"GRUMPYVETTE?

I get a drastic fluctuation in oil pressure everytime i take a left or right turn or if i get on the gas a little hard. In turns and hard acceleration the car will read no pressure but as soon as i straighten out or let up the oil pressure will spike for a moment then returns back to normal. (somewhat) I dont think this is normal. if not, does it pose i potential problem?"

personally Id put the car up on a lift or jack stands and drain the oil then Id get out my lighted visual inspection tool, that slips easily thru the drain plug hole and look for a oil pump pick-up thats loose because thats what it sounds like your problem is

http://www.tooltopia.com/provision-pv618.aspx

GOOGLE (SLIPV618) if the links bad

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=1800&p=5526#p5526

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=2376

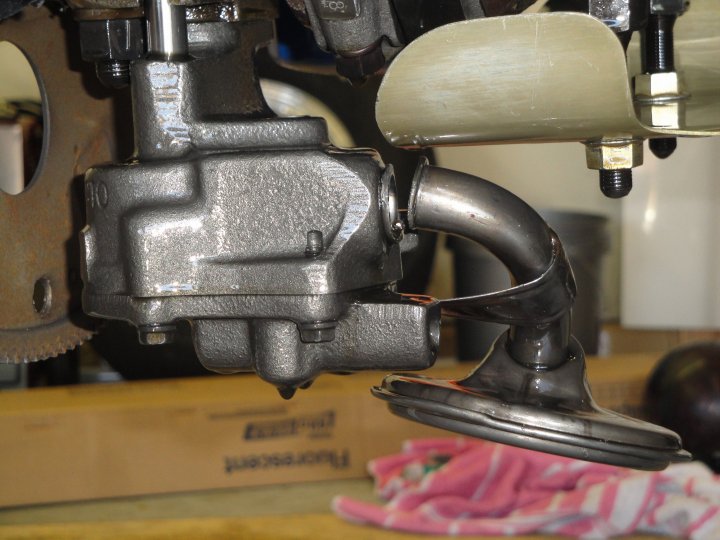

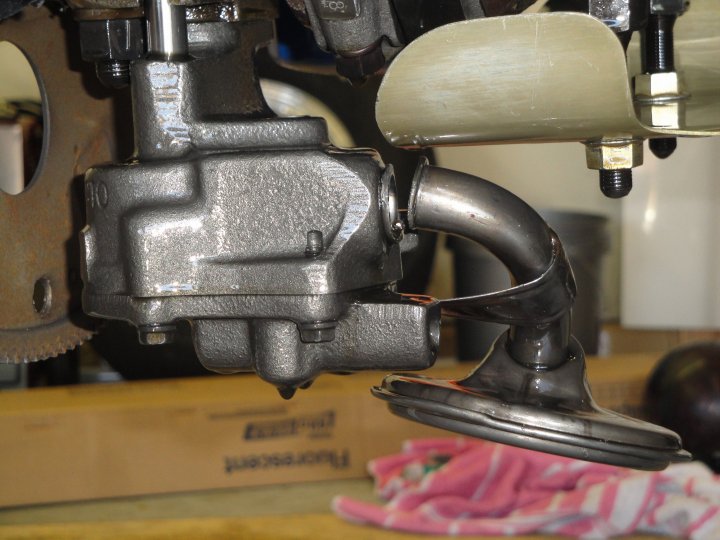

this is a common unsupported or secured oil pump pick-up, they come loose occasionally and fall off resulting in little or no oil pressure under hard acceleration braking turns or high rpms, but decent oil pressure at idle in many cases

first Id point out that if you failed to braze the pick-up tube to the pump body it can vibrate loose and fall out and thats not really rare, and having a pick-up vibrate loose enough that it drops down to touch the oil pan floor has similar symptoms but they generally only occur above 2500rpm,

a simple spot/TACK welding if done with a typical arc welder leaves a brittle weld in some cases, and that BRAZING the complete joint is the PREFERRED method of locking the pick-up tube to the pump body

next, Id suggest a TIG or MIG weld but brazing is a bit more flexible

adding a brace and brazing it to the pick-up tube and use loc-tite on the bolt threads helps durability

brittle welds cause problems, the oil pump pick-up tends to vibrate at some engine speeds and over time it will weaken the joint if thats not braced or supported with a second support point, welding or brazing a brace and bolting it on the pump body helps, but a brazed connection tends to be a bit more flexible. many guys seat the tube with a hammer and flat screw driver blade against the rib on the pick-up tube shoulder with the result that it caused stress risers and the pick-up fails eventually, even if

fully supported but fully supported

bolt on pick-up designs are less likely to fail

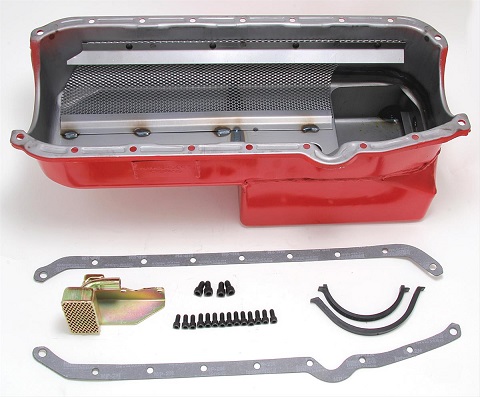

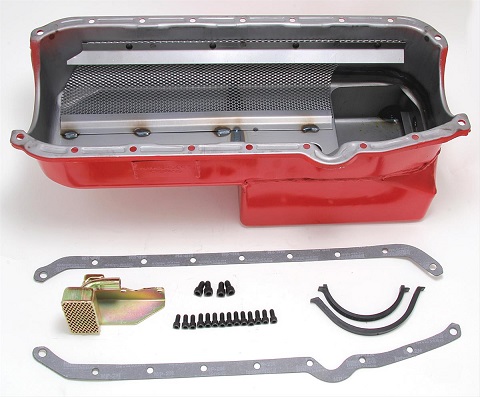

I think the hamburger oil pan is a better value At $242 than most of the common mid priced oil pans

notice the better oil control features

https://www.summitracing.com/parts/ham-1088/overview/

http://www.milodon.com/oil-pans/street-oil-pans-sbchevy.asp

http://www.jegs.com/p/Moroso/Moroso-Street-Strip-Oil-Pans/763991/10002/-1

https://www.summitracing.com/search/brand/hamburgers-performance/part-type/oil-pans

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?search=action&category=1301

http://www.stefsperformance.net/ste...oil-pans/aluminum-oil-pans-pumps#!prettyPhoto

I get a drastic fluctuation in oil pressure everytime i take a left or right turn or if i get on the gas a little hard. In turns and hard acceleration the car will read no pressure but as soon as i straighten out or let up the oil pressure will spike for a moment then returns back to normal. (somewhat) I dont think this is normal. if not, does it pose i potential problem?"

personally Id put the car up on a lift or jack stands and drain the oil then Id get out my lighted visual inspection tool, that slips easily thru the drain plug hole and look for a oil pump pick-up thats loose because thats what it sounds like your problem is

http://www.tooltopia.com/provision-pv618.aspx

GOOGLE (SLIPV618) if the links bad

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=1800&p=5526#p5526

http://forum.grumpysperformance.com/viewtopic.php?f=54&t=2376

this is a common unsupported or secured oil pump pick-up, they come loose occasionally and fall off resulting in little or no oil pressure under hard acceleration braking turns or high rpms, but decent oil pressure at idle in many cases

first Id point out that if you failed to braze the pick-up tube to the pump body it can vibrate loose and fall out and thats not really rare, and having a pick-up vibrate loose enough that it drops down to touch the oil pan floor has similar symptoms but they generally only occur above 2500rpm,

a simple spot/TACK welding if done with a typical arc welder leaves a brittle weld in some cases, and that BRAZING the complete joint is the PREFERRED method of locking the pick-up tube to the pump body

next, Id suggest a TIG or MIG weld but brazing is a bit more flexible

adding a brace and brazing it to the pick-up tube and use loc-tite on the bolt threads helps durability

brittle welds cause problems, the oil pump pick-up tends to vibrate at some engine speeds and over time it will weaken the joint if thats not braced or supported with a second support point, welding or brazing a brace and bolting it on the pump body helps, but a brazed connection tends to be a bit more flexible. many guys seat the tube with a hammer and flat screw driver blade against the rib on the pick-up tube shoulder with the result that it caused stress risers and the pick-up fails eventually, even if

fully supported but fully supported

bolt on pick-up designs are less likely to fail

I think the hamburger oil pan is a better value At $242 than most of the common mid priced oil pans

notice the better oil control features

https://www.summitracing.com/parts/ham-1088/overview/

http://www.milodon.com/oil-pans/street-oil-pans-sbchevy.asp

http://www.jegs.com/p/Moroso/Moroso-Street-Strip-Oil-Pans/763991/10002/-1

https://www.summitracing.com/search/brand/hamburgers-performance/part-type/oil-pans

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?search=action&category=1301

http://www.stefsperformance.net/ste...oil-pans/aluminum-oil-pans-pumps#!prettyPhoto

Last edited by a moderator: