Thanks Grumpy. I was comparing the height of the Edelbrock Performer RPM (not air-gap)

to the Weiand Stealth. The Edelbrock is at least 1" taller than the Stealth, and the Stealth is taller

than the 8000. So I have decided to leave the 8000 in place and try the spacer above with a

screen added.

I bought that bolt-on Ram Air IV hood. I don't know what brand it is, but it certainly is not flimsy

and could weigh almost as much as the stock hood. Not only does it have the "nostrils" to let cool

air in, it also has ovals cut out at the rear under the cowl to either suck in more cool air or can let

hot air out. So I will not have to add heat extractor louvers. The extra height of the hood will let

me add a carb spacer as well as change the air cleaner lid to the taller version so I can use the 1"

taller air filter.

While we are on the subject, while I was looking through my carb spacers and intake manifolds, I

found a few items I bought from ebay that I forgot about. Is this what I have to look forward to as

I get older - I'm only 49.

This may come in handy.

I picked up this Victor Jr intake.....

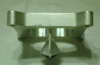

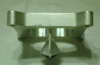

and it came with this home-made turtle spacer.

It will help direct the air/fuel mixture into the runners.

I made this angled spacer a while back. If I ever got around to it, I was going to make a new top plate for a Crossfire

intake manifold and use this to mount the carb.

It started out as one of these. I cut it down the middle and milled each half at an angle. Then I added locating pins

and drilled and tapped for a flat head bolt and bolted the 2 halves together with Permatex in between.

It turns out that someone makes these.

I need to make my engine compartment look like this before I'm ready to install the engine.