- Home

- Forums

- Technical Articles/muscle cars

- American Muscle Cars

- Engine: Repairs , Modifications , Trouble Shooting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello from Indy!!

- Thread starter monsolo2

- Start date

Howdy!

We have the 350 sbc engine that's going to go into it and my 13-year-old son and I are going to rebuild it, hence the reason I joined this cool forum. We're in the process of taking it down to the bare block and heads so as to have themcleaned and magnafluxed. We're going to weld-up our own box-steel frame and buy a salvaged-title C4 Corvette for the Dana 44 rear-end and frot suspension. I know it sounds crazy, but I've never seen anyone use the front suspension from a vette before! This is going to be a unique t-bucket!

We have the 350 sbc engine that's going to go into it and my 13-year-old son and I are going to rebuild it, hence the reason I joined this cool forum. We're in the process of taking it down to the bare block and heads so as to have themcleaned and magnafluxed. We're going to weld-up our own box-steel frame and buy a salvaged-title C4 Corvette for the Dana 44 rear-end and frot suspension. I know it sounds crazy, but I've never seen anyone use the front suspension from a vette before! This is going to be a unique t-bucket!

Attachments

lots of clear pictures of the project as you progress would be very nice!

I intend to!

Grumpy, your the whole reason I joined this site as I know you well (at least your posts) from DigitalCorvettes.com. I really would like to have some basic direction on the rebuild... we don't want a 400+ hp engine. What we want is something with good low-end torque in order to get off the line hard and that souunds like a hotrod engine should... that loping cam sound! This is going into a custom-built t-bucket roadster with some nice wide tires in the back and cool eye-candy. We're going to go cruising the back-country roads at a relaxed pace and attend car shows, that's it. I'm looking for a good build that will give us 300 hp or maybe a little more and sounds like a mean son-of-gun!

Grumpy, your the whole reason I joined this site as I know you well (at least your posts) from DigitalCorvettes.com. I really would like to have some basic direction on the rebuild... we don't want a 400+ hp engine. What we want is something with good low-end torque in order to get off the line hard and that souunds like a hotrod engine should... that loping cam sound! This is going into a custom-built t-bucket roadster with some nice wide tires in the back and cool eye-candy. We're going to go cruising the back-country roads at a relaxed pace and attend car shows, that's it. I'm looking for a good build that will give us 300 hp or maybe a little more and sounds like a mean son-of-gun!

monsolo2 said:I intend to!

Grumpy, your the whole reason I joined this site as I know you well (at least your posts) from DigitalCorvettes.com. I really would like to have some basic direction on the rebuild... we don't want a 400+ hp engine. What we want is something with good low-end torque in order to get off the line hard and that souunds like a hotrod engine should... that loping cam sound! This is going into a custom-built t-bucket roadster with some nice wide tires in the back and cool eye-candy. We're going to go cruising the back-country roads at a relaxed pace and attend car shows, that's it. I'm looking for a good build that will give us 300 hp or maybe a little more and sounds like a mean son-of-gun!

THAT should be very easy to accomplish,but Id need to know your budget,and what type transmission,(if its an automatic the converters stall speed,the heads youll use, the true compression ratio, the type of cam,(hydraulic or solid, flat tappet or roller,) the type of intake, etc. and your rear gear ratio, if youll use headers , what type of exhaust youll use ,if you need to pass emission testing and as much more info as I can get to match the components, also what you currently have to work with and any info on your cars weight, etc.

Id also point out theres huge tendency for most guys to get a parts list, that will work great, and then start substituting cheaper components or parts they have or purchased dirt cheap later ,and have that deer in the head light silly stare when it, gets assembled and runs like crap, because the components they substituted, are not well matched

monsolo2 said:I'm a mechanical/manufacturing engineer for Rolls-Royce here in Indy and know well the consequences of using cheap materials and components! :geek:

Anything to do with the cars or is about engine production?

Can you sneak some pictures and post them here?

grumpyvette said:THAT should be very easy to accomplish,but Id need to know your budget,and what type transmission,(if its an automatic the converters stall speed,the heads youll use, the true compression ratio, the type of cam,(hydraulic or solid, flat tappet or roller,) the type of intake, etc. and your rear gear ratio, if you'll use headers , what type of exhaust you'll use ,if you need to pass emission testing and as much more info as I can get to match the components, also what you currently have to work with and any info on your cars weight, etc.

Id also point out there's huge tendency for most guys to get a parts list, that will work great, and then start substituting cheaper components or parts they have or purchased dirt cheap later ,and have that deer in the head light silly stare when it, gets assembled and runs like crap, because the components they substituted, are not well matched

Ok, my budget will be around $2000 for the entire engine rebuild... more, if needed. We only have the engine and a TH400 tranny so far, which I'm not sure I'll even use because I was told it's set up like manual - not even sure what that means yet. I'd like to just rebuild the engine and go from there... the engine, tranny, and a bunch of components were given to me by a friend of mine who owns a NASCAR truck team and was cleaning out a garage. This engine was given to him by another guy he knows, yada yada... you know how the story goes.

The block casting code is 3956618, meaning late 60's to early 70's pour. The crank is 3932442, pretty standard. It's a 2-bolt main block and the rotatives do still rotate with no hangups or scraping. Not sure of the head casting numbers yet but I don't expect anything out of the ordinary. Will have the cam out and the heads off this weekend. All of the valvetrain looks stock for that age of engine. It came with a very loosely bolted-on Edelbrock high-rise intake #2975 that is not really good for our application - I'm pretty sure it wasn't ever run on this engine. I'm probably going to sell that intake and get one more suited to what we're looking for.

There's no emissions testing required in Indiana so no problem there. Since this is going into a t-bucket, we're going to use blacked-out dual exhaust mounted right off the engine. The extra components are an MSD high-energy distributor, light-weight flywheel, a torque converter for the weird tranny, and a cool-looking carbon-fiber NASCAR air-cleaner scoop.

Here's what I'm wondering... how much do we really need to change in order to get around 300-350 hp? Should I invest in some Vortec heads or just port the ones we have? I'll buy whatever we need so don't hold back! I'm already assuming we'll need to bore the block and journals and grind the crank for oversized bearings.

Teach me, Grumpy!

Indycars said:monsolo2 said:I'm a mechanical/manufacturing engineer for Rolls-Royce here in Indy and know well the consequences of using cheap materials and components! :geek:

Anything to do with the cars or is about engine production?

Can you sneak some pictures and post them here?

Nope, not the cars, unfortunately! Rolls-Royce sold the car division off in 1973 or thereabouts. It's now owned by BMW and they pay us a crapload of $$$ every year to use the logo and the name. The division I work for in Indy actually use to be RR's primary competitor during WW2, Allison Engine Company. They made the venerable V1710 V12 piston engine that helped to win the war in planes like the P-38 Lightning. We now design/make turbojet, turbofan, turboshaft, and turboprop engines for the likes of the V-22 Osprey, the C-130, the Embreaer regional jet, and the F-35 Joint Strike Fighter. I can't get you any pictures beyond what you see on the internet, unfortunately. Look up AE2100, AE3007, AE1107, RR250, RR300 and F-35 Lift Fan... those are the engines we design/make.

because your power goals are rather modest and because the budgets fairly tight lets try and use as much of the current components as you can use from the current collection of parts, step one is total Assembly and inspection of what you currently have on hand, Id suggest you purchase these books

http://www.themotorbookstore.com/resmchstvi.html

http://www.themotorbookstore.com/chevy-small-block.html

and youll need a decent low cost engine stand

http://www.northerntool.com/shop/tools/ ... _200305217

look in your local bargain trader and classified section , craigs list etc, for a decent used engine stand don,t pay over $75 and make darn sure its not the three leg version

any of the three types above are ok.

something like the one pictured below is a trip to the emergency room waiting to happen

viewtopic.php?f=53&t=4294&p=11325&hilit=+books+video#p11325

while that intakes not ideal, it will work, so don,t throw it away, Id also strongly suggest you think about using a mid range solid lifter flat tappet cam and start shopping for decent higher compression pistons IF THE BLOCK NEEDS TO BE BORED OVERSIZE, which a good local machine shop inspection and block cleaning will tell you.

viewtopic.php?f=51&t=125

viewtopic.php?f=51&t=2919

viewtopic.php?f=51&t=976

http://www.themotorbookstore.com/resmchstvi.html

http://www.themotorbookstore.com/chevy-small-block.html

and youll need a decent low cost engine stand

http://www.northerntool.com/shop/tools/ ... _200305217

look in your local bargain trader and classified section , craigs list etc, for a decent used engine stand don,t pay over $75 and make darn sure its not the three leg version

any of the three types above are ok.

something like the one pictured below is a trip to the emergency room waiting to happen

viewtopic.php?f=53&t=4294&p=11325&hilit=+books+video#p11325

while that intakes not ideal, it will work, so don,t throw it away, Id also strongly suggest you think about using a mid range solid lifter flat tappet cam and start shopping for decent higher compression pistons IF THE BLOCK NEEDS TO BE BORED OVERSIZE, which a good local machine shop inspection and block cleaning will tell you.

viewtopic.php?f=51&t=125

viewtopic.php?f=51&t=2919

viewtopic.php?f=51&t=976

monsolo2 said:I can't get you any pictures beyond what you see on the internet, unfortunately. Look up AE2100, AE3007, AE1107, RR250, RR300 and F-35 Lift Fan... those are the engines we design/make.

I kinda figured that about the pictures! That's got to be interesting working with the Turbine type engine, unless it's what you have to do every day, but for the rest of us!!!

In school we had to do a hot section inspection (I think thats what it called) and then the instructor fired one off in the test cell. I remember him pushing it until the compressor stalled. Made a very noticeable noise. I know very little about what I'm talking about, but that's the best my memory can muster from 30 some years ago.

If you need some reading material, check out this thread.

Reher-Morrison Engine Book......For The Price of Shipping [and book rate is usually about $4 in the US.]

viewtopic.php?f=67&t=3513

Just PM your address to 2Loose and he will send it your way. He's finished with the book, so the wait shouldn't be too long. But it will be coming from Maui in Hawaii.

Grumpy, thanks for the info! We already have the engine on a four-castor type stand so we're good to go there. I agree with using as many stock components as possible. Thanks for the tip on the cam... I'll look into what ytou recommend. Do you like Crane cams? I'll buy those books today and start reading. I have used a very engine shop here in indy called Quinlin's Automotive and I'll be taking the block and heads over to get magnfluxed and cleaned next week. I'll talk to them about the need for boring and such. About the intake, you really think I can still use it? I thought those kinds were used more for higher RPM's in racing...

Indycars, you have a good memory! Yes, the hot section is the turbine in the aft of the engine. When he ran the engine all out the compressor was starving for air and stalling... You can't mistake that sound! Turbine engines are a LOT of fun, believe me...you never get tired of them. In fact, we here at Rolls-Royce Indy just formed a company motor club for all of us gearheads. We are launching a cool project of putting a RR250 engine into a NASCAR truck chassis and trying for the world record for the fastest lap by a truck on a closed circuit at Pocono! This will be an involved project but I'll post updates here.

monsolo2 said:Grumpy, thanks for the info! We already have the engine on a four-castor type stand so we're good to go there. I agree with using as many stock components as possible. Thanks for the tip on the cam... I'll look into what ytou recommend. Do you like Crane cams? I'll buy those books today and start reading. I have used a very engine shop here in indy called Quinlin's Automotive and I'll be taking the block and heads over to get magnfluxed and cleaned next week. I'll talk to them about the need for boring and such. About the intake, you really think I can still use it? I thought those kinds were used more for higher RPM's in racing...

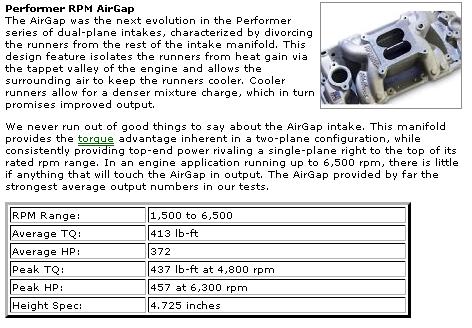

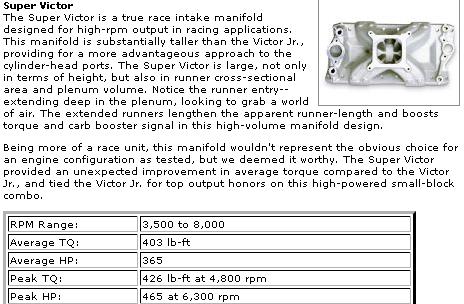

theres no doubt use of that intake will hurt the low rpm torque slightly but its not going to be a huge loss if you select a decent cam and have about 10:1-10.5:1 compression, with a decent cam

as you can see the intake choice is not going to totally kill off results.

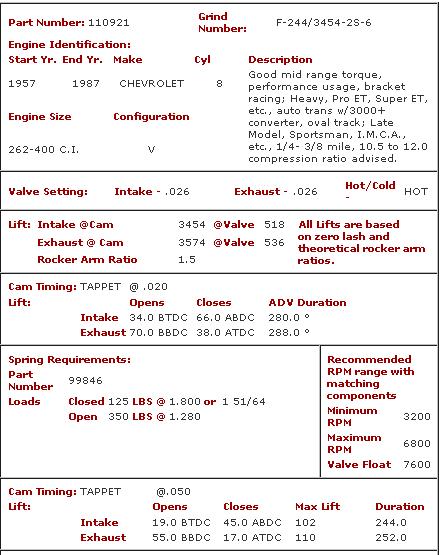

get that compression up in the 10:1 range and use a cam like the crane 110921 and that single plane intake , a decent 700cfm-750 cfm vacume secondary carb,and youll get a very noticeable lope in the idle, but be aware the cams use REQUIRES, that 10.5:1 compression ,matched valve springs, decent quality solid lifters, correct valve geometry, valve train clearances,a 3200rpm stall converter stall speed,and a 3.54:1-3.73:1 rear gear ratio to function correctly

http://www.moparmusclemagazine.com/tech ... ewall.html

http://www.carcraft.com/techarticles/cc ... ewall.html

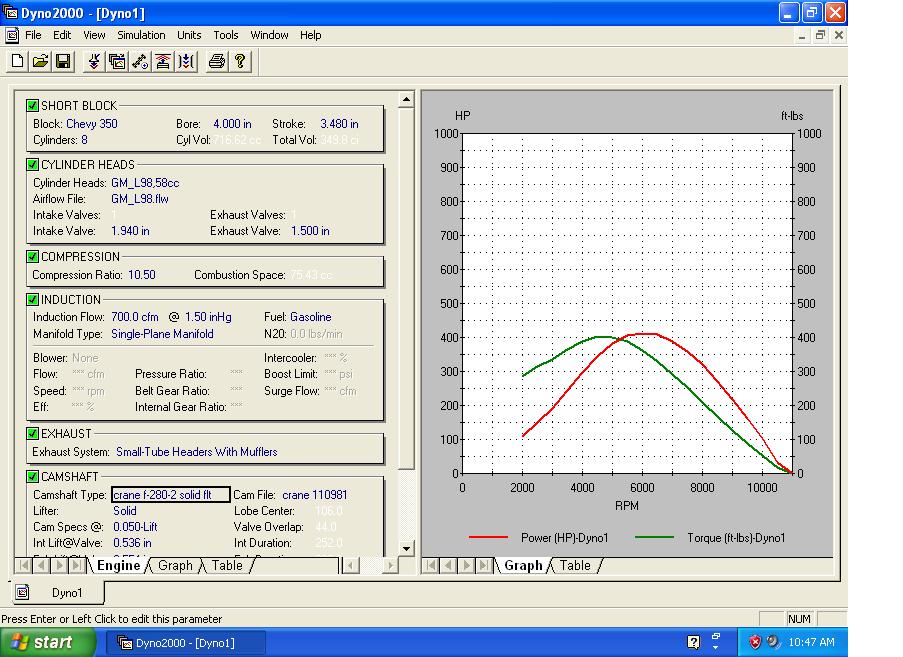

heres what DD2000 says a similar combo might look like

viewtopic.php?f=55&t=58

monsolo2 said:Indycars, you have a good memory! Yes, the hot section is the turbine in the aft of the engine. When he ran the engine all out the compressor was starving for air and stalling... You can't mistake that sound! Turbine engines are a LOT of fun, believe me...you never get tired of them. In fact, we here at Rolls-Royce Indy just formed a company motor club for all of us gearheads. We are launching a cool project of putting a RR250 engine into a NASCAR truck chassis and trying for the world record for the fastest lap by a truck on a closed circuit at Pocono! This will be an involved project but I'll post updates here.

Sounds like an expensive venture, but damn sure would be fun!!!

I guess they are going to demand that you drive......right?

Grumpy, that's awesome!! :shock:

Ok, we'll get started on this with your recommendations in mind. I'll let you know what the machine shop recommends next week. I'll go ahead and keep that intake and throw it in with the block and heads to get it stripped and cleaned as well. This will be a winter project for us and probably won't be done till after the first of the year. I want time for my boys (and I) to learn as we go. We want to do it right and have a nice solid engine when we're done.

Ok, we'll get started on this with your recommendations in mind. I'll let you know what the machine shop recommends next week. I'll go ahead and keep that intake and throw it in with the block and heads to get it stripped and cleaned as well. This will be a winter project for us and probably won't be done till after the first of the year. I want time for my boys (and I) to learn as we go. We want to do it right and have a nice solid engine when we're done.

Indycars, there's no way I'd put myself behind the wheel of that monster!! LOL! We actually have a line, through a connection, on a NASCAR cup driver who would be our "pilot" so to speak. I won't say who right now until we secure his help but this thing will need an experienced driver... the engine, depending on what series RR250 we can secure, will be in the 600+ shaft hp range. Also, there's going to be a whole new set of dynamics at play when taking this truck around the track... we're discussing those right now. We're securing sponsorship from RR and other large companies here in the Indy area to get this project off the ground. We won't see an engine until sometime after the first of the year although we do have the complete chassis already. It's a 2012 certified chassis that's only been run as a trainer so far and never been wrecked: