that looks spectacular !!

as to the oil pressure sensor , I guess I did things just a bit differently, I ran the oil pressure sensor that cuts off power to the fuel pump, in series

with a LED light that indicated power was routed to and getting to the fuel pump as the wire that normally goes directly to the cars frame ground from the fuel pump was routed through a dash LED before going to the frame ground,

thus I could see the led was lit if the fuel pump was running and I had an oil pressure gauge to check also, thus if the LED light was ON I knew the fuel pump was running and I must have oil pressure , plus the oil gauge would show the pressure, and oil temp gauge would show oil temp, if the LED was out I knew the fuel pump was not running and I would also glance at the oil gauges and the fuel pump would not run , nor would the LED light, if oil pressure fell below about 7 psi

BTW if go that route don't panic if the engines running fine and the LED goes out for a few seconds regularly, the fuel pump is also regulated on the high side pressure and it will occasionally go on/ off for a couple seconds, obviously having a fuel pressure gauge is a big help with diagnosing a bad fuel pump along with the LED and oil pressure gauge

Free Shipping - Summit Racing™ Digital Gauge Sending Units with qualifying orders of $109. Shop Gauge Sending Units at Summit Racing.

www.summitracing.com

A recurring theme has been replayed over and over, READ THE LINKED INFO CAREFULLY THERES NOT A DAMN THING YOU CAN'T FIND AND FIX WITH A FEW TOOLS, AND SOME FAMILIARITY WITH THE CORVETTE< A SHOP MANUAL IS A HUGE HELP Id strongly suggest you systematically verify the cause rather than making...

garage.grumpysperformance.com

Ensure max electric fuel pump output and safety with a relay for no voltage drop, plus an oil pressure switch that won’t let the pump run if the engine loses oil pressure.

www.motortrend.com

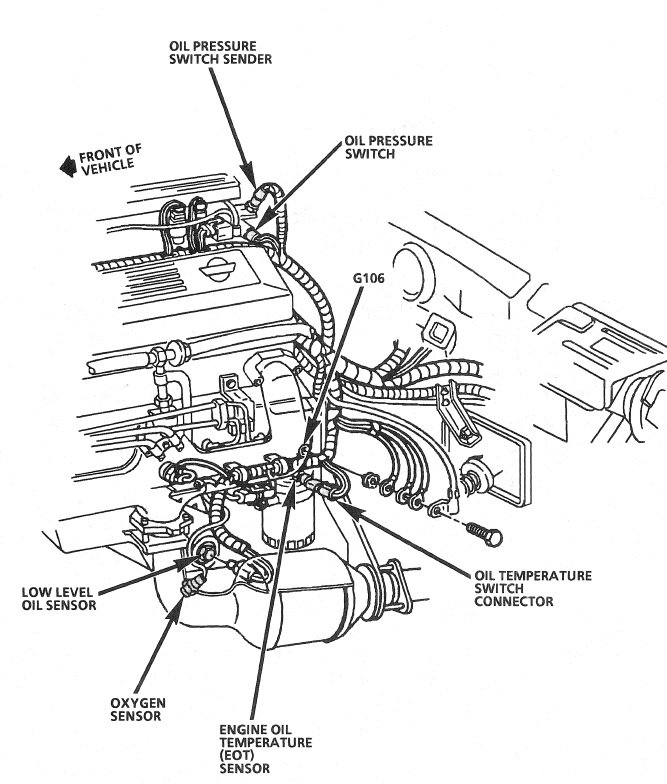

oil pressure sensors usually next to distributor base