I have to wonder if this can be done for $2000. To get the compression needed with 76cc heads

(I'm guessing on chamber size) domed pistons will be required. There is not enough material

on the block and heads for milling to get that compression.

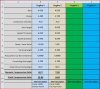

To get near the 10.5 ratio, I had to change the piston from a flat top (+5cc) to a domed

piston (-10cc), that's a 15cc change in the combustion chamber volume. To help compression

you could go with a stroker crank like in the 2nd engine example, but the only thing I found

at Summit for roughly $200 was 3.75" stroke cast steel crankshaft. Now you will have to keep

an eye on the mean piston speed if you are going to use the available RPM with that

camshaft of 6800. But if Monsolo2 doesn't expect to ever get close to the maximum RPM, then.....

Note: I used 75cc in the examples so that a clean up cut could be taken to make sure the

heads are flat.