the surface finish on the rear crank sealing area where the rear main seal rides

MUST BE super smooth ,on the BBC AND SBC engines, or it will very quickly wear through the critical sealing edge of the seal, so a section of leather belt a couple 1.5" wide strips of 1500 grit wet dry sand paper, and a very frequent spray of wd 40 can be used to polish out micro burrs from the rear crank surface, and remember to clean all micro debris from the surface with a clean white cloth, and re-flush with more cutting lube every 30 seconds or so frequent sprays of WD 40. and a shoe shine buff polish, might be beneficial to getting a mirror like surface.

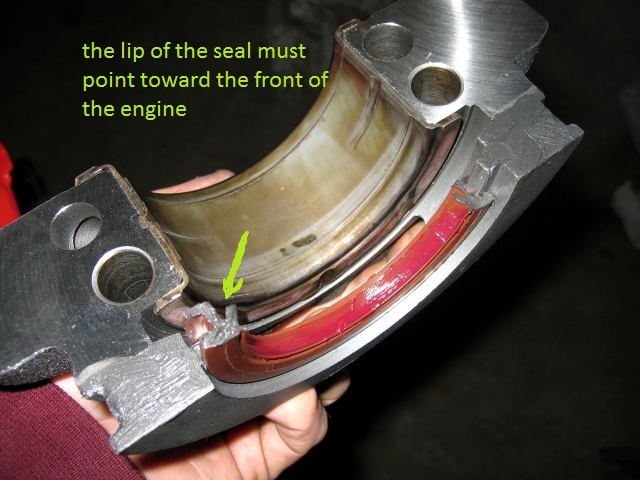

the seal has an INNER and outer facing side, put it in reversed and IT WILL LEAK, the lip faces the front of the engine

IVE installed some rear seals with the ends offset and some flush, Ive never had one leak in 40 plus years, if you have the seal leak its been my experience looking at engines I've repaired that

about 80% of the leaks are due to improper installation and 20% due to rarely if ever doing oil changes so wear was the root cause of the leak due to sludge in the oil.

never install the seal on a dry crank, oil it on the lip area and crank surface with wd40, on a q-tip to insure it won,t be damaged on start-up

Be sure the lip seal is positioned leaning inward towards the front of the engine, and the rear seals off-set from the main cap parting line by about 1/4" to reduce the tendency to leak oil.

the seals end cross section VAGUELY resembles the LETTER K <this side with the flex lip edge,faces the front of the engine or inside the oil pan, they come in at least 4 materials and three different widths, also be darn sure the seal you buy is designed for the engine your working on, not all sbc engines, or BBC engines are identical[/size]

Count on Fel-Pro rear main seal replacement to keep oil from leaking at the rear of the crankshaft. Choose from a variety of materials for the best seal for your repair.

www.felpro.com

Count on Fel-Pro rear main seal replacement to keep oil from leaking at the rear of the crankshaft. Choose from a variety of materials for the best seal for your repair.

www.felpro.com

Learn how install each different type of Fel-Pro rear main seal – one-piece rubber or PTFE, two-piece rubber and rope.

www.felpro.com

rear seals come in, rubber, silicon rubber,.Fluoroelastomer, and Viton , durability vary,s between brands but roughly in that order,they all work if properly installed but VITON usually lasts the longest

keep in mind the seal lip must be properly installed and the seal lip must ride on a mirror smooth lubricated crank journal, if its to last, no seal will last long on a rough or out of round crank that wears that seal lip

http://www.summitracing.com/parts/FEL-BS118291/.. rubber usually GOOD

http://www.summitracing.com/parts/FEL-2900/... Silicone VERY GOOD

http://www.summitracing.com/parts/FEL-2909/ Fluoroelastomer, SLIGHTLY BETTER

http://www.summitracing.com/parts/FEL-2918/..viton SLIGHTLY BETTER STILL IN SOME DESIGNS

ear.

12/13

12/13

All ’87-and-later Chevy blocks come with a one-piece rear-main seal. This requires the use of a late-model one-piece rear-main seal crank. Starting with the ’88s, most passenger-car engines converted to hydraulic roller cams that required a spider. This is a truck block where the spider mounting bosses are not drilled and tapped, because the truck engine used a flat-tappet cam. These can be easily drilled and tapped to mount the spider for a hydraulic roller cam.

Rear main seal leakage remains a problem on engines that still use 2-piece rear main seals. We all know the time honored method of offsetting the seal parting lines so they do not match the main cap to block interface. And many builders still incorporate a small bit of non-hardening sealer on the parting surfaces, but it is still a craps shoot even for experienced builders. For several years now a new type of rear seal has been making the rounds of racing engine builders with great success. This one piece seal from GST RACING SEALS TM is designed to be cut and twisted around the crankshaft for installation. While this seems extreme, it is in fact a brilliant solution.

Rear main seal leakage remains a problem on engines that still use 2-piece rear main seals. We all know the time honored method of offsetting the seal parting lines so they do not match the main cap to block interface. And many builders still incorporate a small bit of non-hardening sealer on the parting surfaces, but it is still a craps shoot even for experienced builders. For several years now a new type of rear seal has been making the rounds of racing engine builders with great success. This one piece seal from GST RACING SEALS TM is designed to be cut and twisted around the crankshaft for installation. While this seems extreme, it is in fact a brilliant solution.

The 1-pc seals are designated “F-Type” because they have built-in flexibility which enables the seals to be opened out around the crankshaft. Before assembly the seal is cut radially in one position using a very sharp blade. This enables the seal body to be opened & twisted around the crankshaft flange before the main bearing cap is installed. The seal has two lips. The flywheel side incorporates a bonded PTFE facing which holds crankcase vacuum without raising friction.

The oil control lip incorporates their highly efficient HD2 Bi-Directional Hydrodynamic helix feature which reduces seal drag & improves sealing reliability. Being bi-directional the seal can also be used in Marine engines with reverse rotation. A further advantage of the seal is that it only has one joint face which is installed towards the top of the engine for maximum effect. When installed the cut surfaces match perfectly and no sealant is required. The cut does not have to be made with any particular precision. It has been test with extreme angles and still works properly.

The seals have been in use for almost 4 race seasons without problems, and many users have advised that the seal solves all of the basic problems with the two piece seals i.e. oil leakage & poor vacuum handling. The BBC seals are being used in race engines at 25.0”Hg vacuum without problems & dyno tests have verified that the engine can produce both extra power & increased torque after fitting the F-Type Seal.

We installed the test seal in the accompanying photos on a 1000+ horsepower big block Chevy and found no leakage after 27 dyno pulls and a half a dozen passes on the car. The held 25" of vacuum consistently and performed flawlessly.

The F-Type seal program currently includes big and small block Chevys, Ford and Mopar seals, & they now offer the seals for Buick/Olds/Pontiac V8 for maximum coverages. GST Racing Seals are now being specified by major race teams, constructors, and engine builders in NASCAR, ARCA, NHRA Pro-Stock, BAJA Off-Road, and Australian Super V8.

Pricing is batch quantity-related but typically a larger Engine Builder may pay $35 – $45 each & a smaller purchaser perhaps $65 – $75 each.

Approved stocking U. S. Distributors include:

Fast Fish Auto Parts

Kannapolis, NC (Chrysler)

704-701-6658

http://www.fastfishautoparts.com

James Engineering (SBC and BBC)

2380 W Midway Blvd # 1

Broomfield, CO 80020

303-941-3970http://

www.james-engineering.com

BOP Engineering (Jefferson, WI) (Buick/Olds/Pontiac

N3651 Schmidt Rd

Jefferson WI 53549-9768

Phone (920) 674-6058

http://www.bopengineering.com

Manufacturers Rep in Concord, NC

Randy Edwards

704-467-2698)

Manaufacturer

GST RACING SEALS TM

148 Earls Road

Southampton

SO14 6TL, U.K.

info@gstracing.co.uk

023 8022 4104

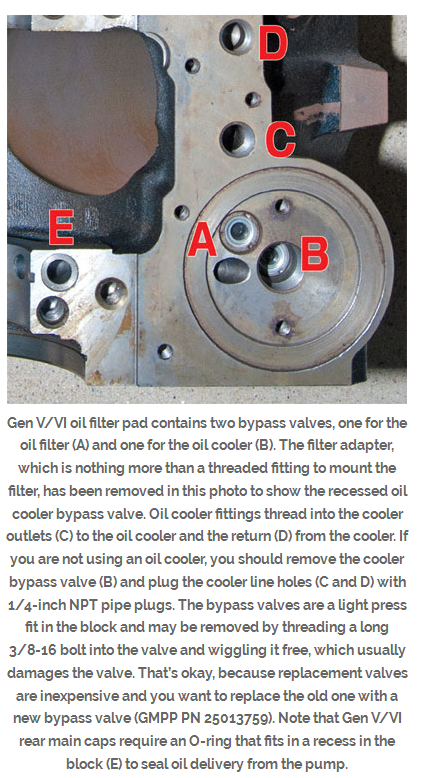

https://www.chevydiy.com/oil-lubrication-systems-guide-big-block-chevy-engines/

Top Seal Install ---

IVE installed some rear seals with the ends offset and some flush, Ive never had one leak in 40 plus years, if you have the seal leak its been my experience looking at engines Ive repaired that about 80% of the leaks are due to improper installation and 20% due to rarely if ever doing oil changes so wear was the root cause of the leak due to sludge in the oil

Be sure the lip seal is positioned leaning inward towards the front of the engine, and the rear seals off-set from the main cap parting line by about 1/4" to reduce the tendency to leak oil

this seal CAN easily be installed backwards - all mating surfaces should be clean and free of oil, but the cranks surface should be lightly oiled to prevent the lip sticking to its surface, a mini- finger tip worth of Vaseline smeared on the crank surface will prevent that

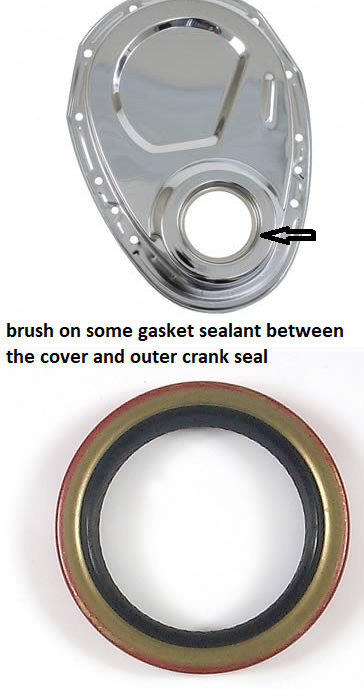

if you have the later one piece rear main seal BBC engine

https://www.summitracing.com/parts/fel-cs8523

sbc rear seal but the BBC is rather similar

(

NOTICE THE DESIGN, and LOCATION,: theres no direct oil pressure, being applied to the rear seal, only oil, mist and blow bye pressure in the oil pan, will exert minimal pressure against the forward facing lip pushing against the lip forcing it to seal against the crank, and lubing the contact point, of the lip so wear is minimized, having a properly functioning PVC and breather combo, helps and having deck plate honed the cylinders and correctly installed the rings limits the crank case pressures)

related info,, read through the threads and sub links

viewtopic.php?f=54&t=206&p=242&hilit=rear+seal#p242

viewtopic.php?f=32&t=474&p=584&hilit=rear+seal#p584

viewtopic.php?f=44&t=805&p=1171&hilit=rear+seal#p1171

http://garage.grumpysperformance.co...hetic-oil-cause-leaky-gaskets.2725/#post-7076

viewtopic.php?f=51&t=1718&p=4257&hilit=rear+seal#p4257

12/13

12/13