IF Im changing just the cam and lifters do I need to recheck the pushrod length?

JUST WONDERING,IF YOU HAVE STOCK LENGTH PUSHRODS,YOU MILL THE HEADS,USE THIN METAL HEAD GASKETS,WOULDN'T THIS PUT THE ROCKER ARM CLOSER TO THE CAM?THEN WHY DO YOU NEED LONGER PUSHRODS WHEN YOU INSTALL A BIGGER CAM THAN STOCK?YOU WOULD THINK YOU WOULD NEED A SHORTER ONE SINCE THE LOBE IS TALLER THAN STOCK AN THE ROCKER ARM IS CLOSER TO THE CAM BECAUSE OF MILLING & THINNER HEADGASKETS.

http://www.popularhotrodding.com/engine ... ables.html

http://www.compcams.com/information/Products/Pushrods/

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.pontiacstreetperformance.com ... ngeom.html

http://www.lunaticams.com/Tech/Valvetra ... metry.aspx

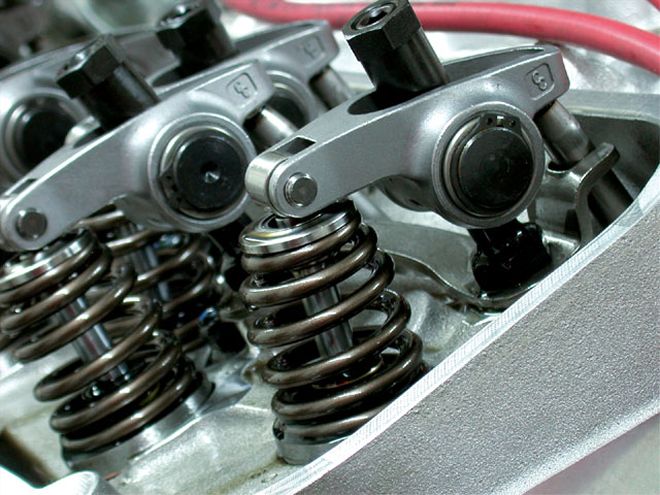

while your correct! the answers not always that simple because the cam base circle dia. on the new cam is frequently a differant dia. than the stock cam and the lifter seat height varies also, it will require verifyiong the correct valve train geometry.

you want the rocker to exert it force as much as possiable on the valve centerline to reduce friction and valve guide wear

YOULL NEED TO CAREFULLY CHECK YOUR PARTICULAR ENGINE!

heres a simple way to get close to the correct length

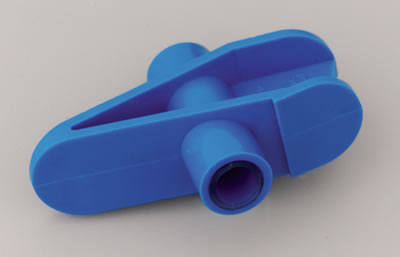

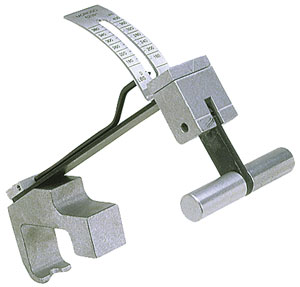

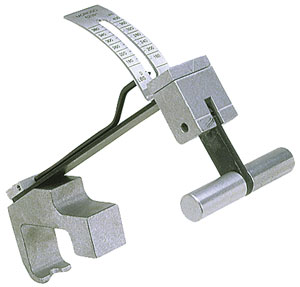

BUY ONE OF THESE

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3567&prmenbr=361

after making sure the valve springs are correctly installed you drop the checker in place on the rocker stud and install your adjustable pushrod

adjust the length to fit and measure the resulting length if its within twenty thousands of the stock length its fine for most applications, if its more than 30 thousands long or short get the closest length set available

<b>btw, if your one of the people that still does not own an adjustable push rod! you can easily make your own by cutting a stock pushrod in 1/2 (2 pieces), removeing 1 inch from the total length an then with about 2 " of a 4 inch section of 3/16 or 1/4" thread rod installed and (in one section epoxy it in place leaving about 2" sticking out thread two nuts onto the thread rod and slip on the other end of the cut pushrod,(no epoxy) use the two nuts to adjust to stock length and let the epoxy harded in the one section[/color] now you can easily measure and order custom push rods useing the pushrod checker and adjustable push rod as tools

AND YEAH IT ONLY WORKS WITH THE CYLINDER HEADS ON AND THE INTAKE REMOVED BECAUSE THE HOLE IN THE CYLINDER HEAD that GUIDEs THE PUSH ROD WON,T ALLOW THE NUTS ON THE ADJUSTABLE PUSHROD TO PASS THRU, UNLESS YOU PLACE THE CUT ABOUT 1" from the UPPER END OF THE ADJUSTABLE TEST PUSHROD BUT I prefer to place the adjusting nuts centered as I like to watch for all clearances with the intake manifold removed while manually checking as I turn the engine over by hand durring assembly, and at that point, while checking all the clearances, I use test springs which apply very little load on the push rod</b>

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3272&prmenbr=361

HERES OTHER TOOLS YOU MIGHT NEED

SOMETHING TO READ

http://www.compcams.com/information/Products/Pushrods/

CCA-7705 5.800 in. to 9.800 in. adjustment range, Master pushrod length checker 4 piece kit ... $78.69

here

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... ckers.html

http://www.compcams.com/Technical/FAQ/V ... ometry.asp

http://www.babcox.com/editorial/ar/eb50232.htm

http://www.customspeedparts.de/content/ ... metrie.php

http://www.hotrod.com/techarticles/cams ... index.html

http://www.eatonbalancing.com/blog/2007 ... -geometry/

JUST WONDERING,IF YOU HAVE STOCK LENGTH PUSHRODS,YOU MILL THE HEADS,USE THIN METAL HEAD GASKETS,WOULDN'T THIS PUT THE ROCKER ARM CLOSER TO THE CAM?THEN WHY DO YOU NEED LONGER PUSHRODS WHEN YOU INSTALL A BIGGER CAM THAN STOCK?YOU WOULD THINK YOU WOULD NEED A SHORTER ONE SINCE THE LOBE IS TALLER THAN STOCK AN THE ROCKER ARM IS CLOSER TO THE CAM BECAUSE OF MILLING & THINNER HEADGASKETS.

http://www.popularhotrodding.com/engine ... ables.html

http://www.compcams.com/information/Products/Pushrods/

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... index.html

http://www.pontiacstreetperformance.com ... ngeom.html

http://www.lunaticams.com/Tech/Valvetra ... metry.aspx

while your correct! the answers not always that simple because the cam base circle dia. on the new cam is frequently a differant dia. than the stock cam and the lifter seat height varies also, it will require verifyiong the correct valve train geometry.

you want the rocker to exert it force as much as possiable on the valve centerline to reduce friction and valve guide wear

YOULL NEED TO CAREFULLY CHECK YOUR PARTICULAR ENGINE!

heres a simple way to get close to the correct length

BUY ONE OF THESE

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3567&prmenbr=361

after making sure the valve springs are correctly installed you drop the checker in place on the rocker stud and install your adjustable pushrod

adjust the length to fit and measure the resulting length if its within twenty thousands of the stock length its fine for most applications, if its more than 30 thousands long or short get the closest length set available

<b>btw, if your one of the people that still does not own an adjustable push rod! you can easily make your own by cutting a stock pushrod in 1/2 (2 pieces), removeing 1 inch from the total length an then with about 2 " of a 4 inch section of 3/16 or 1/4" thread rod installed and (in one section epoxy it in place leaving about 2" sticking out thread two nuts onto the thread rod and slip on the other end of the cut pushrod,(no epoxy) use the two nuts to adjust to stock length and let the epoxy harded in the one section[/color] now you can easily measure and order custom push rods useing the pushrod checker and adjustable push rod as tools

AND YEAH IT ONLY WORKS WITH THE CYLINDER HEADS ON AND THE INTAKE REMOVED BECAUSE THE HOLE IN THE CYLINDER HEAD that GUIDEs THE PUSH ROD WON,T ALLOW THE NUTS ON THE ADJUSTABLE PUSHROD TO PASS THRU, UNLESS YOU PLACE THE CUT ABOUT 1" from the UPPER END OF THE ADJUSTABLE TEST PUSHROD BUT I prefer to place the adjusting nuts centered as I like to watch for all clearances with the intake manifold removed while manually checking as I turn the engine over by hand durring assembly, and at that point, while checking all the clearances, I use test springs which apply very little load on the push rod</b>

http://www.jegs.com/cgi-bin/ncommerce3/ProductDisplay?prrfnbr=3272&prmenbr=361

HERES OTHER TOOLS YOU MIGHT NEED

SOMETHING TO READ

http://www.compcams.com/information/Products/Pushrods/

CCA-7705 5.800 in. to 9.800 in. adjustment range, Master pushrod length checker 4 piece kit ... $78.69

here

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/techarticles ... ckers.html

http://www.compcams.com/Technical/FAQ/V ... ometry.asp

http://www.babcox.com/editorial/ar/eb50232.htm

http://www.customspeedparts.de/content/ ... metrie.php

http://www.hotrod.com/techarticles/cams ... index.html

http://www.eatonbalancing.com/blog/2007 ... -geometry/