years ago chevy made almost exclusively, just standard strait plug head designs, as technology improved, it was found that getting the spark plug as close as you can to both the combustion chamber center and the exhaust valve helped power, as the technology advanced the later design strait plug heads also had the plug location moved, so the original advantage provided by the angle plug design was minimized in the later strait plug designs.

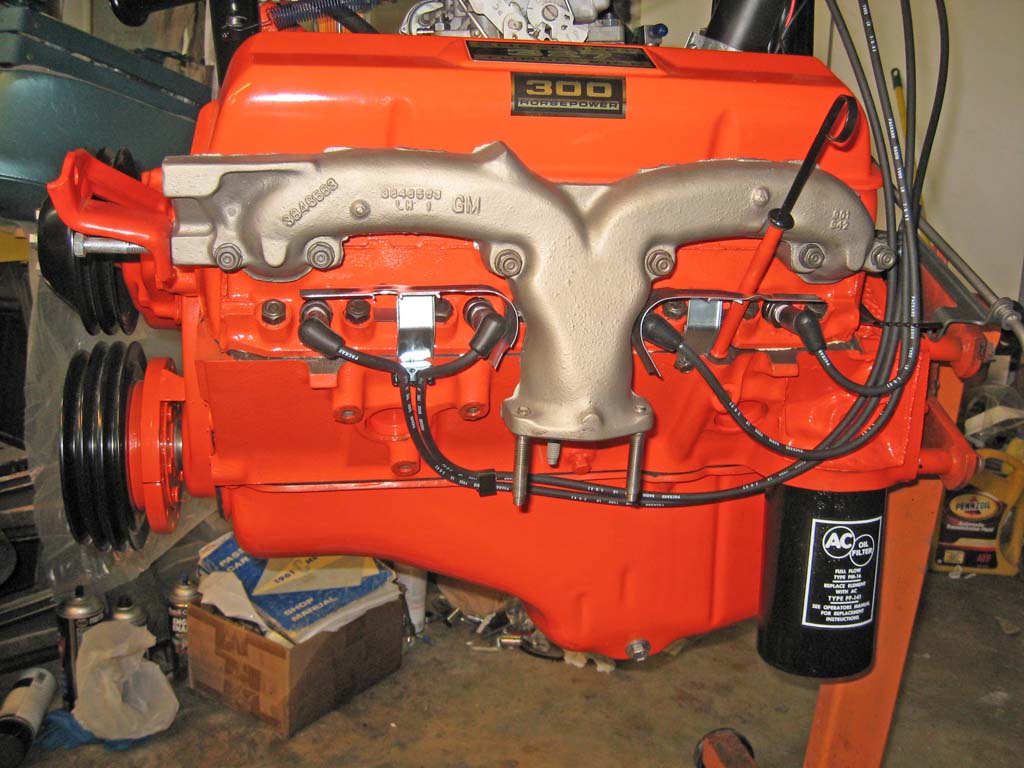

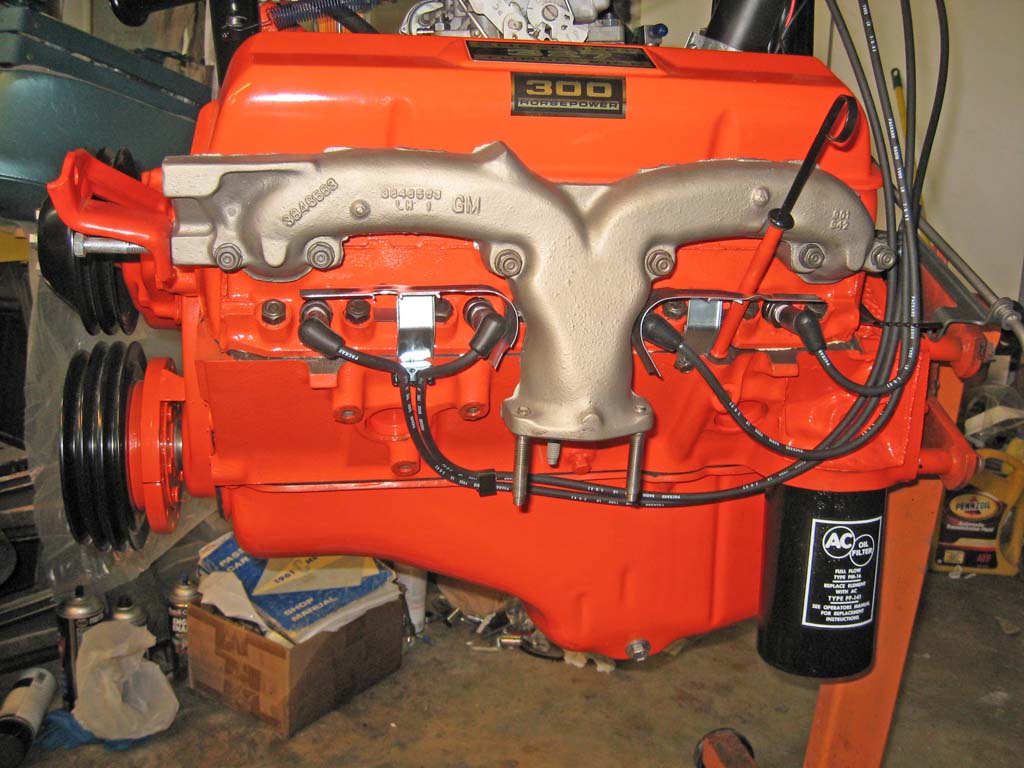

As far as being able to distinguish between the two designs , it is obvious under a close inspection, when you examine them. If they are almost located at a 90 degree angle to the head surface and parallel to one another, they are straight plug. If they are on an obvious angle (15-20 degrees or so?) they are going to be angle plug heads.

chevy found that angling the plus electrode to point at the exhaust valve and locating it closer to the combustion chamber center allowed for a faster burn requiring less ignition advance curve.

any time you can speed the combustion process up, and still get a full burn ,your wasting less energy, during the compression stroke fighting a rapidly expanding and burning mix of fuel/air with the piston trying to resist the engine spinning in the intended direction,before it reaches tdc and using a far greater percentage of the cylinder pressure generated above the piston,to generate torque after the pistons pasted tdc.

the problem is that it takes time to burn the fuel air mix, so the smaller the combustion area and the more efficient the quench is the faster the burn can be within the limitations of flame front speed, detonation and octane limitations.

BE AWARE, that theres a significant variation in spark plug location between different cylinder head designs,made by different manufacturers ,and theres both strait and angle plug heads and even the angle plug heads vary a good deal between designs, and many headers won,t work with a few cylinder heads in some applications so its almost mandatory that you call and talk too the tech support guys from both the cylinder head and headers manufacturers, to ask if any specific combo has a history of clearance issues BEFORE purchasing your headers or cylinder heads or both.

"Straight Plug vs. Angle Plug heads?

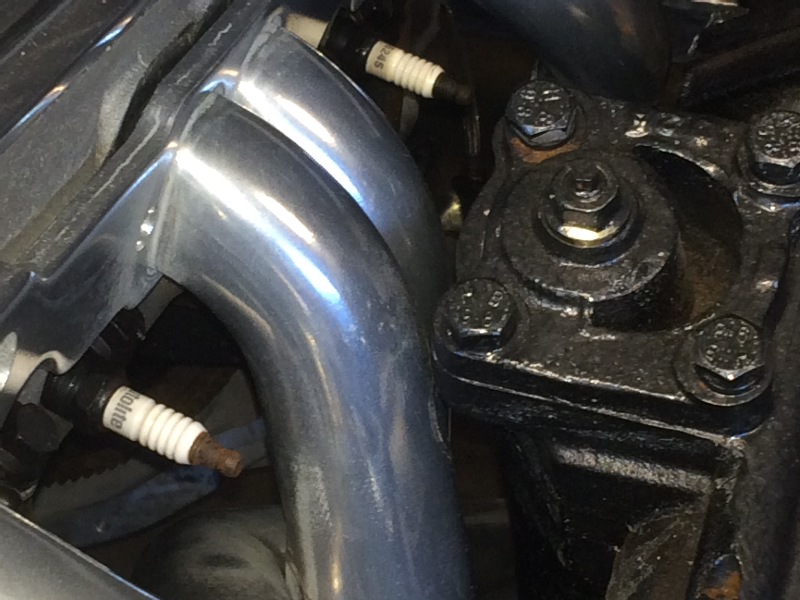

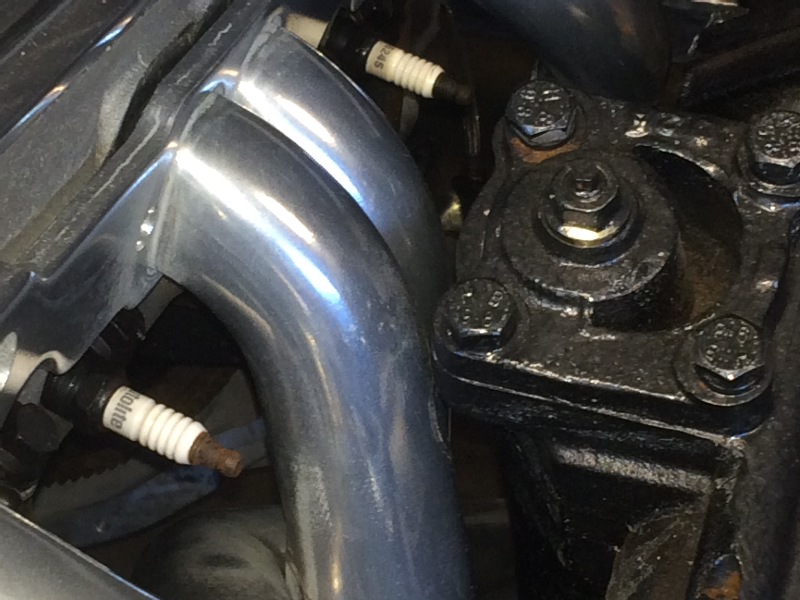

ITS extremely important that you ask questions and get accurate answers , BEFORE purchasing headers about what style cylinder heads the headers are designed to fit, below is pictured a set of headers obviously designed for factory strait plug heads but bolted to a set of angle plug heads making spark plug access and wiring a clearance and heat , destroying ignition wire nightmare

It really looks like those headers ,in the picture you posted directly above, that, your using were designed for use with the angle plug heads,

and use of the strait plug heads causes the spark plug to header tube,

and related ignition wire clearance issues.

this is, unfortunately a very common miss match of components.

look at the heads and the exhaust header tube routing and the difference in clearance,

that the designed angle plug heads use would make on spark plug to header tube clearance.

one of the least understood yet common problems is that the header manufacturers seldom bother to tell you what cylinder heads were used during the header design phase of production of the headers and damn few people purchasing headers bother to do the research or ask detailed questions until they run into problems caused by the design miss match, and yes its very common to find headers designed for strait plug heads can cause similar issues if used with angle plug heads , but that's slightly less common

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

Some people think that angle plug heads produce more power than straight plug heads. This common misconception is not true! In reality, the ONLY benefit to angled plug heads is to provide more spark plug boot clearance with some header designs.

The idea of these designs producing more power came from some early angle designs that placed the plug location closer to the exhaust valve. This WILL create more power, but straight plug designs that have since been moved in the same fashion produce the same power.

BluePrint Engines offers both straight and angle plug design heads – your choice should be based on appearance and cost – not on one being more powerful than the other.

– Tech Tip courtesy of BluePrint Engines"

angle plug

viewtopic.php?f=56&t=3155&p=8423#p8423

with many well designed headers and with rams horn exhaust manifolds the spark plug access is not normally an issue

Stock out of box 461x heads 1.940/1.500

but with very light 3-angle valve job

tested on SF-600 FlowBench

Flow tested at 28" on 4.000 Bore fixture

Lift----Intake----Exhaust

.200---- 99.6-----88.0

.300----155.2-----124.3

.400----189.0-----141.9

.450----190.6----------

.500----190.6-----142.2

.550----192.0----------

.600----192.6-----146.4

*** Short exhaust pipe on exhaust ports

Maxed out porting job, unwelded, 461 X SBC

no epoxy , with 2.055/1.600 valves

tested on SF-600 FlowBench

Flow tested at 28" on 4.000 Bore Fixture

Lift----Intake----Exhaust

.200----131.1-----116.1

.300----187.7-----152.7

.400----230.0-----193.9

.450----243.3----------

.500----259.7-----212.5

.550----266.5----------

.600----273.2-----245.1

.650----278.0----------

.700----282.0-----253.3

.750----283.6----------

***Short exhaust pipe on exhaust ports

Basically this was the sort of Flow

we were getting for C/ED dragster 316 cid

a very long time ago

Note: if ditch near spark plug, between

area around both valves to plug

is welded up ,...then another 4 to 8 cfm

is gained on Intake flow (461 X SBC)

if you also wanted to start welding the entire

chamber floor lowering CCs and increasing

short turn radius on 461x ,

and welding up intake port's roof

water jacket solid .... then it was

worth another 4 to 8 cfm gains .

so some of the very best WELDED up

461x heads were approx 299 cfm @ 28 inches

==========================================

Stock out of box 034 Cast-Iron Bowtie heads

with factory valve job and 2.020/1.600

Tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----117.9----107.9

.300----169.5----123.8

.400----205.0----146.2

.500----216.6----146.6

.550----228.3---------

.600----222.1----148.8

.650----215.8---------

.700----216.8----148.8

.750----217.8---------

***with pipe on exhaust ports

Cast-Iron Chevy Bowtie heads #034 castings

with 2.085/1.580 valves

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----127.7-----104.6

.300----189.2-----158.8

.400----238.5-----204.0

.450----256.6----------

.500----271.0-----216.0

.550----281.5----------

.600----288.6-----218.6

.650----293.3----------

.700----298.4-----221.1

.750----304.3

.800----308.3

.850----311.4

***with pipe on exhaust ports

all out porting but no epoxy or welding

Brodix Track 1 SBC with Manley 2.080/1.600

Best CNC porting ..by Weld Tech

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----125.5-----120.4

.300----189.8-----153.7

.400----245.8-----190.1

.450----269.7----------

.500----286.7-----228.3

.550----295.1----------

.600----294.7-----244.7

.650----301.4----------

.700----301.4-----252.0

.750----300.3----------

***with pipe on exhaust ports

-----------------------------------------

Cast-Iron Chevy Vortec heads #10239906

1.940/1.500 OEM valve job and shape

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----121.4-----98.2

.300----179.4-----123.8

.400----219.2-----137.5

.450----230.6----------

.500----220.8-----146.0

.550----221.6----------

.600----223.1-----151.9

.650----224.7----------

*** No-Pipe attached , bare exhaust ports

--------------------------------------------

Cast-Iron Chevy Vortec heads #10239906

Manley 2.055/1.600 valves

2nd Level porting , not yet all out

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----143.9-----119.5

.300----192.2-----169.9

.400----235.7-----195.5

.450----252.3----------

.500----264.1-----207.0

.550----258.6----------

.600----265.1-----212.6

.650----271.0----------

.700----271.1-----215.6

.750----272.0----------

***No-Pipe attached , bare exhaust ports

-------------------------------------------

Chevy Fast Burn heads with Manley 2.125/1.600

1st Level full porting job, not yet all out

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----134.4

.300----190.0

.400----235.5

.450----254.3

.500----270.4

.550----277.9

.600----270.0

.650----275.0

.700----277.5

.750----279.5

.800----279.5

****No flow numbers available on exhaust

were lost on computer's harddrive !!!

-----------------------------------------

GM Chevy LT-1 aluminum heads 2.055/1.600

1st Level porting

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----138.4----115.3

.300----193.2----154.5

.400----235.7----182.5

.450----250.3---------

.500----261.2----193.2

.550----259.2---------

.600----260.2----200.6

.650----262.2---------

.700----262.2----205.7

.750----263.1---------

.800----264.1---------

***No-Pipe attached , bare exhaust ports

.600" Lift with Pipe flowed = 223.6 cfm

-------------------------------------------

Dart Pro 1 Aluminum 215 CC ports

out of box shape as shipped by Dart

2.055 valve on 2.020 seat lapline

1.600 valve on exhaust

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----128.5----115.3

.300----181.3----148.5

.400----226.3----178.4

.450----243.4---------

.500----257.0----192.1

.550----268.1---------

.600----271.2----198.5

.650----262.2---------

.700----266.1----201.1

.750----266.1---------

.800----261.2----203.2

.850----257.2---------

***No-Pipe attached, bare exhaust ports

------------------------------------------

Dart Pro 1 Aluminum 215 CC ports

2nd Level porting

2.125/1.600 valve combo

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----147.8----111.4

.300----208.0----167.3

.400----251.5----198.9

.450----269.4---------

.500----284.6----214.3

.550----295.3---------

.600----299.6----220.3

.650----304.3---------

.700----308.3----224.1

.750----309.5---------

.800----309.5----227.3

.850----310.3---------

.900----309.9---------

***No-Pipe attached, bare exhaust ports

--------------------------------------------

Dart Pro 1 Aluminum 230 CC ports

out of box shape as shipped by Dart

2.055 / 1.600 Manley valves combo

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----123.0-----117.4

.300----179.4-----147.7

.400----223.1-----175.0

.450----241.7----------

.500----257.0-----193.2

.550----269.6----------

.600----278.7-----193.2

.650----270.4----------

.700----267.3-----204.9

.750----268.1----------

.800----265.7-----208.1

***No-Pipe attached, bare exhaust ports

-----------------------------------------

#492 SBC cast-iron castings (Old LT-1 heads)

Stock out of box factory shape

with 2.020/1.600 valves

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----115.2-----105.4

.300----165.2-----132.5

.400----195.6-----138.5

.450----202.3----------

.500----208.9-----143.0

.550----208.1----------

.600----207.3-----146.6

.650----208.7----------

.700----210.1-----146.6

***with pipe on exhaust ports

---------------------------------------------

World Products - Dart SBC Cast-Iron heads

stock out of box shape and valve job

( as produced for sale in Aug 1988 )

these were some old flow test numbers

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----127.5-----107.9

.300----180.7-----136.8

.400----208.9-----145.8

.450----219.4----------

.500----220.4-----150.5

.550----226.8----------

.600----233.3-----154.4

.650----236.7----------

.700----238.3-----155.7

***with pipe on exhaust ports

--------------------------------------------

TrickFlow aluminum SBC heads with 2.020/1.600

out of box shape and valve job, as shipped

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----139.9-----100.3

.300----200.1-----133.2

.400----234.6-----155.8

.450----238.5----------

.500----237.7-----174.2

.550----238.1----------

.600----237.5-----183.5

.650----236.9----------

.700----238.9-----189.9

***No-Pipe attached, bare exhaust ports

at .700" Lift Exhaust flows =208.7 CFM @ 28

with short pipe attached to heads

-----------------------------------

------------------

MaxRace Software

Meaux Racing Heads

ET_Analyst for DragRacers

Support Israel - Gen 12:3

As far as being able to distinguish between the two designs , it is obvious under a close inspection, when you examine them. If they are almost located at a 90 degree angle to the head surface and parallel to one another, they are straight plug. If they are on an obvious angle (15-20 degrees or so?) they are going to be angle plug heads.

chevy found that angling the plus electrode to point at the exhaust valve and locating it closer to the combustion chamber center allowed for a faster burn requiring less ignition advance curve.

any time you can speed the combustion process up, and still get a full burn ,your wasting less energy, during the compression stroke fighting a rapidly expanding and burning mix of fuel/air with the piston trying to resist the engine spinning in the intended direction,before it reaches tdc and using a far greater percentage of the cylinder pressure generated above the piston,to generate torque after the pistons pasted tdc.

the problem is that it takes time to burn the fuel air mix, so the smaller the combustion area and the more efficient the quench is the faster the burn can be within the limitations of flame front speed, detonation and octane limitations.

BE AWARE, that theres a significant variation in spark plug location between different cylinder head designs,made by different manufacturers ,and theres both strait and angle plug heads and even the angle plug heads vary a good deal between designs, and many headers won,t work with a few cylinder heads in some applications so its almost mandatory that you call and talk too the tech support guys from both the cylinder head and headers manufacturers, to ask if any specific combo has a history of clearance issues BEFORE purchasing your headers or cylinder heads or both.

"Straight Plug vs. Angle Plug heads?

ITS extremely important that you ask questions and get accurate answers , BEFORE purchasing headers about what style cylinder heads the headers are designed to fit, below is pictured a set of headers obviously designed for factory strait plug heads but bolted to a set of angle plug heads making spark plug access and wiring a clearance and heat , destroying ignition wire nightmare

It really looks like those headers ,in the picture you posted directly above, that, your using were designed for use with the angle plug heads,

and use of the strait plug heads causes the spark plug to header tube,

and related ignition wire clearance issues.

this is, unfortunately a very common miss match of components.

look at the heads and the exhaust header tube routing and the difference in clearance,

that the designed angle plug heads use would make on spark plug to header tube clearance.

one of the least understood yet common problems is that the header manufacturers seldom bother to tell you what cylinder heads were used during the header design phase of production of the headers and damn few people purchasing headers bother to do the research or ask detailed questions until they run into problems caused by the design miss match, and yes its very common to find headers designed for strait plug heads can cause similar issues if used with angle plug heads , but that's slightly less common

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

Some people think that angle plug heads produce more power than straight plug heads. This common misconception is not true! In reality, the ONLY benefit to angled plug heads is to provide more spark plug boot clearance with some header designs.

The idea of these designs producing more power came from some early angle designs that placed the plug location closer to the exhaust valve. This WILL create more power, but straight plug designs that have since been moved in the same fashion produce the same power.

BluePrint Engines offers both straight and angle plug design heads – your choice should be based on appearance and cost – not on one being more powerful than the other.

– Tech Tip courtesy of BluePrint Engines"

angle plug

viewtopic.php?f=56&t=3155&p=8423#p8423

with many well designed headers and with rams horn exhaust manifolds the spark plug access is not normally an issue

Stock out of box 461x heads 1.940/1.500

but with very light 3-angle valve job

tested on SF-600 FlowBench

Flow tested at 28" on 4.000 Bore fixture

Lift----Intake----Exhaust

.200---- 99.6-----88.0

.300----155.2-----124.3

.400----189.0-----141.9

.450----190.6----------

.500----190.6-----142.2

.550----192.0----------

.600----192.6-----146.4

*** Short exhaust pipe on exhaust ports

Maxed out porting job, unwelded, 461 X SBC

no epoxy , with 2.055/1.600 valves

tested on SF-600 FlowBench

Flow tested at 28" on 4.000 Bore Fixture

Lift----Intake----Exhaust

.200----131.1-----116.1

.300----187.7-----152.7

.400----230.0-----193.9

.450----243.3----------

.500----259.7-----212.5

.550----266.5----------

.600----273.2-----245.1

.650----278.0----------

.700----282.0-----253.3

.750----283.6----------

***Short exhaust pipe on exhaust ports

Basically this was the sort of Flow

we were getting for C/ED dragster 316 cid

a very long time ago

Note: if ditch near spark plug, between

area around both valves to plug

is welded up ,...then another 4 to 8 cfm

is gained on Intake flow (461 X SBC)

if you also wanted to start welding the entire

chamber floor lowering CCs and increasing

short turn radius on 461x ,

and welding up intake port's roof

water jacket solid .... then it was

worth another 4 to 8 cfm gains .

so some of the very best WELDED up

461x heads were approx 299 cfm @ 28 inches

==========================================

Stock out of box 034 Cast-Iron Bowtie heads

with factory valve job and 2.020/1.600

Tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----117.9----107.9

.300----169.5----123.8

.400----205.0----146.2

.500----216.6----146.6

.550----228.3---------

.600----222.1----148.8

.650----215.8---------

.700----216.8----148.8

.750----217.8---------

***with pipe on exhaust ports

Cast-Iron Chevy Bowtie heads #034 castings

with 2.085/1.580 valves

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----127.7-----104.6

.300----189.2-----158.8

.400----238.5-----204.0

.450----256.6----------

.500----271.0-----216.0

.550----281.5----------

.600----288.6-----218.6

.650----293.3----------

.700----298.4-----221.1

.750----304.3

.800----308.3

.850----311.4

***with pipe on exhaust ports

all out porting but no epoxy or welding

Brodix Track 1 SBC with Manley 2.080/1.600

Best CNC porting ..by Weld Tech

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----125.5-----120.4

.300----189.8-----153.7

.400----245.8-----190.1

.450----269.7----------

.500----286.7-----228.3

.550----295.1----------

.600----294.7-----244.7

.650----301.4----------

.700----301.4-----252.0

.750----300.3----------

***with pipe on exhaust ports

-----------------------------------------

Cast-Iron Chevy Vortec heads #10239906

1.940/1.500 OEM valve job and shape

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----121.4-----98.2

.300----179.4-----123.8

.400----219.2-----137.5

.450----230.6----------

.500----220.8-----146.0

.550----221.6----------

.600----223.1-----151.9

.650----224.7----------

*** No-Pipe attached , bare exhaust ports

--------------------------------------------

Cast-Iron Chevy Vortec heads #10239906

Manley 2.055/1.600 valves

2nd Level porting , not yet all out

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----143.9-----119.5

.300----192.2-----169.9

.400----235.7-----195.5

.450----252.3----------

.500----264.1-----207.0

.550----258.6----------

.600----265.1-----212.6

.650----271.0----------

.700----271.1-----215.6

.750----272.0----------

***No-Pipe attached , bare exhaust ports

-------------------------------------------

Chevy Fast Burn heads with Manley 2.125/1.600

1st Level full porting job, not yet all out

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----134.4

.300----190.0

.400----235.5

.450----254.3

.500----270.4

.550----277.9

.600----270.0

.650----275.0

.700----277.5

.750----279.5

.800----279.5

****No flow numbers available on exhaust

were lost on computer's harddrive !!!

-----------------------------------------

GM Chevy LT-1 aluminum heads 2.055/1.600

1st Level porting

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----138.4----115.3

.300----193.2----154.5

.400----235.7----182.5

.450----250.3---------

.500----261.2----193.2

.550----259.2---------

.600----260.2----200.6

.650----262.2---------

.700----262.2----205.7

.750----263.1---------

.800----264.1---------

***No-Pipe attached , bare exhaust ports

.600" Lift with Pipe flowed = 223.6 cfm

-------------------------------------------

Dart Pro 1 Aluminum 215 CC ports

out of box shape as shipped by Dart

2.055 valve on 2.020 seat lapline

1.600 valve on exhaust

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----128.5----115.3

.300----181.3----148.5

.400----226.3----178.4

.450----243.4---------

.500----257.0----192.1

.550----268.1---------

.600----271.2----198.5

.650----262.2---------

.700----266.1----201.1

.750----266.1---------

.800----261.2----203.2

.850----257.2---------

***No-Pipe attached, bare exhaust ports

------------------------------------------

Dart Pro 1 Aluminum 215 CC ports

2nd Level porting

2.125/1.600 valve combo

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----147.8----111.4

.300----208.0----167.3

.400----251.5----198.9

.450----269.4---------

.500----284.6----214.3

.550----295.3---------

.600----299.6----220.3

.650----304.3---------

.700----308.3----224.1

.750----309.5---------

.800----309.5----227.3

.850----310.3---------

.900----309.9---------

***No-Pipe attached, bare exhaust ports

--------------------------------------------

Dart Pro 1 Aluminum 230 CC ports

out of box shape as shipped by Dart

2.055 / 1.600 Manley valves combo

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----123.0-----117.4

.300----179.4-----147.7

.400----223.1-----175.0

.450----241.7----------

.500----257.0-----193.2

.550----269.6----------

.600----278.7-----193.2

.650----270.4----------

.700----267.3-----204.9

.750----268.1----------

.800----265.7-----208.1

***No-Pipe attached, bare exhaust ports

-----------------------------------------

#492 SBC cast-iron castings (Old LT-1 heads)

Stock out of box factory shape

with 2.020/1.600 valves

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----115.2-----105.4

.300----165.2-----132.5

.400----195.6-----138.5

.450----202.3----------

.500----208.9-----143.0

.550----208.1----------

.600----207.3-----146.6

.650----208.7----------

.700----210.1-----146.6

***with pipe on exhaust ports

---------------------------------------------

World Products - Dart SBC Cast-Iron heads

stock out of box shape and valve job

( as produced for sale in Aug 1988 )

these were some old flow test numbers

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----127.5-----107.9

.300----180.7-----136.8

.400----208.9-----145.8

.450----219.4----------

.500----220.4-----150.5

.550----226.8----------

.600----233.3-----154.4

.650----236.7----------

.700----238.3-----155.7

***with pipe on exhaust ports

--------------------------------------------

TrickFlow aluminum SBC heads with 2.020/1.600

out of box shape and valve job, as shipped

Flow tested on SF-600 FlowBench

Flow tested at 28" on 4.000" Bore Fixture

Lift----Intake----Exhaust

.200----139.9-----100.3

.300----200.1-----133.2

.400----234.6-----155.8

.450----238.5----------

.500----237.7-----174.2

.550----238.1----------

.600----237.5-----183.5

.650----236.9----------

.700----238.9-----189.9

***No-Pipe attached, bare exhaust ports

at .700" Lift Exhaust flows =208.7 CFM @ 28

with short pipe attached to heads

-----------------------------------

------------------

MaxRace Software

Meaux Racing Heads

ET_Analyst for DragRacers

Support Israel - Gen 12:3

Last edited by a moderator: