THREAD

viewtopic.php?f=70&t=251&p=299#p299

MALLORY SELLS A NEW QUALITY DUAL POINT CORVETTE STYLE DISTRIBUTOR #2664501

these are small base and easy to use with a tunnel ram intake which makes then very useful if you don,t want to spent the cash for a vertex magneto

Last edited by a moderator: