I'm new to this site and hope someone can help me with my problem. My project car has a 350 mated to a muncie 4-speed using an 11" clutch and 168 tooth flywheel with a make-shift hydraulic linkage. The clutch pedal is terribly stiff and I want to upgrade to something that will be easier to operate.

I found an 84-88 corvette bellhousing with the hydraulic slave and thought this might solve my stiff pedal. However, the bellhousing won't fit over the 11" clutch. This is where my memory is failing-do I need to get a 153 tooth flywheel and a smaller clutch or find a 168 tooth flywheel tapped for the smaller clutch? Or is there some flywheel/clutch combination that is particular to this bellhousing?

I do have a bellhousing from an 88 truck with the hydraulic slave, but my car is already really low to the ground and the slave on that bell is about an inch lower than normal. I'm reluctant to use this because of the ground clearance.

All I have are 168 tooth flywheels for 11" clutches, so I don't have anything to compare. So far all I have is the bellhousing and I don't want to spend anymore money on parts I may not need.

Any ideas? Thanks

it sure sounds like the Z-bar geometry is less than ideal or perhaps you have the z-bar installed up-side down, keep in mind one arms longer (that one goes to the clutch petal.)

keep in mind on hydraulic clutches the master and slave cylinders can have different sizes thus the effort required can be changed

read ALL the links

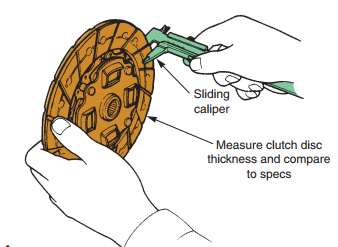

since youve already replaced the clutch disc and pressure plate, I'd point out that,

many times clutch chatter is the result of an un-even flywheel surface, any decent machine shop can surface grind the existing friction surface a few thousands to correct that issue.

clutch chatter is the result of un-evenly applied clamping surfaces, usually a high spot(S) on the clutch pressure plate its housing or the flywheel surface, but grease and or oil on the clutch disk, or loose disc pads could also be too blame , but heat warping or a broken spring or mis-aligned spring will also cause this symptom.

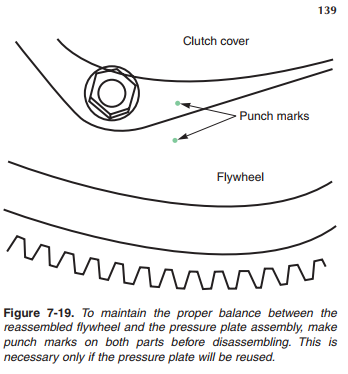

the flywheel should be torqued to the crank flange, an impact gun should never be used as its possible to warp the mount surfaces is tightened un-evenly

if the clutch vibration does not go away once the clutch locks up,

you've more than likely, got a drive line component alignment or rotation assembly or drive line balance issue.

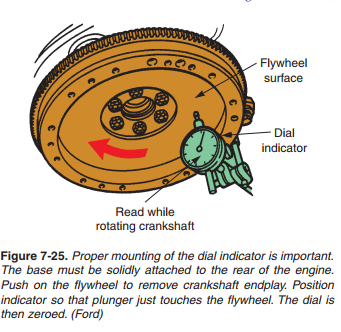

you'll want to verify the flywheels mounted so its not wobbling, it may be warped,

or the crank flange its mounted too has been bent or theres debris between the flywheel and crank flange,

you,ll want too use a dial indicator mounted on the block and rotate the flywheel to find out,

if the flywheel friction surface or outer diameter

,changes its distance from the block as it rotates

read ALL the links

http://www.freeasestudyguides.com/manual-transmission-clutch-chatter.html

http://www.brakeandfrontend.com/causes-clutch-failure-diagnosing-chatter/

http://www.onallcylinders.com/2012/10/02/clutch-tips-troubleshooting-faqs-from-the-experts/

https://www.schaeffler.com/remoteme...ler_2/symposia_1/downloads_11/2_chatter_1.pdf

https://www.g-w.com/pdf/sampchap/9781605252131_ch07.pdf

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/#post-59459

http://garage.grumpysperformance.com/index.php?threads/huge-vibration-issue.12548/#post-63812

http://garage.grumpysperformance.co...rrectly-installing-bellhousings.584/#post-785

http://garage.grumpysperformance.co...rnal-balance-crank-question.13560/#post-70119

http://garage.grumpysperformance.co...tion-about-throw-out-bearing.6258/#post-19701

http://garage.grumpysperformance.co...ools-diagnosing-clutch-issues.3553/#post-9431

look through the links

http://garage.grumpysperformance.com/index.php?threads/a-brief-look-at-clutches.447/

http://garage.grumpysperformance.co...gs-and-correctly-installing-bellhousings.584/

hydraulic

MASTER/SLAVE CYLINDER

http://garage.grumpysperformance.co...ools-diagnosing-clutch-issues.3553/#post-9431

http://garage.grumpysperformance.co...ch-master-and-slave-cylinders.3190/#post-8505

RELATED INFO

http://garage.grumpysperformance.co...ack-makes-all-the-difference.5512/#post-43359

http://garage.grumpysperformance.com/index.php?threads/pilot-bushing-installation.2596/#post-6689

HYDRAULIC THROW-OUT BEARING

http://garage.grumpysperformance.com/index.php?threads/hydraulic-throw-out-bearings.1122/#post-2236

https://www.google.com/search?q=ble....16602j0j4&sourceid=chrome&ie=UTF-8#kpvalbx=1

https://m.wikihow.com/Bleed-a-Slave-Cylinder

Part 2 Bleeding Your Clutch

- Check the fluid level in the master cylinder. ...

- Locate the bleed screw on the slave cylinder. ...

- Attach the hose to the bleed screw. ...

- Open the bleed screw on the slave cylinder. ...

- Have a friend press the clutch pedal in and hold it. ...

- Close the bleed screw. ...

- Have your friend release the clutch pedal.

this is for brakes but the basic concept is similar for a clutch slave cylinder

http://www.aaawholesalecompany.com/bem-484410-pk.html

NOTICE THEY COME singly for about $8-$9 each or 12 to a carton and cost about $60 a dozen so get two to 6 buddies to split the cost

medical supplys can be useful bleeding brakes

"Ive only found one semi-fool proof way, and that's with two guys, doing the old...

check the fluid level, pump the brake pedal,several times,....., hold it,firmly to the pressure point f,...release the bleeder valve, on the wheel, let the pedal hit the floor,...close the bleeder valve, only then, let the pedal up, repeat, about 4 times than refill the master cylinder,repeat until you get clear new fluid and no air in the clear tubing, routine, on each wheel with a 1/4 diam section of 3 ft long clear plastic tube routing the old brake fluid into a large plastic container, all the time getting feed back on feel from the guy pumping the brakes who's also and making sure the brake fluid reservoir never gets low

Last edited: