legerwn

Active Member

Whats your thoughts on using aluminum tubing for fuel lines?

Looking over the internet some suggest not using it due to hardening and becoming brittle but the retailers offer it as a replacement.

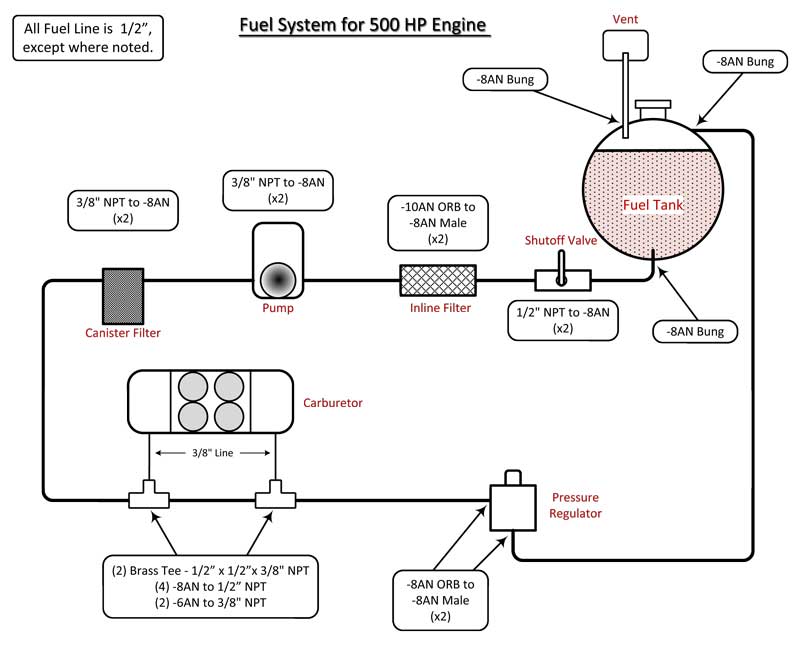

Not interested in adding a sump to my tank but would like to add a couple of fuel cell bulkhead fittings to help the electric pump out so it don't have to lift the fuel.

Was also going to add a small baffle to the internal of the tank around the bulkhead fittings to reduce the chance of fuel leaving the area around the bulkhead fittings when the fuel level gets low.

Read where grumpyvette has the local hose shop make fuel lines for him, may go talk with them and see what they can do.

thanks

Neal

Looking over the internet some suggest not using it due to hardening and becoming brittle but the retailers offer it as a replacement.

Not interested in adding a sump to my tank but would like to add a couple of fuel cell bulkhead fittings to help the electric pump out so it don't have to lift the fuel.

Was also going to add a small baffle to the internal of the tank around the bulkhead fittings to reduce the chance of fuel leaving the area around the bulkhead fittings when the fuel level gets low.

Read where grumpyvette has the local hose shop make fuel lines for him, may go talk with them and see what they can do.

thanks

Neal