INSTALLING AN (X) PIPE IN THE EXHAUST ON A DUAL EXHAUST CAR

Magnaflow sells them in stainless:

https://www.magnaflow.com/products?partNumber=10782

Dynomax (aluminized):

Dynomax 88328: X-Pipe Outer diameter: 3" | JEGS

Flowtech (aluminized):

Flowtech 53621: FlowTech Exhaust X-Pipe 3" | JEGS

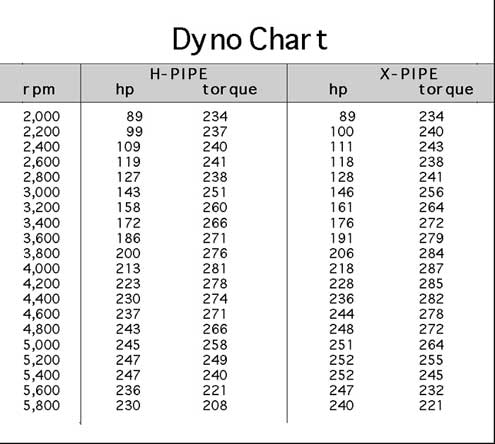

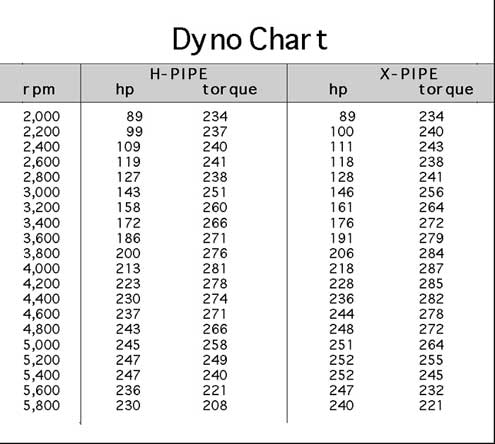

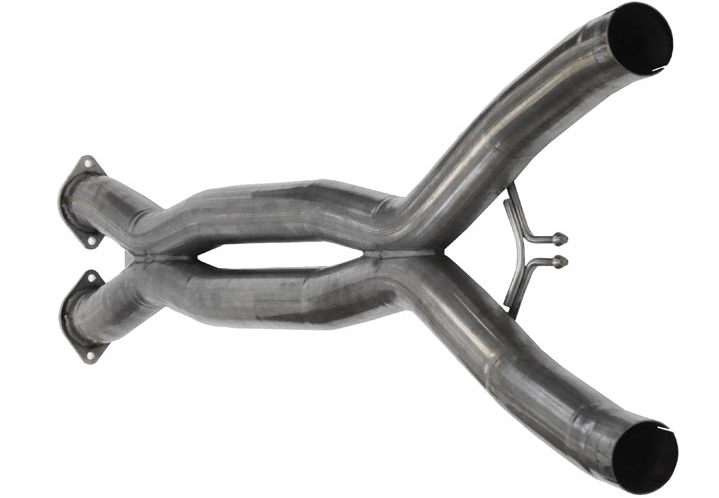

http://pypesexhaust.com/p-13194-dyno-tests.html

https://www.summitracing.com/parts/sum-640701

https://www.summitracing.com/parts/cse-14173

just having your own MIG or better yet TIG welder,

and having learned the skills to use it correctly,

can save you hundreds of dollars in EVERY ,

exhaust system install

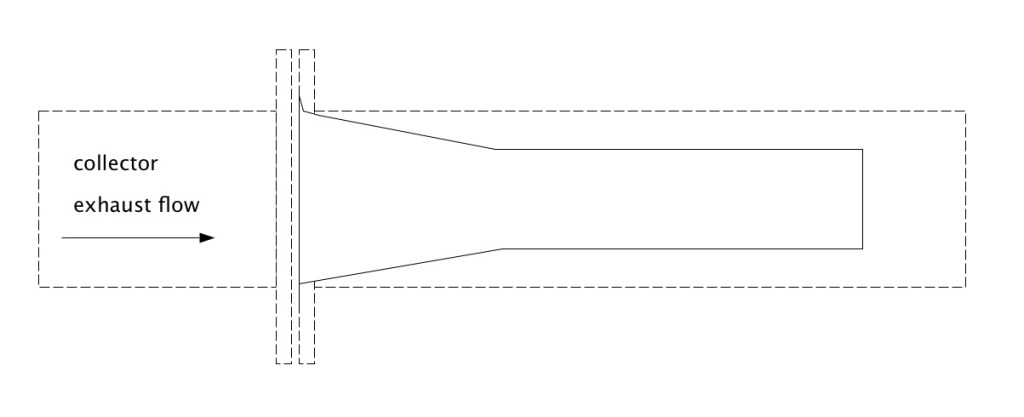

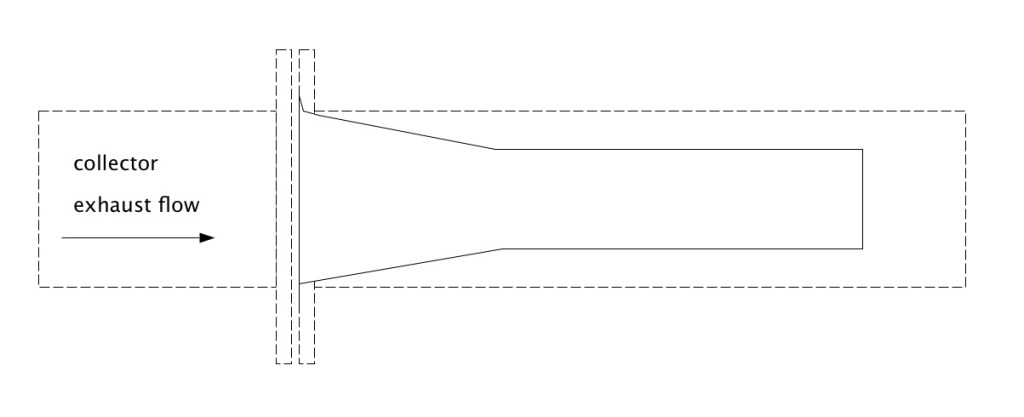

adding an anti-reversion baffle to a 18"-24" longer collector on open headers with the internal pipe about 1/2 the collector length tends to help scavenging on some engines, no header will function to full efficiency with any significant back pressure so take the effort to accurately measure any restriction to exhaust flow AT your upper rpm range of your engines power band and be darn sure its not choking your power curve.

http://www.wallaceracing.com/intake-runner-length.php

http://www.bgsoflex.com/intakeln.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator3.htm

http://www.velocity-of-sound.com/velocity_of_sound/velocity_stacks.htm

http://www.swartzracingmanifolds.com/tech/index.htm

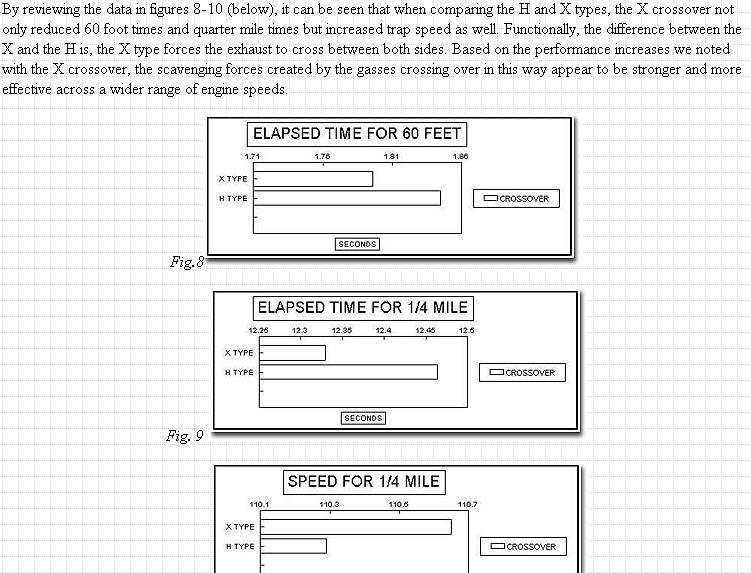

Hot rod (oct. 2000)

355 SBC

9:1

trickflow alum heads

2.02''/1.06'' valves

comp magnum 286 hyd. cam (236/236 deg @ .050'', .490''/.490'' lift, 110 lsa)

286 hyd. cam (236/236 deg @ .050'', .490''/.490'' lift, 110 lsa)

edelbrock performer rpm intake

demon 750 cfm carb

3'' dual pipes

flowmaster "big block" mufflers

hooker 1-5/8'' long tube headers

Headers Headers with X-pipe

RPM HP TQ RPM HP TQ HP gain TQ gain

3000 219.8 384.7 3000 231.2 404.7 11.4 20.0

3100 224.5 380.4 3100 235.3 398.7 10.8 18.3

3200 229.7 377.0 3200 242.6 398.2 12.9 21.2

3300 234.6 373.4 3300 252.0 401.0 17.4 27.6

3400 240.1 370.9 3400 262.1 404.9 22.0 34.0

3500 246.5 370.0 3500 271.2 406.9 24.7 36.9

3600 255.5 372.8 3600 280.5 409.3 25.0 36.5

3700 269.1 381.9 3700 290.3 412.1 21.2 30.2

3800 283.8 392.3 3800 300.3 415.0 16.5 22.7

3900 295.5 397.9 3900 308.6 415.6 13.1 17.7

4000 307.6 403.9 4000 317.4 416.7 9.8 12.8

4100 320.7 410.8 4100 326.9 418.8 6.2 8.0

4200 332.6 415.9 4200 337.0 421.4 4.4 5.5

4300 343.5 419.5 4300 345.7 422.2 2.2 2.7

4400 351.8 419.9 4400 352.9 421.2 1.1 1.3

4500 358.7 418.7 4500 358.7 418.7 0 0

4600 362.5 413.9 4600 363.7 415.2 1.2 1.3

4700 367.1 410.3 4700 369.5 412.9 2.4 2.6

4800 371.2 406.2 4800 375.8 411.1 4.6 4.9

4900 374.8 401.7 4900 380.1 407.4 5.3 5.7

5000 376.7 395.7 5000 381.8 401.1 5.1 5.4

5100 378.2 389.5 5100 381.1 392.5 2.9 3.0

5200 380.8 384.6 5200 381.5 385.3 0.7 0.7

5300 383.8 380.4 5300 384.0 380.5 0.2 0.1

5400 387.0 376.4 5400 387.7 377.0 0.7 1.4

5500 390.0 372.4 5500 391.9 374.3 1.9 1.9

5600 394.8 370.3 5600 395.6 371.0 0.8 0.7

5700 397.2 366.0 5700 400.0 368.6 2.8 2.6

5800 397.1 359.6 5800 402.9 364.9 5.8 5.3

5900 393.3 350.1 5900 401.2 357.2 7.9 7.1

6000 388.0 339.6 6000 394.8 345.6 6.8 6.0

peak HP gain 25.0 @ 3600 rpm

peak TQ gain 36.9 @ 3500 rpm

AVG. HP from 3000-6000 rpm 7.99

AVG. TQ from 3000-6000 rpm 11.1

AVG. HP from 3000-4500 rpm 25.8

AVG. TQ from 3000-4500 rpm 17.2

71RS/SS396

exhaust gas flow is never constant it comes in pulses that vary in pressure , some what in volume and ignition timing changes or duration as the rpms change, thus the ideal cross sectional area required in the exhaust header and exhaust pipe,

for a given engine displacement and rpm also varies

your also dealing in most cases with an un-equalized firing order where each cylinder bank does not always alternate equally.

thus two properly sized exhaust headers blending and flowing into an x-pipe to dual exhaust beyond will generally provide a slight improvement over a single merged exhaust.

two blended exhaust paths of total equal cross-sectional area at least, in theory, allow for maintaining a marginally higher gas flow speed increasing cylinder scavenging energy

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/x-or-h-pipe.1503/

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.co...-03-12-with-wave-action-analysis.15764/page-2

theres a good deal of info here in the sub links that might help, including some dyno results

btw, learning to welds , a bit like GREAT SEX, if youve never been involved you don,t see the advantages but once you are, you wonder how you could ever have gone without having constant access!

(and an exhaust system is a great place to learn)

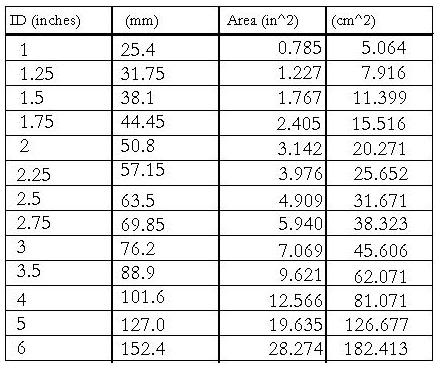

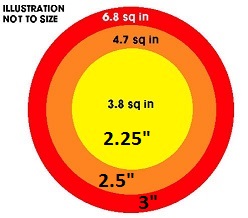

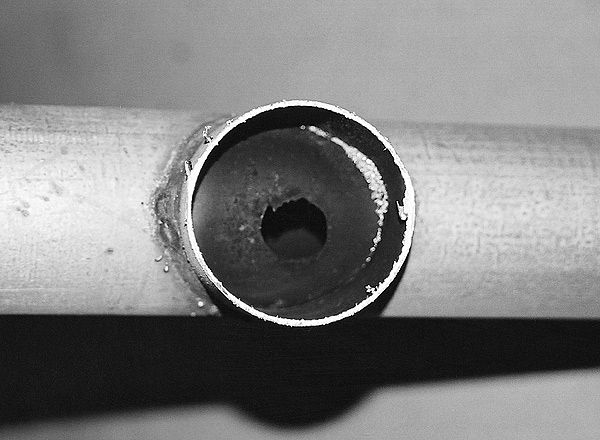

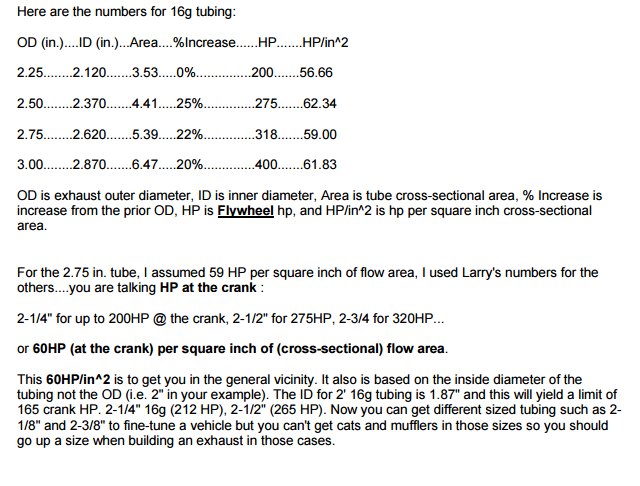

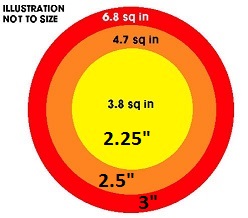

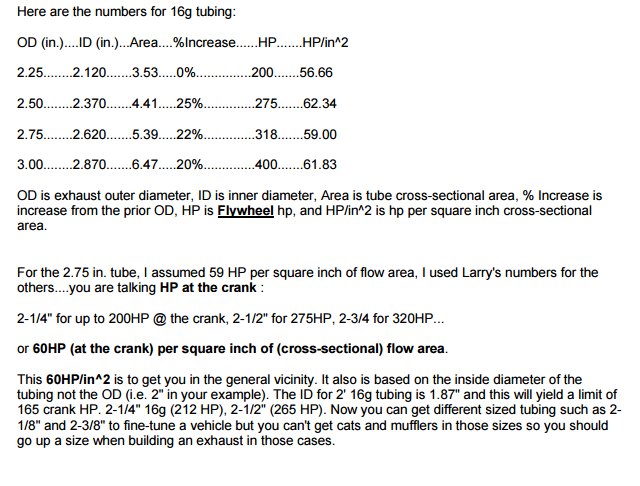

These three circles illustrate the difference in internal square-inch area between 2.25-, 2.50-, and 3-inch exhaust pipes. Weâve calculated the area based on a wall thickness of 0.065. The 2.25-inch pipe has a flow area of 3.80 square inches, a 2.5-inch system increases the area 25 percent to 4.7 square inches, and a 3-inch pipe pumps the area up to 6.8 square inches.

Understand the different concepts ,adding an (X) pipe effectively doubles the exhaust cross sectional area , as your effectively allowing both sides of the dual exhaust to carry only half the flow that the single side of the exhaust can flow, this is cutting the resistance to exhaust flow restriction nearly in half and increases scavenging, this blends and smooths the exhaust flow, remember you get a pulse of exhaust every 90 degrees of engine rotation,

Since V8’s fire unevenly, exhaust exits in pulses rather than a steady flow. While one pipe is filled with pressure the other pipe is at far less , or lower pressure, or relatively low pressure.

but the connecting of the two pipes in a Siamese pattern with an (X) pipe allows pressure to be released to and equalize to the other side, this instantly doubles the exhaust cross section and blends the pulse,and reduces flow restriction,. This action allows the exhaust to pass through the pipe quicker and this better ‘breathing’ increases horsepower, but it also effectively extends the low pressure at the other exhaust ports if the length is correctly calculated or tuned. THUS a properly set up exhaust can SCAVENGE the cylinders increasing intake flow efficiency significantly.

the "drone, sound you hear with some exhaust systems " has a great deal too do with muffler PLACEMENT and pipe diameter,and distance from the header collectors and use of an (X) pipe or (h) PIPE placement ,AND MUFFLER DESIGN USED, all of those factors will effect the rpm level or frequency that "DRONE" may occur at with almost any exhaust, ADDING AN (x) PIPE OR ADDING A SECOND (x) PIPE OR MOVING ITS LOCATION OR ADDING LENGTH TO THE TAIL PIPE CAN OFTEN REDUCE OR ELIMINATE THE DRONE IN AN OBJECTIONABLE RPM RANGE

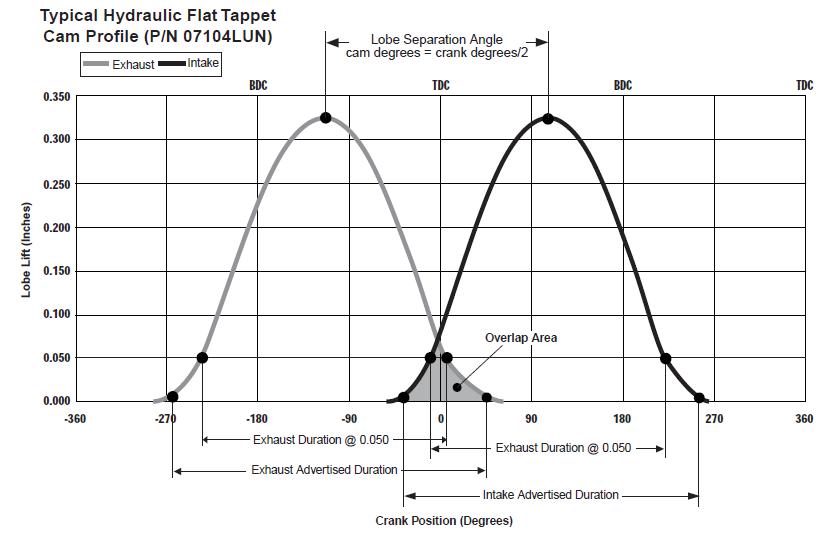

Id also point out that cam timing matched to the exhaust scavenging has a huge effect on potential intake flow rates

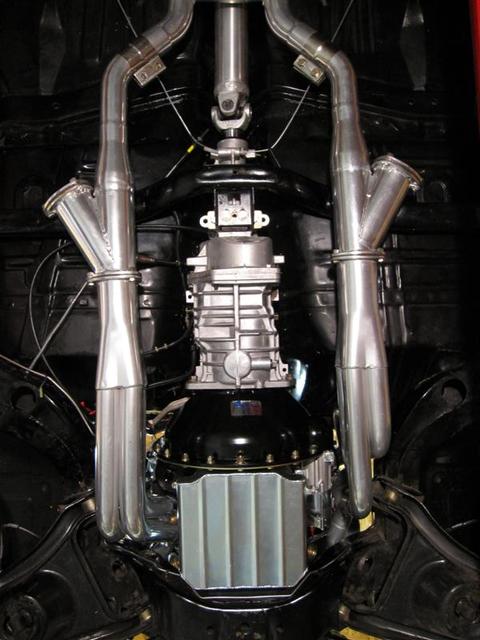

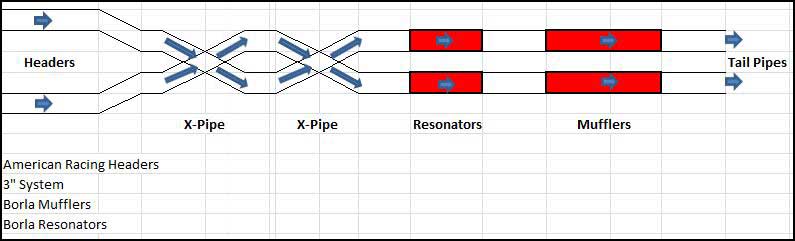

HERES A GOOD EXAMPLE OF A CUSTOM FABRICATED EXHAUST

looks like a well done job CONGRATS!

heres a video of it,running

http://www.youtube.com/watch?v=EGqRfsqf ... e=youtu.be

If your looking to reduce noise installing several x-pipes in series, blends and reduces the exhaust pulse strength,yes Im sure it could, if theres enough physical real estate under the car, or truck ,available to allow it to be installed,

but I found a full length 3" exhaust with just two 3" X-pipes mounted as close as you can get them too the header collectors

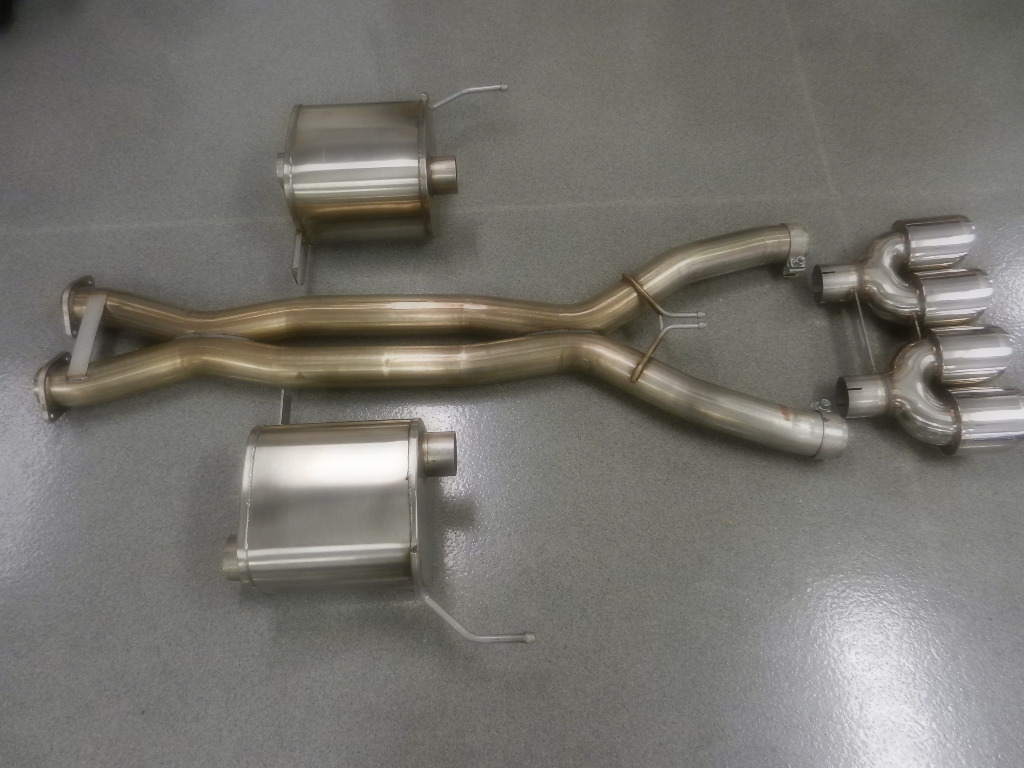

x-pipes like this in series and, two 3" inlet and dual outlet ,

mount the mufflers as far back as you can and be sure to have the tail pipes exit past the cars bumper and point back and downward at about a 45 degree exit

low flow restriction mufflers does a reasonably good job at reducing the sound levels

that adding just two, 3" x-pipes in close series does make a significant difference in noise levels , is well proven, if you could fit 3 that would certainly not hurt.

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

spacing, of the second (X) cross over in a dual (X) 3" exhaust, is generally not extremely critical,

but I generally try hard to get it in the 18"-to-22" range as I found that seems to work best,

obviously under the car clearance effects your options

DUAL X-PIPES TEND TO RESULT IN MORE EFFECTIVE CYLINDER SCAVENGING,BY BLENDING EXHAUST PULSE DURATION, AND A BROADER TORQUE CURVE AND MELLOWER EXHAUST TONE

I did dual x pipes similar too this picture , on four different muscle cars and corvettes so far with good results,it tends to mellow the tone noticeably

http://www.hotrod.com/how-to/engine...y-horsepower-but-which-is-best-for-your-ride/

http://www.summitracing.com/parts/sum-642030

http://garage.grumpysperformance.co...or-tube-to-reduce-stop-drone.7590/#post-25712

http://static.summitracing.com/global/images/instructions/sum-642025.pdf

one more in an endless list of reasons you NEED a good MIG or TIG WELDER

in an ideal set up the exhaust system beyond the header collectors has a very low restriction to flow, and there will be an (X) pipe to effectively double the exhaust cross sectional area to significantly lower resistance to exhaust flow restriction still further, to increase the header,s ability to scavenge the cylinders efficiently in the intended power & rpm band, keep in mind your goal is or should be in most cases to maximize the torque in the intended rpm range that your engine combo produces.

every change you make, or part you select either enhances or restricted the engine power potential, at some point in the power band[/b]

WATCH THIS VIDEO

http://www.youtube.com/watch?v=yMyKv_P8 ... re=related

viewtopic.php?f=60&t=77

http://www.circletrack.com/enginetech/c ... ewall.html

viewtopic.php?f=60&t=1594

http://www.spintechmufflers.com/x-pipes ... t_139.html

http://www.carcraft.com/techarticles/ex ... index.html

http://www.pontiacstreetperformance.com ... haust.html

viewtopic.php?f=60&t=72

viewtopic.php?f=56&t=1166

http://metalgeek.com/static/cope.pcgi

http://www.pontiacstreetperformance.com ... haust.html

viewtopic.php?f=56&t=1503

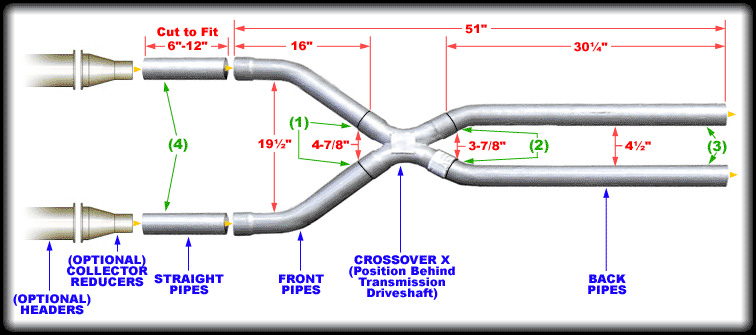

a simple basic exhaust system like these 3" pipes bolted to the header collectors, and leading too an (X) pipe and dual 3" or -3.5" dual mufflers can produce excellent results if you have room under the car

an (x) pipe effectively reduces the flow restriction by increasing the cross sectional area of the exhaust system, and by BLENDING the individual exhaust pulses,remember a cylinder fires every 90 degrees of engine rotation, meaning the pressure and volume in the exhaust comes down the exhaust in pressure waves, thus an (x) pipe splitting and blending the pulse pressure wave is effectively reducing the strength and noise levels, as the gasses rapidly expand to double the previous pipe cross sectional area, and by reducing the pressure, velocity and resistance to flow in each side of a dual exhaust, an (H) is LESS effective , because it doesn,t blend the exhaust pulse it only allows the pressure to equalize to some extent, between the two sides of the engine, but its not nearly as efficient at reducing the pressure difference but its still an improvement over having no connection between cylinder banks, it should be obvious that having a PROPERLY tuned exhaust header mounted between the cylinder heads and (X) pipe and exhaust pipe sizes matching the displacement and intended rpm range of the engine will increase cylinder scavenging

http://www.pontiacstreetperformance.com ... aust3.html

SHORT H PIPES LIKE THIS ONE ABOVE that are full pipe diameter are FAR more effective than longer cross over versions, (LIKE THE LONGER H-PIPE BELOW)but they still don,t blend the exhaust gas pulse inertia nearly as effectively as a true (X PIPE)

http://www.mustang50magazine.com/techar ... index.html

http://www.automedia.com/Exhaust_XPipes/pht20011101xp/1

http://www.superchevy.com/technical/eng ... index.html

http://www.boyleworks.com/ta400/psp/exhaust3.html

viewtopic.php?f=56&t=495

http://www.burnsstainless.com/crossoversmain.aspx

there are mufflers with internal x pipe designs

placing two 3" x pipes in sequence seems to work well at both mellowing the exhaust note, and increasing the exhaust scavenging of the cylinders as it blends and smooths out the exhaust flow by allowing the individual cylinder pulse strength to dissipate rapidly, the first (x) reduces flow restriction, the second allows the exhaust pulse to run into itself further disrupting the individual pulse strength

READ THRU ALL THE SUB LINKED INFO IN THIS THREAD ALSO

viewtopic.php?f=56&t=185&p=219#p219

http://home.flash.net/~ivc1/cobra/xpipes.html

keep in mind installing an (X) almost increases the effective cross sectional area,of the dual exhaust ,to double what it had been behind a single header collector, by doubling the area that the exhaust flow sees, dropping the restriction to flow almost in half

buy this TOOL and custom fit the (X) INTO YOUR EXHAUST SYSTEM youll want to use a decent welder but its fast and a no-brainer AS LONG AS YOU REMEMBER TO CAREFULLY MEASURE BOTH THE (X) AND THE PROPOSED OPENING TO BE CUT,BEFORE CUTTING AND HAVE THE (X) BE A BIT LONGER THAN THE OPENING BETWEEN THE OLD PIPE WHERE ITS INSTALLED FOR AN OVERLAP NOT A BUTT WELD

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?function=Search

ITEM 37354-9VGA

$10.99 YOU CAN,T AFFORD NOT TO HAVE THIS TOOL IF YOU DO EXHAUST PIPE MODS, PERSONALLY I LIKE AN OXY-ACETOLENE TORCH FOR THIS TYPE WELD BUT ALMOST ANY WELDER WILL WORK, this is one area those little 110 volt migs are great for!

http://www.autoanything.com/exhausts-mufflers/69A2672A0A0.aspx

http://store.summitracing.com/partdetail.asp?autofilter=1&part=MPE-10792&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=HED-18830&N=700+115&autoview=sku

http://www.edelbrock.com/automotive_new ... ipes.shtml

WHY INSTALL AN (X)???

The lower your restriction to exhaust flow the better, past the headers collectors

An (X) basically allows BOTH sides of your exhaust system to share and split the exhaust flow, a 3†pipe has approximately a 7 sq inch cross section, splitting the flow doubles the area and tends to reduce the back pressure a good deal as your now using 14 sq inches vs 7†to allow the gases to both expand and cool, remember as hot exhaust gases cool the volume shrinks, and an added benefit is a mellower exhaust tone.

exhaust flow is NOT constant its in pulsed slugs as the piston on the exhaust stroke and the high pressure in the cylinder try to rapidly exit the cylinder of the previously burn fuel/air mix, if the headers are designed correctly the previous rapidly exiting mass tends to drag the next intake charge into the cylinder and a small percentage out the exhaust, thus clearing and filling the cylinder for the next compression stroke.

yes I strongly advise upgrading a corvettes exhaust on a performance build to 3" from the header collectors and back!most guys I talk and deal with,seem to think that slapping a set of headers on their car is all that's required to boost performance....ANY HEADERS! ...and they fail to realize that both the header design and the exhaust system behind them require a good deal of thought if you want the maximum benefits, and that simply hooking a restrictive exhaust system to the collectors on the best headers will negate most of their potential benefits.

most commercial headers are designed mostly for ease of manufacturing and ease of installation,little thought goes into maximizing the cylinder scavenging which is their main function.

your fooling yourself if you think headers will provide a big boost in hp/tq without the low restriction exhaust behind them,and in most cases that requires a larger diam. exhaust system and adding an (X) to the system and extending the header collectors at their full diam. up till at least the exit of the (X) so the twin exhaust pipes cross sectional area can provide that reduced restriction to flow, rather than the reducers many guys install to the collector exits to adapt them to the stock exhaust system.

With an 'X' type crossover arrangement, design ( the angle of convergence, tubing cross sectional size, volume, or area where they converge) and placement or distance from the header collectors are very important. If possible, an 'X' type crossover should be placed at the exact point in the system (measured length) that you would terminate tuned collector length in an open header system having no mufflers nor tailpipes, as the correctly sized (x) provides a sudden reduction in restriction similar to having open header collectors exit to the open air in some respects

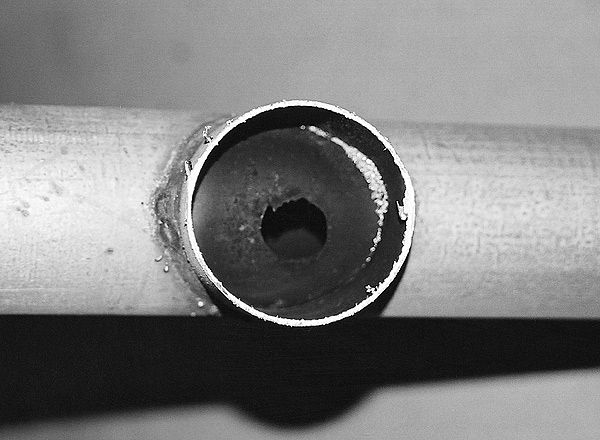

heres a great example of really crappy quality install, done by a muffler shop ,and one reason an (H) pipe that is not installed correctly will tend to have a rather bad reputation, as too equalizing the exhaust flow rates or pressure, keep in mind at higher rpms you might easily have 50 exhaust pulses per second, making an (H) pipe all but useless,, especially if the connecting passage is far smaller than the pipe diameter, while a properly installed (X) pipe blends the pulses very efficiently

(H) PIPE

example of a well laid out exhaust (MELROSE)

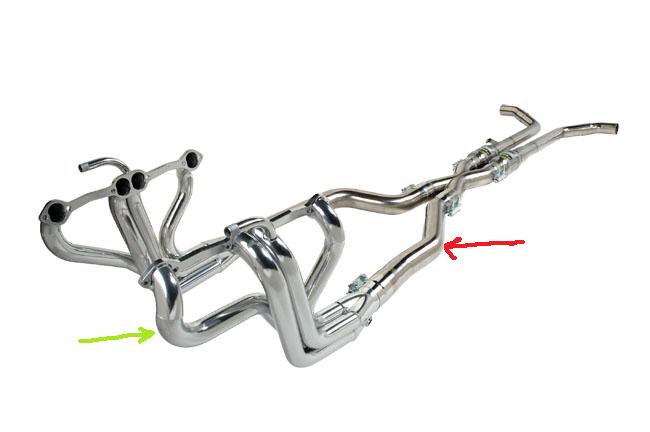

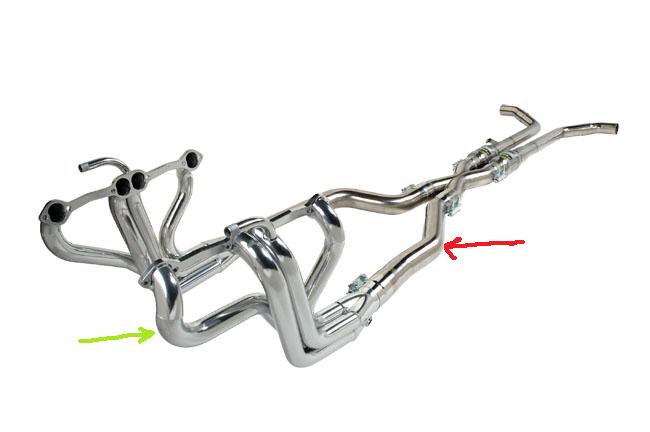

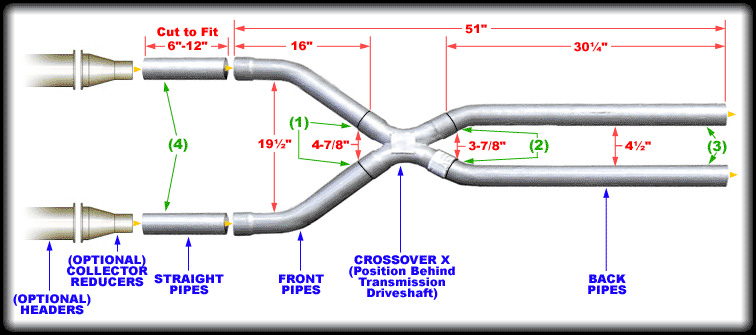

on most SBC or LS based high performance engines of at least 350 cubic inches, designed to exceed 400 hp, the GREEN ARROW primaries should be 1 3/4" and at least 33 -38" long the RED ARROW or exhaust will usually perform well with a 3" diameter

if you look closely youll see the major difference is how easily exhaust flow pulses can move into the adjacent pipe to balance flow, the (H) pipe requires two 90 degree turns while the (X) pipe can easily balance with only part of a pulse expanding as it passes the (X) PIPE) merge point, the ease in balancing pressure, and reducing restriction greatly favors the (X PIPE DESIGN)

notice the X pipe design has several variations, the type above is more effective than the type below at blending and equalizing the pulse volume from either side but even the more restrictive version below still works well.

heres a good example showing why an (X) pipe is very efficient at equalizing and blending exhaust pulse flow rates

Heres a fairly standard (H) pipe exhaust lay out (above)

one lesson most guys don,t usually learn right away, that I constantly try to point out is that buying a few CAREFULLY SELECTED,QUALITY COMPONENTS usually is a far better route to take when building an engine than buying a greater number of lower quality components, like a decent roller cam, heads and a good low restriction exhaust

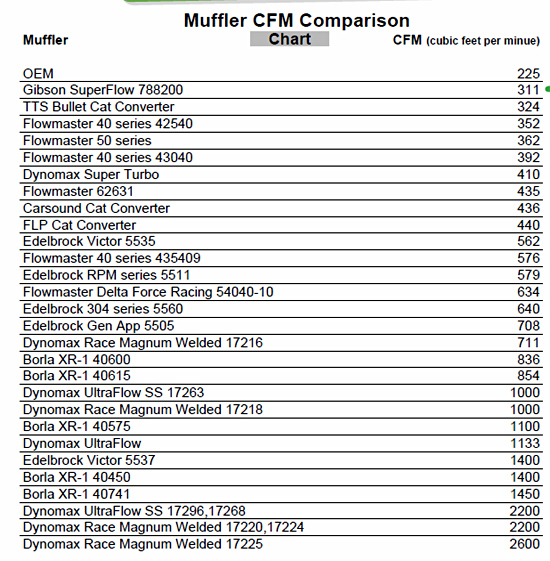

but even that system could be hurt if you slap restrictive mufflers on it

bjhines posted these and their good examples

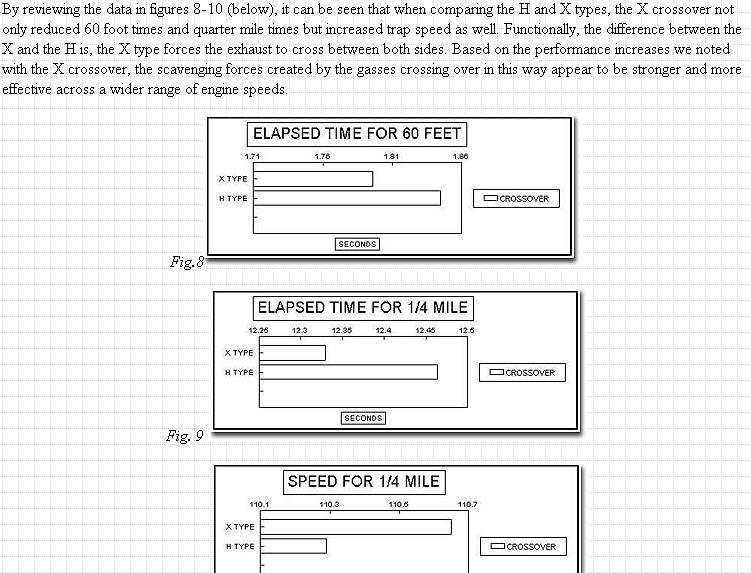

looking thru an (X) pipe

mocking it up, this type of (X) pipe generally provides a noticeable reduction in the restriction to flow that helps hp

http://www.fordmuscle.com/archives/2000 ... ndex.shtml

It's long been known that connecting the two sides of a dual exhaust system, shortly after the headers, increases power and reduces sound. However in a traditional "H" pipe,its mostly, only sound and pressure waves that cross through the connection. most of the Gasses take the route of lowest pressure, which is straight out the pipe, rather than making a 90 degree turn in to the H.

Indy and Nascar teams have been using "X" type crossovers for quite some time. In an "X" pipe the gasses from both cylinder banks actually pass through a common area. This not only provides the benefits of some sound wave cancellation, but also increases the scavenging effect, helping draw out spent charge from the combustion chamber.

So how much of an increase does an X gain over an H? It's hard to say, especially considering that every combination will yield varying gains. In theory an X will work better as rpms go up. Considering the Flowtech X-Terminator pieces are priced under $50; you're much better off getting that, rather than having a shop fab up a crude 'H' piece."

viewtopic.php?f=79&t=497

viewtopic.php?f=56&t=1730

read thru ALL the sub linked info in this thread, and ITS SUB LINKED THREADS

its not at all rare for a swap from 2.5"-to-3" exhaust on a sbc or mild bbc or from 3"-to-3.5" on a radical big block to add 5-15hp,OR MORE, depending on the restriction that was removed behind the collectors or exhaust manifolds, back pressure reduces the effectiveness of the exhaust cylinder scavenging, and once you tune the engine to take full advantage of that reduced restriction and better cylinder scavenging factor you get the full benefits that the reduced back pressure tends to provide.

keep in mind the lower rpm TORQUE LOSS thats occasionally reported is FREQUENTLY a tuning issue as the more effective scavenging tends to lean out the effective fuel/air ratio

what most guys don,t understand is that your results will depend to some degree on the cam timing and engine displacement, intake runner design, and the rpm range the engines run in,its the length and diameter. of the header collectors ,entering the point where the (X) or (H) is located AND the flow restriction in the exhaust system in the collectors and primaries that will effect the cylinder scavenging,and the restriction to exhaust flow rates BEYOND that point, that the mufflers provide that will effect the results, and some those factors will change as the rpms increase.

HAVING the ability to test the vacuum or back-pressure, at the x or h pipe and beyond, will usually give you some indication of the exhaust system efficiency, what your trying to do, in most cases is increase the volumetric efficiency of the engine thru more effectively scavenging the cylinder in your intended power band, by reducing the exhaust system back pressure at and beyond the (H) or (X) pipe by splitting high pressure pulsed flow from each collector into the lower restriction , blended flow into two exhaust, pipes sharing the flow which at least in theory cuts the restriction, past that point noticeably.

if you can increase the rpm range, that the cylinder scavenge effectively at, with a low restriction beyond the tuned collectors, thru higher volumetric efficiency in the upper rpm band, power tends to increase

viewtopic.php?f=56&t=495

http://www.superchevy.com/how-to/ex...y-horsepower-but-which-is-best-for-your-ride/

viewtopic.php?f=56&t=1730

viewtopic.php?f=56&t=789

http://garage.grumpysperformance.co...-descriptions-dont-tell-you.12357/#post-61139

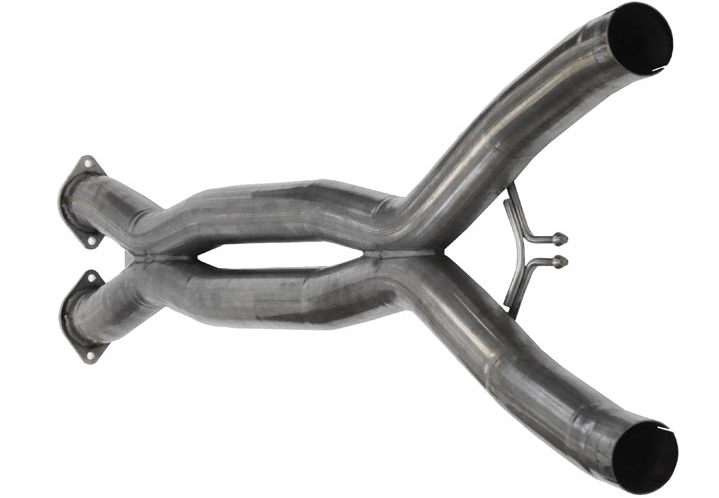

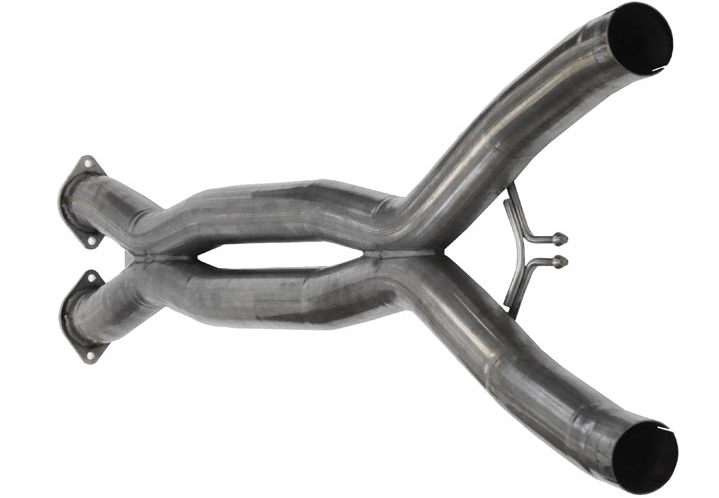

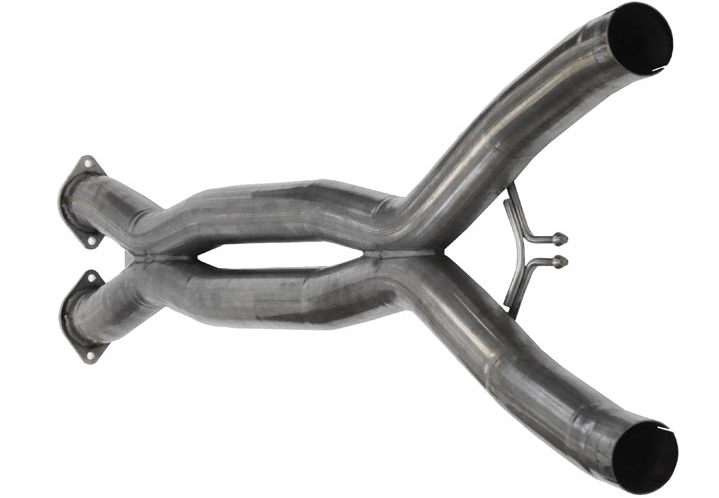

here above is a rather typical (X) pipe, the exhaust pressure pulse splits its flow and significantly reduces back pressure as the pulse enters the (X) as its effective cross sectional area almost DOUBLES , dropping that back pressure almost in half at that point, which usually increases cylinder scavenging potential of tuned headers, and increasing higher rpm power if used, and usually reducing noise as the frequency is disrupted, inducing a mellower tone.

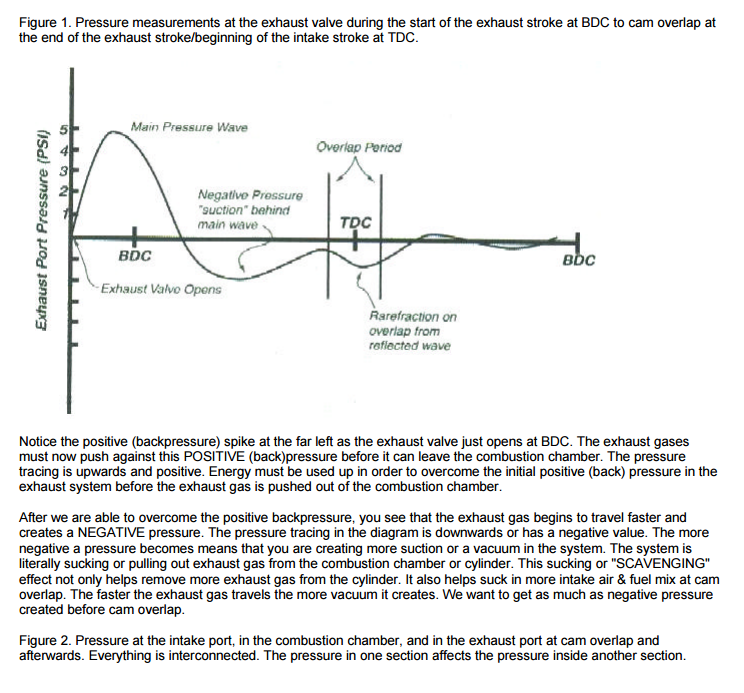

EXHAUST flow is not at a constant pressure, its in pressure waves

an (X) and to a lesser extent an (H) pipe in an exhaust doesn,t BALANCE the flow, it effectively DOUBLES the area each separate PULSE of high pressure exhaust, in each cylinder, sees as its dumped into the collectors,each pulse in the header primaries introduces a high pressure wave into the collector as it enters the collector and introduces a low pressure reflective wave back up the header primary, if the size and length are correctly calculated that negative pressure reaches the exhaust port at time the exhaust valve from the next following exhaust cycle exits the cylinder to increase the scavenging of the cylinder ,helping to draw more of the intake charge from the intake runners during the overlap period and into the cylinder to increase volumetric efficiency in the intended rpm band.

in a correctly designed system the header collectors feed directly into the junction of the (X),or (H)at the same diam. as the collector diam., and only after the junction point is the exhaust pipe diam. reduced (IF THEN)

remember the goal is to increase the cylinder scavenging to increase the volumetric efficiency and thus extend the torque curve, by reducing back pressure and increasing the length and strength of the negative pressure wave that helps scavenge the cylinders, and that pulse helps draw in the intake runner charge of fresh f/a charge, as its fast exiting inertia drags the intake charge along with it.

in fact its not unusual for a correctly designed exhaust with a matched cam timing to draw a small percentage of the intake charge thru the intake and out thru the exhaust valve as the piston descends on the intake stroke during the cams overlap period.

The idea behind an exhaust header is to eliminate the exhaust manifold's back pressure. Instead of a common manifold that all of the cylinders share, each cylinder gets its own exhaust pipe. These pipes come together in a larger pipe called the collector. The individual pipes are cut and bent so that each one is the same or nearly the same length as the others. By making them the same length, it tends too guarantee that each cylinder's exhaust gases arrive in the collector spaced out equally so there is little or no effective back pressure restricting flow generated by the cylinders sharing the collector.

theres a great deal of info on the site about selecting or building headers, but one major factor is that a NON-RESTRICTIVE exhaust system MUST be installed with ANY HEADERS to allow them to work correctly. for headers to work correctly they require an exhaust pulse to allow its inertial energy to drag the following charge along with it out the exhaust.

if you can,t visualize that it might help to find a 3 ft long section of 2.5" pvc pipe and wrap a bit of tape around a full coke can so it slides easily thru the PVC, pipe but fills its interior diam., now place the pipe horizontally insert the coke can and drop the opposite end strait down while you hold your hand over the end the coke can was inserted into, as the mass of the coke can falls you'll feel air dragged with it , the same basic thing happens with an exhaust pulse, its mass is far less but its traveling much much faster, and depending on the rpm and displacement it does generate significant energy that can be used to draw the next intake runners charge into the cylinder as it draws out the next exhaust charge during the cams overlap duration (LOOK INTO CAM TIMING)

keep in mind the LENGTH of the header tube effects the rpm levels and energy transferred as it takes time for that mass of hot exhaust gas to travel thru the primary tube, naturally a longer distance tends to require a longer time and the longer duration tends to impart a longer and stronger negative pressure wave to assist the next pulse IF ITS TIMED CORRECTLY and the header primary tube is the correct diam. and length for the engines displacement,compression, cam timing, and several other factors, but again, it works far more effectively if the exhaust system is a low restriction design that doesn,t reduce the scavenging effect of the pulse waves, and the tubing is long enough to work effectively

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=480

viewtopic.php?f=56&t=352

viewtopic.php?f=56&t=1166

http://www.slowgt.com/Calc2.htm#Header

http://www.bgsoflex.com/auto.html

these threads might help

http://www.pontiacracing.net/js_header_length1.htm

Magnaflow sells them in stainless:

https://www.magnaflow.com/products?partNumber=10782

Dynomax (aluminized):

Dynomax 88328: X-Pipe Outer diameter: 3" | JEGS

Flowtech (aluminized):

Flowtech 53621: FlowTech Exhaust X-Pipe 3" | JEGS

http://pypesexhaust.com/p-13194-dyno-tests.html

https://www.summitracing.com/parts/sum-640701

https://www.summitracing.com/parts/cse-14173

just having your own MIG or better yet TIG welder,

and having learned the skills to use it correctly,

can save you hundreds of dollars in EVERY ,

exhaust system install

adding an anti-reversion baffle to a 18"-24" longer collector on open headers with the internal pipe about 1/2 the collector length tends to help scavenging on some engines, no header will function to full efficiency with any significant back pressure so take the effort to accurately measure any restriction to exhaust flow AT your upper rpm range of your engines power band and be darn sure its not choking your power curve.

http://www.wallaceracing.com/intake-runner-length.php

http://www.bgsoflex.com/intakeln.html

http://www.velocity-of-sound.com/velocity_of_sound/calculator3.htm

http://www.velocity-of-sound.com/velocity_of_sound/velocity_stacks.htm

http://www.swartzracingmanifolds.com/tech/index.htm

Hot rod (oct. 2000)

355 SBC

9:1

trickflow alum heads

2.02''/1.06'' valves

comp magnum

edelbrock performer rpm intake

demon 750 cfm carb

3'' dual pipes

flowmaster "big block" mufflers

hooker 1-5/8'' long tube headers

Headers Headers with X-pipe

RPM HP TQ RPM HP TQ HP gain TQ gain

3000 219.8 384.7 3000 231.2 404.7 11.4 20.0

3100 224.5 380.4 3100 235.3 398.7 10.8 18.3

3200 229.7 377.0 3200 242.6 398.2 12.9 21.2

3300 234.6 373.4 3300 252.0 401.0 17.4 27.6

3400 240.1 370.9 3400 262.1 404.9 22.0 34.0

3500 246.5 370.0 3500 271.2 406.9 24.7 36.9

3600 255.5 372.8 3600 280.5 409.3 25.0 36.5

3700 269.1 381.9 3700 290.3 412.1 21.2 30.2

3800 283.8 392.3 3800 300.3 415.0 16.5 22.7

3900 295.5 397.9 3900 308.6 415.6 13.1 17.7

4000 307.6 403.9 4000 317.4 416.7 9.8 12.8

4100 320.7 410.8 4100 326.9 418.8 6.2 8.0

4200 332.6 415.9 4200 337.0 421.4 4.4 5.5

4300 343.5 419.5 4300 345.7 422.2 2.2 2.7

4400 351.8 419.9 4400 352.9 421.2 1.1 1.3

4500 358.7 418.7 4500 358.7 418.7 0 0

4600 362.5 413.9 4600 363.7 415.2 1.2 1.3

4700 367.1 410.3 4700 369.5 412.9 2.4 2.6

4800 371.2 406.2 4800 375.8 411.1 4.6 4.9

4900 374.8 401.7 4900 380.1 407.4 5.3 5.7

5000 376.7 395.7 5000 381.8 401.1 5.1 5.4

5100 378.2 389.5 5100 381.1 392.5 2.9 3.0

5200 380.8 384.6 5200 381.5 385.3 0.7 0.7

5300 383.8 380.4 5300 384.0 380.5 0.2 0.1

5400 387.0 376.4 5400 387.7 377.0 0.7 1.4

5500 390.0 372.4 5500 391.9 374.3 1.9 1.9

5600 394.8 370.3 5600 395.6 371.0 0.8 0.7

5700 397.2 366.0 5700 400.0 368.6 2.8 2.6

5800 397.1 359.6 5800 402.9 364.9 5.8 5.3

5900 393.3 350.1 5900 401.2 357.2 7.9 7.1

6000 388.0 339.6 6000 394.8 345.6 6.8 6.0

peak HP gain 25.0 @ 3600 rpm

peak TQ gain 36.9 @ 3500 rpm

AVG. HP from 3000-6000 rpm 7.99

AVG. TQ from 3000-6000 rpm 11.1

AVG. HP from 3000-4500 rpm 25.8

AVG. TQ from 3000-4500 rpm 17.2

71RS/SS396

exhaust gas flow is never constant it comes in pulses that vary in pressure , some what in volume and ignition timing changes or duration as the rpms change, thus the ideal cross sectional area required in the exhaust header and exhaust pipe,

for a given engine displacement and rpm also varies

your also dealing in most cases with an un-equalized firing order where each cylinder bank does not always alternate equally.

thus two properly sized exhaust headers blending and flowing into an x-pipe to dual exhaust beyond will generally provide a slight improvement over a single merged exhaust.

two blended exhaust paths of total equal cross-sectional area at least, in theory, allow for maintaining a marginally higher gas flow speed increasing cylinder scavenging energy

http://garage.grumpysperformance.com/index.php?threads/calculating-required-exhaust-pipe-size.11552/

http://garage.grumpysperformance.com/index.php?threads/x-or-h-pipe.1503/

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.co...-03-12-with-wave-action-analysis.15764/page-2

theres a good deal of info here in the sub links that might help, including some dyno results

btw, learning to welds , a bit like GREAT SEX, if youve never been involved you don,t see the advantages but once you are, you wonder how you could ever have gone without having constant access!

(and an exhaust system is a great place to learn)

These three circles illustrate the difference in internal square-inch area between 2.25-, 2.50-, and 3-inch exhaust pipes. Weâve calculated the area based on a wall thickness of 0.065. The 2.25-inch pipe has a flow area of 3.80 square inches, a 2.5-inch system increases the area 25 percent to 4.7 square inches, and a 3-inch pipe pumps the area up to 6.8 square inches.

Understand the different concepts ,adding an (X) pipe effectively doubles the exhaust cross sectional area , as your effectively allowing both sides of the dual exhaust to carry only half the flow that the single side of the exhaust can flow, this is cutting the resistance to exhaust flow restriction nearly in half and increases scavenging, this blends and smooths the exhaust flow, remember you get a pulse of exhaust every 90 degrees of engine rotation,

Since V8’s fire unevenly, exhaust exits in pulses rather than a steady flow. While one pipe is filled with pressure the other pipe is at far less , or lower pressure, or relatively low pressure.

but the connecting of the two pipes in a Siamese pattern with an (X) pipe allows pressure to be released to and equalize to the other side, this instantly doubles the exhaust cross section and blends the pulse,and reduces flow restriction,. This action allows the exhaust to pass through the pipe quicker and this better ‘breathing’ increases horsepower, but it also effectively extends the low pressure at the other exhaust ports if the length is correctly calculated or tuned. THUS a properly set up exhaust can SCAVENGE the cylinders increasing intake flow efficiency significantly.

the "drone, sound you hear with some exhaust systems " has a great deal too do with muffler PLACEMENT and pipe diameter,and distance from the header collectors and use of an (X) pipe or (h) PIPE placement ,AND MUFFLER DESIGN USED, all of those factors will effect the rpm level or frequency that "DRONE" may occur at with almost any exhaust, ADDING AN (x) PIPE OR ADDING A SECOND (x) PIPE OR MOVING ITS LOCATION OR ADDING LENGTH TO THE TAIL PIPE CAN OFTEN REDUCE OR ELIMINATE THE DRONE IN AN OBJECTIONABLE RPM RANGE

Id also point out that cam timing matched to the exhaust scavenging has a huge effect on potential intake flow rates

HERES A GOOD EXAMPLE OF A CUSTOM FABRICATED EXHAUST

looks like a well done job CONGRATS!

heres a video of it,running

http://www.youtube.com/watch?v=EGqRfsqf ... e=youtu.be

If your looking to reduce noise installing several x-pipes in series, blends and reduces the exhaust pulse strength,yes Im sure it could, if theres enough physical real estate under the car, or truck ,available to allow it to be installed,

but I found a full length 3" exhaust with just two 3" X-pipes mounted as close as you can get them too the header collectors

x-pipes like this in series and, two 3" inlet and dual outlet ,

mount the mufflers as far back as you can and be sure to have the tail pipes exit past the cars bumper and point back and downward at about a 45 degree exit

low flow restriction mufflers does a reasonably good job at reducing the sound levels

that adding just two, 3" x-pipes in close series does make a significant difference in noise levels , is well proven, if you could fit 3 that would certainly not hurt.

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

spacing, of the second (X) cross over in a dual (X) 3" exhaust, is generally not extremely critical,

but I generally try hard to get it in the 18"-to-22" range as I found that seems to work best,

obviously under the car clearance effects your options

DUAL X-PIPES TEND TO RESULT IN MORE EFFECTIVE CYLINDER SCAVENGING,BY BLENDING EXHAUST PULSE DURATION, AND A BROADER TORQUE CURVE AND MELLOWER EXHAUST TONE

I did dual x pipes similar too this picture , on four different muscle cars and corvettes so far with good results,it tends to mellow the tone noticeably

http://www.hotrod.com/how-to/engine...y-horsepower-but-which-is-best-for-your-ride/

http://www.summitracing.com/parts/sum-642030

http://garage.grumpysperformance.co...or-tube-to-reduce-stop-drone.7590/#post-25712

http://static.summitracing.com/global/images/instructions/sum-642025.pdf

one more in an endless list of reasons you NEED a good MIG or TIG WELDER

in an ideal set up the exhaust system beyond the header collectors has a very low restriction to flow, and there will be an (X) pipe to effectively double the exhaust cross sectional area to significantly lower resistance to exhaust flow restriction still further, to increase the header,s ability to scavenge the cylinders efficiently in the intended power & rpm band, keep in mind your goal is or should be in most cases to maximize the torque in the intended rpm range that your engine combo produces.

every change you make, or part you select either enhances or restricted the engine power potential, at some point in the power band[/b]

WATCH THIS VIDEO

http://www.youtube.com/watch?v=yMyKv_P8 ... re=related

viewtopic.php?f=60&t=77

http://www.circletrack.com/enginetech/c ... ewall.html

viewtopic.php?f=60&t=1594

http://www.spintechmufflers.com/x-pipes ... t_139.html

http://www.carcraft.com/techarticles/ex ... index.html

http://www.pontiacstreetperformance.com ... haust.html

viewtopic.php?f=60&t=72

viewtopic.php?f=56&t=1166

http://metalgeek.com/static/cope.pcgi

http://www.pontiacstreetperformance.com ... haust.html

viewtopic.php?f=56&t=1503

a simple basic exhaust system like these 3" pipes bolted to the header collectors, and leading too an (X) pipe and dual 3" or -3.5" dual mufflers can produce excellent results if you have room under the car

an (x) pipe effectively reduces the flow restriction by increasing the cross sectional area of the exhaust system, and by BLENDING the individual exhaust pulses,remember a cylinder fires every 90 degrees of engine rotation, meaning the pressure and volume in the exhaust comes down the exhaust in pressure waves, thus an (x) pipe splitting and blending the pulse pressure wave is effectively reducing the strength and noise levels, as the gasses rapidly expand to double the previous pipe cross sectional area, and by reducing the pressure, velocity and resistance to flow in each side of a dual exhaust, an (H) is LESS effective , because it doesn,t blend the exhaust pulse it only allows the pressure to equalize to some extent, between the two sides of the engine, but its not nearly as efficient at reducing the pressure difference but its still an improvement over having no connection between cylinder banks, it should be obvious that having a PROPERLY tuned exhaust header mounted between the cylinder heads and (X) pipe and exhaust pipe sizes matching the displacement and intended rpm range of the engine will increase cylinder scavenging

http://www.pontiacstreetperformance.com ... aust3.html

SHORT H PIPES LIKE THIS ONE ABOVE that are full pipe diameter are FAR more effective than longer cross over versions, (LIKE THE LONGER H-PIPE BELOW)but they still don,t blend the exhaust gas pulse inertia nearly as effectively as a true (X PIPE)

http://www.mustang50magazine.com/techar ... index.html

http://www.automedia.com/Exhaust_XPipes/pht20011101xp/1

http://www.superchevy.com/technical/eng ... index.html

http://www.boyleworks.com/ta400/psp/exhaust3.html

viewtopic.php?f=56&t=495

http://www.burnsstainless.com/crossoversmain.aspx

there are mufflers with internal x pipe designs

placing two 3" x pipes in sequence seems to work well at both mellowing the exhaust note, and increasing the exhaust scavenging of the cylinders as it blends and smooths out the exhaust flow by allowing the individual cylinder pulse strength to dissipate rapidly, the first (x) reduces flow restriction, the second allows the exhaust pulse to run into itself further disrupting the individual pulse strength

READ THRU ALL THE SUB LINKED INFO IN THIS THREAD ALSO

viewtopic.php?f=56&t=185&p=219#p219

http://home.flash.net/~ivc1/cobra/xpipes.html

keep in mind installing an (X) almost increases the effective cross sectional area,of the dual exhaust ,to double what it had been behind a single header collector, by doubling the area that the exhaust flow sees, dropping the restriction to flow almost in half

buy this TOOL and custom fit the (X) INTO YOUR EXHAUST SYSTEM youll want to use a decent welder but its fast and a no-brainer AS LONG AS YOU REMEMBER TO CAREFULLY MEASURE BOTH THE (X) AND THE PROPOSED OPENING TO BE CUT,BEFORE CUTTING AND HAVE THE (X) BE A BIT LONGER THAN THE OPENING BETWEEN THE OLD PIPE WHERE ITS INSTALLED FOR AN OVERLAP NOT A BUTT WELD

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?function=Search

ITEM 37354-9VGA

$10.99 YOU CAN,T AFFORD NOT TO HAVE THIS TOOL IF YOU DO EXHAUST PIPE MODS, PERSONALLY I LIKE AN OXY-ACETOLENE TORCH FOR THIS TYPE WELD BUT ALMOST ANY WELDER WILL WORK, this is one area those little 110 volt migs are great for!

http://www.autoanything.com/exhausts-mufflers/69A2672A0A0.aspx

http://store.summitracing.com/partdetail.asp?autofilter=1&part=MPE-10792&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=HED-18830&N=700+115&autoview=sku

http://www.edelbrock.com/automotive_new ... ipes.shtml

WHY INSTALL AN (X)???

The lower your restriction to exhaust flow the better, past the headers collectors

An (X) basically allows BOTH sides of your exhaust system to share and split the exhaust flow, a 3†pipe has approximately a 7 sq inch cross section, splitting the flow doubles the area and tends to reduce the back pressure a good deal as your now using 14 sq inches vs 7†to allow the gases to both expand and cool, remember as hot exhaust gases cool the volume shrinks, and an added benefit is a mellower exhaust tone.

exhaust flow is NOT constant its in pulsed slugs as the piston on the exhaust stroke and the high pressure in the cylinder try to rapidly exit the cylinder of the previously burn fuel/air mix, if the headers are designed correctly the previous rapidly exiting mass tends to drag the next intake charge into the cylinder and a small percentage out the exhaust, thus clearing and filling the cylinder for the next compression stroke.

yes I strongly advise upgrading a corvettes exhaust on a performance build to 3" from the header collectors and back!most guys I talk and deal with,seem to think that slapping a set of headers on their car is all that's required to boost performance....ANY HEADERS! ...and they fail to realize that both the header design and the exhaust system behind them require a good deal of thought if you want the maximum benefits, and that simply hooking a restrictive exhaust system to the collectors on the best headers will negate most of their potential benefits.

most commercial headers are designed mostly for ease of manufacturing and ease of installation,little thought goes into maximizing the cylinder scavenging which is their main function.

your fooling yourself if you think headers will provide a big boost in hp/tq without the low restriction exhaust behind them,and in most cases that requires a larger diam. exhaust system and adding an (X) to the system and extending the header collectors at their full diam. up till at least the exit of the (X) so the twin exhaust pipes cross sectional area can provide that reduced restriction to flow, rather than the reducers many guys install to the collector exits to adapt them to the stock exhaust system.

With an 'X' type crossover arrangement, design ( the angle of convergence, tubing cross sectional size, volume, or area where they converge) and placement or distance from the header collectors are very important. If possible, an 'X' type crossover should be placed at the exact point in the system (measured length) that you would terminate tuned collector length in an open header system having no mufflers nor tailpipes, as the correctly sized (x) provides a sudden reduction in restriction similar to having open header collectors exit to the open air in some respects

heres a great example of really crappy quality install, done by a muffler shop ,and one reason an (H) pipe that is not installed correctly will tend to have a rather bad reputation, as too equalizing the exhaust flow rates or pressure, keep in mind at higher rpms you might easily have 50 exhaust pulses per second, making an (H) pipe all but useless,, especially if the connecting passage is far smaller than the pipe diameter, while a properly installed (X) pipe blends the pulses very efficiently

(H) PIPE

example of a well laid out exhaust (MELROSE)

on most SBC or LS based high performance engines of at least 350 cubic inches, designed to exceed 400 hp, the GREEN ARROW primaries should be 1 3/4" and at least 33 -38" long the RED ARROW or exhaust will usually perform well with a 3" diameter

if you look closely youll see the major difference is how easily exhaust flow pulses can move into the adjacent pipe to balance flow, the (H) pipe requires two 90 degree turns while the (X) pipe can easily balance with only part of a pulse expanding as it passes the (X) PIPE) merge point, the ease in balancing pressure, and reducing restriction greatly favors the (X PIPE DESIGN)

notice the X pipe design has several variations, the type above is more effective than the type below at blending and equalizing the pulse volume from either side but even the more restrictive version below still works well.

heres a good example showing why an (X) pipe is very efficient at equalizing and blending exhaust pulse flow rates

Heres a fairly standard (H) pipe exhaust lay out (above)

one lesson most guys don,t usually learn right away, that I constantly try to point out is that buying a few CAREFULLY SELECTED,QUALITY COMPONENTS usually is a far better route to take when building an engine than buying a greater number of lower quality components, like a decent roller cam, heads and a good low restriction exhaust

but even that system could be hurt if you slap restrictive mufflers on it

bjhines posted these and their good examples

looking thru an (X) pipe

mocking it up, this type of (X) pipe generally provides a noticeable reduction in the restriction to flow that helps hp

http://www.fordmuscle.com/archives/2000 ... ndex.shtml

h-pipes are no where near as efficient or effective at equalizing or reducing individual, bank to bank exhaust pulse strength,or reducing the restriction to exhaust flow, as a similarly placed (X-pipe )

if you have the room two (X-PIPES in sequence have been repeatedly been tested,

and repeatedly found to provide a minor but measurably better result in increasing cylinder scavenging and a mellower exhaust sound

your not going to see any huge gains from either configuration, but a single (X-pipe generally produces a bit better and a wider torque curve ,

and two x-pipes in series is not all that rare recently even on the higher end performance cars

It's long been known that connecting the two sides of a dual exhaust system, shortly after the headers, increases power and reduces sound. However in a traditional "H" pipe,its mostly, only sound and pressure waves that cross through the connection. most of the Gasses take the route of lowest pressure, which is straight out the pipe, rather than making a 90 degree turn in to the H.

Indy and Nascar teams have been using "X" type crossovers for quite some time. In an "X" pipe the gasses from both cylinder banks actually pass through a common area. This not only provides the benefits of some sound wave cancellation, but also increases the scavenging effect, helping draw out spent charge from the combustion chamber.

So how much of an increase does an X gain over an H? It's hard to say, especially considering that every combination will yield varying gains. In theory an X will work better as rpms go up. Considering the Flowtech X-Terminator pieces are priced under $50; you're much better off getting that, rather than having a shop fab up a crude 'H' piece."

viewtopic.php?f=79&t=497

viewtopic.php?f=56&t=1730

read thru ALL the sub linked info in this thread, and ITS SUB LINKED THREADS

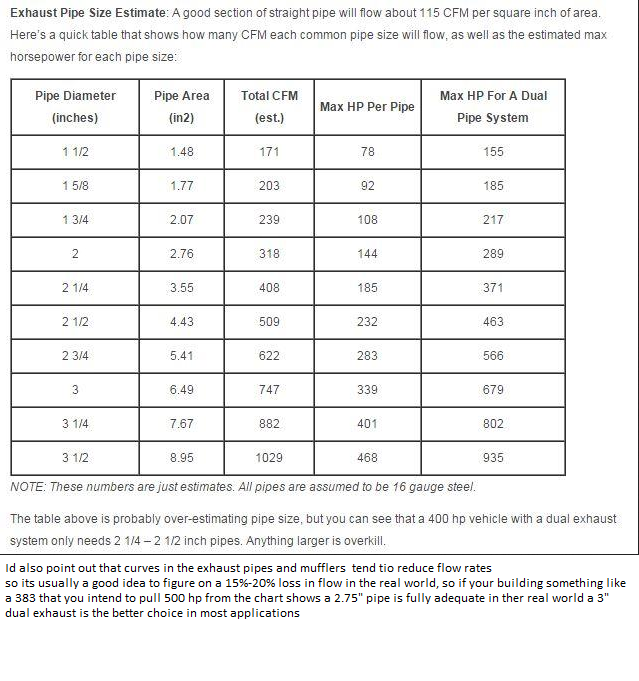

its not at all rare for a swap from 2.5"-to-3" exhaust on a sbc or mild bbc or from 3"-to-3.5" on a radical big block to add 5-15hp,OR MORE, depending on the restriction that was removed behind the collectors or exhaust manifolds, back pressure reduces the effectiveness of the exhaust cylinder scavenging, and once you tune the engine to take full advantage of that reduced restriction and better cylinder scavenging factor you get the full benefits that the reduced back pressure tends to provide.

keep in mind the lower rpm TORQUE LOSS thats occasionally reported is FREQUENTLY a tuning issue as the more effective scavenging tends to lean out the effective fuel/air ratio

what most guys don,t understand is that your results will depend to some degree on the cam timing and engine displacement, intake runner design, and the rpm range the engines run in,its the length and diameter. of the header collectors ,entering the point where the (X) or (H) is located AND the flow restriction in the exhaust system in the collectors and primaries that will effect the cylinder scavenging,and the restriction to exhaust flow rates BEYOND that point, that the mufflers provide that will effect the results, and some those factors will change as the rpms increase.

HAVING the ability to test the vacuum or back-pressure, at the x or h pipe and beyond, will usually give you some indication of the exhaust system efficiency, what your trying to do, in most cases is increase the volumetric efficiency of the engine thru more effectively scavenging the cylinder in your intended power band, by reducing the exhaust system back pressure at and beyond the (H) or (X) pipe by splitting high pressure pulsed flow from each collector into the lower restriction , blended flow into two exhaust, pipes sharing the flow which at least in theory cuts the restriction, past that point noticeably.

if you can increase the rpm range, that the cylinder scavenge effectively at, with a low restriction beyond the tuned collectors, thru higher volumetric efficiency in the upper rpm band, power tends to increase

viewtopic.php?f=56&t=495

http://www.superchevy.com/how-to/ex...y-horsepower-but-which-is-best-for-your-ride/

viewtopic.php?f=56&t=1730

viewtopic.php?f=56&t=789

http://garage.grumpysperformance.co...-descriptions-dont-tell-you.12357/#post-61139

here above is a rather typical (X) pipe, the exhaust pressure pulse splits its flow and significantly reduces back pressure as the pulse enters the (X) as its effective cross sectional area almost DOUBLES , dropping that back pressure almost in half at that point, which usually increases cylinder scavenging potential of tuned headers, and increasing higher rpm power if used, and usually reducing noise as the frequency is disrupted, inducing a mellower tone.

EXHAUST flow is not at a constant pressure, its in pressure waves

an (X) and to a lesser extent an (H) pipe in an exhaust doesn,t BALANCE the flow, it effectively DOUBLES the area each separate PULSE of high pressure exhaust, in each cylinder, sees as its dumped into the collectors,each pulse in the header primaries introduces a high pressure wave into the collector as it enters the collector and introduces a low pressure reflective wave back up the header primary, if the size and length are correctly calculated that negative pressure reaches the exhaust port at time the exhaust valve from the next following exhaust cycle exits the cylinder to increase the scavenging of the cylinder ,helping to draw more of the intake charge from the intake runners during the overlap period and into the cylinder to increase volumetric efficiency in the intended rpm band.

in a correctly designed system the header collectors feed directly into the junction of the (X),or (H)at the same diam. as the collector diam., and only after the junction point is the exhaust pipe diam. reduced (IF THEN)

remember the goal is to increase the cylinder scavenging to increase the volumetric efficiency and thus extend the torque curve, by reducing back pressure and increasing the length and strength of the negative pressure wave that helps scavenge the cylinders, and that pulse helps draw in the intake runner charge of fresh f/a charge, as its fast exiting inertia drags the intake charge along with it.

in fact its not unusual for a correctly designed exhaust with a matched cam timing to draw a small percentage of the intake charge thru the intake and out thru the exhaust valve as the piston descends on the intake stroke during the cams overlap period.

The idea behind an exhaust header is to eliminate the exhaust manifold's back pressure. Instead of a common manifold that all of the cylinders share, each cylinder gets its own exhaust pipe. These pipes come together in a larger pipe called the collector. The individual pipes are cut and bent so that each one is the same or nearly the same length as the others. By making them the same length, it tends too guarantee that each cylinder's exhaust gases arrive in the collector spaced out equally so there is little or no effective back pressure restricting flow generated by the cylinders sharing the collector.

theres a great deal of info on the site about selecting or building headers, but one major factor is that a NON-RESTRICTIVE exhaust system MUST be installed with ANY HEADERS to allow them to work correctly. for headers to work correctly they require an exhaust pulse to allow its inertial energy to drag the following charge along with it out the exhaust.

if you can,t visualize that it might help to find a 3 ft long section of 2.5" pvc pipe and wrap a bit of tape around a full coke can so it slides easily thru the PVC, pipe but fills its interior diam., now place the pipe horizontally insert the coke can and drop the opposite end strait down while you hold your hand over the end the coke can was inserted into, as the mass of the coke can falls you'll feel air dragged with it , the same basic thing happens with an exhaust pulse, its mass is far less but its traveling much much faster, and depending on the rpm and displacement it does generate significant energy that can be used to draw the next intake runners charge into the cylinder as it draws out the next exhaust charge during the cams overlap duration (LOOK INTO CAM TIMING)

keep in mind the LENGTH of the header tube effects the rpm levels and energy transferred as it takes time for that mass of hot exhaust gas to travel thru the primary tube, naturally a longer distance tends to require a longer time and the longer duration tends to impart a longer and stronger negative pressure wave to assist the next pulse IF ITS TIMED CORRECTLY and the header primary tube is the correct diam. and length for the engines displacement,compression, cam timing, and several other factors, but again, it works far more effectively if the exhaust system is a low restriction design that doesn,t reduce the scavenging effect of the pulse waves, and the tubing is long enough to work effectively

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=333

viewtopic.php?f=52&t=480

viewtopic.php?f=56&t=352

viewtopic.php?f=56&t=1166

http://www.slowgt.com/Calc2.htm#Header

http://www.bgsoflex.com/auto.html

these threads might help

http://www.pontiacracing.net/js_header_length1.htm

Last edited by a moderator: