brian, your calcs are WRONG!,

if isky suggested a cam with LESS duration that will produce MORE compression

will work ,how can a similar cam with marginally longer duration produce higher compression in the same engine? (it won,t it will result in marginally lower effective dynamic compression)

Ive used that cam in similar engines with zero issues,

if a slightly milder cam in ricks T-bucket in a similar engine,works rather well,

and the crane cam has a slightly longer valve timing holding the valves open slightly longer,

that effectively results in even lower dynamic compression, will tend to reduce marginally the effective compression, but remember were talking only a couple degrees different, probably less than .2 in compression, (8.2 vs 8.1)

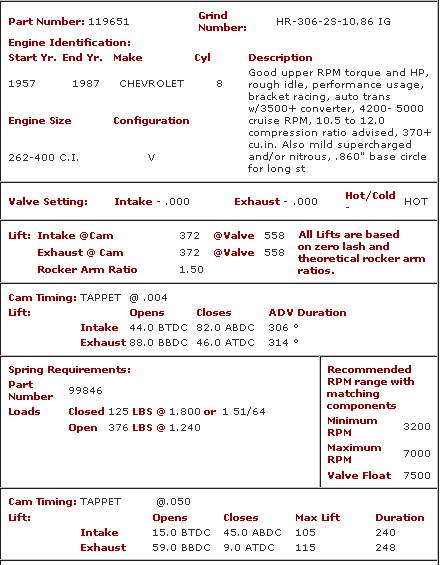

that issky cam has a .050 intake valve close at 42 abdc

that crower cam has a .050 intake valve close at 44 abdc

that crane cam has a .050 intake valve close at 45 abdc

look heres several cam manufacturers numbers why not call each, and average the suggested cams duration and lca

read this thread

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

crane (386)310-4875

crower 619.661.6477

https://www.crower.com/camshafts.html?cat=854

erson 800-641-7920

http://www.pbm-erson.com/UserFiles/Documents/Catalogs/2013 erson catalog.pdf

lunati..662-892-1500

http://www.lunatipower.com/Performance-Cams.aspx

ISKY 323.770.0930

clay smith 714-523-0530

herbert cams 714-491 -2267

if isky suggested a cam with LESS duration that will produce MORE compression

will work ,how can a similar cam with marginally longer duration produce higher compression in the same engine? (it won,t it will result in marginally lower effective dynamic compression)

Ive used that cam in similar engines with zero issues,

if a slightly milder cam in ricks T-bucket in a similar engine,works rather well,

and the crane cam has a slightly longer valve timing holding the valves open slightly longer,

that effectively results in even lower dynamic compression, will tend to reduce marginally the effective compression, but remember were talking only a couple degrees different, probably less than .2 in compression, (8.2 vs 8.1)

that issky cam has a .050 intake valve close at 42 abdc

that crower cam has a .050 intake valve close at 44 abdc

that crane cam has a .050 intake valve close at 45 abdc

look heres several cam manufacturers numbers why not call each, and average the suggested cams duration and lca

read this thread

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

crane (386)310-4875

crower 619.661.6477

https://www.crower.com/camshafts.html?cat=854

erson 800-641-7920

http://www.pbm-erson.com/UserFiles/Documents/Catalogs/2013 erson catalog.pdf

lunati..662-892-1500

http://www.lunatipower.com/Performance-Cams.aspx

ISKY 323.770.0930

clay smith 714-523-0530

herbert cams 714-491 -2267

Last edited: