-Wet Flow Technology for Cylinder Heads

1/2/2010

David Hughes

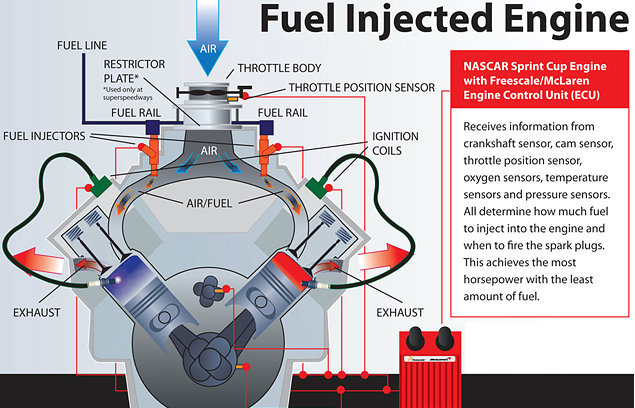

Engine power technology has a new area of research that will help pro-stockers as well as RV's. Wet flow technology has to do with the air and fuel mixture that flows thru the intake ports. This is one step beyond the normal dry air-flow testing that has been the focus of engine builders for the past 60 years.

For all these years engine builders have worked with flow of "dry" air thru the intake system, and power has increased in great part because of it. However, the true medium flowing thru the ports is a mixture of air and liquid fuel. This A/F (air/fuel) mixture acts differently and responds differently to ports shapes and modifications than the wet A/F mixture. This situation has lead to the seeming contradictory situations where small, low flowing ports produce more power than larger high, flowing ports. This fact flew in the face of the rule of More, if some (air flow) is good More (air flow) must be better! Now the cylinder head ads that had listed massive air flow numbers started changing their heads to "high velocity". The higher velocity was a better answer, but the velocity needed to be harnessed, as not all high velocity heads produce good power. What the higher velocity did was atomize the fuel much better and that resulted in a more burnable mixture in the combustion chamber. Shazam! More power out of the same engine.

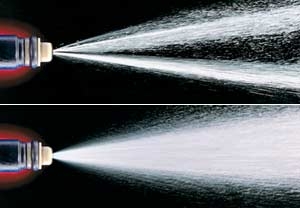

The finer the fuel droplets are (better atomized) in the combustion chamber the faster and more completely they burn. This creates more power out of the same amount of fuel and less emissions because there is less raw and unburnt gas running out of the exhaust.

Until recently designing the intake system for proper atomization has been a rather clumsy procedure of trial and error. The burn pattern (carbon residue) in the combustion chamber was "read" and changes in the intake system were made to change the pattern. The burn pattern is controlled in great part by how well the fuel is atomized as it enters the combustion chamber.

In the past clear plastic cylinder heads were built and modeled after existing heads. An air and colored fluid mixture was flowed thru them to visualize what was happing in the port. In some testing, the inside of the ports were lined with tiny pressure sensors to detect the airflow movements while the engine was running. All of this was an effort to improve the mixture reaching the combustion chamber.

Now, the legendary, Joe Mondello who could easily be considered the father if not the grandfather of Americas cylinder head porting industry has addressed this problem. Joe has developed a wet flow system that allows viewing of the A/F mixture as it enters the combustion chamber. His patented wet flow bench blows a mixture of air and a liquid dye with a similar viscosity of gasoline thru the intake system into the combustion chamber. When operational the air/liquid mixture can be viewed, studied and modified.

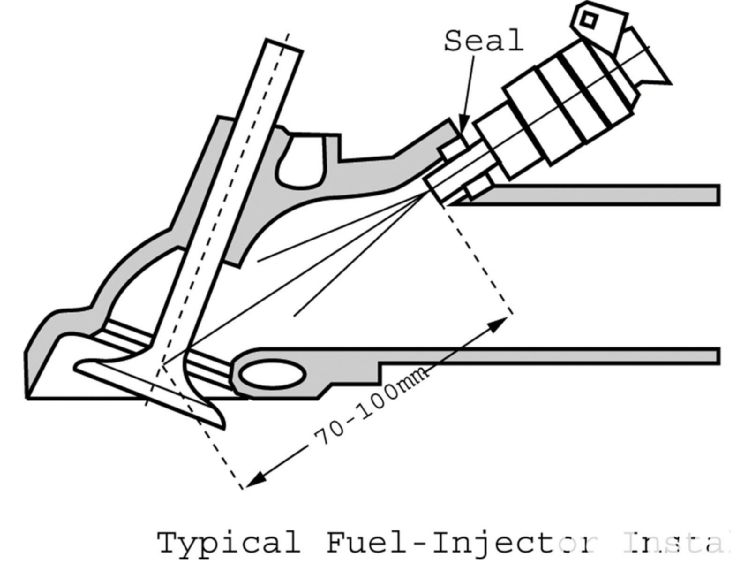

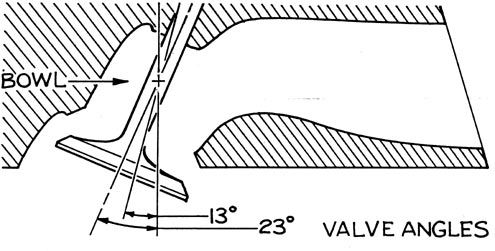

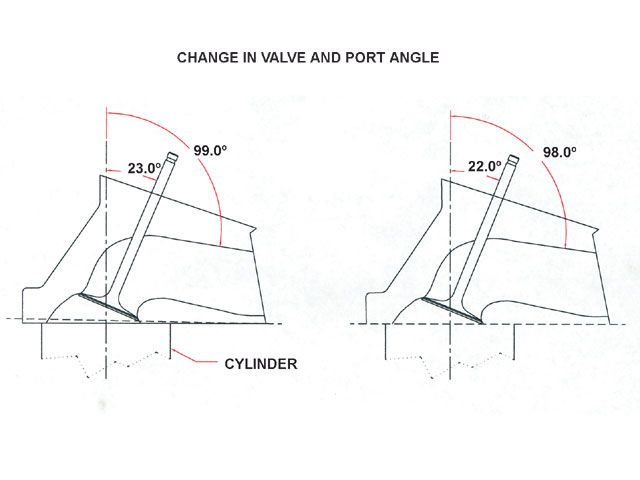

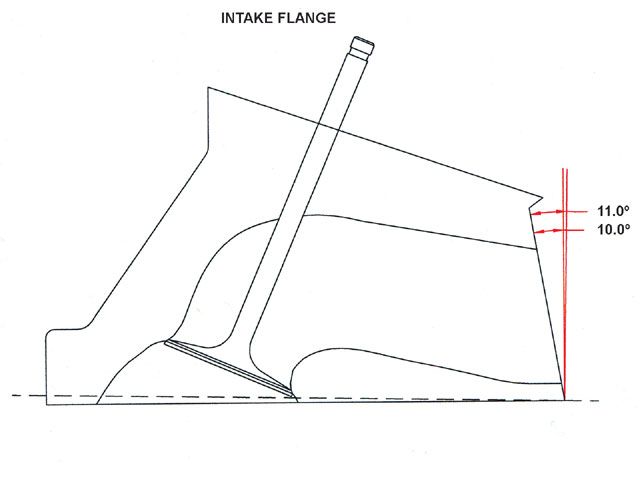

Changes to the port, valve, seat, chamber, and etc. can quickly made and retested similar to a dry flow bench operation. What we are looking for is a finely atomized A/F mixture that flows out of the valve and seat area in a pattern that will increase its burn ability. Wet flow testing can also show fuel puddling or fuel washing, in action, in the chamber.

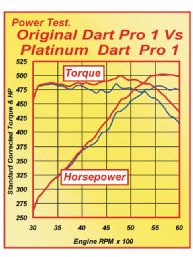

The wet flow technology is in its infancy, so it is not yet known how or what can actually be read in the flow patterns. Some of the things that have been discovered is that the long known "most critical area of the port", the seats area, seems to effect the wet flow the most. This indicates that in some cases the CFM numbers may be affected, probably in a negative way. This begs the question of which is the most important, wet or dry flow? Time will tell but early testing has shown early wet flow improvements translate into net power gains even though the dry flow numbers decreased. In the end it will be another compromise, we just need to learn how much of one to "trade-off" for the other.

One interesting discovery was that in some cases the spark plug ground strap could create a puddling situation. Simply re-indexing the plug eliminated the puddle problem and power increased.

This wet flow technology and the potential power improvements are very exciting with lots of discoveries to be made. What at first may be considered a drawback could actually prove to be a blessing in disguise. How will heads be rated or classified? The clumsy old way of rating them by cubic feet per minute {CFM} will no longer mean anything. However, as we have all found out the CFM numbers can be very misleading. The larger airflow numbers do not always translate into more power. This will be yet another example of the folly of "the biggest is always the best" type of thinking, and the advertising that preys on that ignorance.