Re: Will a main girdle fit with the stock oil pan on Gen1 SB

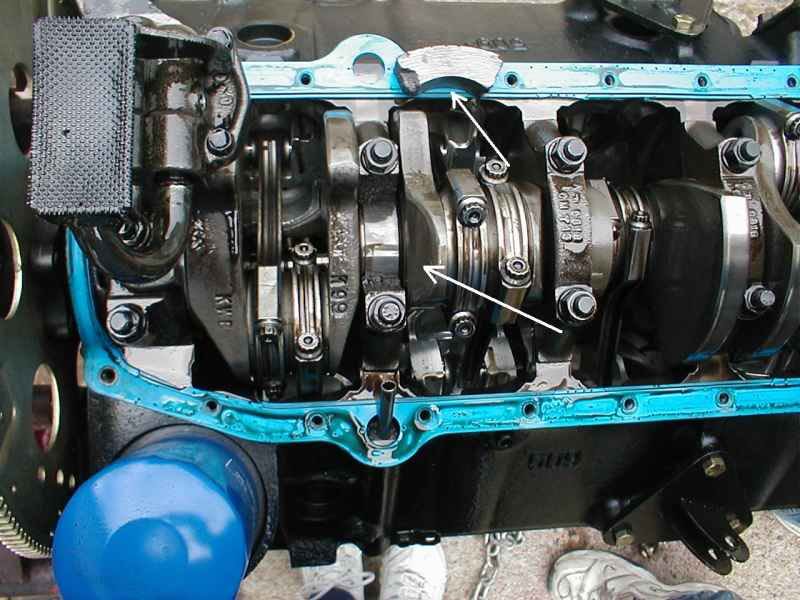

the correctly installed windage screen ,actually HELPS lubricate the the cam, as it insures the oil flow remains consistent, the cam is lubricated by oil flow from the cam bearings rod and main bearings pressurized oil flow constantly squirting out of the bearing edges and oil draining back to the sump from the upper engines, lifter gallery, "splash oiling" is a mis -conception in a SBC with pressurized oiling , the early flat head fords actually used "SPLASH OILING" and bearings rarely lasted 30K miles between requiring replacement

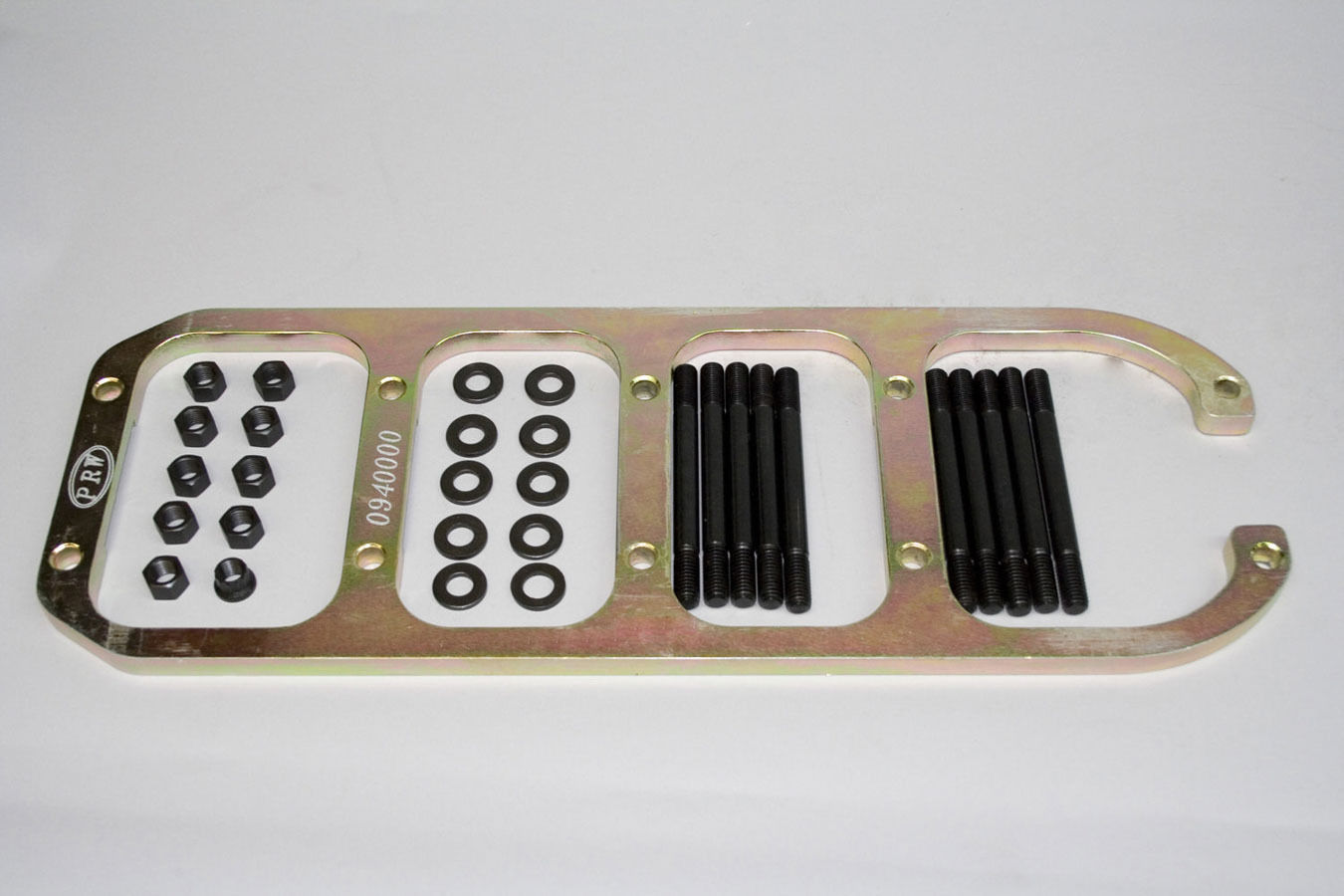

the answer as to what block you need will of course depend on what you intend to DO- WITH THE COMPLETED engine,yes a common upgrade is to use the stock main caps and ARP main studs can be used but the difference in tension may require the block gets line honed to maintain the correct crank bearing alignment compared to the factory main cap bolts ,and this generally works ok up to the 450-475 hp level, and yes theres stronger billet aftermarket main caps, splayed main caps and main cap girdles that can be used to increase the blocks strength and rigidity, but the aftermarket blocks use thicker castings of a sightly better design making them significantly stronger and a splaid main cap is structurally a stronger design.

Most OEM production SBC blocks are factory rated for under 400 hp use, we all know people that have pushed the limits to 450-500 hp but theres a huge difference, in stress between the malt shop hero who got his car dyno tested at 475 hp who spends 97% of his time cruising around to impress his buddies with the cars lumpy idle, and racing once every few months , and some guys racing a stock car for several 50 lap races at 6500 rpm every Saturday night, in what you can reasonably expect from the main cap durability and main cap stability

because stress is CUMULATIVE !

you can get away with amazing amounts of abuse SHORT TERM, that will EVENTUALLY cause major parts , durability issues & failures

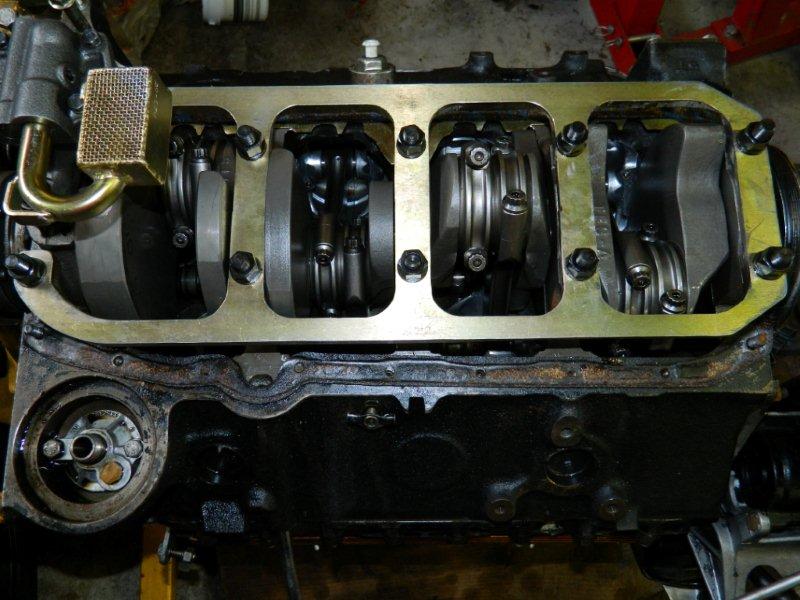

Yes there are main cap girdles and individual main cap straps available, but that set of two bolt main cap straps or a main cap girdle used on a O.E.M. block, is a band aid for the comparatively weak, cast main caps and in no way does in compare to the strength youll get from

installing billet steel spayed main caps with the proper ARM studs on the O.E.M. block but even then they can,t compare to a DART block that has a significantly stronger and thicker casting from a better high strength alloy

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-24529

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-51651

http://garage.grumpysperformance.co...bearing-studs-torque-stretch.9409/#post-34241

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-33362

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

http://garage.grumpysperformance.com/index.php?threads/splayed-main-caps.1014/#post-12226

if you check you'll find that stud girdle use does little or nothing for the individual main cap strength but it does marginally increase main cap stability and block flex.

now the potential difference is probably not worth the expense, in that your generally spending cash that would be better used in the purchase of the stronger aftermarket block casting from a known source like DART.

look through the links and read the sub links

the billet splayed main caps on the aftermarket block is the stronger route, but Id bet 90% of the guys building their first engine think they will save money using the O.E.M. block they already own.....well, until... they add up all the machine work costs and price of parts like aftermarket splayed caps, ARP main studs ,the labor costs from the machine shop, etc. but by that time the machine shop owner is smiling all the way to the bank, and youve just figured out the true cost of that cheaper O.E.M BLOCK

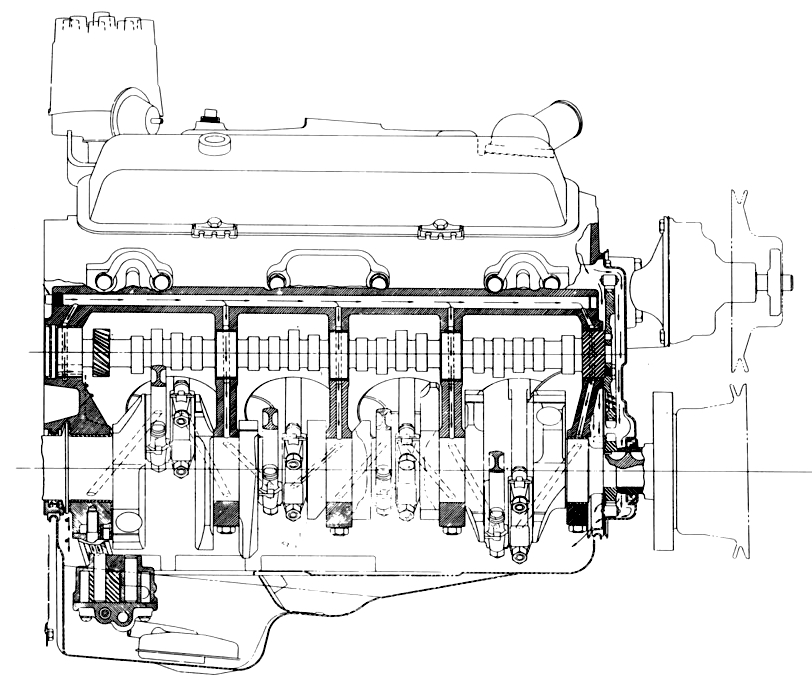

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

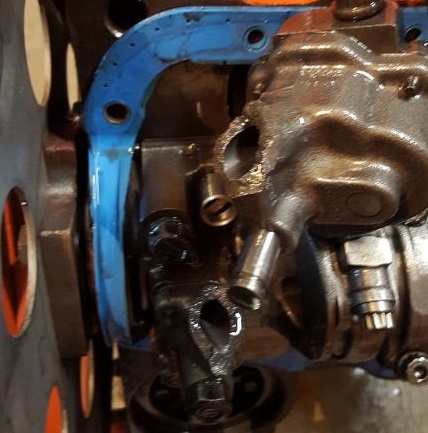

aftermarket blocks like dart have significantly thicker bore walls, main cap webs, decks, can be ordered with splayed and billet main caps

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=52

a stud girdle will have only a minor effect on the engines bottom end strength, use of ARP main studs and aftermarket 4340 forged steel bodys and connecting rods with ARP rod bolts will provide a good deal more effective strength than the main cap girdle, its the stock connecting rods and rod bolts and

the stock 4-5 quart un-baffled oil pan, based lubrication system, and cast crankshaft and limitations on the stock valve train and detonation with crappy octane fuel, thats putting the stock bearings at risk, and I'd bet 90% of lower end failures I've seen are the result of improper lubrication, detonation, or improper clearances on the bearings closely followed by use of stock connecting rods and rod bolts.

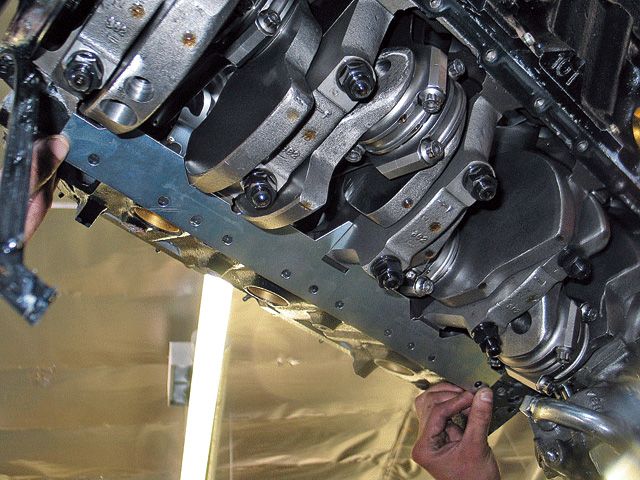

I'd put a great deal more time into having the block line honed after installing main cap studs and selecting a 7-8 quart baffled oil pan, and 7/16' rod bolt rods and a balanced forged rotating assembly than in worrying about a main cap stud girdle.

Id bet a FAR greater percentages of races are lost due to lack of engine durability issues,

related to lack of consistent lubrication or cooling or improper clearances

or driver errors than are ever due to having slightly less horsepower than the next guys car.

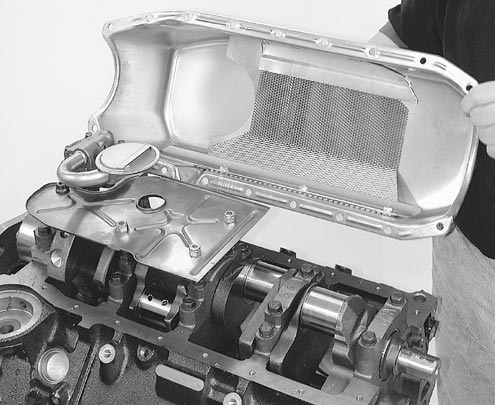

having a properly set up 7-8 quart baffled oil pan and matching windage screen and checking clearances goes a long way towards increased durability

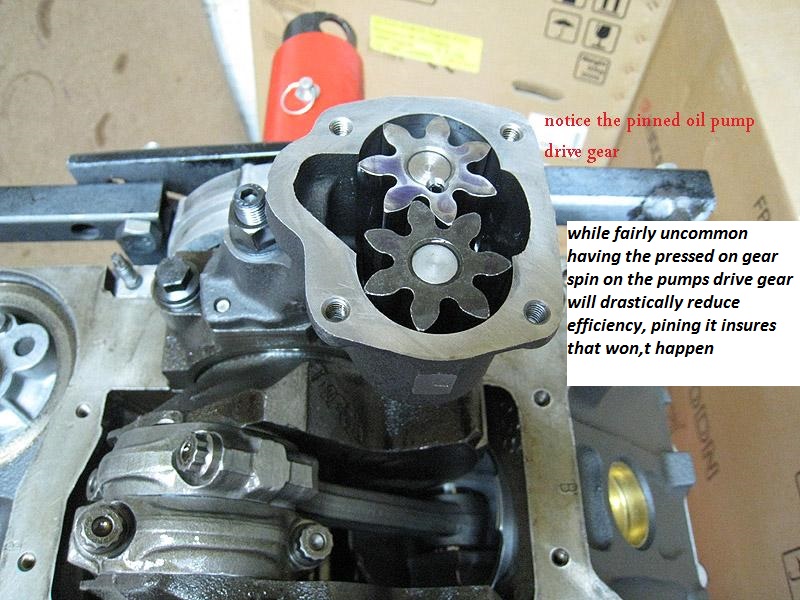

the better machine shops pin or sleeve the main caps to prevent movement

if some internal engine oil control components breaking,in engines, theres a reason,

and its frequently related to either inferior materials being used or component design,

not having the operational stress being induced taken into account in the design phase.

or the components not having been ,manufactured or installed correctly.

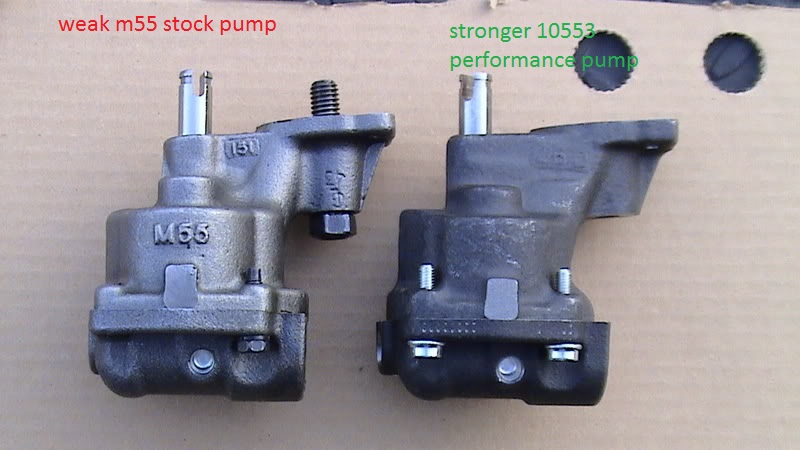

example

for awhile SBC oil pumps were breaking after the manufacturer,

tried to save some cash by reducing the thickness of the housing casting ,

this was a really stupid change that cost them a great deal, in customer confidence,

and potential future sales are word, of the defective pump, got around quickly

theres some vibration stress on any oil pump, and the manufacturer rapidly found ,

they were forced to revert to the original older design.

trying to save a few cents per pump so they could undercut the cost,

of the pumps of other manufacturers, and gain an advantage,

cost them rather dearly in sales.

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

viewtopic.php?f=44&t=623&p=834&hilit=camaro+crossram#p834

http://www.camaro-untoldsecrets.com/art ... ossram.htm

http://www.summitracing.com/search/Prod ... Stud-Kits/

http://hotrodenginetech.com/how-to-inst ... cap-studs/

viewtopic.php?f=53&t=204

https://chevroletperformanceparts.com/catalog/chevrolet-performance-engines

viewtopic.php?f=50&t=3156&p=14918&hilit=caps+walking#p14918

viewtopic.php?f=53&t=1168

viewtopic.php?f=51&t=5945

viewtopic.php?f=53&t=341

viewtopic.php?f=53&t=510

viewtopic.php?f=50&t=9816&p=37278&hilit=detonation#p37278

viewtopic.php?f=54&t=3519&p=10293&hilit=melling+oil+pump#p10293