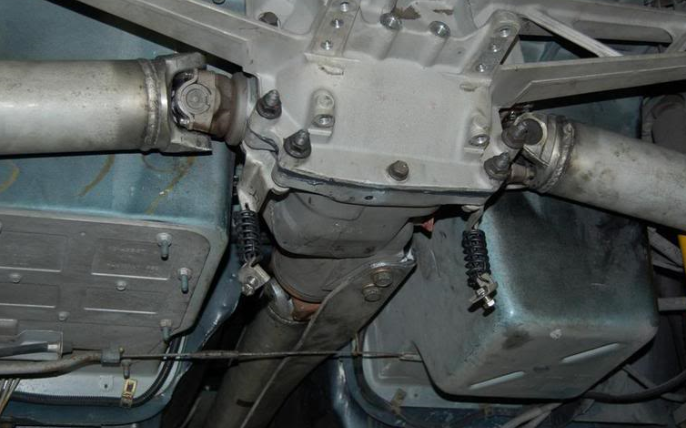

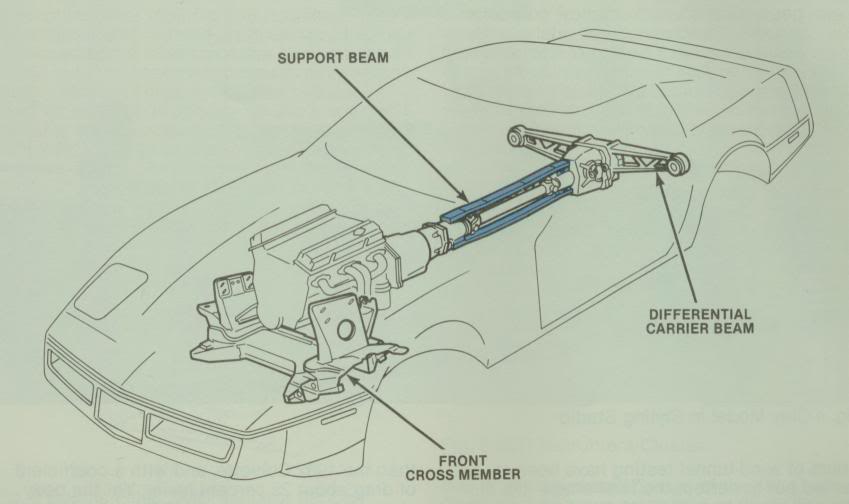

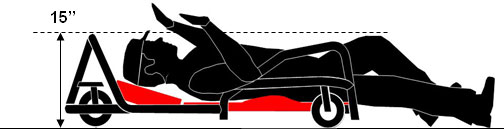

I'm working out some details related to rebuilding my transmission, biggest issues I'm running into is getting the car high enough to use a transmission jack.

Most of the guys I know that have a lift in their garage cannot have the car left for more than a very short period of time so I'm still weighing having the car towed home during the rebuild, and then towed back to have the transmission installed (via flat bed).

For the rebuild kit I'm looking at this:

http://www.ebay.com/itm/171415505977

Then sunshell

http://www.ebay.com/itm/111662857784

Separator plate:

http://www.ebay.com/itm/320730662018

For the bushings I may just buy a tool kit, however it's possible a camshaft bearing tool might do the job.

I also might be able to find a local builder that can swap the bushings out for me.

and then I need to select a torque converter... one thing I'm not totally clear on is how a higher stall will affect highway driving.

say if I install a 2,000 rpm stall and my highway cruise is more like 1,500 rpm will I run into issues ect...

This will be my first transmission rebuild, I did do a valve body on my S10 a few years back, I used the HD separator plate while at it.

it went pretty well overall, the hardest part was keeping track of the metal balls, however with instructions it was pretty easy to find their proper location.

Reading up on the transmission teardown it does not look all that bad, I already have a clutch spring compressor on order, I just need some heavy duty snap ring plyers...