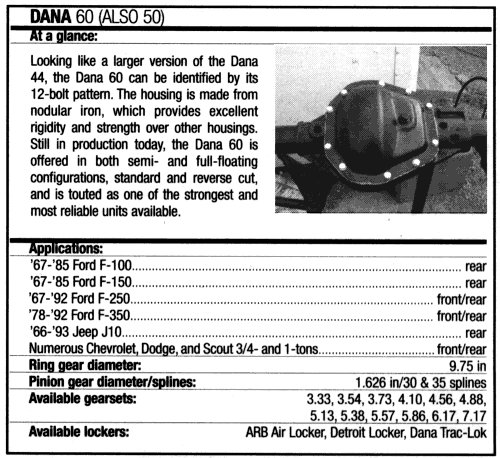

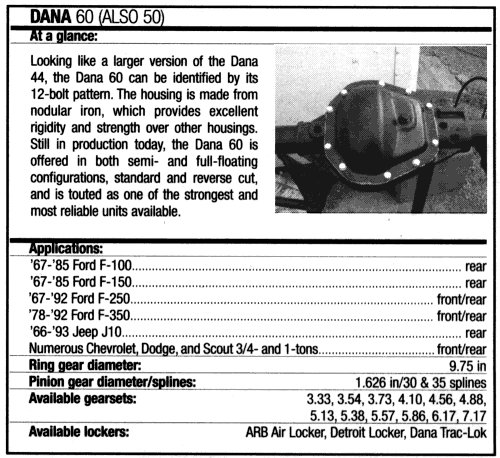

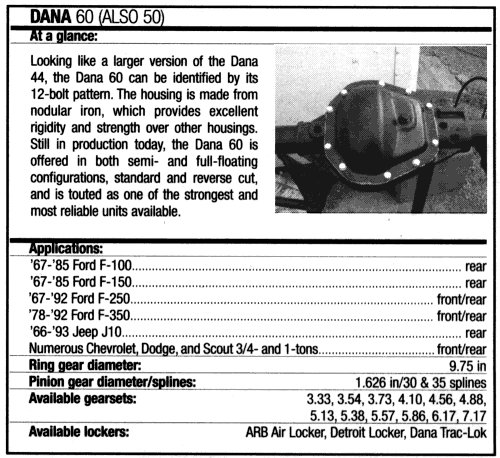

IVE used ford 9", Chevy 12 bolt, 10 bolt Pontiac rears and several others ( EVENTUALLY COMPONENTS OF EACH WERE TWISTED INTO SCRAP IN MOST CASES),now I'll admit I have limited experience with the ,smaller imports and z cars , having only helped on a few , maybe a dozen v8 conversions and generally build big block muscle cars , like GTO, chevelles, camaros, novas , firebirds,corvettes, and street rods like t-buckets and vegas with big block engines, but Ive certainly shredded my share of 10 bolt, and 12 bolt chevy and a few 9" ford differentials in the process and learned what parts hold up as a result. I'm a firm believer in the use of the DANA 60 , as it is without doubt the TOUGHEST of the bunch and the strongest rear differential IVE used, IVE NEVER MANAGED TO HURT ONE YET!

heres the main point I worry about, in a differential, its durability once you install a serious engine, and its the fact that I,ve shredded several 12 bolt rear differentials in the past in camaros, chevelles and similar cars and when you break a stock 12 bolt rear axle the wheels come off the car.

the hot ticket was supposed to be a 9" ford with aftermarket axles, but Ive busted those also.

Ive used dana 60 rear differentials in most of my serious race car builds and have never yet hurt one even with a 750 hp/700 ft lbs torque nitrous big block running slicks

Id also point out that a 12 bolt rear differential will need aftermarket axles and C-clip eliminators to be safe with the use of slicks and high torque load launches.

if you have a car with a G.M. rear the FORD 9" is a popular upgrade but I much prefer the DANA 60

Ive shredded, and destroyed, several stock and 12 bolt differentials modified with aftermarket axles with a few big block engines Ive built so I generally advise use of a DANA 60 based rear differential, as Ive yet to break a properly set up DANA 60 and Ive had 750 hp cars beating on them for several seasons racing.

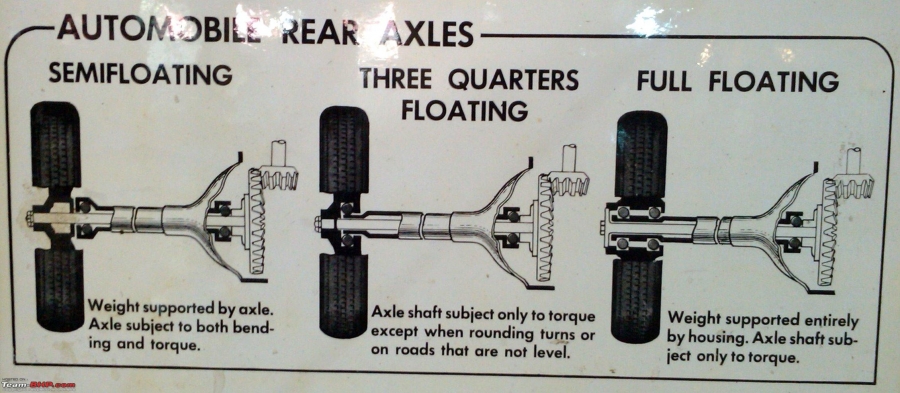

IF you some how manage to snap a dana 60 axle the car coasts to a stop with no engine power reaching the rear tires, do that same ,snap an axle trick with a stock 12 bolt G.M. differential and the axle and tire comes out of the differential while your driving , which can be a huge problem

http://www.markwilliams.com/bulletproof.aspx

http://www.moserengineering.com/moser-60-musclepak-muscle-pak-pack-dana.item

http://www.hotrod.com/techarticles/driv ... l_install/

http://www.carcraft.com/techarticles/11 ... ewall.html

http://www.taylor-race.com/pdf/understa ... ntials.pdf

http://www.strangeengineering.net/websi ... stallation

http://www.rogueengineering.com/bmw/DIFF.html

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.streetperformance.com/index.html?catid=2460

http://www.billavista.com/tech/Articles/Dana_60_Front_Axle_Bible/

http://static.summitracing.com/global/i ... 890633.pdf

http://www.raceindustry.com/index.html?catid=2460

http://www.bing.com/videos/search?q=rac ... 9243EF6FCC

http://www.strangeengineering.net/high-performance-street/complete-rear-end-assemblies/s60.html

http://www2.dana.com/pdf/XGI.pdf

http://www.strangeengineering.net/

http://www.circletrack.com/drivetrainte ... _delivery/

http://www.chevyhiperformance.com/techa ... omparison/

http://www.crawlpedia.com/thick_gears.htm

http://www.strangeengineering.net/catal ... ?q=dana+60

http://www.strangeengineering.net/gm-12 ... spool.html

http://www.strangeengineering.net/catal ... olt+c-clip

http://www.strangeengineering.net/catal ... ++complete

http://www.strangeengineering.net/high- ... nents.html

http://www.rsgear.com/articles/1996_08.pdf

READ THRU THE LINKED INFO

http://www.carcraft.com/techarticles/cc ... to_01.html

http://www.carcraft.com/techarticles/cc ... ewall.html

https://en.wikipedia.org/wiki/Dana_60

viewtopic.php?f=71&t=1934&p=5126#p5126

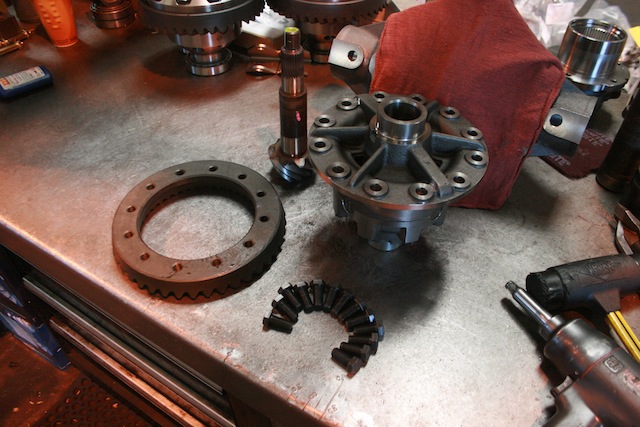

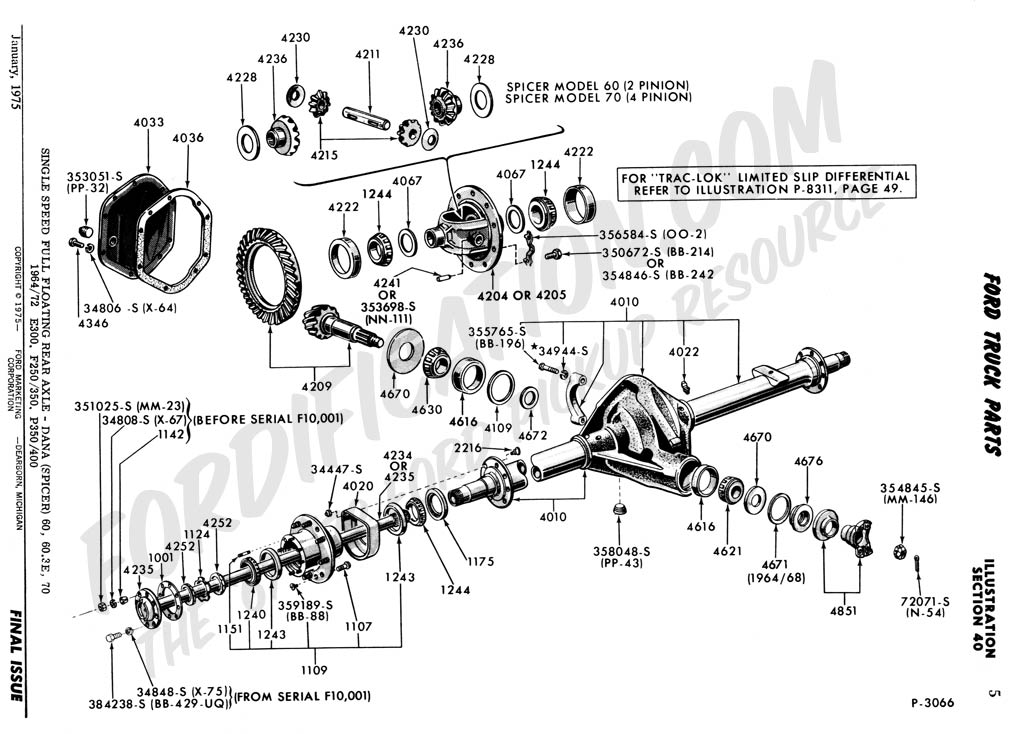

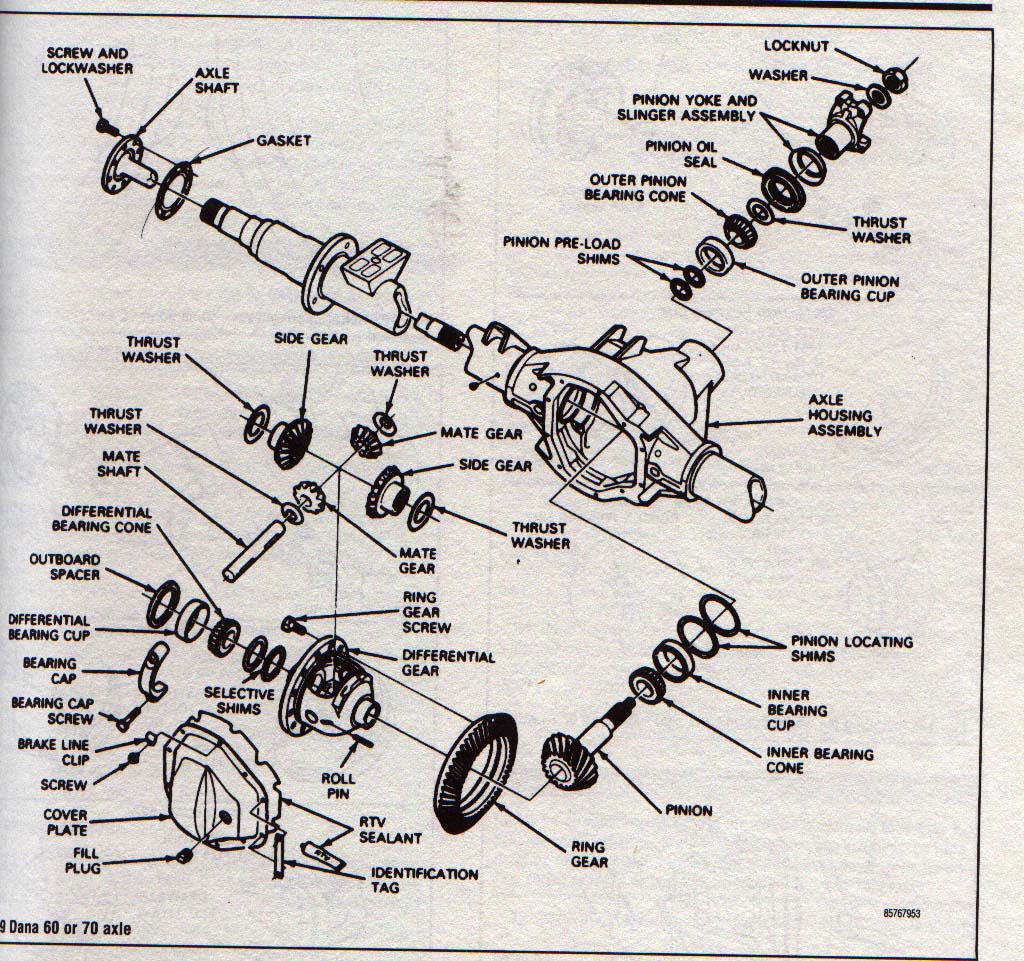

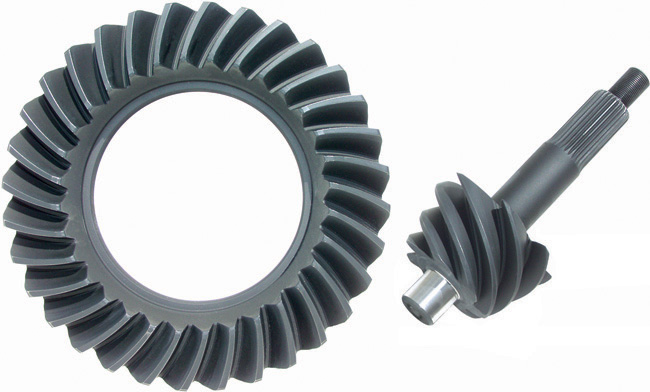

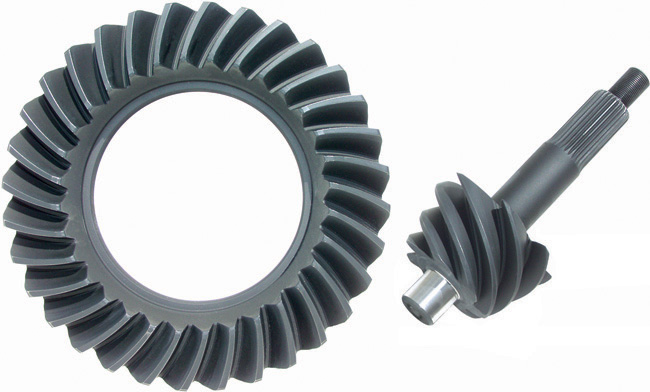

notice the extended pinion support on the ford pinion gear

BTW just like on an engine installing a STRONG MAGNET near a lubricant drain plug on a differential too trap metallic debris from gear ear tends to increase durability

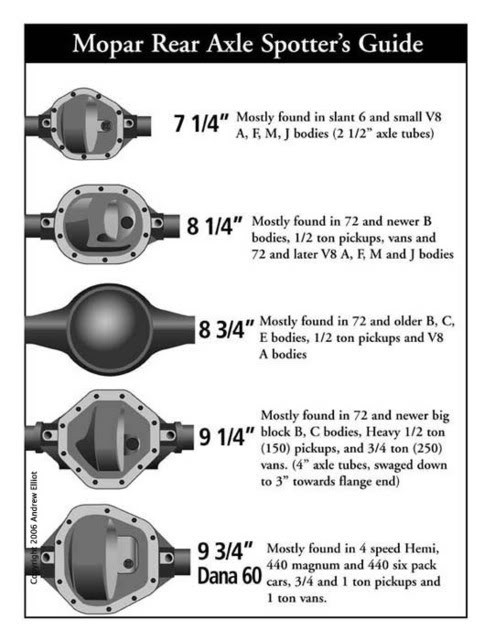

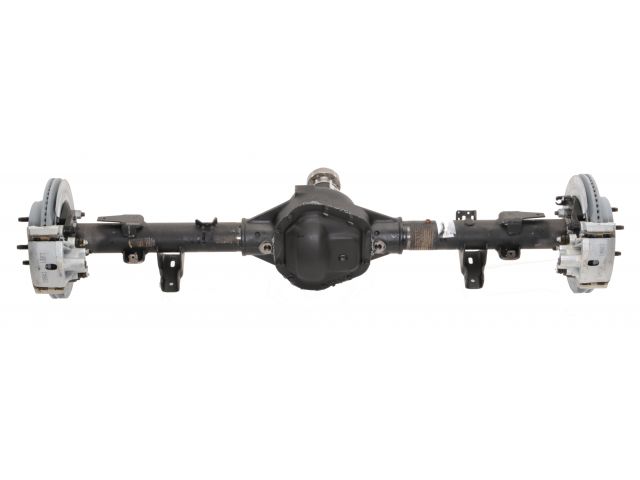

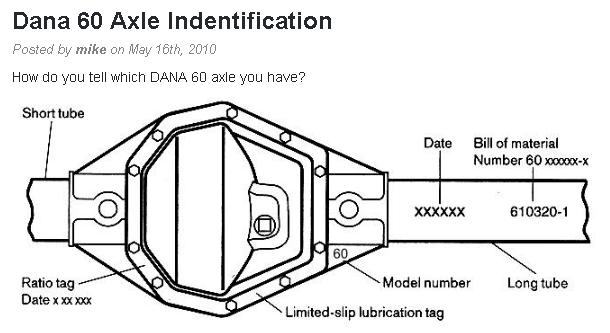

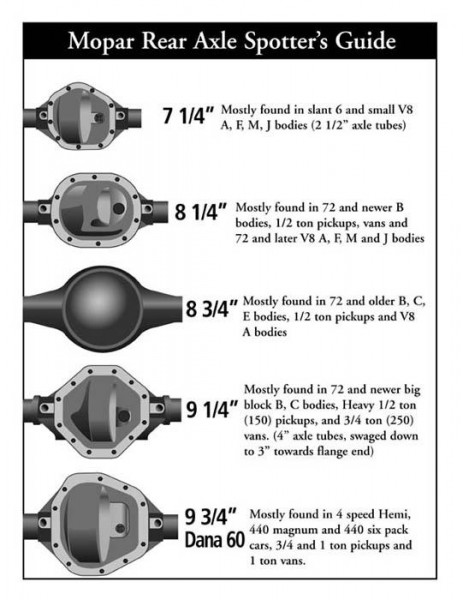

If your looking in salvage yards for a dana 60 rear differential, the forward housing, on performance car versions has 5 lug axles,it has provisions to bolt on a snubber on the car versions thats missing on the truck versions and the

u-joint, yoke or hub used on trucks doesn,t interchange with the car version

some truck versions use different axles

there are 6 lug and full float versions in trucks and a very similar looking dana 70

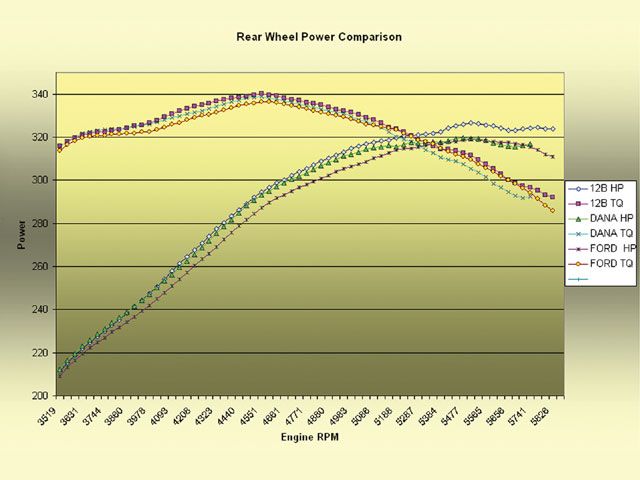

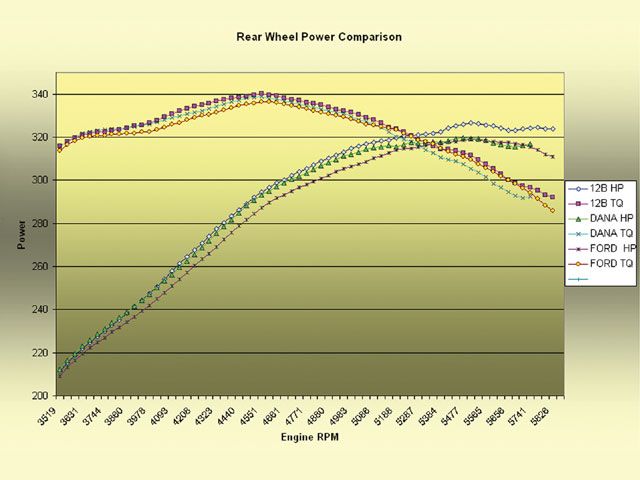

dana 60 vs 12 bolt chevy

http://www.hemmings.com/mus/stories/200 ... ure27.html

http://www.drivetrain.com/parts_catalog ... parts.html

viewtopic.php?f=71&t=4810

http://en.wikipedia.org/wiki/Dana_60

http://www.moparmusclemagazine.com/tech ... index.html

http://www.currieenterprises.com/cestor ... rends.aspx

http://www.autohobbydigest.com/dana.html

viewtopic.php?f=71&t=10690&p=46305#p46305

http://www.spohn.net/shop/1982-1992-GM- ... plete.html

http://www.carcraft.com/techarticles/cc ... to_01.html

http://broncograveyard.com/bronco/c-244 ... 0_rear.htm

http://broncograveyard.com/bronco/b-495 ... ana_60.htm

viewtopic.php?f=71&t=555

http://www.diffgears.com/shop/dana-60

http://www.moserengineering.com/Pages/D ... etrac.html

http://www.cachassisworks.com/CatPages/CAC/CAC0204.pdf

BTW banjo fittings require a seal washer on both sides

keep in mind , when your fabricating a rear differential that a good custom shop has little problem producing axles that fit custom bearing sizes and lengths, or can center the differential with different than stock axle lengths ,theres no reason that lets say the axle tubes on the dana rear can,t be cut shorter and have ford outer bearings and flanges welded on and ford brakes and a chevy lug bolt pattern fabricated, you need to discus your options not just assume everything remains constant or single brand consistent

Popular Axle Carrier Breaks

Axle Low Carrier High Carrier

AAM 9.25" All / No Break Same

AAM 9.25" IFS All / No Break Same

AAM 10.5" All / No Break Same

AAM 11.5" All / No Break Same

AMC Model 20 2.73 & Down 3.08 & Up

AMC Model 35 3.31 & Down 3.54 & Up

Chrysler 7.25" 2.47 & Down 2.76 & Up

Chrysler 8.25" 2.47 & Down 2.76 & Up

Chrysler 8.75" (All) All / No Break Same

Chrysler 9.25" All / No Break Same

Chrysler 10.5" All / No Break Same

Chrysler 11.5" All / No Break Same

Dana 27 3.73 & Down 3.92 & Up

Dana 30 3.54 & Down 3.73 & Up

Dana 35 3.31 & Down 3.54 & Up

Dana 36 ICA 2.73 & Down 3.07 & Up

Dana 44 3.73 & Down 3.92 & Up

Dana 50 All / No Break Same

Dana 60 4.10 & Down 4.56 & Up

Dana 61 All / No Break Same

Dana 70 4.10 & Down 4.56 & Up

Dana 80 3.73 & Down 4.10 & Up

Ford 7.5" All / No Break Same

Ford 8" All / No Break Same

Ford 8.8" All / No Break Same

Ford 9 Inch All / No Break Same

Ford 9.75" All / No Break Same

Ford 10.25" / 10.5" All / No Break Same

Axle Low Carrier High Carrier

GM 7.2" IFS 3.08 & Down 3.42 & Up

GM 7.5" / 7.6" 3.08 & Down 3.23 & Up

GM 8.0" 3.08 & Down 3.31 & Up

GM 8.2" 2.76 & Down 3.07 & Up

GM 8.2" BOP 2.76 & Down / 2.94 to 3.23 / 3.31 & Up

GM 8.25" IFS All / No Break Same

GM 8.5" / 8.6" 2.56 & Down 2.73 & Up

GM 9.25" IFS All / No Break Same

GM 9.5" All / No Break Same

GM 10.5" 14 Bolt 4.10 & Down 4.56 & Up

GM 11.5" All / No Break Same

GM 55P / 55T All / No Break Same

GM 12 Bolt Car 2.76 & Down / 3.07 to 3.90 / 4.10 & Up

GM 12 Bolt Truck 2.73 & Down / 2.76 to 3.42 / 3.73 & Up

Suzuki Samurai All / No Break Same

Toyota 7.5" All / No Break Same

Toyota 8" (4Cyl) All / No Break Same

Toyota 8" TV6 All / No Break Same

Toyota T100 All / No Break Same

Toyota 9.5" All / No Break Same

Toyota 10.5" All / No Break Same

Land Cruiser 8" All / No Break Same

Land Cruiser 9.5" All / No Break Same

Axle Carrier Break data is ©Copyright Crawlpedia.com - Please provide a link back to this page when copying.

Data is accurate to the best of our knowledge through 2013 and is offered as-is with no guarantee.

Other Ring and Pinion Gear Resources

Gear Ratio Finder

Gear Ratio Calculator

Ring and Pinion Setup Specs

Shop: Yukon Ring and Pinion Gears

heres the main point I worry about, in a differential, its durability once you install a serious engine, and its the fact that I,ve shredded several 12 bolt rear differentials in the past in camaros, chevelles and similar cars and when you break a stock 12 bolt rear axle the wheels come off the car.

the hot ticket was supposed to be a 9" ford with aftermarket axles, but Ive busted those also.

Ive used dana 60 rear differentials in most of my serious race car builds and have never yet hurt one even with a 750 hp/700 ft lbs torque nitrous big block running slicks

Id also point out that a 12 bolt rear differential will need aftermarket axles and C-clip eliminators to be safe with the use of slicks and high torque load launches.

if you have a car with a G.M. rear the FORD 9" is a popular upgrade but I much prefer the DANA 60

Ive shredded, and destroyed, several stock and 12 bolt differentials modified with aftermarket axles with a few big block engines Ive built so I generally advise use of a DANA 60 based rear differential, as Ive yet to break a properly set up DANA 60 and Ive had 750 hp cars beating on them for several seasons racing.

IF you some how manage to snap a dana 60 axle the car coasts to a stop with no engine power reaching the rear tires, do that same ,snap an axle trick with a stock 12 bolt G.M. differential and the axle and tire comes out of the differential while your driving , which can be a huge problem

http://www.markwilliams.com/bulletproof.aspx

http://www.moserengineering.com/moser-60-musclepak-muscle-pak-pack-dana.item

http://www.hotrod.com/techarticles/driv ... l_install/

http://www.carcraft.com/techarticles/11 ... ewall.html

http://www.taylor-race.com/pdf/understa ... ntials.pdf

http://www.strangeengineering.net/websi ... stallation

http://www.rogueengineering.com/bmw/DIFF.html

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.streetperformance.com/index.html?catid=2460

http://www.billavista.com/tech/Articles/Dana_60_Front_Axle_Bible/

http://static.summitracing.com/global/i ... 890633.pdf

http://www.raceindustry.com/index.html?catid=2460

http://www.bing.com/videos/search?q=rac ... 9243EF6FCC

http://www.strangeengineering.net/high-performance-street/complete-rear-end-assemblies/s60.html

http://www2.dana.com/pdf/XGI.pdf

http://www.strangeengineering.net/

http://www.circletrack.com/drivetrainte ... _delivery/

http://www.chevyhiperformance.com/techa ... omparison/

http://www.crawlpedia.com/thick_gears.htm

http://www.strangeengineering.net/catal ... ?q=dana+60

http://www.strangeengineering.net/gm-12 ... spool.html

http://www.strangeengineering.net/catal ... olt+c-clip

http://www.strangeengineering.net/catal ... ++complete

http://www.strangeengineering.net/high- ... nents.html

http://www.rsgear.com/articles/1996_08.pdf

READ THRU THE LINKED INFO

http://www.carcraft.com/techarticles/cc ... to_01.html

http://www.carcraft.com/techarticles/cc ... ewall.html

https://en.wikipedia.org/wiki/Dana_60

viewtopic.php?f=71&t=1934&p=5126#p5126

notice the extended pinion support on the ford pinion gear

BTW just like on an engine installing a STRONG MAGNET near a lubricant drain plug on a differential too trap metallic debris from gear ear tends to increase durability

If your looking in salvage yards for a dana 60 rear differential, the forward housing, on performance car versions has 5 lug axles,it has provisions to bolt on a snubber on the car versions thats missing on the truck versions and the

u-joint, yoke or hub used on trucks doesn,t interchange with the car version

some truck versions use different axles

there are 6 lug and full float versions in trucks and a very similar looking dana 70

dana 60 vs 12 bolt chevy

http://www.hemmings.com/mus/stories/200 ... ure27.html

http://www.drivetrain.com/parts_catalog ... parts.html

viewtopic.php?f=71&t=4810

http://en.wikipedia.org/wiki/Dana_60

http://www.moparmusclemagazine.com/tech ... index.html

http://www.currieenterprises.com/cestor ... rends.aspx

http://www.autohobbydigest.com/dana.html

viewtopic.php?f=71&t=10690&p=46305#p46305

http://www.spohn.net/shop/1982-1992-GM- ... plete.html

http://www.carcraft.com/techarticles/cc ... to_01.html

http://broncograveyard.com/bronco/c-244 ... 0_rear.htm

http://broncograveyard.com/bronco/b-495 ... ana_60.htm

viewtopic.php?f=71&t=555

http://www.diffgears.com/shop/dana-60

http://www.moserengineering.com/Pages/D ... etrac.html

http://www.cachassisworks.com/CatPages/CAC/CAC0204.pdf

BTW banjo fittings require a seal washer on both sides

keep in mind , when your fabricating a rear differential that a good custom shop has little problem producing axles that fit custom bearing sizes and lengths, or can center the differential with different than stock axle lengths ,theres no reason that lets say the axle tubes on the dana rear can,t be cut shorter and have ford outer bearings and flanges welded on and ford brakes and a chevy lug bolt pattern fabricated, you need to discus your options not just assume everything remains constant or single brand consistent

Popular Axle Carrier Breaks

Axle Low Carrier High Carrier

AAM 9.25" All / No Break Same

AAM 9.25" IFS All / No Break Same

AAM 10.5" All / No Break Same

AAM 11.5" All / No Break Same

AMC Model 20 2.73 & Down 3.08 & Up

AMC Model 35 3.31 & Down 3.54 & Up

Chrysler 7.25" 2.47 & Down 2.76 & Up

Chrysler 8.25" 2.47 & Down 2.76 & Up

Chrysler 8.75" (All) All / No Break Same

Chrysler 9.25" All / No Break Same

Chrysler 10.5" All / No Break Same

Chrysler 11.5" All / No Break Same

Dana 27 3.73 & Down 3.92 & Up

Dana 30 3.54 & Down 3.73 & Up

Dana 35 3.31 & Down 3.54 & Up

Dana 36 ICA 2.73 & Down 3.07 & Up

Dana 44 3.73 & Down 3.92 & Up

Dana 50 All / No Break Same

Dana 60 4.10 & Down 4.56 & Up

Dana 61 All / No Break Same

Dana 70 4.10 & Down 4.56 & Up

Dana 80 3.73 & Down 4.10 & Up

Ford 7.5" All / No Break Same

Ford 8" All / No Break Same

Ford 8.8" All / No Break Same

Ford 9 Inch All / No Break Same

Ford 9.75" All / No Break Same

Ford 10.25" / 10.5" All / No Break Same

Axle Low Carrier High Carrier

GM 7.2" IFS 3.08 & Down 3.42 & Up

GM 7.5" / 7.6" 3.08 & Down 3.23 & Up

GM 8.0" 3.08 & Down 3.31 & Up

GM 8.2" 2.76 & Down 3.07 & Up

GM 8.2" BOP 2.76 & Down / 2.94 to 3.23 / 3.31 & Up

GM 8.25" IFS All / No Break Same

GM 8.5" / 8.6" 2.56 & Down 2.73 & Up

GM 9.25" IFS All / No Break Same

GM 9.5" All / No Break Same

GM 10.5" 14 Bolt 4.10 & Down 4.56 & Up

GM 11.5" All / No Break Same

GM 55P / 55T All / No Break Same

GM 12 Bolt Car 2.76 & Down / 3.07 to 3.90 / 4.10 & Up

GM 12 Bolt Truck 2.73 & Down / 2.76 to 3.42 / 3.73 & Up

Suzuki Samurai All / No Break Same

Toyota 7.5" All / No Break Same

Toyota 8" (4Cyl) All / No Break Same

Toyota 8" TV6 All / No Break Same

Toyota T100 All / No Break Same

Toyota 9.5" All / No Break Same

Toyota 10.5" All / No Break Same

Land Cruiser 8" All / No Break Same

Land Cruiser 9.5" All / No Break Same

Axle Carrier Break data is ©Copyright Crawlpedia.com - Please provide a link back to this page when copying.

Data is accurate to the best of our knowledge through 2013 and is offered as-is with no guarantee.

Other Ring and Pinion Gear Resources

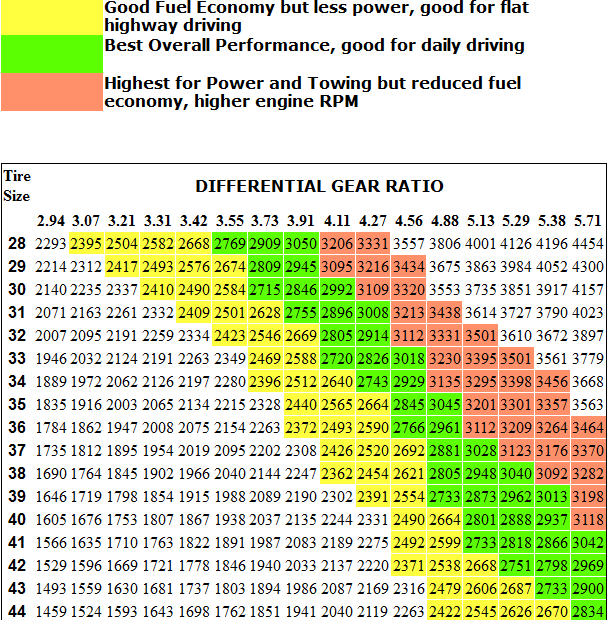

Gear Ratio Finder

Gear Ratio Calculator

Ring and Pinion Setup Specs

Shop: Yukon Ring and Pinion Gears

Last edited by a moderator: