A warm hello to all. I am running a 67SS Chevelle, look forward to experience of so many knowledgeable people on the site!

Hi,

I guess first off I should be clear and honest to myself about my goal, which when I first started the year before last I was thinking street /strip. I am looking more for street I guess in most terms as that is what I use it for. I did not make it out once to the track last year, possibly get there this year but nothing serious really, some fun ¼ mile runs , But definitely always take it out on the street a few times a week on nice evenings.

I run street tires , BF Goodrich P265-60-15’s so nothing too fancy, and with correct combination on a 496 you would think they would be quite easy to spin the rubber right off if you felt like it on a roll. Currently I could only get a small chirp when putting it down and had to rev it up quite a bit to let the back end loose. I couldn’t get it to let loose say between shifts 1 to 2, or 2-3 etc. Once revs up to 6000, seemed to respond much better of course which corresponds to upper band setup as if for track.

67 SS Chevelle, M21 4 speed, 3:90 gears in rear end.

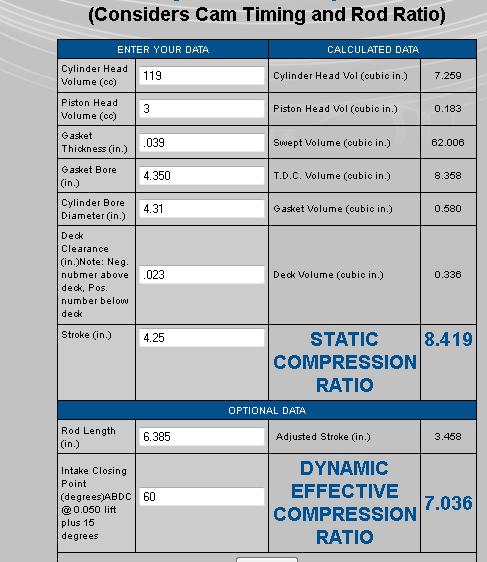

Originally had the following:

· Eagle forged internal balanced stroker crank

· H Beam 6.385 rods / ARP 7/16 bolts

· Mahle Flat Top -3cc Pistons

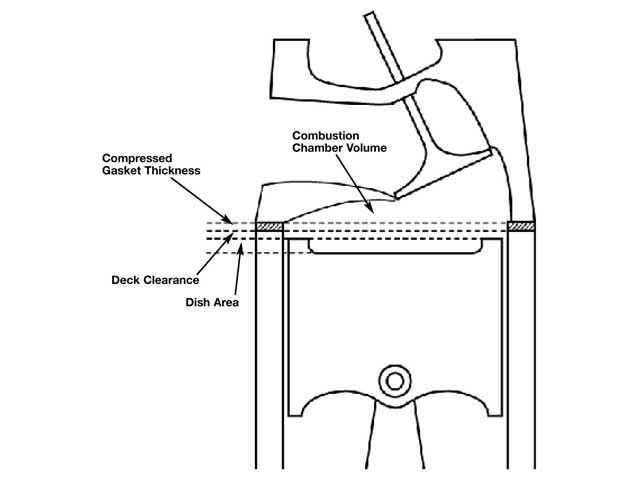

· UNDECKED block, pistons in the hole from .018 to .023

· Ran .039 compressed gasket so quench was too big

· New Brodix RR-Ovals, 119cc chamber, not with CNC option though

· Edelbrock performer RPM airgap manifold

· AED 750HOM carb

· B&B oil pan with windage tray and scraper

· 1 7/8 headers with 3 inch pipe to mufflers, then 2 ½” tailpipes after

· True roller timing chain with 9 keyway adjustable crank sprocket

· Morel 4603 Roller Lifters

· Scorpion rockers

· Custom grind Hydraulic roller …240/255@.050, 292/312@.006 LSA 109, degreed to a 103 centerline on cam card

That was last summer’s fresh build before I pulled it out this fall again, it sounded deadly at idle, and ran relatively good once revs got up there, but a dog at lower end. Also had a slight surge from idle until about 2000 rpm I couldn’t get rid of, wasn’t a miss but like a lean surge almost. If I just let the clutch out driving normally, it would almost buck the car enough I had to clutch in and rev up a few hundred RPM to clear that up. I could put as much advance timing as I wanted to and it didn’t affect it. My static compression test, although even on all cylinders which is good, seemed low to me at 120psi.

Now I have changed the following, (much to my own blame I should have read and learned more prior to doing this the second time,but whats done was done and I am learning a lot throughout this so I love it):

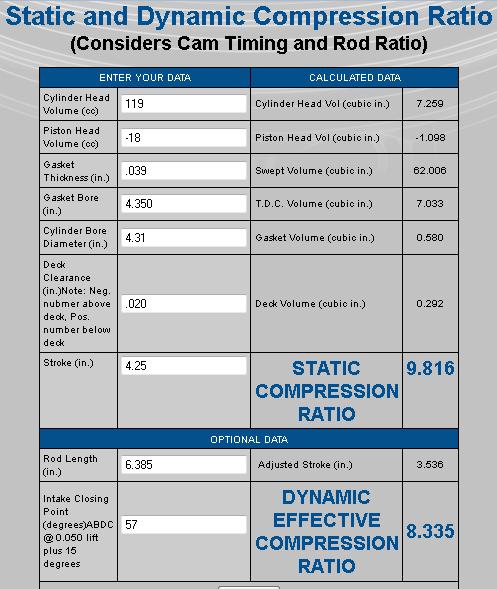

· Blocked deck .020 and leveled

· Replacing flat tops with Mahle 18cc domes

· Had complete crank, rods, pistons, flywheel, vibration damper balanced again

· My new quench will be .037-.039

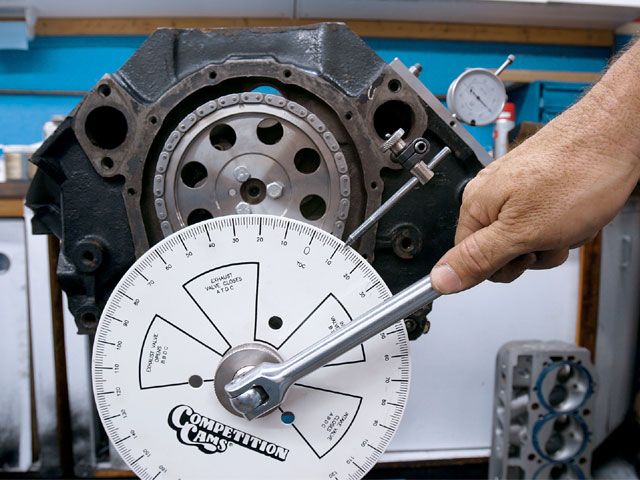

· Rechecked my cam timing and found I was retarded about 3 degrees at last build. I did not degree it to the centerline on the cam card as I was told that is not an accurate way due to being an asymmetric design. My card called for an opening of 17@.050 intake opening, and I found it dot to dot to be opening at 14, so therefore closing late as well and really affecting my dynamic ratio. I installed my crank sprocket at 2 advanced and it is opening bang on the 17 mark now, closing at 43, exhaust opening at 62.5 per car, and the only one that is giving me a difference is the exhaust closing, card calls for 12.5 and I am reading 15 for that (these are all at .050 measurements)

· Heads, exhaust, intake and carb I am planning to leave as is, I have acquired an innovate AF meter to help myself out with carb adjustments this spring.

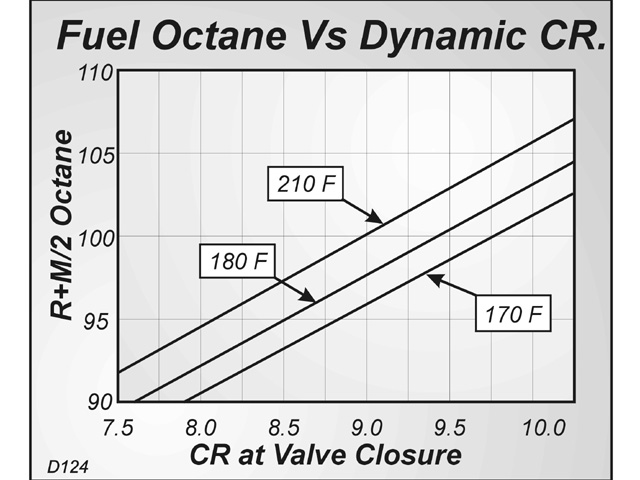

So in sum, my static compression will be raised from about 8:1ish to 10.22:1. I think that will be a much better match for that cam and heads. With the cam timing corrected to card the extra 3 degrees advanced, that should help my dynamic out considerably.

Do you think these changes alone will make a big seat of the pants difference? Or is my cam combination still going to hurt my lower end and move my power band too high up in the RPM range to obtain my accomplishments? I hope to keep expenses down and use the cam, BUT if it is not the optimum grind for my goals then I would look at a different one.

I hope to have my wife, kids, AND the dog scream when I punch the throttle

Thanks so much for your input.

Cheers, Bob

Hi,

I guess first off I should be clear and honest to myself about my goal, which when I first started the year before last I was thinking street /strip. I am looking more for street I guess in most terms as that is what I use it for. I did not make it out once to the track last year, possibly get there this year but nothing serious really, some fun ¼ mile runs , But definitely always take it out on the street a few times a week on nice evenings.

I run street tires , BF Goodrich P265-60-15’s so nothing too fancy, and with correct combination on a 496 you would think they would be quite easy to spin the rubber right off if you felt like it on a roll. Currently I could only get a small chirp when putting it down and had to rev it up quite a bit to let the back end loose. I couldn’t get it to let loose say between shifts 1 to 2, or 2-3 etc. Once revs up to 6000, seemed to respond much better of course which corresponds to upper band setup as if for track.

67 SS Chevelle, M21 4 speed, 3:90 gears in rear end.

Originally had the following:

· Eagle forged internal balanced stroker crank

· H Beam 6.385 rods / ARP 7/16 bolts

· Mahle Flat Top -3cc Pistons

· UNDECKED block, pistons in the hole from .018 to .023

· Ran .039 compressed gasket so quench was too big

· New Brodix RR-Ovals, 119cc chamber, not with CNC option though

· Edelbrock performer RPM airgap manifold

· AED 750HOM carb

· B&B oil pan with windage tray and scraper

· 1 7/8 headers with 3 inch pipe to mufflers, then 2 ½” tailpipes after

· True roller timing chain with 9 keyway adjustable crank sprocket

· Morel 4603 Roller Lifters

· Scorpion rockers

· Custom grind Hydraulic roller …240/255@.050, 292/312@.006 LSA 109, degreed to a 103 centerline on cam card

That was last summer’s fresh build before I pulled it out this fall again, it sounded deadly at idle, and ran relatively good once revs got up there, but a dog at lower end. Also had a slight surge from idle until about 2000 rpm I couldn’t get rid of, wasn’t a miss but like a lean surge almost. If I just let the clutch out driving normally, it would almost buck the car enough I had to clutch in and rev up a few hundred RPM to clear that up. I could put as much advance timing as I wanted to and it didn’t affect it. My static compression test, although even on all cylinders which is good, seemed low to me at 120psi.

Now I have changed the following, (much to my own blame I should have read and learned more prior to doing this the second time,but whats done was done and I am learning a lot throughout this so I love it):

· Blocked deck .020 and leveled

· Replacing flat tops with Mahle 18cc domes

· Had complete crank, rods, pistons, flywheel, vibration damper balanced again

· My new quench will be .037-.039

· Rechecked my cam timing and found I was retarded about 3 degrees at last build. I did not degree it to the centerline on the cam card as I was told that is not an accurate way due to being an asymmetric design. My card called for an opening of 17@.050 intake opening, and I found it dot to dot to be opening at 14, so therefore closing late as well and really affecting my dynamic ratio. I installed my crank sprocket at 2 advanced and it is opening bang on the 17 mark now, closing at 43, exhaust opening at 62.5 per car, and the only one that is giving me a difference is the exhaust closing, card calls for 12.5 and I am reading 15 for that (these are all at .050 measurements)

· Heads, exhaust, intake and carb I am planning to leave as is, I have acquired an innovate AF meter to help myself out with carb adjustments this spring.

So in sum, my static compression will be raised from about 8:1ish to 10.22:1. I think that will be a much better match for that cam and heads. With the cam timing corrected to card the extra 3 degrees advanced, that should help my dynamic out considerably.

Do you think these changes alone will make a big seat of the pants difference? Or is my cam combination still going to hurt my lower end and move my power band too high up in the RPM range to obtain my accomplishments? I hope to keep expenses down and use the cam, BUT if it is not the optimum grind for my goals then I would look at a different one.

I hope to have my wife, kids, AND the dog scream when I punch the throttle

Thanks so much for your input.

Cheers, Bob