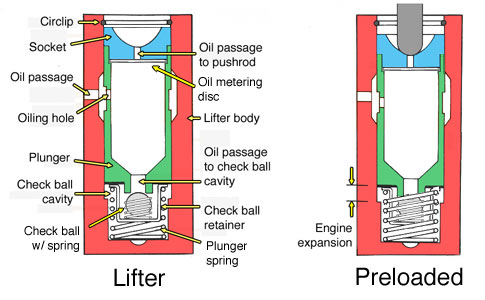

ITS very hard to effectively judge, from the video clip, simply because I can,t see the push rod to guide slot clearances, or judge the force used on the rocker,in the brief film clip, I don,t know if the rocker stud is under size ,if the rocker bearings are loose, I don,t know if its the screw-in style, rocker stud, and its come loose or the press-in style and its pulling out of the head,or if the rocker trunnion is drilled oversize, rockers are supposed to have some slack to allow them to self align to some extent and much of the clearance can be the result of miss-alignment, worn push rods, loose threads on the adjustment lock nut to stud clearance, or the hydraulic lifter seat not maintaining its supporting oil pressure, after the engines oil pressure dropped, or it might be installed with less than ideal geometry, Id suggest checking the condition of the valve tips, push rod seats and compare it to the other rockers.

on a hydraulic rocker you can usually adjust the slack at idle by backing off until the rocker clicks at idle, then slowly turning in the lock nut until the noise/clicking has stopped then adding an additional 1/4 turn, just like the stock stamped rockers .

careful side bye side inspection of the suspect defective rocker and comparing it with what appears to be a good rocker then swapping their locations and retesting, while watching the results should isolate the cause, bearing and bearing retainers can wear or come loose so check,, if you adjusted them cold without the engine at idle I frequently see a couple rockers exhibit that slack after running a few hours, but adjusting them at idle tends to eliminate that problem.

by the way, once you get them adjusted with the 1/4 turn past the clicking has stopped at idle and locked the set screw in the center of the lock nut with an allen key you generally use a 5/8" wrench to give the adjustment nut about an 1/8th turn to remove all slack or they can come loose over time, so in effect you have the adjustment at about 3/8th of a turn tighter than just at the point the rocker stopped clicking at idle.

yes having a tall valve cover with the center cut out for doing valve adjustments is usually a good idea as it limits oil splash on the engine during the process.self aligning rockers have ridges to prevent the rocker from moving off the valve stem