custom welded aluminum valve cover breathers are an option,

http://auto.howstuffworks.com/positive-crankcase-ventilation-system.htm

http://garage.grumpysperformance.com/index.php?threads/tracking-down-an-oil-leak.1430/#post-3168

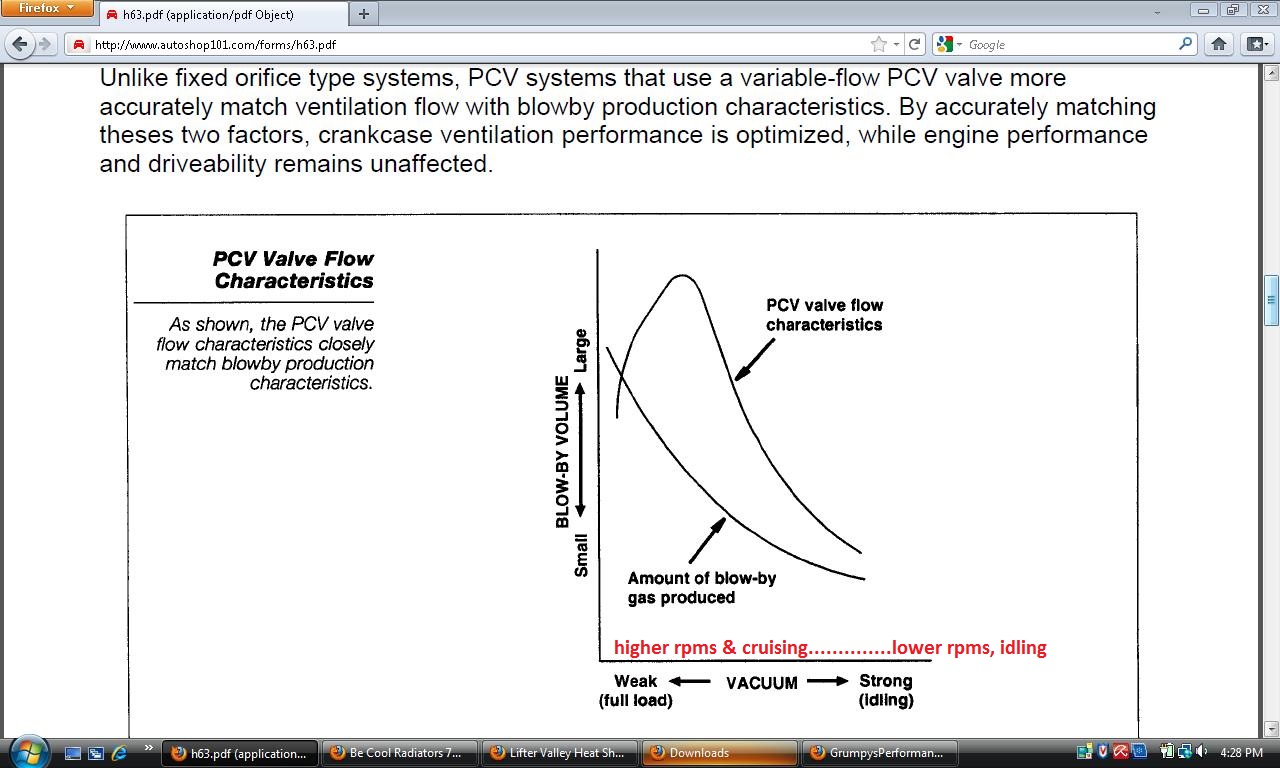

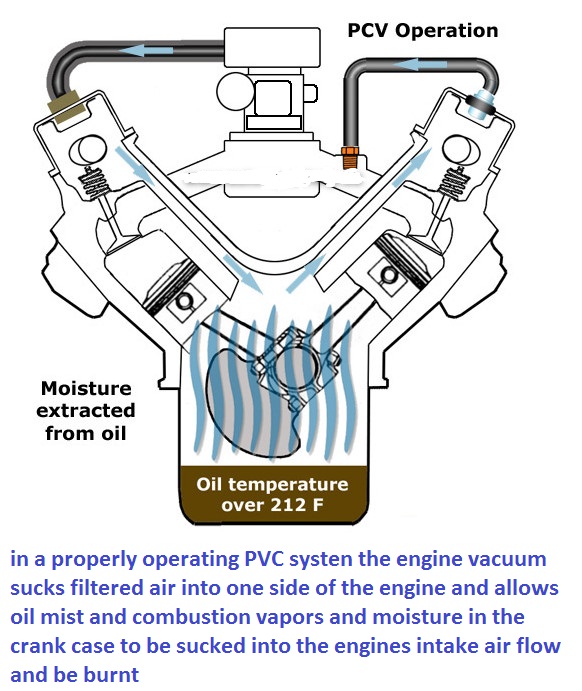

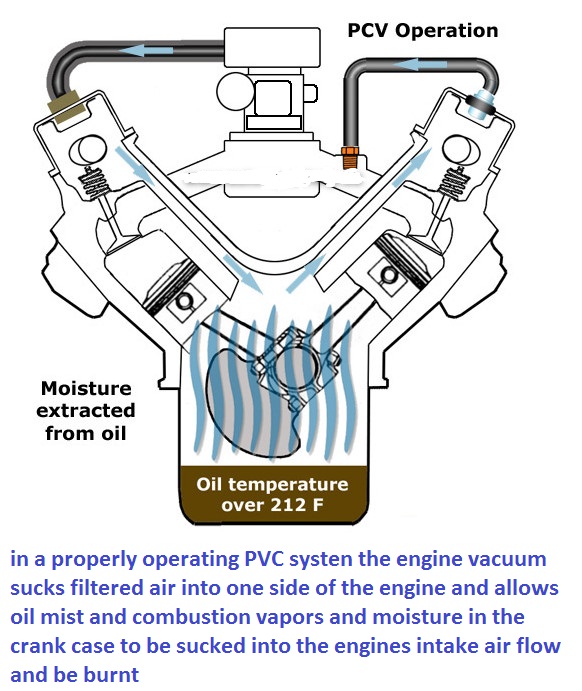

you really don,t need to know much more than, you ideally allow filtered air into one valve cover and suck exhaust gases that got past the rings out the other side of the engine, as long as the pressure in the crank case stays low at all operational levels your fine

read thru this related thread

viewtopic.php?f=52&t=2005&p=5328&hilit=positive+crankcase#p5328

http://www.harborfreight.com/knockout-p ... 91201.html

in some covers you will need to punch a hole and add a grommet

theres several sources for oil fill caps that can be welded in or use rubber grommets

http://www.pitstopusa.com/detail.aspx?ID=8726

morroso sells these,kits you can weld into your valve covers, thier used too connect two valve covers at the front of the engine,and the location prevents a good deal of oil from reaching the breathers, Ive seen guys weld up their own custom version using 1" EMT conduit and have virtually nothing in cost if they have a welder and two tall sheet metal style valve covers, (a great reason to own a decent MIG or TIG)and weld in a washer inside each tube to act as a baffle, (this helps)

http://www.metalgeek.com/static/cope.pcgi

and then hook up the PVC to the vertical section and get very low oil flow into the PVC due mostly to both the distance and location on the front over the T-stat housing being far further up and forward reducing the oils tendency to flow to the PVC

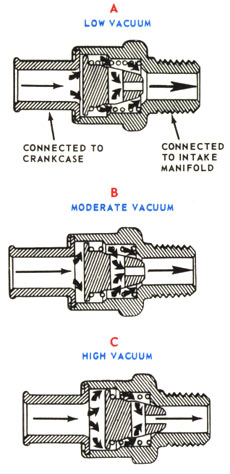

If you have oil mist or drips of oil exiting the breathers theres potentially several reasons the cause is likely to be a badly designed non baffled breather or a defective PVC valve that's not allowing air flow to be sucked IN thru the breather, , rather than crank case pressure allowing oil mist to exit the breather

(1) the engines rings are not sealing correctly resulting in higher than ideal crank case pressures.

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/

http://garage.grumpysperformance.com/index.php?threads/installing-rings-in-piston-grooves.9490/

(2) defective PVC valve

http://garage.grumpysperformance.co...lve-cover-breather-hole-in-valve-covers.2005/

http://forum.grumpysperformance.com/viewtopic.php?f=87&t=4636&p=12451#p12451

without proper venting an engines internal pressure builds , due to cylinder pressure leaking past the rings,and eventually will cause oil seals or gaskets to leak oil.

READ THE LINK

http://garage.grumpysperformance.co...stalling-the-intake-manifold-distributor.464/

(3) improper breather design or improper location on the valve cover

http://www.jegs.com/i/JEGS-Performance-Products/555/52205/10002/-1?parentProductId=763433

In a properly functioning engine the PVC valve allows engine vacuum to draw fresh outside air into the engine as it operates through the breather,

pressure in the crank case, you see as blow-bye out the breathers on valve covers is the result of cylinder combustion pressure, or to a far lower degree compression, getting past the ring to bore wall seal,the obvious best answer to reducing it is better ring seal.

now doing a ring and bearing refresh/and rebuild is just a weekend deal if your set up with the tools and have a place to work, but of course you may need a re-bore and new pistons, if the bores worn. and if thats true it will take longer and get more expensive due to the labor and machine shop costs and parts required, intermittent blow by is frequently the result of minimal ring damage due to detonation

most installed engines are slightly tilted towards the rear to help oil flow return, to the sump, in the crank case thus the forward 1/3rd of the upper inside roof of the valve covers tends to be a better place to locate breathers and PVC valves to limit oil loss, on most V 8 engines.

Last edited by a moderator: