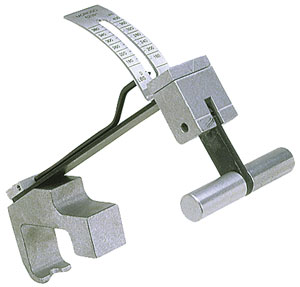

now if your like most guys if youve never done it your thinking it a huge complicated deal, ITS NOT,just follow the instructions in the links, Id advise you read them all because some are more clear on some parts of the process than others and youll get a better over/all feel for the process. all you need is a degree wheel, a dial indicator , a solid lifter and a pocket calculator and its something you can do in about 15 minutes time.

NOW youll be asking WHY BOTHER?

well its RARE for the index marks on the timing gears and the cam index pin to place the cam lobe rotation EXACTLY where it was intended to be and a shift of only a few degrees can and does move the power curve a hundred or more rpm up or down in the rpm range. now thats not huge but in a few cases youll find the cams significantly differant than the specs indicate and you could easily be down 5-20hp or have it idle like crap, if its indexed wrong, Id be very surprised if some guys cars ran worth a crap or at all if you just slapped in useing the cam gear index marks.

and in one case I found the cam gear in a imported timing sets chain drive to be off almost 9 degrees, if you had installed that IM sure the car would run like crap, that cam gear was manufactured in INDIA and it was purchased at discount auto about 10 years ago, so there ARE crap parts out there in the market place.

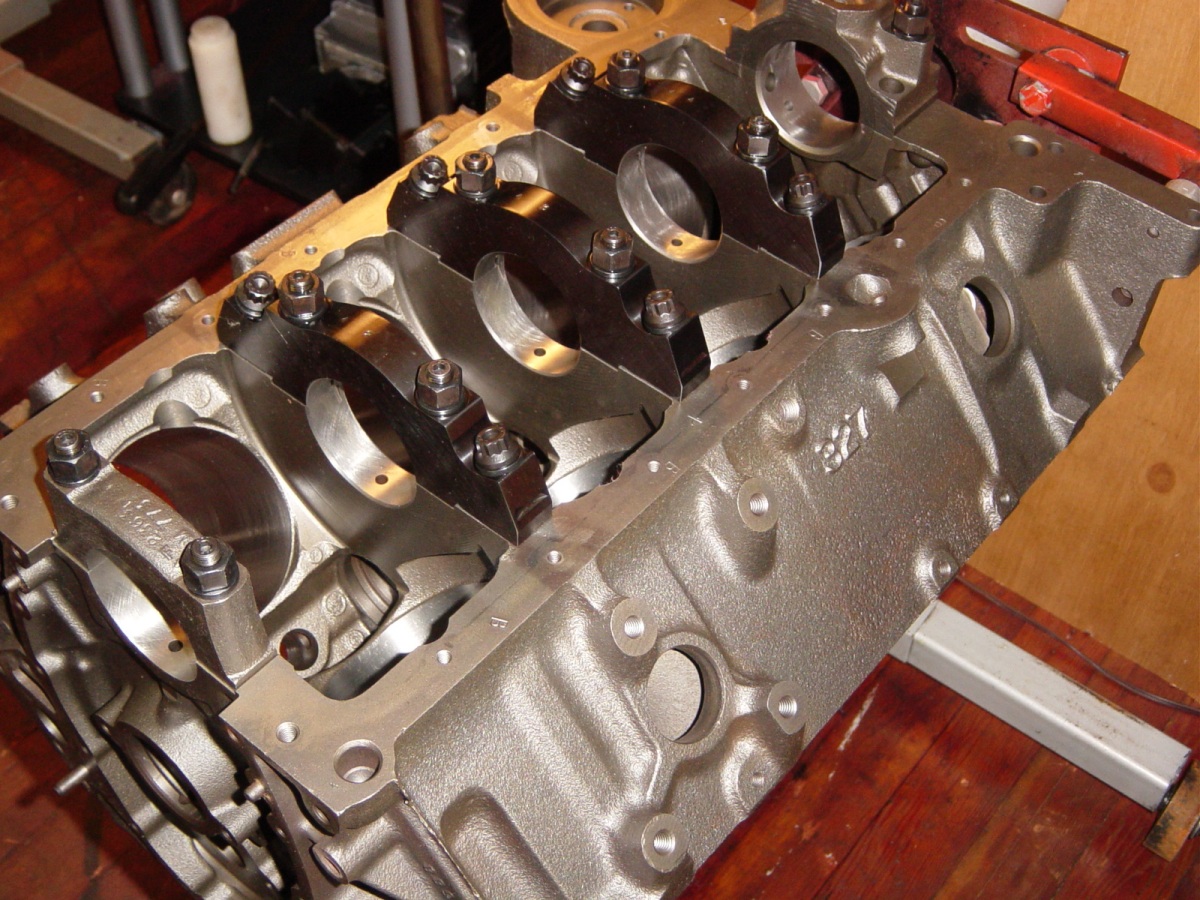

BTW alot of cam drive gear sets come with 3 crank slots and 3 marks on the cam timing gears that need to match to index the cam and if you screw it up durring the install is possiable to totally screw up the relationship between the cam and crank, degreeing in the cam points that mistake out vividly

youll need a few basic tools and a good understanding of what your doing, but its certainly not all that difficult.

I was asked where to get a CHEAP degree wheel

here is one you can print out and save for engine builds on the engine stand

http://www.summitracing.com/parts/mor-62191

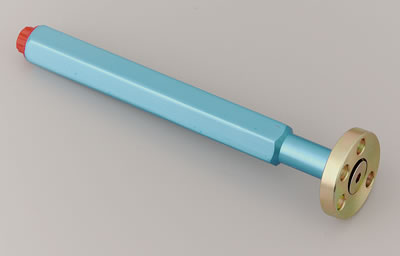

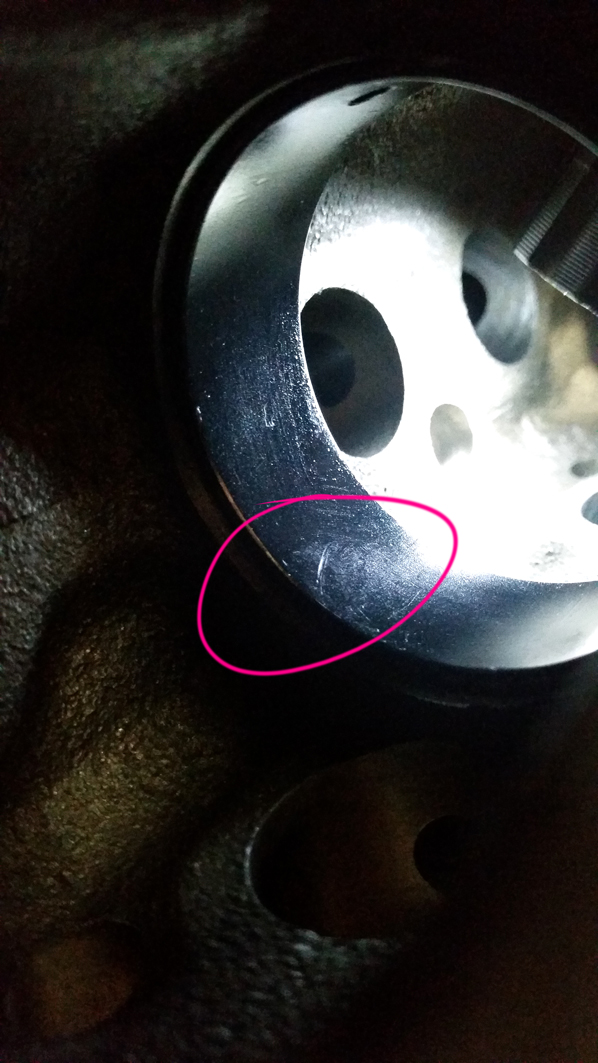

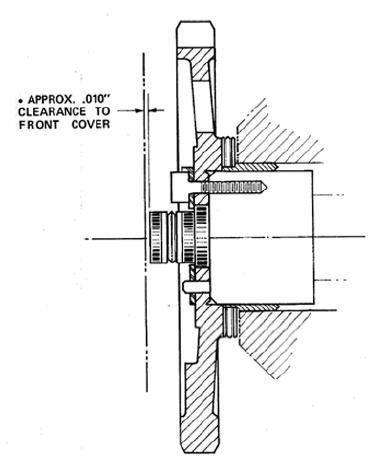

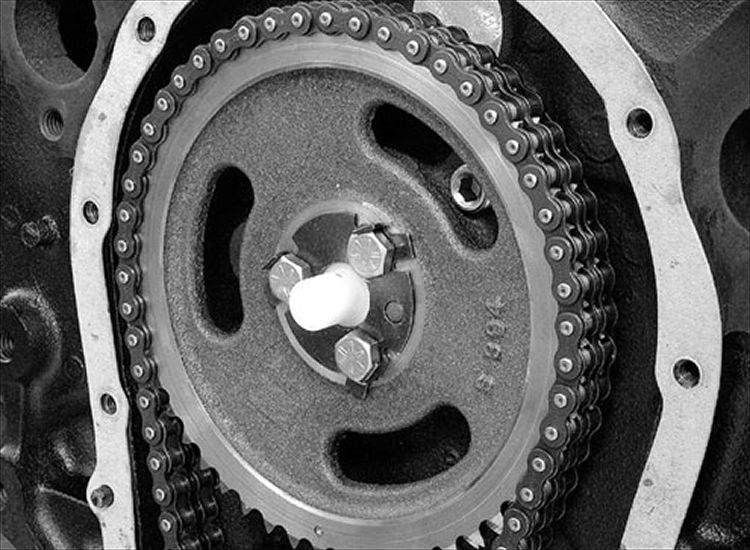

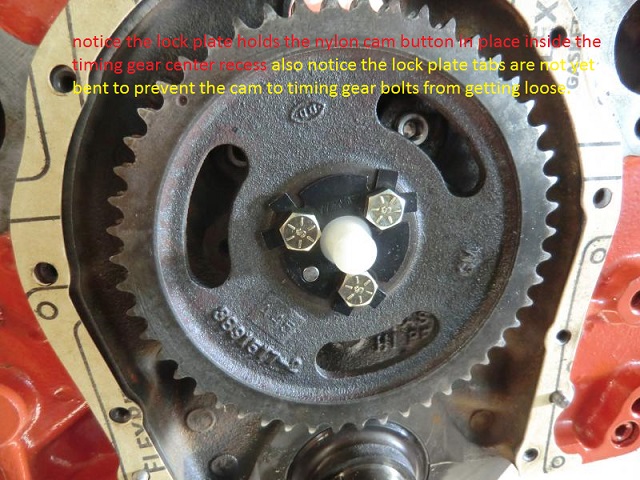

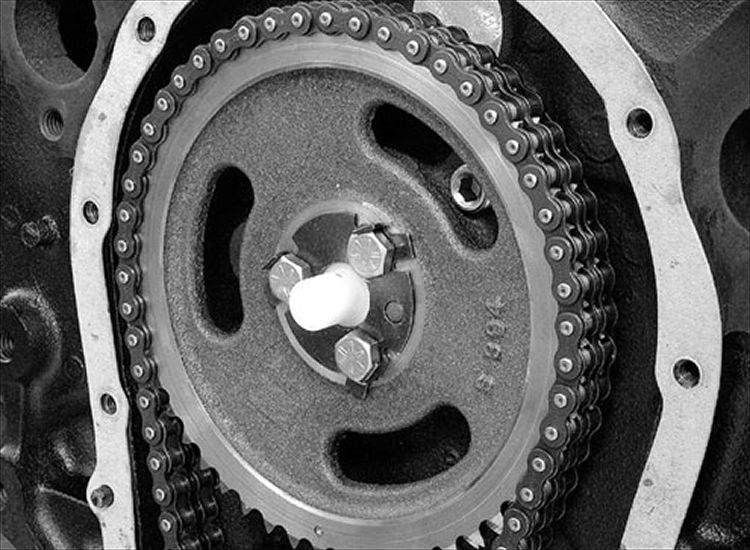

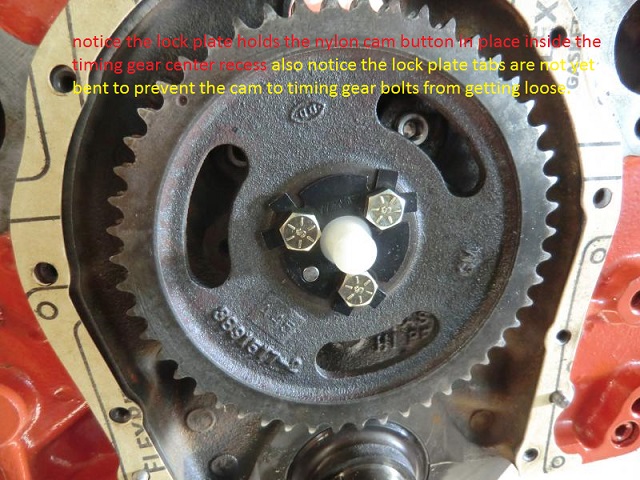

use loc-tite on the threads and a cam button and cam button retainer plate , if its the early style with out the step nose and retainer plate design

I've seen a good many chevy cams ,

but I have yet to see one where they failed to thread the timing chain gear bolt holes, obviously you could drill and tap that cam core,

but I would ask for a replacement simply because if the manufacturers quality control team missed that, check on the cams fabrication,

theres a chance they also missed other quality control checks, clearances etc.

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-32126

http://garage.grumpysperformance.com/index.php?threads/cam-gear-and-timing-marks-etc.724/#post-1021

http://garage.grumpysperformance.com/index.php?threads/degree-in-that-cam-correctly.27/#post-35

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12048

http://garage.grumpysperformance.com/index.php?threads/cam-spacer-buttons.1793/

BTW you CAN advance or retard the roller timing chain its done bye drilling out the cam index pin hole in the timing gear and installing an off set bushing

http://www.summitracing.com/parts/cca-4760

you could buy these from summit racing or similar parts from jegs

this is 180 degrees out (the distrib rotor points at cylinder #6, so before you drop in the distrib rotate the crank 360 degrees bring both marks to the 12 o-clock location, then drop in the distrib pointing to cylinder #1, and adjust ignition timing from that point

this is 180 degrees out (the distrib rotor points at cylinder #6, so before you drop in the distrib rotate the crank 360 degrees bring both marks to the 12 o-clock location, then drop in the distrib pointing to cylinder #1, and adjust ignition timing from that point

http://www.summitracing.com/

http://www.jegs.com sells this KIT

Comp Cams #249-4796

http://www.jegs.com/i/Comp Cams/249/4796/10002/-1

and you can buy these

MOR-62191 $44 (wheel)

MOR-61755 $47 (SBC)

MOR-61756 $47.(BBC)crank sockets

SUM-900188 $17 (piston stop, head off)

SUM-900189 $6.95(piston stop, head on)

TFS-90000 $94.95 (degree kit)

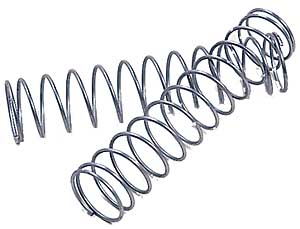

youll also want two flat tappet solid lifters and two weak check springs

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66838&N=700+115&autoview=sku

http://www.totalengineairflow.com/tools

instructions

http://www.iskycams.com/camshaft.html

http://www.thedirtforum.com/degree.htm

http://www.ridgenet.net/~biesiade/camdegree.htm

http://www.hotrodder.com/kwkride/degree.html

http://www.cranecams.com/pdf/803.pdf

http://www.pontiacstreetperformance.com/psp/camshaft.html

http://www.compcams.com/Technical/Instructions/Files/145.pdf

NOW youll be asking WHY BOTHER?

well its RARE for the index marks on the timing gears and the cam index pin to place the cam lobe rotation EXACTLY where it was intended to be and a shift of only a few degrees can and does move the power curve a hundred or more rpm up or down in the rpm range. now thats not huge but in a few cases youll find the cams significantly differant than the specs indicate and you could easily be down 5-20hp or have it idle like crap, if its indexed wrong, Id be very surprised if some guys cars ran worth a crap or at all if you just slapped in useing the cam gear index marks.

and in one case I found the cam gear in a imported timing sets chain drive to be off almost 9 degrees, if you had installed that IM sure the car would run like crap, that cam gear was manufactured in INDIA and it was purchased at discount auto about 10 years ago, so there ARE crap parts out there in the market place.

BTW alot of cam drive gear sets come with 3 crank slots and 3 marks on the cam timing gears that need to match to index the cam and if you screw it up durring the install is possiable to totally screw up the relationship between the cam and crank, degreeing in the cam points that mistake out vividly

youll need a few basic tools and a good understanding of what your doing, but its certainly not all that difficult.

I was asked where to get a CHEAP degree wheel

here is one you can print out and save for engine builds on the engine stand

http://www.summitracing.com/parts/mor-62191

use loc-tite on the threads and a cam button and cam button retainer plate , if its the early style with out the step nose and retainer plate design

I've seen a good many chevy cams ,

but I have yet to see one where they failed to thread the timing chain gear bolt holes, obviously you could drill and tap that cam core,

but I would ask for a replacement simply because if the manufacturers quality control team missed that, check on the cams fabrication,

theres a chance they also missed other quality control checks, clearances etc.

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-32126

http://garage.grumpysperformance.com/index.php?threads/cam-gear-and-timing-marks-etc.724/#post-1021

http://garage.grumpysperformance.com/index.php?threads/degree-in-that-cam-correctly.27/#post-35

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.co...hanics-of-adv-ret-a-camshaft.4532/#post-12048

http://garage.grumpysperformance.com/index.php?threads/cam-spacer-buttons.1793/

BTW you CAN advance or retard the roller timing chain its done bye drilling out the cam index pin hole in the timing gear and installing an off set bushing

http://www.summitracing.com/parts/cca-4760

you could buy these from summit racing or similar parts from jegs

http://www.summitracing.com/

http://www.jegs.com sells this KIT

Comp Cams #249-4796

http://www.jegs.com/i/Comp Cams/249/4796/10002/-1

and you can buy these

MOR-62191 $44 (wheel)

MOR-61755 $47 (SBC)

MOR-61756 $47.(BBC)crank sockets

SUM-900188 $17 (piston stop, head off)

SUM-900189 $6.95(piston stop, head on)

TFS-90000 $94.95 (degree kit)

youll also want two flat tappet solid lifters and two weak check springs

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66838&N=700+115&autoview=sku

http://www.totalengineairflow.com/tools

instructions

http://www.iskycams.com/camshaft.html

http://www.thedirtforum.com/degree.htm

http://www.ridgenet.net/~biesiade/camdegree.htm

http://www.hotrodder.com/kwkride/degree.html

http://www.cranecams.com/pdf/803.pdf

http://www.pontiacstreetperformance.com/psp/camshaft.html

http://www.compcams.com/Technical/Instructions/Files/145.pdf

Attachments

Last edited by a moderator: