grumpyvette said:

have you found anything interesting, you want to discuss or can you post questions ?

what did you find in the book that was not explained well and do you think it was worth the cost?

are you likely to buy the software package?

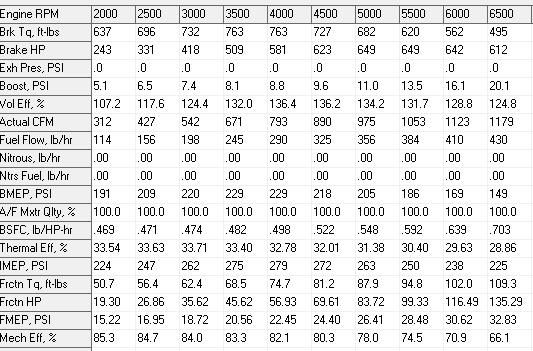

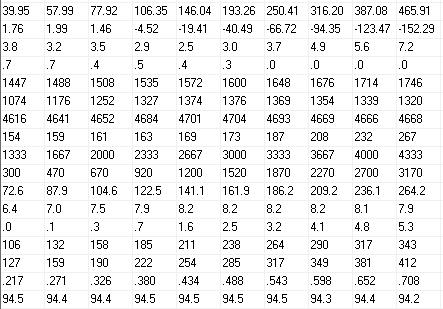

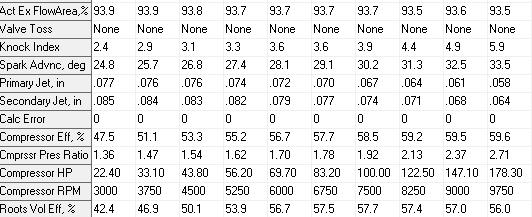

Unfortunately, I have only made if half way through the book. Work travel has intervened. It’s an easy read and each of the section describing the ‘Seven Cycles’ presents a good summary and focuses on parameters that make the most impact on performance for each cycle. The premise of the book is that there are seven cycles that an engine goes through each time a cylinder fires, and these have to be optimized individually and with respect to the previous and next cycles in order to get the most performance out of an engine.

The seven cycles are:

- Intake pumping, where the piston going down into the bore creates a vacuum and pumps air/fuel charge into the cylinder.

- Intake ramming, which starts after BDC , where the piston is coming up in the bore and is no longer pumping, but the momentum of the column of air/fuel going through the port allows it to continue to fill the cylinder. The book claims that this is the process which allows very high volumetric efficiencies in some racing engines.

- Compression, which starts when the intake valve closes and the pistons starts compressing the air/fuel mixture.

- Fuel burning and expansion, which starts when the plug fires and continues to TDC and through when the piston is pushed back down the bore.

- Exhaust blowdown, which starts when the exhaust valve opens and the higher pressure in the cylinder blows out through the exhaust valve.

- Exhaust pumping, which starts at BDC of the exhaust stroke, when the piston starts to move up and pump the exhaust out of the cylinder.

- Valve overlap, when the exhaust valve is closing and the intake valve is opening near top dead center.

It seems that the book is actually a reprint, under a different title, of a 2007 book called "Engine Pro - the Book". Being a computer nerd, I find the insight to the formulas the Engine Pro software uses interesting. For example, they describe in detail the formula to calculate dynamic compression based in intake valve closing angle. I can see myself playing around with these formulas in Excel.

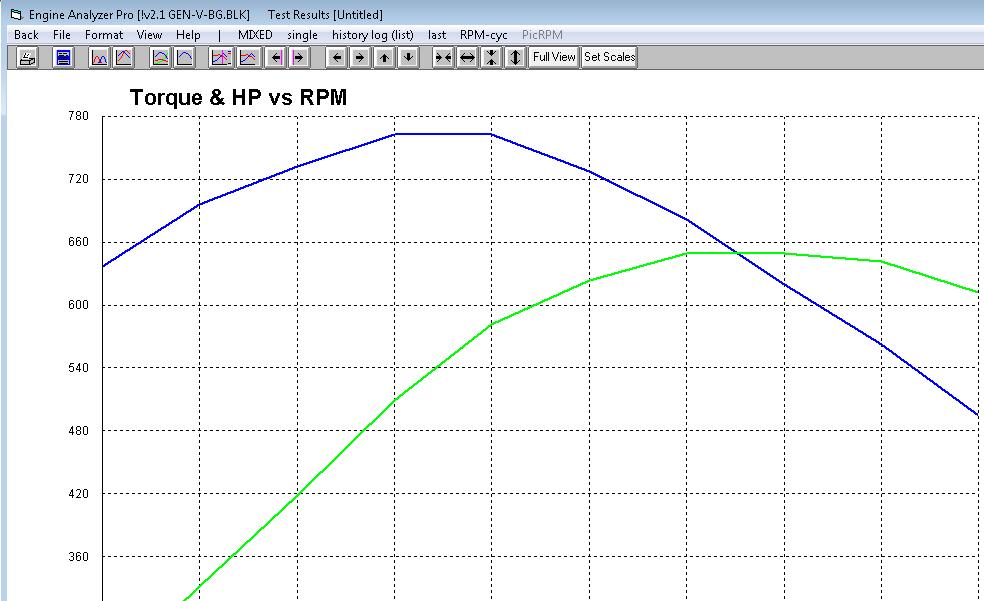

I have DynoSim 5 so I wouldn’t be interested in the Engine Pro software.

As far as, is the book worth it? I think so, epically since we split the cost. One of the benefits of the forum..

I should be done with it by next weekend; I’ll get it out to the next guy in the chain.