I managed to have a crack at measuring my piston to deck clearance this evening... which is the next step in confirming which heads I'm going to buy..... The machine shop recommended that I go with 64cc heads, potentially the e-streets, for value for money.. I was wondering if I might be better with the 70cc, both for getting the right compression ratios and also as Grumpy mentioned the bigger chamber is less likely to shroud or restrict valve curtain flow.

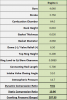

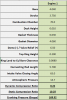

I now have one more piece of the puzzle figured out Now I'm after some help filling the blanks in Rick's great compression ratio calculator, with an end goal of confirming a cam and heads..

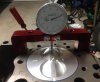

I seemed to get approximately the same measurement in all four corners of the block.. I say approximately because my cheap dial gauge was a little temperamental and I found that how the rod sat on the crank and other directions of wiggle, tended to change the measurement.. I used the same rod and piston and edged the piston with tape to steady it in the bore, which helped. I measured along the centreline of the wrist pin at each end. All four corners were approx 0.009" give or take...

(I'm reading that right yes?)

So that can now go into the calculator... There are still a lot of gaps... I have bore 4.040 and stroke 3.750, deck height 0.009

, the valve reliefs I'm estimating at 6cc? based on other info online.. I'll contact the distributor and find out.. they have 4 valve reliefs, as you can see in the pic above.. then there are the couple of less important measurements I have left alone and the rod length at 5.7..

I need help and recommendations on:

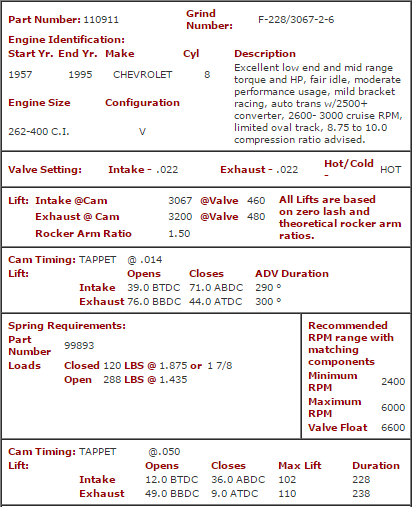

1. Cam - Grumpy has made a few recommendations... I recall a Crane Cam 110911 being a possibility

http://www.cranecams.com/product/cart.php?m=product_detail&p=23967

How do I enter that into the Intake Valve Closing Angle Calculator?

1. Head chamber size - I'm going to have to compromise on the heads and probably go with the e-streets, which will not take much lift... But I can change springs etc to help with that yes? They come in 64cc and 70cc - so with IVCA and the appropriate gasket diameter and thickness, which chamber size do I need, to get the best DCR/SCR? Keeping in mind that it will run on 98RON which is equivalent to 93-94 in US..

How do I fill these gaps?