- Home

- Forums

- Technical Articles/muscle cars

- Engine & transmission Swaps, related info

- Engine: Selection and Modification

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why is the LS Engine so good..

- Thread starter bytor

- Start date

TheNovaMan;65715634 said:I'm rebuilding a junkyard Vortec 350. I threw away the crank position sensor reluctor wheel because it's going to be carbureted, but I didn't realize the damper seats against the reluctor, so now I need to buy or make a spacer. Does anyone know what thickness I need?

Here's what the reluctor looks like:

https://www.summitracing.com/parts/ati-916320

ATI Crank Hub Spacers 916320

Image is a representation of this item.

Actual item may vary.

the reluctors .093" or about 2.38mm

Reluctor thickness is 2.38mm, if you have a non vortec balancer, you can just use it. They cut the balancer snout down to fit the reluctor.

Loves302Chevy

"One test is worth a thousand expert opinions."

OK, so the LS engine is 20 years old, and now retired. But I have to ask, does anyone know if

anyone has tried the FITech self-learning fuel injection system on top of the Edelbrock or Holley

carbureted LS intake manifold? That's right - NO fuel rails or injectors!

I'm still a carb guy, but if I ever decided to go fuel injected, this would be the way I would do it.

Like this:

Or with the dual plane intake.

https://www.hotrod.com/articles/20-ls1-intake-manifolds-tested/

https://racemagazine.com.au/cars/ls1-manifold-comparison-data-analysis

just so others can look over the test results, on those ls intakes

both cross sectional area, and length effect flow but remember, displacement compression and cam timing also are major factors.

what most people fail to take into account is that the cam timing and exhaust scavenging being properly matched is critical.

changing the cam timing or header configuration would change some of the resulting intake flow rankings

big improvement in totally different ,but bolt on, ls heads

that require a non-stock intake manifold and headers

yes you'll need non-stock valve train components

( and not direct replacement for stock heads) LS heads

anyone has tried the FITech self-learning fuel injection system on top of the Edelbrock or Holley

carbureted LS intake manifold? That's right - NO fuel rails or injectors!

I'm still a carb guy, but if I ever decided to go fuel injected, this would be the way I would do it.

Like this:

Or with the dual plane intake.

https://www.hotrod.com/articles/20-ls1-intake-manifolds-tested/

https://racemagazine.com.au/cars/ls1-manifold-comparison-data-analysis

both cross sectional area, and length effect flow but remember, displacement compression and cam timing also are major factors.

what most people fail to take into account is that the cam timing and exhaust scavenging being properly matched is critical.

changing the cam timing or header configuration would change some of the resulting intake flow rankings

big improvement in totally different ,but bolt on, ls heads

that require a non-stock intake manifold and headers

yes you'll need non-stock valve train components

( and not direct replacement for stock heads) LS heads

Last edited by a moderator:

the LS series engines were designed to be individual direct port injection, so a single plane intake with a common plenum makes sense as its more consistent and effective, at mid and upper rpms,

EXAMPLE

similar to this design

yes you can revert to either a common single plenum, or split dual plenum wet centralized EFI fogger EFI type system, and it has some minor advantages over a carburetor, but, part of the advantage of the dual plane intake design, commonly used with carburetors, is that at lower engine rpms it keeps the air speeds in the runners high enough,

to keep the fuel droplets from a carburetor in suspension from the plenum to the back of the intake valve, if you select an intake with individual injectors that are located in the lower intake manifold runners pointed to flow a fog at the back of the intake valve most of the intake plenum and runner system is flowing basically dry air and sensors maintain the correct fuel/air ratio based on what each cylinder shows.

if you revert to a single central wet fogger system, even with several individual fuel injectors supplying fuel into a common plenum you've effectively lost at least some control over the fuel distribution.

youll find that a efi throttle body controlling air flow and individual injectors with matched sensors provide the best power and lower emissions

http://www.hotrod.com/articles/giant-ls3-intake-manifold-dyno-shootout/

Dura-Bond LS Cam Bearing Sets

1999-2006 first design

position 1&5 bore 2.326 / 2.328

CH-10, CHP-10, CHP-10T

2003-2009 sec design

position 1&5 bore 2.346 / 2.348

CH-23, CHP-23, CHP-23T

2007-2013

position 1&5 bore 2.346-2.348

CH-25, CHP-25, CHP-25T

** All CH-25 sets will work in place of the CH-23 sets

EXAMPLE

similar to this design

yes you can revert to either a common single plenum, or split dual plenum wet centralized EFI fogger EFI type system, and it has some minor advantages over a carburetor, but, part of the advantage of the dual plane intake design, commonly used with carburetors, is that at lower engine rpms it keeps the air speeds in the runners high enough,

to keep the fuel droplets from a carburetor in suspension from the plenum to the back of the intake valve, if you select an intake with individual injectors that are located in the lower intake manifold runners pointed to flow a fog at the back of the intake valve most of the intake plenum and runner system is flowing basically dry air and sensors maintain the correct fuel/air ratio based on what each cylinder shows.

if you revert to a single central wet fogger system, even with several individual fuel injectors supplying fuel into a common plenum you've effectively lost at least some control over the fuel distribution.

youll find that a efi throttle body controlling air flow and individual injectors with matched sensors provide the best power and lower emissions

http://www.hotrod.com/articles/giant-ls3-intake-manifold-dyno-shootout/

Dura-Bond LS Cam Bearing Sets

1999-2006 first design

position 1&5 bore 2.326 / 2.328

CH-10, CHP-10, CHP-10T

2003-2009 sec design

position 1&5 bore 2.346 / 2.348

CH-23, CHP-23, CHP-23T

2007-2013

position 1&5 bore 2.346-2.348

CH-25, CHP-25, CHP-25T

** All CH-25 sets will work in place of the CH-23 sets

Last edited:

Loves302Chevy

"One test is worth a thousand expert opinions."

OK, so no dual plane. But I did find this on the FITech site: http://fitechefi.com/products/30002/

This method might (probably) not be as precise as separate fuel injectors in each port, but

it has to be better than a carburetor. I like K.I.S.S. and I'm just not a fan of all that plumbing and

sensors and wiring running all over the place. When I pop a hood, I like to see an air cleaner.

This method might (probably) not be as precise as separate fuel injectors in each port, but

it has to be better than a carburetor. I like K.I.S.S. and I'm just not a fan of all that plumbing and

sensors and wiring running all over the place. When I pop a hood, I like to see an air cleaner.

yes it has several advantages over a carburetor,in that its rather easily installed,

and theres only a few additional supporting mandatory accessories required,

too function,and in some configs a self learning self tuning mode is the major one.

and theres only a few additional supporting mandatory accessories required,

too function,and in some configs a self learning self tuning mode is the major one.

Last edited:

http://dirtydingo.com/shop/pages.php?pID=8&CDpath=4

www.summitracing.com

www.summitracing.com

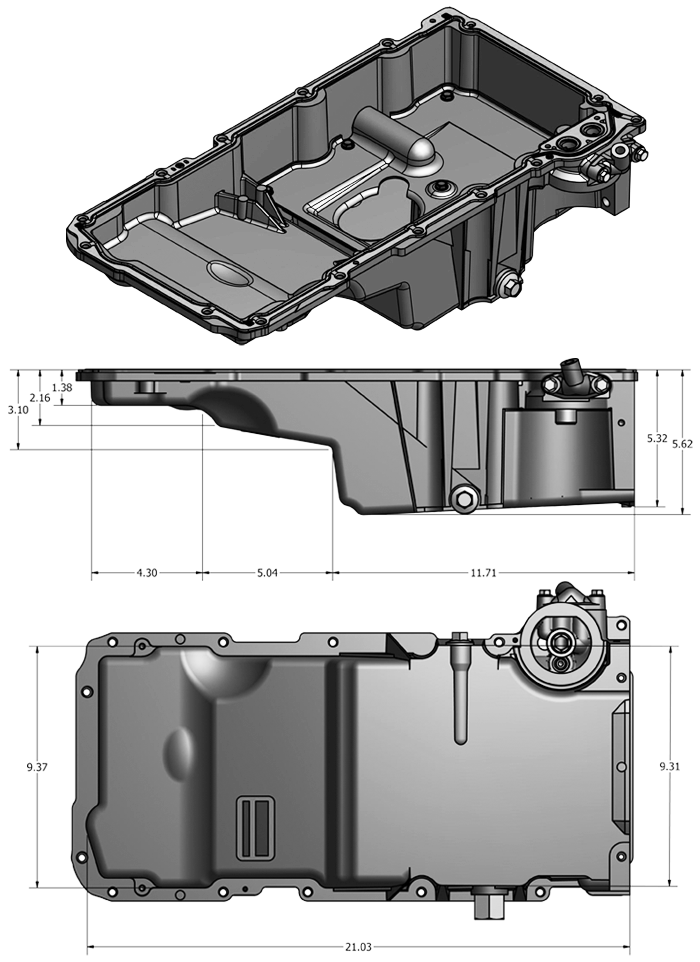

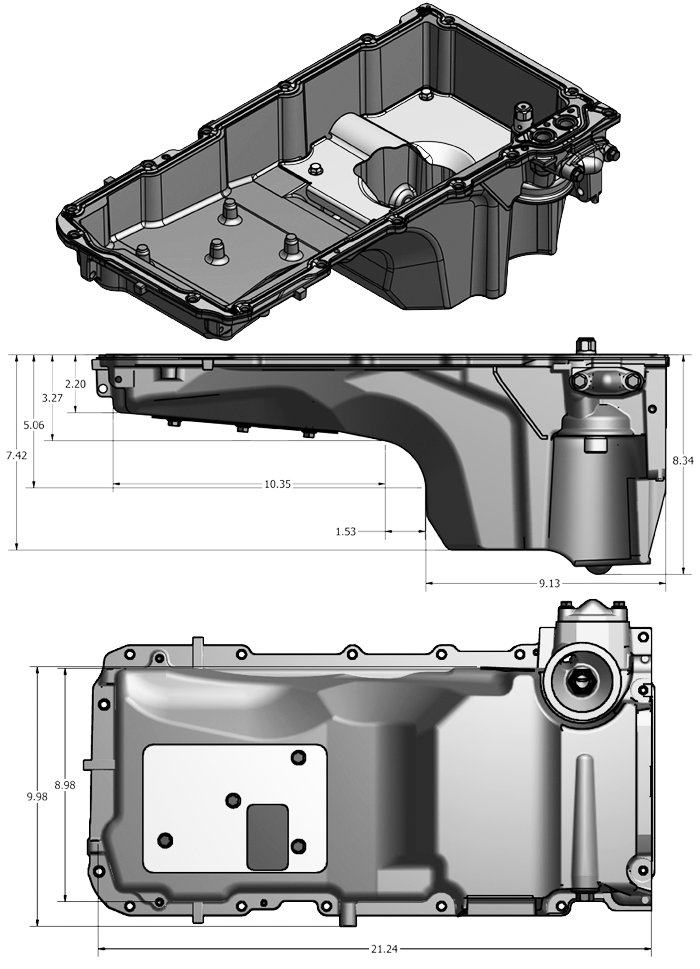

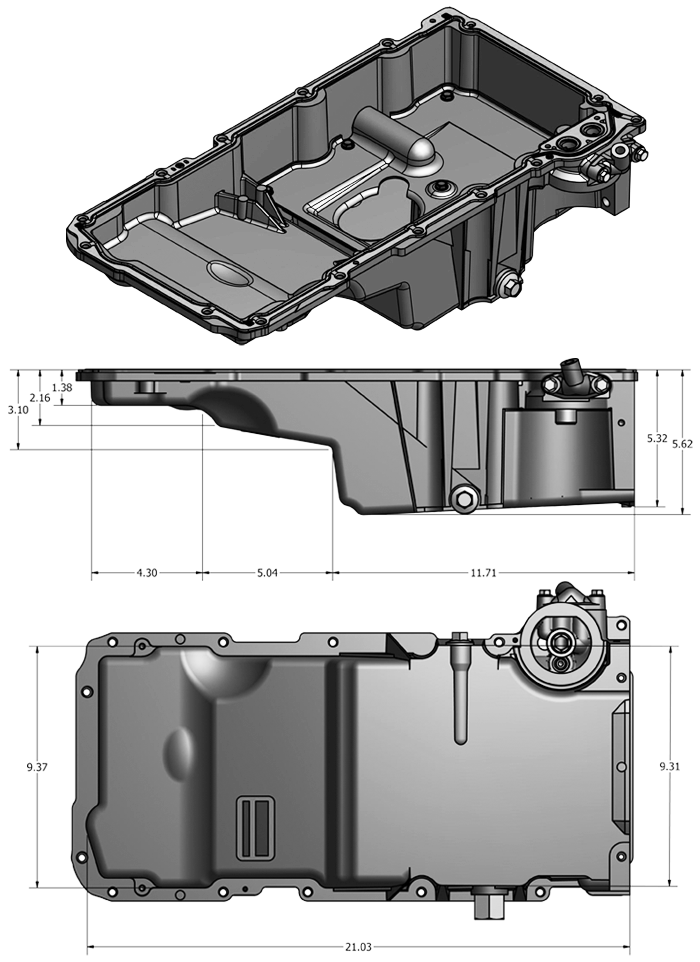

LS Oil Pan Information

GM LS-Series Engine Oil Pan Dimensions

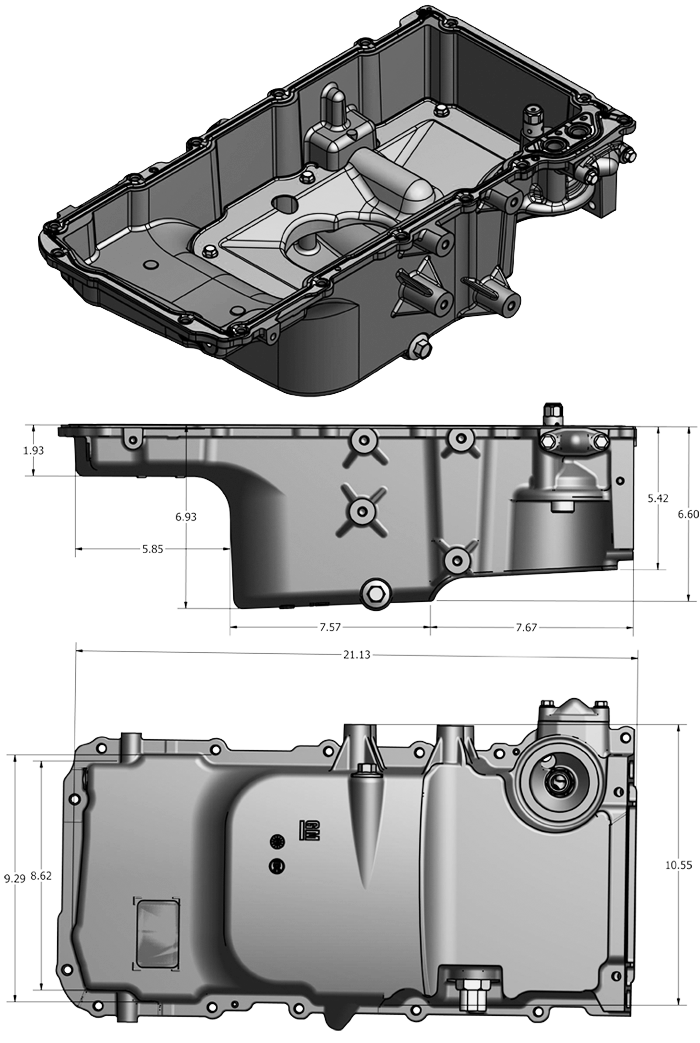

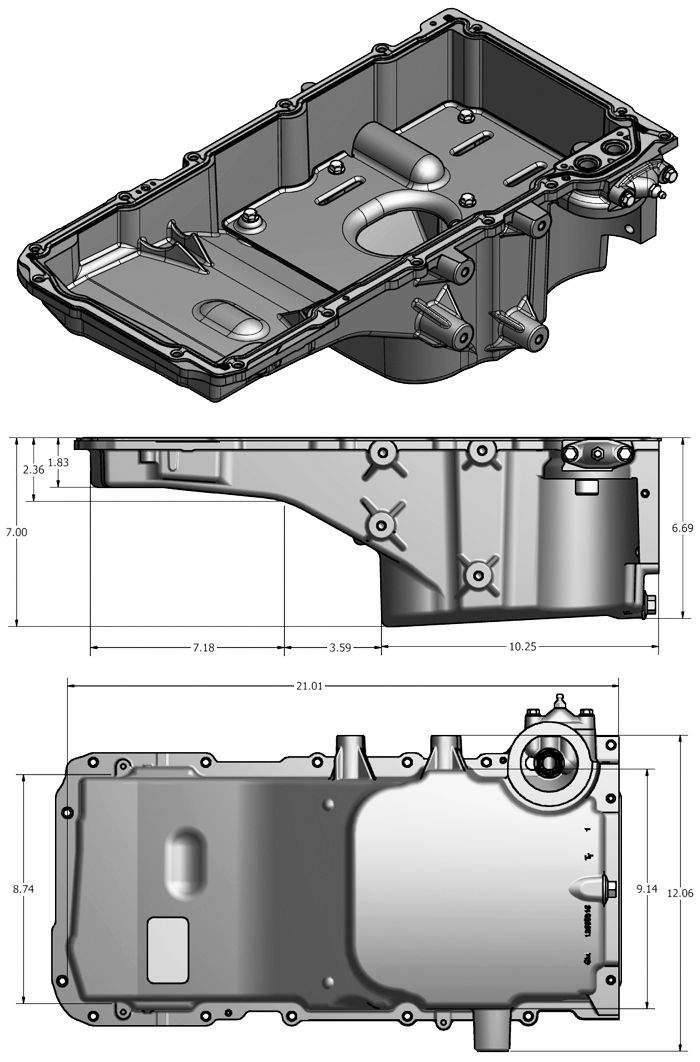

F-Body Camaro/Firebird LS1 Oil Pan

Vehicles:

1998-2002 Chevrolet Camaro (5.7L V8)

2002 Pontiac Firebird (5.7L V8)

Capacity:

5.5 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12628771

Pickup tube:

12558251

Windage tray:

12558253

Dip stick:

12551581

Dip stick tube:

12551577

Pickup tube o-ring:

12557752

Gasket:

12612350

2010-2015 LS3 Camaro / G8 Oil Pan

Vehicles:

2010-Present Chevrolet Camaro SS

2008-2009 Pontiac G8

2006-Present Holden VE Commodore

Capacity:

8 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

- Part Numbers -

Oil pan:

12640748

Pickup tube:

12611904

Windage tray:

12611129

Dip stick:

12634547

Dip stick tube:

12625031

Pickup tube o-ring:

12557752

Gasket:

12612350

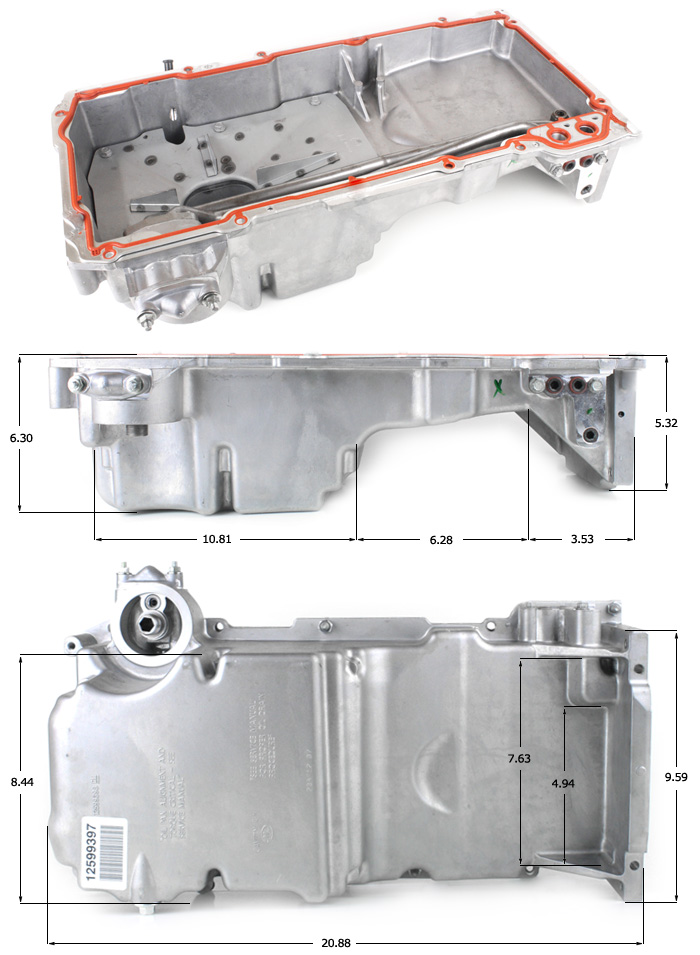

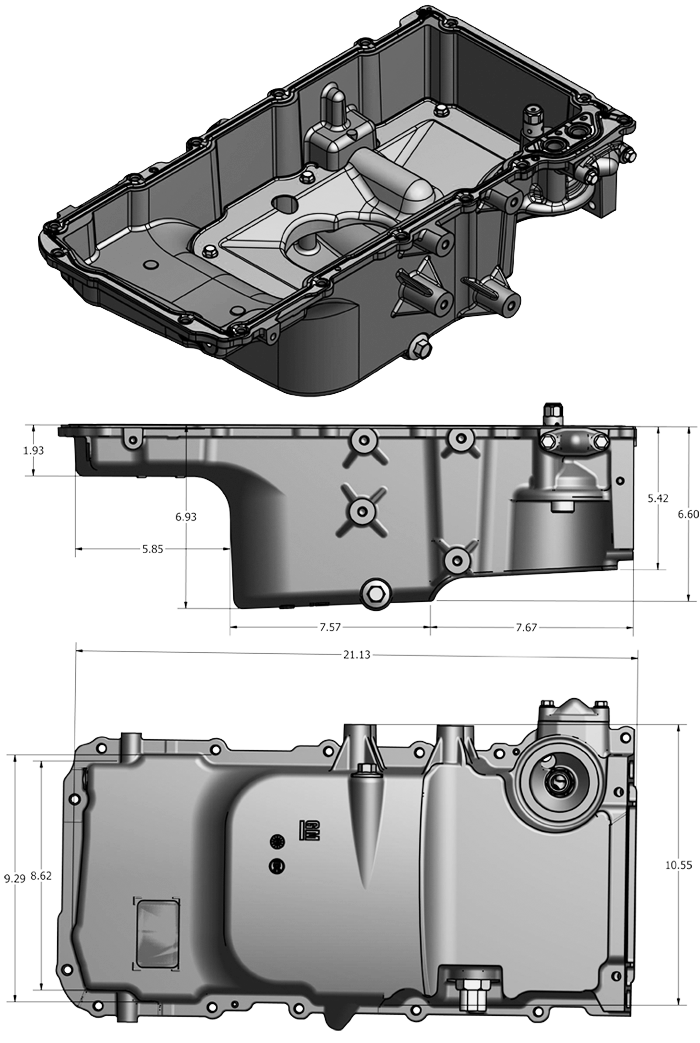

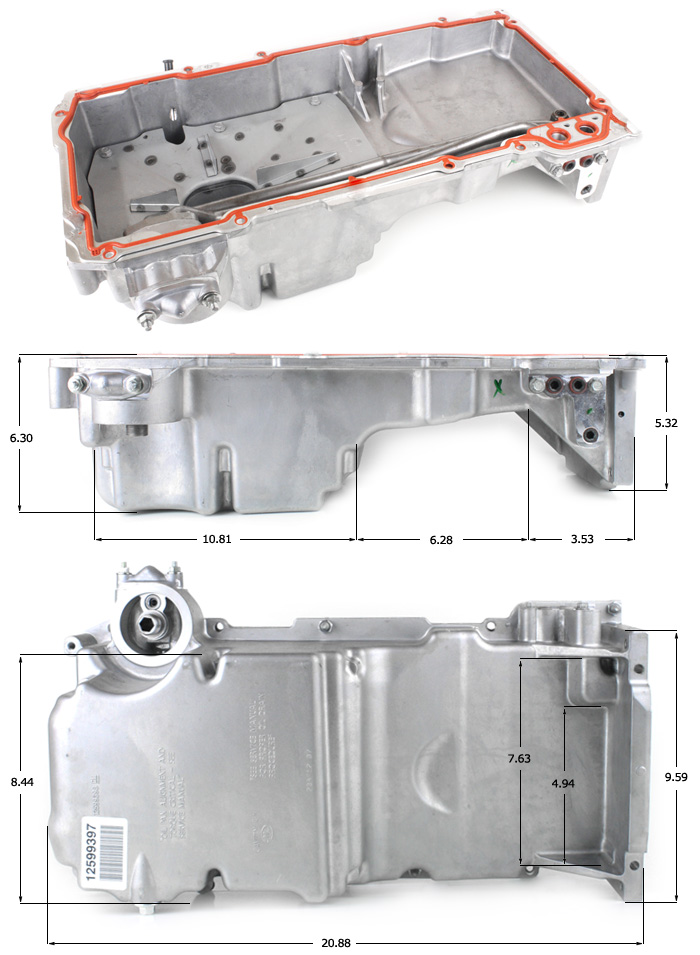

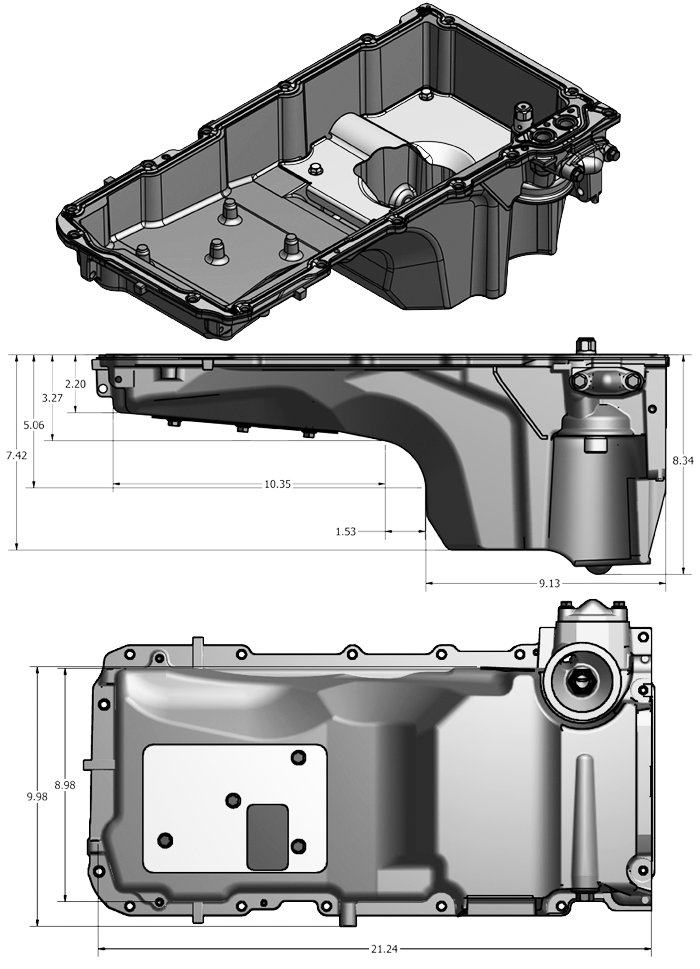

GTO / VZ Commodore Oil Pan (Front Sump)

Vehicles:

2004-2006 Pontiac GTO

2001-2005 Holden Monaro (VZ)

2004-2006 Holden Commodore (VZ)

2001-2005 Vauxhall Monaro

Capacity:

6 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12581209 up to 2004; 12599397 2005 and later. Only difference between part numbers is the newer model has a built-in pressure relief valve.

Pickup tube:

12572654

Windage tray:

12558189

Dip stick:

92067147

Dip stick tube:

92066941

Pickup tube o-ring:

12557752

Gasket:

12612350

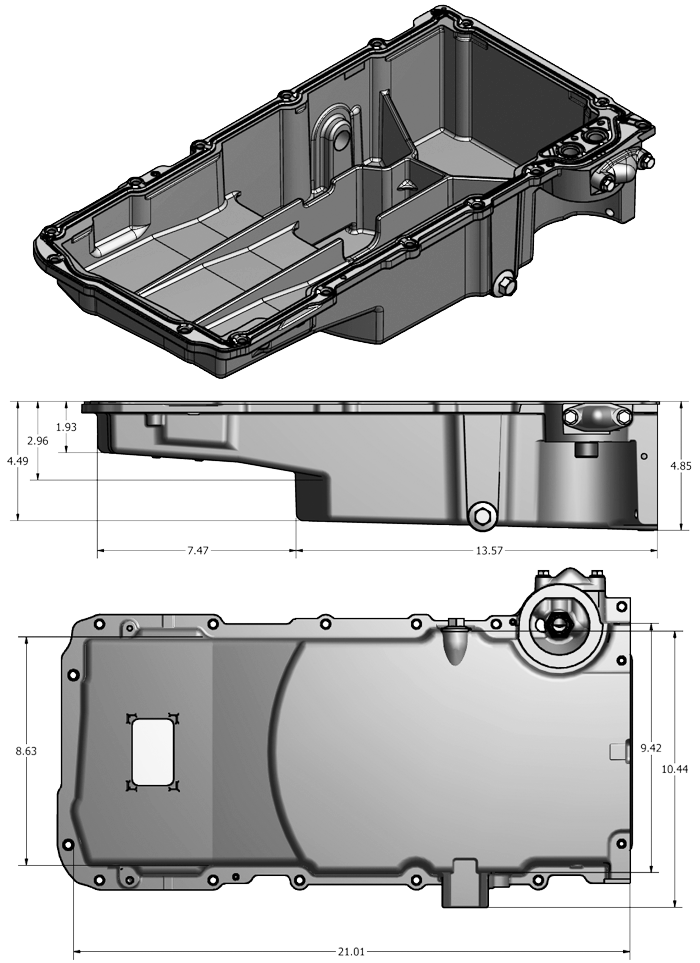

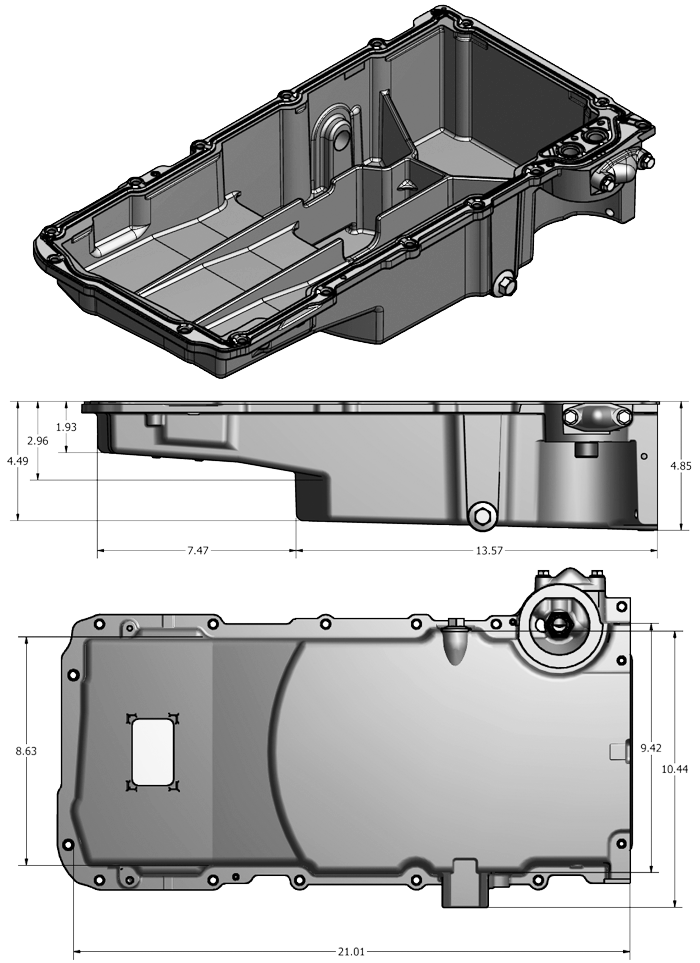

C6 Corvette LS2/LS3 Oil Pan (Wet Sump)

Vehicles:

2005-Present Chevrolet Corvette (non-dry sump)

Capacity:

5.5 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12624617

Pickup tube:

12624497

Windage tray:

12558189

Dip stick:

12570788

Dip stick tube:

12570787

Pickup tube o-ring:

12557752

Gasket:

12612350

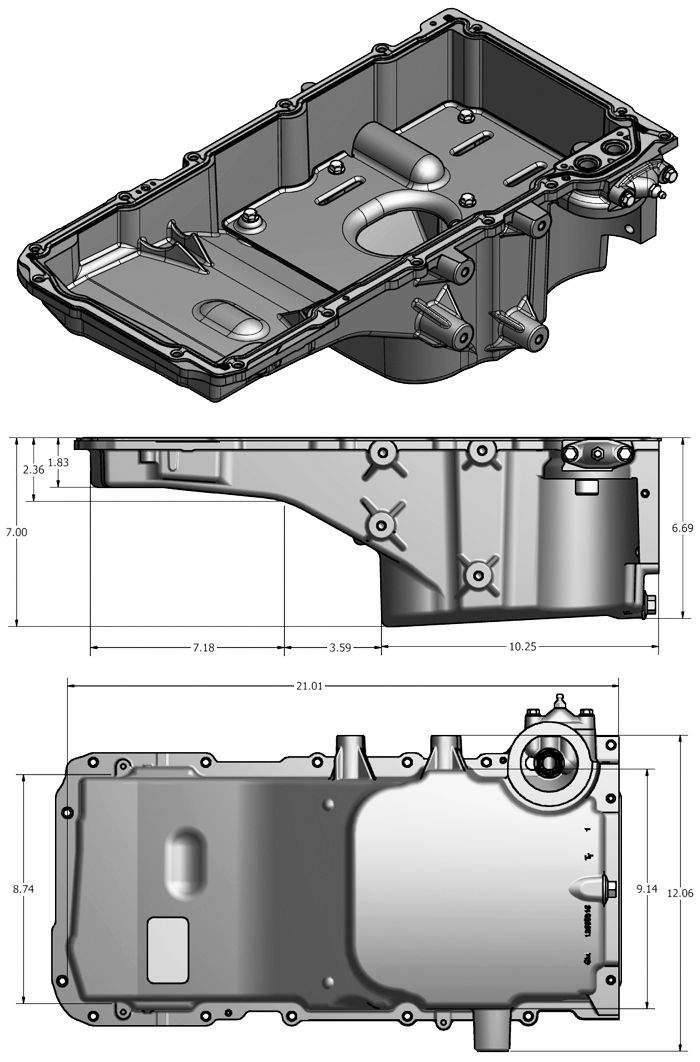

2009-Present Cadillac CTS-V Oil Pan LS2/ LS6 / LSA

Vehicles:

2009 Cadillac CTS-V

Capacity:

6 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

Factory only

- Part Numbers -

Oil pan:

12631828 (current), 12605814 (previous), 12628451 (previous)

Pickup tube:

12621299

Windage tray:

12611129

Dip stick:

12584737

Dip stick tube:

12584738

Pickup tube o-ring:

12557752

Gasket:

12612350

GM Truck / SUV Oil Pan

Vehicles:

2007-Present Cadillac Escalade

2007-Present Chevrolet Avalanche

2008-Present Chevrolet Express

2007-Present Chevrolet Silverado

2007-Present Chevrolet Suburban

2007-Present Chevrolet Tahoe

Capacity:

6 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

Factory only

- Part Numbers -

Oil pan:

12640746

Pickup tube:

12608579

Windage tray:

12611129

Dip stick:

12622055

Dip stick tube:

12609269

Pickup tube o-ring:

12557752

Gasket:

12612350

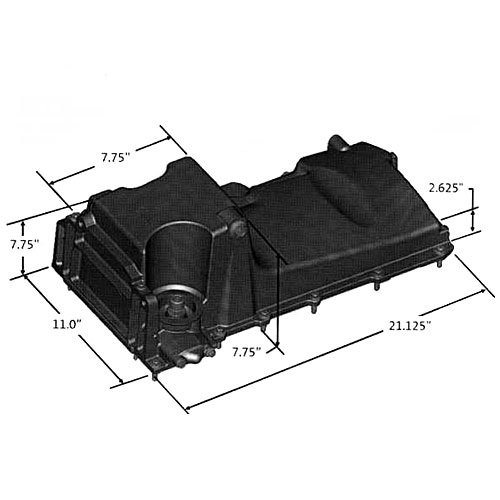

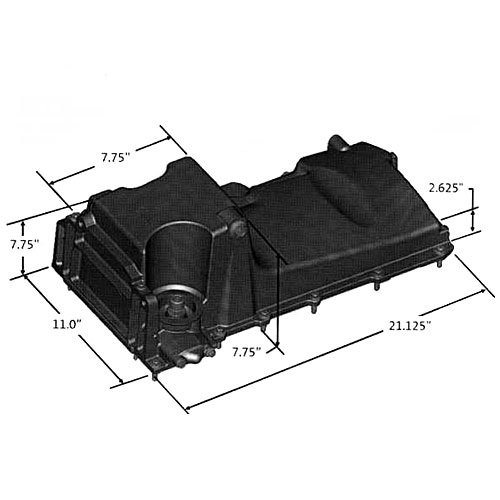

Hummer (GM Muscle Hot Rod Pan) Oil Pan (Wet Sump)

Vehicles-

H3 Hummer

Capacity:

5.5 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12614821

Pickup tube:

12608593

Windage tray:

12612728

Dip stick:

12603506

Dip stick tube:

12612015

Pickup tube o-ring:

12557752

Gasket:

12612350

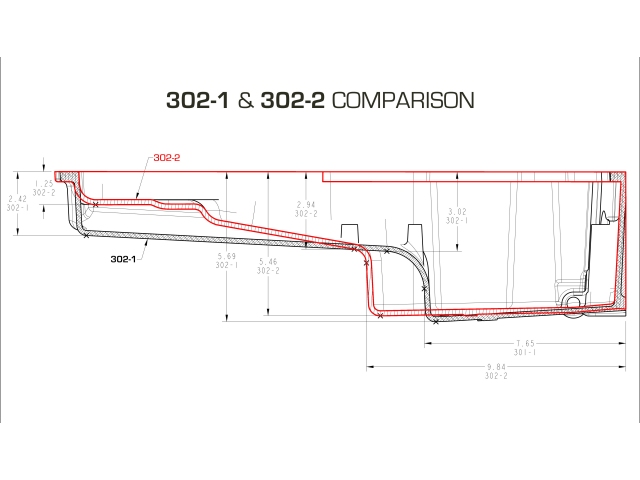

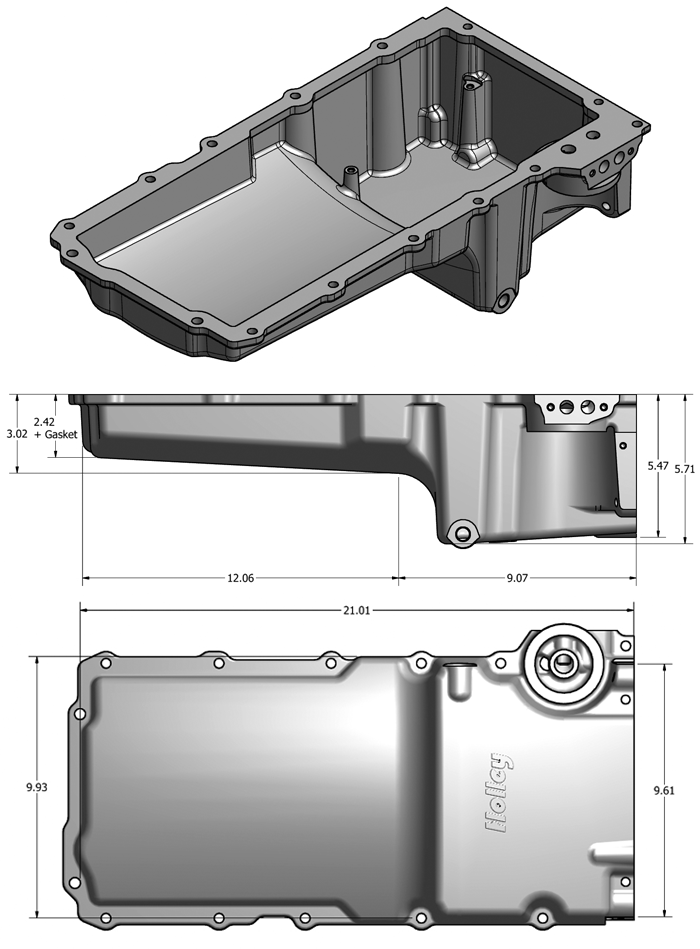

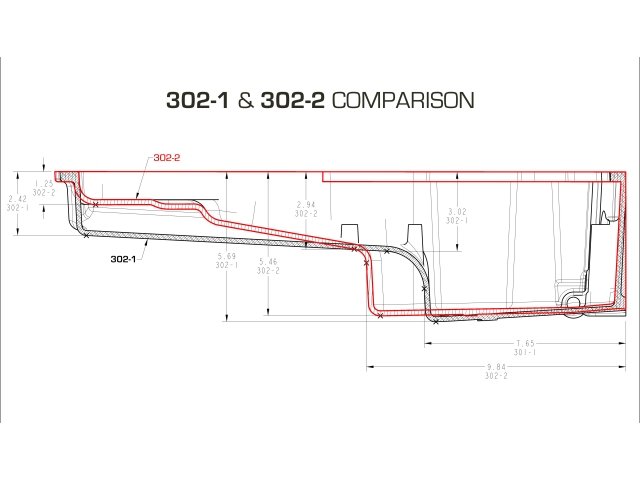

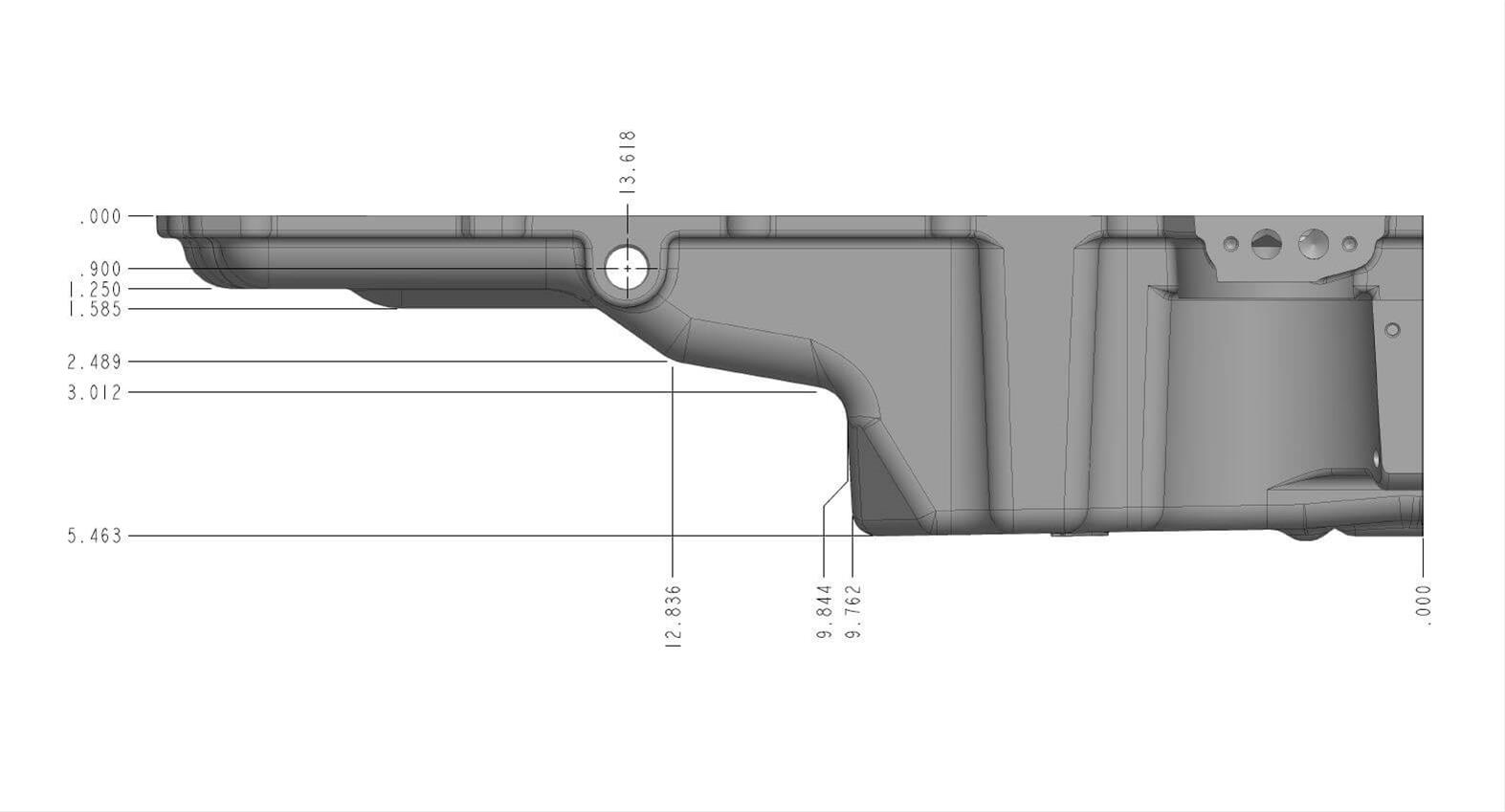

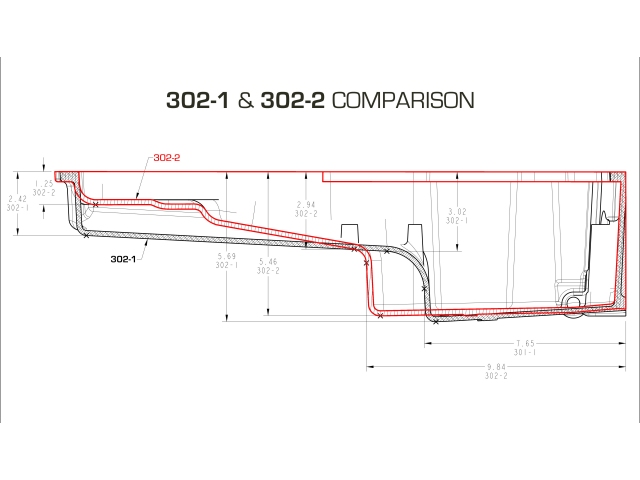

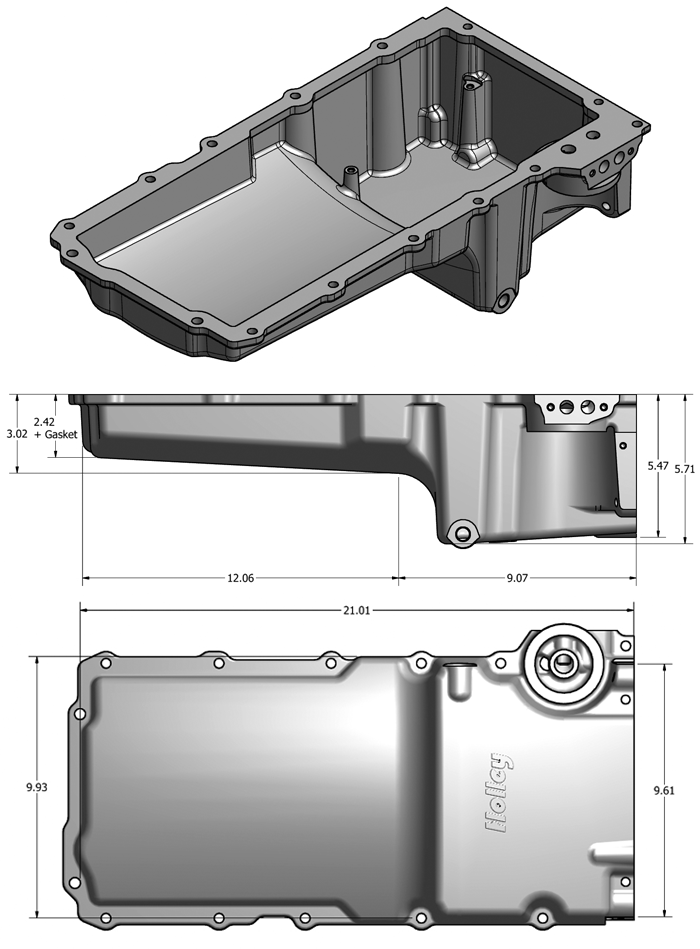

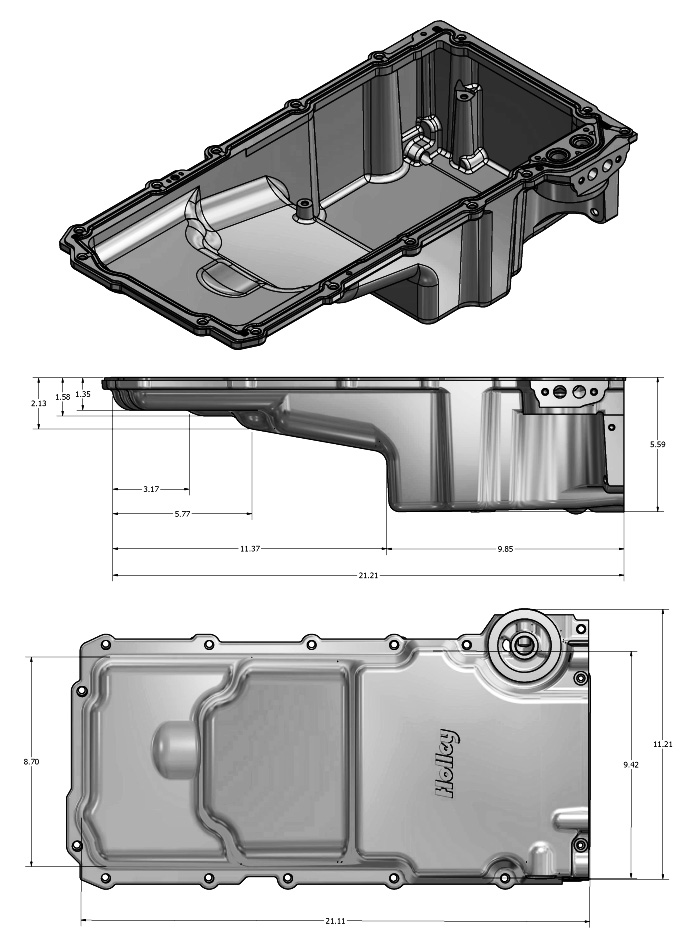

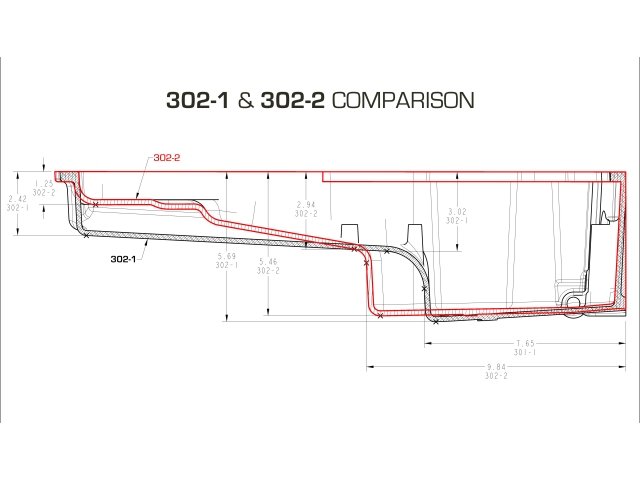

Holley 302-1 LS Retro-Fit Oil Pan

Vehicles: Various GM muscle/classic car and truck chassis

Capacity: 6 quarts

Oil Filter Thread: M22 x 1.5mm

Baffles: Holley, Part No. 302-10

- Part Numbers -

Oil pan:

Holley Part No. 302-1

Pickup tube: Supplied with pan

Windage tray: 12611129

Dip stick: 12634547

Dip stick tube: 12625031

Pickup tube o-ring: 12557752

Gasket: 12612350

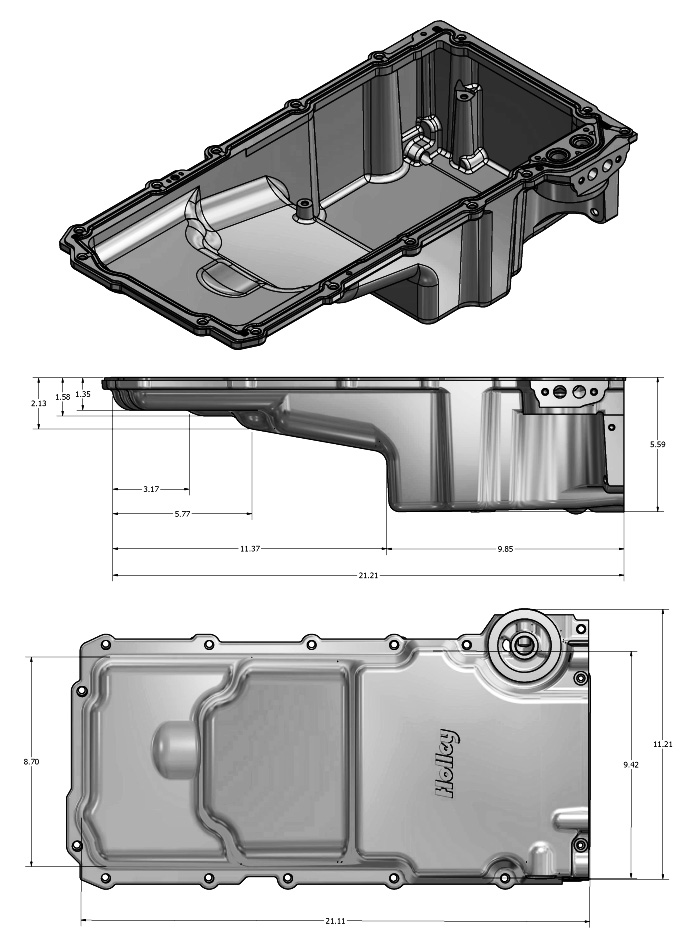

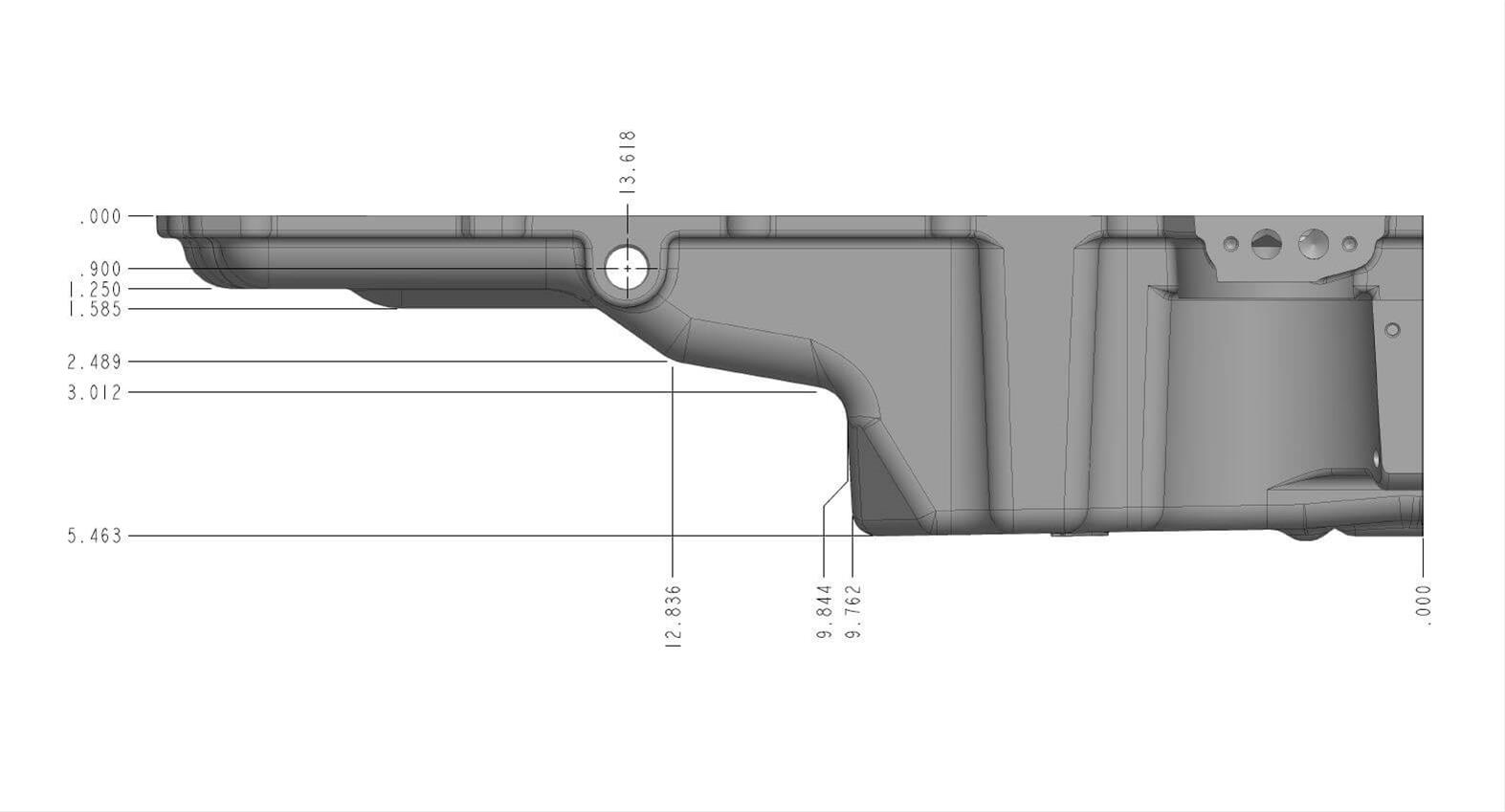

Holley 302-2 Front Clearance LS Retro Fit Oil Pan

Vehicles:

Various GM muscle/classic car and truck chassis

Capacity:

6.2 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

.

- Part Numbers -

Oil pan:

Holley Part No. 302-2

Pickup tube:

Supplied with pan

Windage tray:

12558253

Dip stick:

12634547

Dip stick tube:

12625031

Pickup tube o-ring:

12557752

Gasket:

12612350

Holley 302-3 Front Clearance LS Retro Fit Oil Pan with Turbo Drains

Vehicles:

Various GM muscle/classic car and truck chassis

Capacity:

5.9 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

.

- Part Numbers -

Oil pan:

Holley Part No. 302-3

Pickup tube:

Supplied with pan

Windage tray:

12558253

Dip stick:

12634547

Dip stick tube:

12625031

Pickup tube o-ring:

12557752

Gasket:

12612350

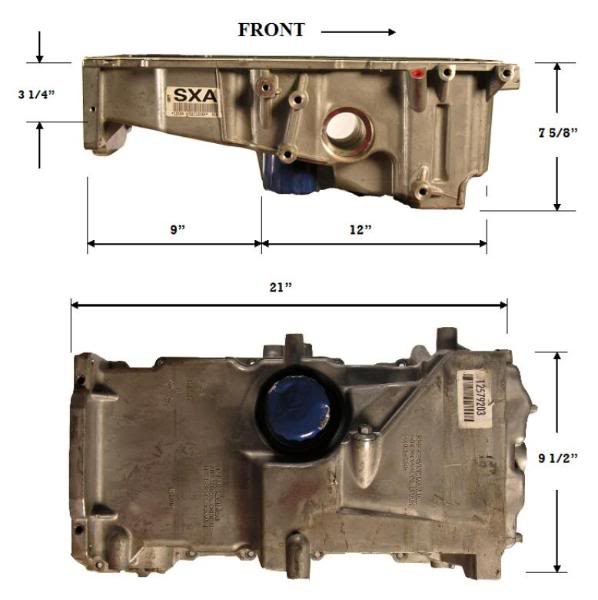

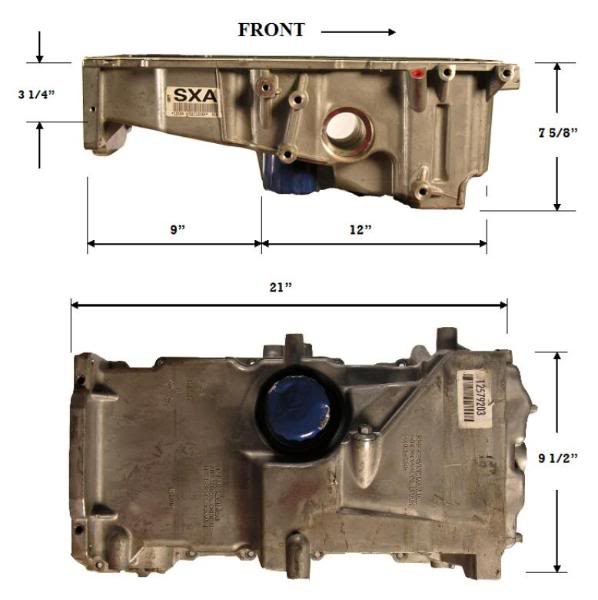

SSR & Trailblazer SS Oil Pan

Vehicles-

H3 Hummer

Capacity:

6 quarts

- Part Numbers -

Oil pan:

12579203

OTHER-

Long oil filter: ACDelco PN PF59

Short oil filter: ACDelco PN PF44

Oil Drain Plug (magnetic) 23011420

<< LS Swap Info < Back to List > LS Swap Info >>

Summit Racing SUM-G3611 Summit Racing™ Economy Oil Pans | Summit Racing

Free Shipping - Summit Racing™ Economy Oil Pans with qualifying orders of $109. Shop Oil Pans at Summit Racing.

LS Oil Pan Information

GM LS-Series Engine Oil Pan Dimensions

F-Body Camaro/Firebird LS1 Oil Pan

Vehicles:

1998-2002 Chevrolet Camaro (5.7L V8)

2002 Pontiac Firebird (5.7L V8)

Capacity:

5.5 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12628771

Pickup tube:

12558251

Windage tray:

12558253

Dip stick:

12551581

Dip stick tube:

12551577

Pickup tube o-ring:

12557752

Gasket:

12612350

2010-2015 LS3 Camaro / G8 Oil Pan

Vehicles:

2010-Present Chevrolet Camaro SS

2008-2009 Pontiac G8

2006-Present Holden VE Commodore

Capacity:

8 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

- Part Numbers -

Oil pan:

12640748

Pickup tube:

12611904

Windage tray:

12611129

Dip stick:

12634547

Dip stick tube:

12625031

Pickup tube o-ring:

12557752

Gasket:

12612350

GTO / VZ Commodore Oil Pan (Front Sump)

Vehicles:

2004-2006 Pontiac GTO

2001-2005 Holden Monaro (VZ)

2004-2006 Holden Commodore (VZ)

2001-2005 Vauxhall Monaro

Capacity:

6 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12581209 up to 2004; 12599397 2005 and later. Only difference between part numbers is the newer model has a built-in pressure relief valve.

Pickup tube:

12572654

Windage tray:

12558189

Dip stick:

92067147

Dip stick tube:

92066941

Pickup tube o-ring:

12557752

Gasket:

12612350

C6 Corvette LS2/LS3 Oil Pan (Wet Sump)

Vehicles:

2005-Present Chevrolet Corvette (non-dry sump)

Capacity:

5.5 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12624617

Pickup tube:

12624497

Windage tray:

12558189

Dip stick:

12570788

Dip stick tube:

12570787

Pickup tube o-ring:

12557752

Gasket:

12612350

2009-Present Cadillac CTS-V Oil Pan LS2/ LS6 / LSA

Vehicles:

2009 Cadillac CTS-V

Capacity:

6 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

Factory only

- Part Numbers -

Oil pan:

12631828 (current), 12605814 (previous), 12628451 (previous)

Pickup tube:

12621299

Windage tray:

12611129

Dip stick:

12584737

Dip stick tube:

12584738

Pickup tube o-ring:

12557752

Gasket:

12612350

GM Truck / SUV Oil Pan

Vehicles:

2007-Present Cadillac Escalade

2007-Present Chevrolet Avalanche

2008-Present Chevrolet Express

2007-Present Chevrolet Silverado

2007-Present Chevrolet Suburban

2007-Present Chevrolet Tahoe

Capacity:

6 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

Factory only

- Part Numbers -

Oil pan:

12640746

Pickup tube:

12608579

Windage tray:

12611129

Dip stick:

12622055

Dip stick tube:

12609269

Pickup tube o-ring:

12557752

Gasket:

12612350

Hummer (GM Muscle Hot Rod Pan) Oil Pan (Wet Sump)

Vehicles-

H3 Hummer

Capacity:

5.5 quarts

Oil Filter Thread:

Post June 2007 M22 x 1.5mm, Pre June 2007 13/16"-16

Baffles:

- Part Numbers -

Oil pan:

12614821

Pickup tube:

12608593

Windage tray:

12612728

Dip stick:

12603506

Dip stick tube:

12612015

Pickup tube o-ring:

12557752

Gasket:

12612350

Holley 302-1 LS Retro-Fit Oil Pan

Vehicles: Various GM muscle/classic car and truck chassis

Capacity: 6 quarts

Oil Filter Thread: M22 x 1.5mm

Baffles: Holley, Part No. 302-10

- Part Numbers -

Oil pan:

Holley Part No. 302-1

Pickup tube: Supplied with pan

Windage tray: 12611129

Dip stick: 12634547

Dip stick tube: 12625031

Pickup tube o-ring: 12557752

Gasket: 12612350

Holley 302-2 Front Clearance LS Retro Fit Oil Pan

Vehicles:

Various GM muscle/classic car and truck chassis

Capacity:

6.2 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

.

- Part Numbers -

Oil pan:

Holley Part No. 302-2

Pickup tube:

Supplied with pan

Windage tray:

12558253

Dip stick:

12634547

Dip stick tube:

12625031

Pickup tube o-ring:

12557752

Gasket:

12612350

Holley 302-3 Front Clearance LS Retro Fit Oil Pan with Turbo Drains

Vehicles:

Various GM muscle/classic car and truck chassis

Capacity:

5.9 quarts

Oil Filter Thread:

M22 x 1.5mm

Baffles:

.

- Part Numbers -

Oil pan:

Holley Part No. 302-3

Pickup tube:

Supplied with pan

Windage tray:

12558253

Dip stick:

12634547

Dip stick tube:

12625031

Pickup tube o-ring:

12557752

Gasket:

12612350

SSR & Trailblazer SS Oil Pan

Vehicles-

H3 Hummer

Capacity:

6 quarts

- Part Numbers -

Oil pan:

12579203

OTHER-

Long oil filter: ACDelco PN PF59

Short oil filter: ACDelco PN PF44

Oil Drain Plug (magnetic) 23011420

<< LS Swap Info < Back to List > LS Swap Info >>

Last edited: