Junkman2008 said:Hey Grumpy, you always hear that headers give you more horsepower. How does that work and what formula can you use to determine the horsepower gain that a given set of headers may bring?

that questions a bit like asking how good a girl might be in bed based on the color of her hair brush, yes theres a mathematical formula , in fact several, but theres a whole bunch of factors that determine the results, like cam timing, compression,cylinder head flow, back pressure,engine displacement , header primary and collector length and diameter,exhaust temps,etc.

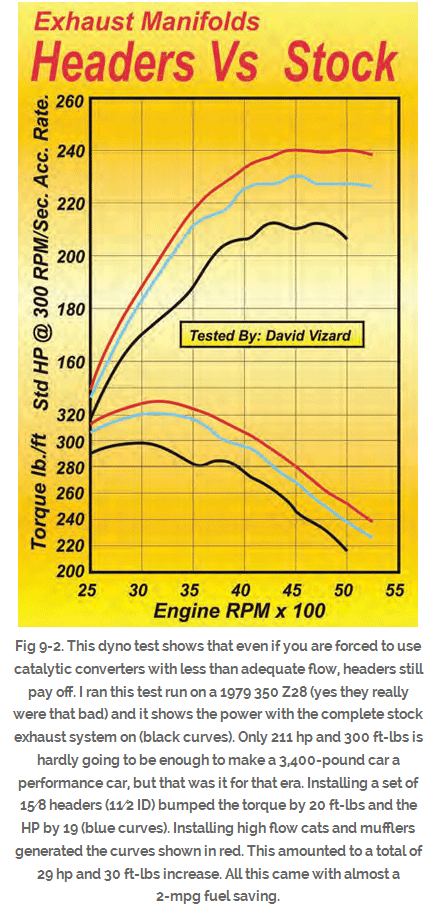

the more back pressure the exhaust system beyond the header collectors has the less effective the headers will be, but if you have a low restriction exhaust and a ram tuned intake with a matched cam timing, a tuned header can in some cases produce gains in excess of 60 hp.

as a general rule Id say your safe expecting a 25-40 hp increase in peak hp from good long tube tuned headers over stock cast iron exhaust manifolds that come on most passenger cars, but with properly matched components on a high compression engine more can be gained.

READ THESE

http://victorylibrary.com/mopar/header-tech-c.htm

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

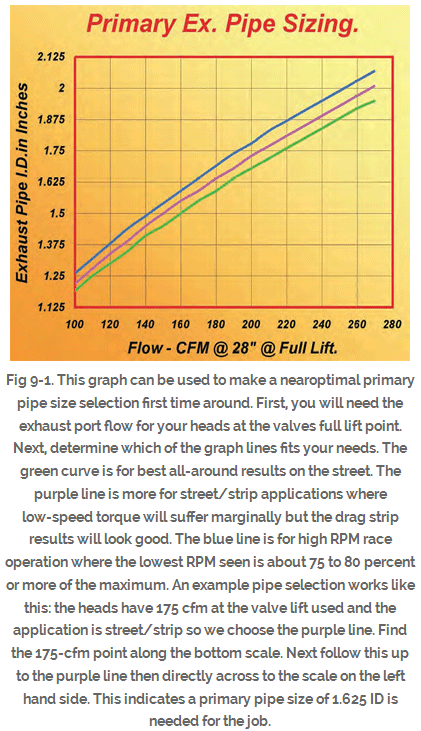

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.pontiacracing.net/js_header_length1.htm

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/Calculators.htm

https://robrobinette.com/et.htm

https://www.gregraven.org/hotwater/calculators/qm-from-wt-hp.php

http://www.bgsoflex.com/auto.html

http://www.mk5cortinaestate.co.uk/calculator5.php

http://www.can-of-whoopass.com/index.php?pageID=car_stuff&calculator=primaries

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=495&p=613#p613

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=1303

viewtopic.php?f=56&t=572&p=35352&hilit=rams+horn#p35352

http://forum.grumpysperformance.com/viewtopic.php?f=56&t=185

http://www.chevydiy.com/chevy-small-block-engine-guide-exhaust-systems/

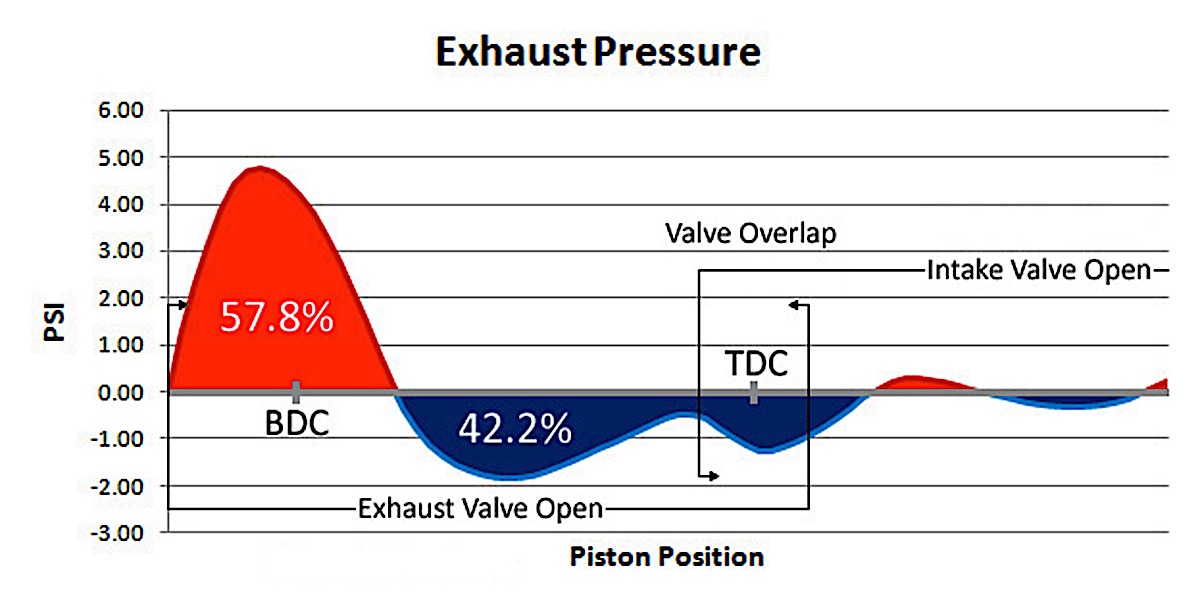

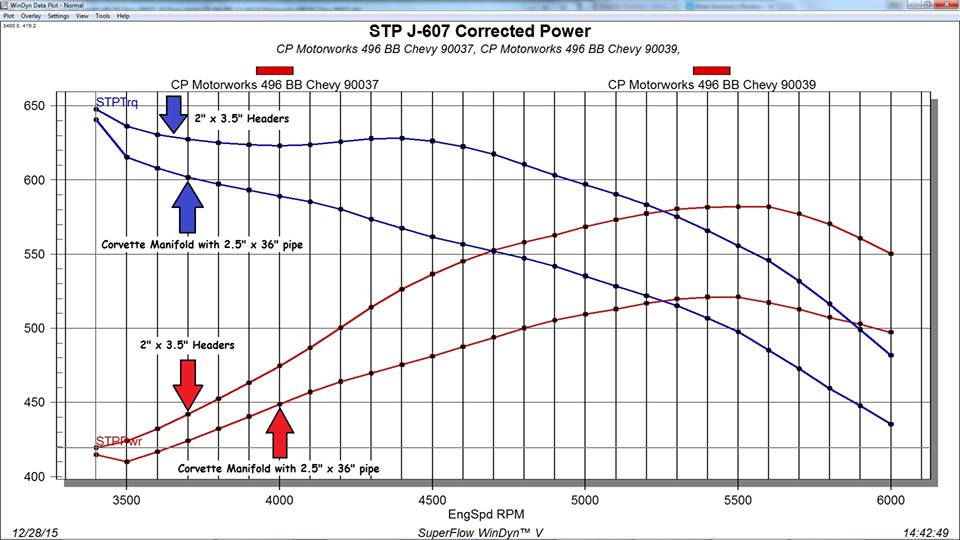

I find this graph very useful, it shows stock corvette exhaust manifolds vs headers on the same 496 BBC engine dyno test

Last edited by a moderator: