Aluminum heads and spark plug seizure, one factor I see thats becoming more common with the newer cars engines as aluminum is used for the cylinder heads more and more is that spark plugs on newer cars can last for 100K miles and that allows time for thousands of heat and cooling cycles, and corrosion to take place in the cylinder head threads,

I see this, spark plug thread damage rather frequently on the LT1 heads now that the cars are 20 plus years old.

I was curious how many of you with high miles like, 80K- 100k or more have found thread seizure to be an issue when you went to change your spark plugs . This is a common problem with aluminum heads, that have had plugs threaded into the heads and left without being changed for years.

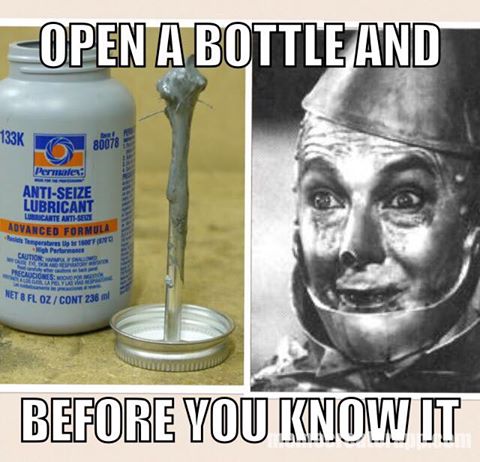

it is recommended on most cars that use aluminum cylinder heads to use anti-seize on the plug threads before each is installed,

but if it was not used before the last set of plugs was installed and its been a few years , when you try to remove the plugs it can pull or damage the threads out with the plugs being removed , ruining the head, requiring an expensive repair.. When I am removing anything from an aluminum head or block, that seems to be seized a spray of 50% acetone and 50% marvel mystery oil as a penetration oil used to seep into the threads , this penetrating oil will tend to help, loosen the threads in the head.

If you suspect the threads are binding ,don,t force it and ruin the heads, let the repeated spray mix, you spray, on the heads where the plugs are inserted, seep in over several days if necessary.

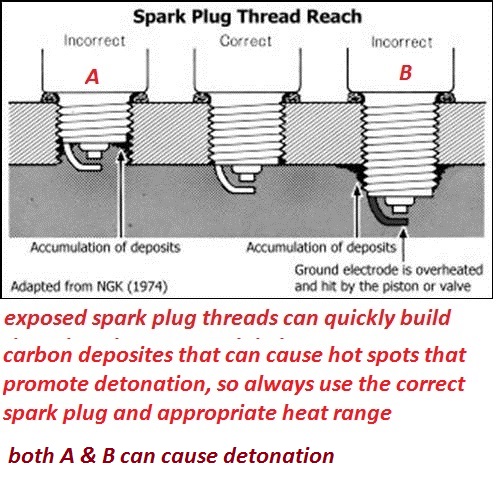

Since our plugs are supposed to last 50K- 100k, between the necessity to be replaced, I thought I would make anyone aware of the potential problem before it happens. I have seen this thread binding problem occasionally , especially on older LT1-4 engines, the spray lubricant and penetrating oil works, at loosening old plugs, but having anti seize on the plug threads and not getting into a rush and cross threading, or over tightening the plugs is also a good way to avoid the problem.

http://www.ngksparkplugs.com/pdf/dyk_5points.pdf

http://www.ngksparkplugs.com/techinfo/spark_plugs/installation.asp

http://www.autolite.com/product-information/tech-specs.aspx

http://www.autolite.com/media/11853/torquespecs.pdf

removing loctited ford and similar frame/body mount bolts

yes the tools expensive and you probably won't use it regularly, but if you've ever had to partially remove the trucks interior to get the bolts locking nuts out, from under the seats and carpet, you may see it as a BARGAIN...

garage.grumpysperformance.com

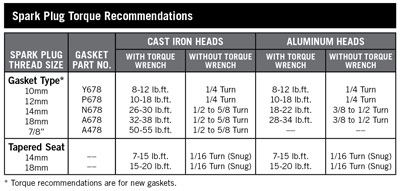

Apply a thin coat of anti-seize compound to the spark plug threads, being careful not to get any near the lower threads.- Thread one of the new plugs into the spark plug hole until you can no longer turn it with your fingers, then use a torque wrench to tighten it to the specification listed in your service manual. It is a good idea to slip a short length of rubber hose over the end of the plug to use as a tool to thread it into place. The hose will grip the plug well enough to turn it, but will start to slip if the plug begins to cross-thread in the hole – this will prevent damaged threads.

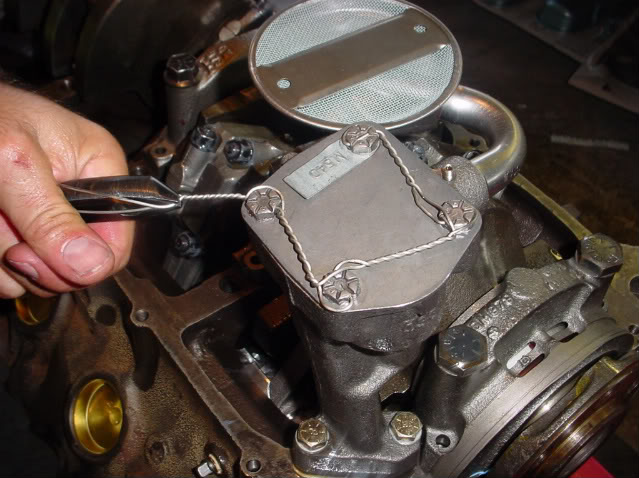

if you plug comes out with aluminum stuck in the threads like this the heads damaged

oil pump mods & related info

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=3%2F4%22%20tube%20oil%20pump%20pickups https://www.jegs.com/webapp/wcs/stores/servlet/SearchResultsPageCmd?q=big+block+chevy+oil+pumps&storeId=10001&catalogId=10002&langId=-1...

garage.grumpysperformance.com

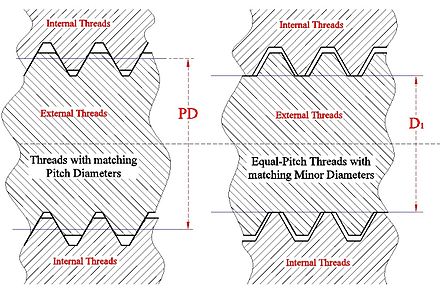

there IS BY DESIGN, some thread clearance between the spark plug threads and cylinder head threads, use of anti-seize on those threads reduces the area moisture can cause corrosion on.

Last edited by a moderator: