every shop needs a decent work bench thats capable of holding significant weight and giving you room to work at waist level with good lighting, thats clean and well lighted enough for small projects like carburetor and distributor rebuilds and strong enough to work on a rear differential or transmission.

theres two basic designs and your shops floor space will probably influence your choice.

theres the typical stand alone bench and those that may be characterized as a wall shelf , in either case for a work bench used for automotive repair work ,you'll probably want a minimum of a 36" wide x 48-96" long bench minimum size, with a stainless steel top surface capable of holding about 750-1000 lbs so clean up and oil spilled will not be a major issue,and you've got a significant safety margin.

youll want at least one dual 110 volt outlet in easy reach.

Ive used both types and both styles have distinct advantages, the stand alone bench allows access from both sides, but it may need to be bolted to the floor for stability in some cases if its not fairly large and well designed, while the wall mount shelf frees up a bit more floor space, your shop wall structure may not be able to support the shelf, so think thru your options.

you must decide on a comfortable work height, if you intend to use a chair or bar stool, that limits the bench top to about a 30"-33" height for easy access. if you prefer to stand while working a 42"-44" height is a good choice

three layers of 3/4" plywood, glued together with carpenters glue and bolted to the support frame over the support frame rails along all edges with the legs anchored to the wall and or floor usually makes a solid surface, to glue, or bolt the upper steel surface too,having a raised lip or edge on all sides to reduce oil spills running off the bench surface is usually a good idea, having the support legs secure to the floor is optional but a good idea in most cases.

look thru the links below for some basic ideas to work from,and remember you should built it strong/heavy because if it were to collapse, during use it could result in significant injury or expense or both, and adding a parts washer to the shop at the same time might be a good idea

http://www.workbenchdesign.net/rplansfree.html

http://www.freeww.com/workbenches.html

http://www.freebenchplans.com/workbenchplans.html

http://www.hammerzone.com/archives/work ... w20xl.html

http://www.freeww.com/garageworkbenches.html

http://www.plansnow.com/workbenchplans.html

http://www.ezwoodshop.com/workbench-plans.html

http://www.wayneofthewoods.com/workbench.html

viewtopic.php?f=27&t=970&p=18907#p18907

now in an ideal world where youve got extra cash, you can buy an install a shelf, under the bench and install a secondary tool storage chest

http://www.harborfreight.com/56-inch-11 ... 67681.html

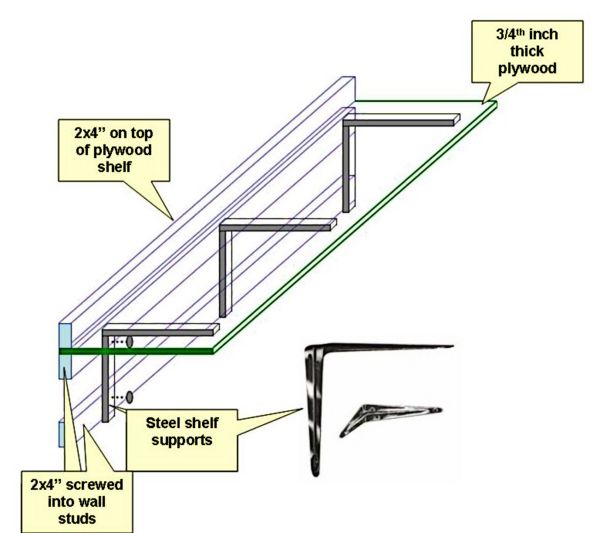

this looks a bit flimsy but if done correctly, especially if the upper table surface is made from 3/4" thick plywood glued, and sheet rock screwed, to the particle board under it,too add significant rigidity, you get the basic idea. ID have used BOTH vertical braces bolted to the wall to support the inner wall edge of the bench and several angled 2"x 4" braces from the bench support bracing fastened to the wall with a 4x4" footer for the braces lower end support bolted to the wall about 6" above the floor to make sweeping up easy, extending up at about a 40 degree angle to the upper bench under surface

if you can find a food preparation table at a restaurant that's going out of business , or theres a used restaurant equipment supply near you,that's potentially an excellent start point

parts washer thread[/color]

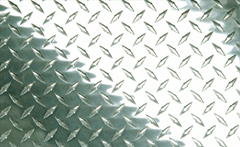

you can frequently find sheets of 1/8" aluminum diamond plate cheap also that can be screwed to plywood FOR A DESK OR BENCH TOP

viewtopic.php?f=27&t=2886&p=7597&hilit=+washer#p7597

theres two basic designs and your shops floor space will probably influence your choice.

theres the typical stand alone bench and those that may be characterized as a wall shelf , in either case for a work bench used for automotive repair work ,you'll probably want a minimum of a 36" wide x 48-96" long bench minimum size, with a stainless steel top surface capable of holding about 750-1000 lbs so clean up and oil spilled will not be a major issue,and you've got a significant safety margin.

youll want at least one dual 110 volt outlet in easy reach.

Ive used both types and both styles have distinct advantages, the stand alone bench allows access from both sides, but it may need to be bolted to the floor for stability in some cases if its not fairly large and well designed, while the wall mount shelf frees up a bit more floor space, your shop wall structure may not be able to support the shelf, so think thru your options.

you must decide on a comfortable work height, if you intend to use a chair or bar stool, that limits the bench top to about a 30"-33" height for easy access. if you prefer to stand while working a 42"-44" height is a good choice

three layers of 3/4" plywood, glued together with carpenters glue and bolted to the support frame over the support frame rails along all edges with the legs anchored to the wall and or floor usually makes a solid surface, to glue, or bolt the upper steel surface too,having a raised lip or edge on all sides to reduce oil spills running off the bench surface is usually a good idea, having the support legs secure to the floor is optional but a good idea in most cases.

look thru the links below for some basic ideas to work from,and remember you should built it strong/heavy because if it were to collapse, during use it could result in significant injury or expense or both, and adding a parts washer to the shop at the same time might be a good idea

http://www.workbenchdesign.net/rplansfree.html

http://www.freeww.com/workbenches.html

http://www.freebenchplans.com/workbenchplans.html

http://www.hammerzone.com/archives/work ... w20xl.html

http://www.freeww.com/garageworkbenches.html

http://www.plansnow.com/workbenchplans.html

http://www.ezwoodshop.com/workbench-plans.html

http://www.wayneofthewoods.com/workbench.html

viewtopic.php?f=27&t=970&p=18907#p18907

now in an ideal world where youve got extra cash, you can buy an install a shelf, under the bench and install a secondary tool storage chest

http://www.harborfreight.com/56-inch-11 ... 67681.html

this looks a bit flimsy but if done correctly, especially if the upper table surface is made from 3/4" thick plywood glued, and sheet rock screwed, to the particle board under it,too add significant rigidity, you get the basic idea. ID have used BOTH vertical braces bolted to the wall to support the inner wall edge of the bench and several angled 2"x 4" braces from the bench support bracing fastened to the wall with a 4x4" footer for the braces lower end support bolted to the wall about 6" above the floor to make sweeping up easy, extending up at about a 40 degree angle to the upper bench under surface

if you can find a food preparation table at a restaurant that's going out of business , or theres a used restaurant equipment supply near you,that's potentially an excellent start point

parts washer thread[/color]

you can frequently find sheets of 1/8" aluminum diamond plate cheap also that can be screwed to plywood FOR A DESK OR BENCH TOP

viewtopic.php?f=27&t=2886&p=7597&hilit=+washer#p7597