Electric fans are all done. I ran the engine again today and had the following observations .....

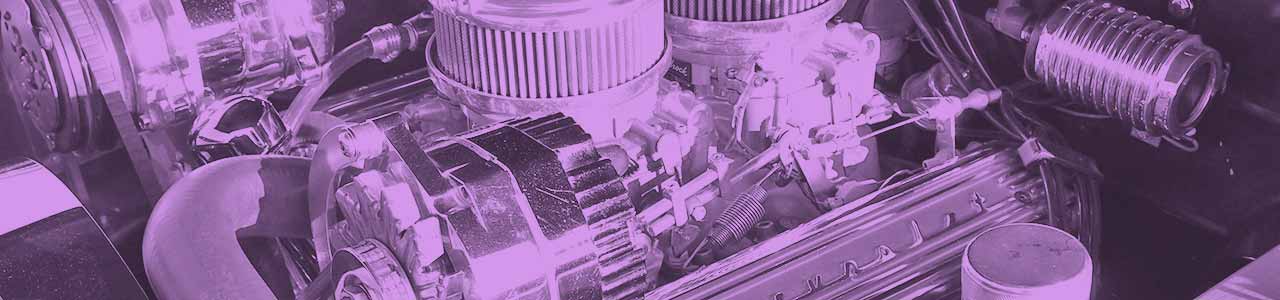

I don't want to jinx it, but even taking into account the engine is in a non-load situation (no transmission), it runs perfectly. I've tweaked it a bit more and it's sensitive to carb/ignition changes as it should be. The initial slightly louder lifter noise is virtually gone. No smoke at all. Throttle response is very snappy and it just sounds great.

Oil pressure at idle.

No issues with electrical, wiring, etc. Alternator is fully charging the battery at over 14v. New PMGR starter with 1/0 cable cranks the engine over great.

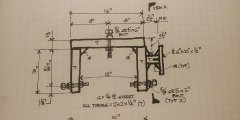

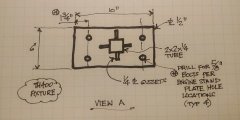

Cooling - the electric fans function well, no electrical or overload glitches. Lots of airflow (puller fans). Each fan is on its own circuit for redundancy. Battery power is run thru a circuit breaker to relay term 30, fan load to relay term 87, fused ignition power to relay term 86, ground from manifold water temp sensor to relay term 85. I used ignition feed to the relay so that the fans would not run with the engine off. The water temp sensor is set for 210d/on, 180d/off - when the temp sensor sees 210d, it closes to ground and activates the relay (fan).

This is the battery power fuse/relay block I put together (passenger side). There's an ignition power unit on the driver side. Those are the relays for each fan circuit. Disregard the red wires at the bottom - just temporary power I'm pulling.

Fan wiring harness routes from the fans through the firewall panel and attaches directly to the relay terminal block. I do this for higher draw circuits just to minimize connectors. Other stuff plugs into that panel. Have I mentioned that I love using nutserts lol - they make it so easy to attach loom clamps, the fuel system stuff, etc.

Fan wire loom goes right through the panel, other engine wiring is simply plugged in. The other exception is the HEI power feed that goes all the way to the ignition switch, no intermediate connector. Just want to ensure the HEI is getting a full 12v, using 12ga wire.

Now, here's what else I observed. I had commented earlier that the engine always seemed to run on the hot side before the rebuild - really had to be careful in hot weather or traffic. Initial startup and running had a house fan on a chair, which really wasn't optimum, water temp still crept up due to not great airflow.

So today, with the electric fans installed, water temp remained in control, which was great. But here's an anomaly that I need to check out.

Note the gauge reading below - that reading of 195-200ish is where the electric fans cut off. According to the water temp sensor for the fans, this would be about 180, but as you can see there's about a 15 degree discrepancy between the water temp (fan) sensor and the gauge sensor. Both are in the same general location on the intake - one on each side of the thermostat housing.

I need to verify which sensor is telling the truth. Using a laser temp gun it appears that the temp gauge is reading high, as the fitting boss on the intake reads about 185. I think that over the years I replaced the gauge sender, so there may be a slight mis-match between sender and gauge. I think I may have kept the old (maybe original sender) so if I did, I'll install that. Or I may just get another gauge. As you can see both the oil pressure and the water temp gauges are SunTune which I don't think are even made anymore. They are probably at least 20 years old, so new gauges may be reasonable. My gut feeling is that the engine coolant temperature isn't out of line and I just need to iron out these details.

I don't want to jinx it, but even taking into account the engine is in a non-load situation (no transmission), it runs perfectly. I've tweaked it a bit more and it's sensitive to carb/ignition changes as it should be. The initial slightly louder lifter noise is virtually gone. No smoke at all. Throttle response is very snappy and it just sounds great.

Oil pressure at idle.

No issues with electrical, wiring, etc. Alternator is fully charging the battery at over 14v. New PMGR starter with 1/0 cable cranks the engine over great.

Cooling - the electric fans function well, no electrical or overload glitches. Lots of airflow (puller fans). Each fan is on its own circuit for redundancy. Battery power is run thru a circuit breaker to relay term 30, fan load to relay term 87, fused ignition power to relay term 86, ground from manifold water temp sensor to relay term 85. I used ignition feed to the relay so that the fans would not run with the engine off. The water temp sensor is set for 210d/on, 180d/off - when the temp sensor sees 210d, it closes to ground and activates the relay (fan).

This is the battery power fuse/relay block I put together (passenger side). There's an ignition power unit on the driver side. Those are the relays for each fan circuit. Disregard the red wires at the bottom - just temporary power I'm pulling.

Fan wiring harness routes from the fans through the firewall panel and attaches directly to the relay terminal block. I do this for higher draw circuits just to minimize connectors. Other stuff plugs into that panel. Have I mentioned that I love using nutserts lol - they make it so easy to attach loom clamps, the fuel system stuff, etc.

Fan wire loom goes right through the panel, other engine wiring is simply plugged in. The other exception is the HEI power feed that goes all the way to the ignition switch, no intermediate connector. Just want to ensure the HEI is getting a full 12v, using 12ga wire.

Now, here's what else I observed. I had commented earlier that the engine always seemed to run on the hot side before the rebuild - really had to be careful in hot weather or traffic. Initial startup and running had a house fan on a chair, which really wasn't optimum, water temp still crept up due to not great airflow.

So today, with the electric fans installed, water temp remained in control, which was great. But here's an anomaly that I need to check out.

Note the gauge reading below - that reading of 195-200ish is where the electric fans cut off. According to the water temp sensor for the fans, this would be about 180, but as you can see there's about a 15 degree discrepancy between the water temp (fan) sensor and the gauge sensor. Both are in the same general location on the intake - one on each side of the thermostat housing.

I need to verify which sensor is telling the truth. Using a laser temp gun it appears that the temp gauge is reading high, as the fitting boss on the intake reads about 185. I think that over the years I replaced the gauge sender, so there may be a slight mis-match between sender and gauge. I think I may have kept the old (maybe original sender) so if I did, I'll install that. Or I may just get another gauge. As you can see both the oil pressure and the water temp gauges are SunTune which I don't think are even made anymore. They are probably at least 20 years old, so new gauges may be reasonable. My gut feeling is that the engine coolant temperature isn't out of line and I just need to iron out these details.