I'm going to contact Straub Tech today to talk about cams. But I wanted to reinforce something posted by Grumpy about talking to the mfg and verifying cam specs and not just taking them off of a website.

Earlier, I mentioned about the discrepancy in the Clay Smith cam from BOTH Summit and SC websites. I first thought I was looking at a cam from Summit with .542 duration. The real cam info was very different.

I also found another discrepancy in the CS 160-3101 cam. Perhaps small but it reinforces the point about talking with the mfg.

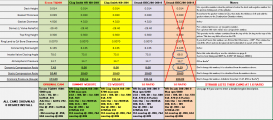

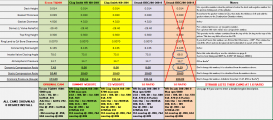

Summit website lift on this is .600/.569, CS website shows .590/.570. Here's another chart I made to look side by side:

Since Straub can sell CS as well, I'll ask not just for their cam recommendation, but also what their data shows on the CS cam.

CS cam shown at 1.7 RR, Straub shown at 1.6 RR.

Earlier, I mentioned about the discrepancy in the Clay Smith cam from BOTH Summit and SC websites. I first thought I was looking at a cam from Summit with .542 duration. The real cam info was very different.

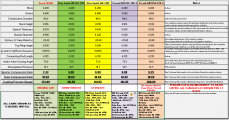

I found a discrepancy in the CS cam data that I'll resolve today. Summit lists both the 012 and 013 cams at .542 lift, but the CS website lists them at .510 lift. Using 1.70 ratio.

I'll call the mfg today to ask about this and to see what they recommend for valve springs as well.

Perhaps I'm comparing apples and oranges due to different durations and LCA/ICA but I was anticipating that a bit more lift than the current Erson cam at .514 would be of benefit.

EDIT: I spoke with CS cams and both lift numbers are incorrect. The correct lift is .500, so now I think I may need to look at either a custom grind from them or going back to my other alternatives. I don't think the .5 lift will be my best choice. Is this a reasonable approach?

I also found another discrepancy in the CS 160-3101 cam. Perhaps small but it reinforces the point about talking with the mfg.

Summit website lift on this is .600/.569, CS website shows .590/.570. Here's another chart I made to look side by side:

Since Straub can sell CS as well, I'll ask not just for their cam recommendation, but also what their data shows on the CS cam.

CS cam shown at 1.7 RR, Straub shown at 1.6 RR.

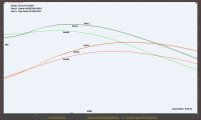

Not a done deal by any means but considering the engine factors we've discussed, I'm leaning to the Straub 288/294 (SIM 12). That's just expressing my thought.

Not a done deal by any means but considering the engine factors we've discussed, I'm leaning to the Straub 288/294 (SIM 12). That's just expressing my thought.