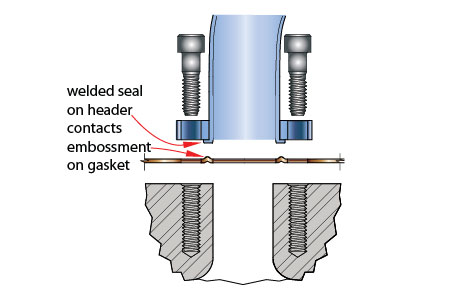

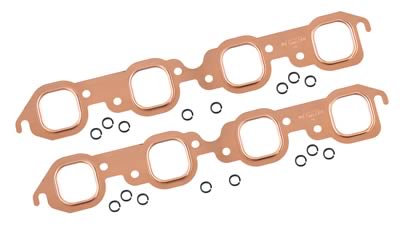

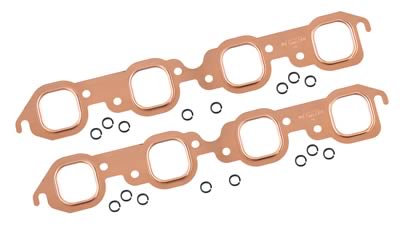

if the header flange is strait and flat and your using a decent header gasket youll rarely have problems with any material,(personally I prefer the copper ones) and if youve coated the bolt or stud threads in the heads with ANTI-SEIZE like you should have, almost any decent 6"-8" box end wrench can be used to snug the bolts or nuts on the studs up firmly.

but at times youll want those header bolts or socket head cap screw bolts

due to clearance or tool access issues, but if you can use STUDS as they provide a better clamp force and are far less likely to screw up the threaded holes in the cylinder heads

on aluminum head its almost alway's best to use studs to secure headers when you can,

as a stud has the threads full length engaged and very low stress , and significantly more surface area spreading the load,

than a bolt will ever allow,

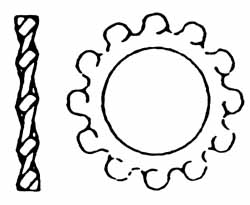

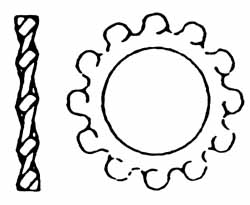

STAR LOCK WASHERS GO BETWEEN THE CLAMP WASHER AND STUD NUTS

this is very common on some heads and the brand of header , its gasket flange design and the type of exhaust gasket used effects your results, paper or paper with metallic foil composite gaskets tend to burn thru if not 100% evenly clamped, as the least leak allows burn thru,copper header gaskets and use of proper bolts on the header flange tends to help, anti seize on the threads helps

http://www.summitracing.com/parts/MRG-3409/?rtype=10

http://www.summitracing.com/parts/SUM-111405/

http://garage.grumpysperformance.com/index.php?threads/sources-for-headers.1247/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://www.stage8.com

http://store.summitracing.com/partdetail.asp?part=ARP-400-1101&autoview=sku

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-SP1502&N=700+324400+115&autoview=sku

http://store.summitracing.com/egnsearch.asp?N=700+115+317370&D=317370

I think youll find that in some applications socket head cap screws are easier to use/install

if your having a difficult time accessing the header bolts due to wrench or socket clearance issures

try 12 point metric sockets also, once thier out out replace all the bolts with stainless socket head cap screws, and use anti seize on the threads, with star lock washers under thier heads

but at times youll want those header bolts or socket head cap screw bolts

due to clearance or tool access issues, but if you can use STUDS as they provide a better clamp force and are far less likely to screw up the threaded holes in the cylinder heads

on aluminum head its almost alway's best to use studs to secure headers when you can,

as a stud has the threads full length engaged and very low stress , and significantly more surface area spreading the load,

than a bolt will ever allow,

STAR LOCK WASHERS GO BETWEEN THE CLAMP WASHER AND STUD NUTS

this is very common on some heads and the brand of header , its gasket flange design and the type of exhaust gasket used effects your results, paper or paper with metallic foil composite gaskets tend to burn thru if not 100% evenly clamped, as the least leak allows burn thru,copper header gaskets and use of proper bolts on the header flange tends to help, anti seize on the threads helps

http://www.summitracing.com/parts/MRG-3409/?rtype=10

http://www.summitracing.com/parts/SUM-111405/

http://garage.grumpysperformance.com/index.php?threads/sources-for-headers.1247/

http://garage.grumpysperformance.com/index.php?threads/building-custom-headers.961/

http://www.stage8.com

http://store.summitracing.com/partdetail.asp?part=ARP-400-1101&autoview=sku

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-SP1502&N=700+324400+115&autoview=sku

http://store.summitracing.com/egnsearch.asp?N=700+115+317370&D=317370

I think youll find that in some applications socket head cap screws are easier to use/install

if your having a difficult time accessing the header bolts due to wrench or socket clearance issures

try 12 point metric sockets also, once thier out out replace all the bolts with stainless socket head cap screws, and use anti seize on the threads, with star lock washers under thier heads

Last edited by a moderator: