Hey All,

Time to step up...

I did a run just a few days ago with a babyblown SBC 400 with roller cam and AFR 210 heads. and the very best I could get out of it was high 12s.

I guess I out grew that B&M 144. It improves the mid range decently, but the top end falls short of my expectations. Back from dyno, I managed to squeeze out 478 HP at 5000 rpm and 520 TQ at 3500/4500. PSI ranged from 5 to 7 and that was pushing the blower to the limit. At the track the guy on the other side would get away at the top of each gear.

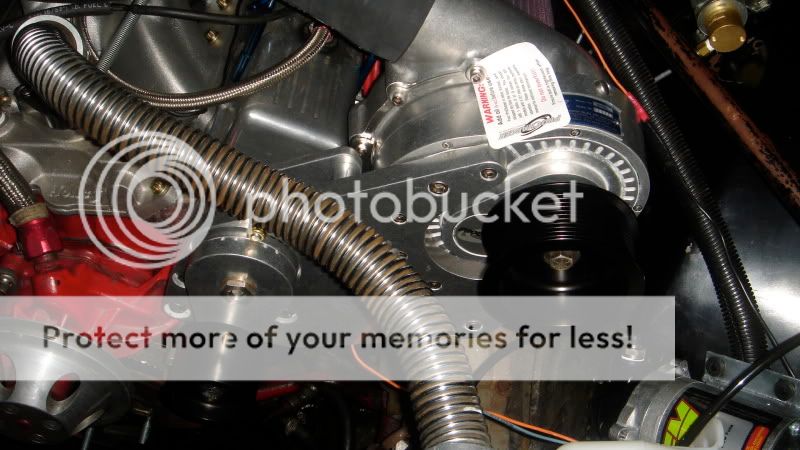

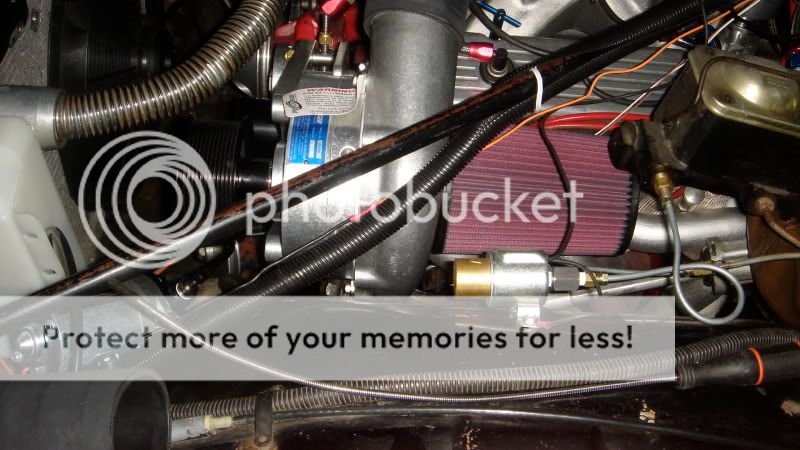

Soooo, I decided to resell my baby and step up to a D1-SC.

I'll document and post dyno results here.

:mrgreen: D

Time to step up...

I did a run just a few days ago with a babyblown SBC 400 with roller cam and AFR 210 heads. and the very best I could get out of it was high 12s.

I guess I out grew that B&M 144. It improves the mid range decently, but the top end falls short of my expectations. Back from dyno, I managed to squeeze out 478 HP at 5000 rpm and 520 TQ at 3500/4500. PSI ranged from 5 to 7 and that was pushing the blower to the limit. At the track the guy on the other side would get away at the top of each gear.

Soooo, I decided to resell my baby and step up to a D1-SC.

I'll document and post dyno results here.

:mrgreen: D