Id strongly suggest you look into , and consider going with the option of a hydraulic roller cam, UPGRADE

as they (if properly installed, with matched valve springs,)

tend to last over 100K miles rather easily in a daily driver,

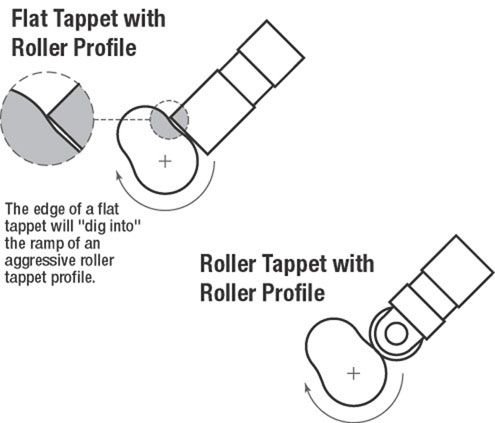

where a flat tappet hydraulic ,PERFORMANCE AFTERMARKET CAM,

with higher lift and more aggressive ramp designs,

is prone to lobe wear in many cases before 100K miles,

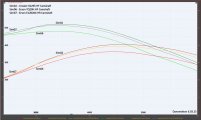

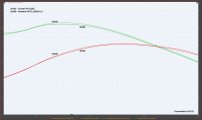

and generally you'll gain 20-25 plus hp even with similar lift and duration , using a hydraulic roller cam,

due to more average peak lift per degree of rotation and lower friction losses.

but you'll generally find you have access to significantly greater lift and power.

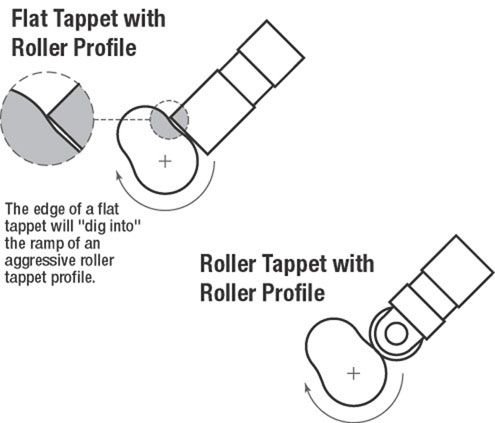

using the hydraulic ROLLER lifter designs

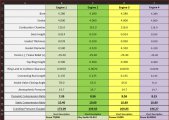

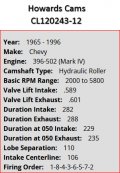

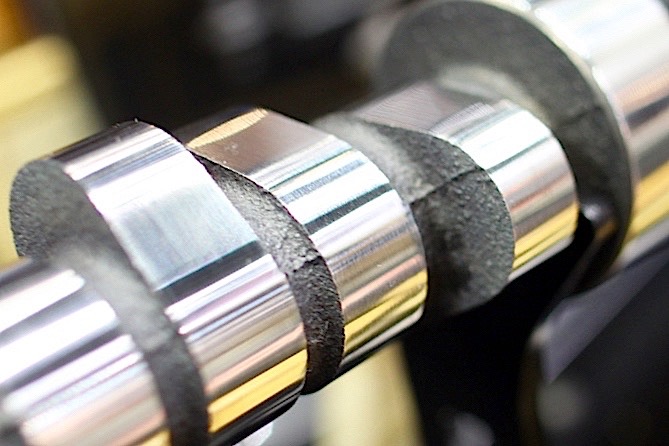

something like this instantly jumps into mind

(obviously only one of dozens of your options)

but it looks good for your application

READ LINKED INFO

as they (if properly installed, with matched valve springs,)

tend to last over 100K miles rather easily in a daily driver,

where a flat tappet hydraulic ,PERFORMANCE AFTERMARKET CAM,

with higher lift and more aggressive ramp designs,

is prone to lobe wear in many cases before 100K miles,

and generally you'll gain 20-25 plus hp even with similar lift and duration , using a hydraulic roller cam,

due to more average peak lift per degree of rotation and lower friction losses.

but you'll generally find you have access to significantly greater lift and power.

using the hydraulic ROLLER lifter designs

something like this instantly jumps into mind

(obviously only one of dozens of your options)

but it looks good for your application

READ LINKED INFO

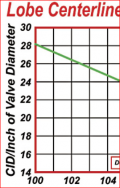

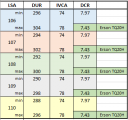

is a roller cam worth the extra cost vs a flat tappet design

heres some info from COMP CAMS " Flat Tappet vs. Roller Tappet Lifters theres far more than just the cam and lifters required to swap types of cams, if your engines currently equipped with a flat tappet cam your almost sure to need a new timing chain set cam button new push rods obviously a new...

garage.grumpysperformance.com

oil system mods that help

heres a short list REMEMBER the object or goal in building and maintaining the lubrication system is too maintain a 100% dependable pressurized cooling flow of lubricant to the bearings, rockers ,valves etc. your most important tool, is your ability to think about how things are supposed to...

garage.grumpysperformance.com

cam wear,articles you need to read

before, you start reading through the thread and links below, Ill point out that I've done the forensics on quite a few failed cams over the years, that guys have brought to my shop and Id say about 60% of the failed cam lobe & lifter problems were traced to a failure to check clearances or...

garage.grumpysperformance.com

degree it in correctly and get it to last,cam install info,

IM frequently asked (why bother degreeing in a cam, the timing set comes with index marks to install it?) it basically comes down to, a question of do you accept a random install where the timing can be almost any place randomly or do you insist on maximizing the engines potential and know...

garage.grumpysperformance.com

sellecting valve springs, and setting up the valve train

How do you determine the spring pressure needed to keep the valves under control for a given lift, duration, and max rpm. It might take you several hours to read thru all the links and sub links but its time very well spent as it could save your engine from destruction and save you thousands of...

garage.grumpysperformance.com

Build Engine For Long Term Durability

STINKY HERE< I am opening a can of worms here, and boys, you keep it civil. What is the best SBC? I am not talking about the one the will put out the most TQ and HP...which one will last for 300K, or more, in a PU, or in your wife's car. Which one lasts the longest, and won't mysteriously just...

garage.grumpysperformance.com

Using Rare Earth Magnets

Using rare earth magnets on/in your oil pan, drain plug, etc.. Do you do it? Or at least when breaking in a motor? You can get them for free if you have any old computer hard drives laying around. I split and opened up a total of 14 older apple hard drives that I had down in the basement, took...

garage.grumpysperformance.com

yes the oil filter you sellect does make a differance

READ THRU THESE SUB LINKS CAREFULLY theres a great deal of info here to look thru. pay attention to filter construction and the filter materials and total filter medium area, when discussing oil filters keep in mind their intended function, which is mostly too efficiently trap and remove...

garage.grumpysperformance.com

Last edited: