its foolish to spend cash unless your expenditure gives you positive results, CORRECTLY SELECTED AND INSTALLED,

beehive springs generally add several hundred rpm to your power band, but spending cash to correct problems you don,t have is wasted effort, if the current springs control the valve train well, its an unnecessary extra expense to swap springs,

I suggest trying what you currently have for valve springs if the clearances and load rates match the new cam, you've selected ,before spending the time and effort to swap, to new springs,IF and only IF you run into valve control, clearance or load rate issues will swapping to new springs be necessary, now that's not saying they are or are not superior under some conditions, but verifying your needs before spending over $100 you may not need to spend seems like the smart route..

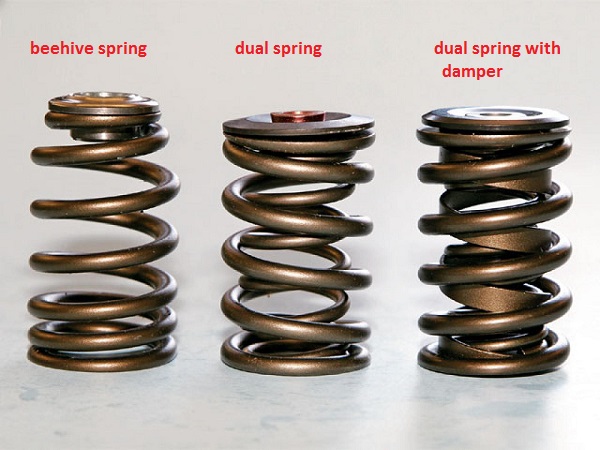

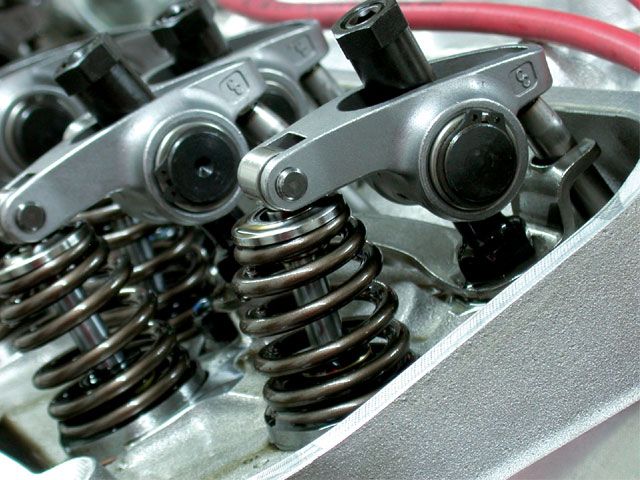

keep in mind beehive springs will generally remove weight/mass from the valve train as your removing dual springs and replacing them with a single spring and a much smaller and lighter spring retainer, thus changing the inertial loads and valve train harmonics, use of a Single valve spring generates significantly less heat as compared to a dual spring valve train with a damper. Dual springs with a damper will always generate more heat and require a higher spring load rate to to over-come the friction the springs and damper produce , which can easily require an additional 10% higher spring load rates , just to compensate for increased mass and frictional losses. the beehive spring being smaller in diameter requires a smaller and lighter weight retainer,again reducing inertia loads on the valve train. while beehive springs have limitations in the applications they can be used in they also have distinct advantages in many applications, and frequently allow higher rpms with lower load rates thus reducing heat and wear

if you run into clearance issues , during the assembly checking and cam installation, process,getting the correct load rate beehive springs, and smaller matching diam, spring retainers (TITANIUM RETAINERS ARE NICE , DUE TO LIGHTER WEIGHT,BUT EXPENSIVE, IF YOU SHOP AROUND YOU'LL FIND STEEL RETAINERS THAT STILL SAVE SOME WEIGHT) And will most likely be a good idea, but if your not running into problems Id keep the current valve train components

reading thru the sub linked info will give your hundreds of times more info that just glancing thru this post

reading thru the links below is well worth the time and effort

Beehive valve springs have been known in the industry as having a lower mass at the retainer end thus allowing for better valve control. This is only partially the reason for the better valve control. Beehive valve springs are unique when it comes to coil spacing, rate control, and also using a MA wire cross section. Beehive springs benefit from utilizing ovate shaped wire. This wire more effectively distributes the stress over the entire wire area allowing for more complexity within the spring improving the fatigue life of the spring

viewtopic.php?f=52&t=697&p=968#p968

http://www.corvettefever.com/roadtests/ ... index.html

http://www.lunatipower.com/News.aspx?id=9

viewtopic.php?f=52&t=2768&p=7190#p7190

viewtopic.php?f=52&t=181&p=2342&hilit=+beehive#p2342

http://www.ovaltracking.com/tech/2006/i ... ive-3.html

http://www.carcraft.com/techarticles/vo ... index.html

http://www.fordmuscle.com/archives/2007 ... /index.php

http://www.performanceproductreview.com ... eehive.pdf

http://www.chevyhiperformance.com/tech/ ... index.html

http://www.hotrod.com/how-to/engine/hrdp-1011-what-you-need-to-know-about-valvesprings/

viewtopic.php?f=52&t=282

viewtopic.php?f=52&t=181 )

)