I hope this is where build threads go.

I came up with this after months of (sometimes painful) questions and reading. Mostly from grumpy threads and posts here, and a Facebook group where people set me straight.

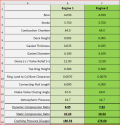

My setup is this for daily street engine, 3200lb 700r4 with air conditioning and brake booster, edelbrock avs2 800. Dual plane intake manifold, edelbrock performer. 2.5 inch collector long tube header with 1 5/8 main pipes, mated to 2.5 inch free flow muffler exhaust.

Dart 200cc SHP Heads

Cam Info (Howard 110245-12)

LSA 112

Intake Centerline 108

Duration at 050 inch Lift:

225 int./231 exh.

Valve Lift: .500 int/.510 exhaust

1.6 Roller Rockers (to get that lift up, it needs to be at 550 for my heads ideally but there is no cam that combines everything I want perfectly)

2800 Stall Converter

12cc dished SpeedPro pistons.

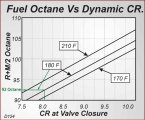

Decked so pistons are .005 in the hole, with a thick gasket to get me the ideal quench for aluminum heads at around 10.2 compression.

This is the kit I am ordering with upgraded 6 inch rods (scat 7/16" stroker clearanced rods ). Internal balance crank plus they balance the rest of the assembly. ARP bolts on everything. Northern is really good about customizing and getting you exactly what you want. With my various upgrades the total will be closer to $1,900. Pistons are the weakest point in the build so I'm going to ask about forged options there, but I really like the 12cc dish size.

www.northernautoparts.com

www.northernautoparts.com

The only thing I haven't picked is my oil pan, oil pump, and water pump because I haven't researched those things yet. I know I'll be beating my oil pan with a hammer for stroker clearance.

I came up with this after months of (sometimes painful) questions and reading. Mostly from grumpy threads and posts here, and a Facebook group where people set me straight.

My setup is this for daily street engine, 3200lb 700r4 with air conditioning and brake booster, edelbrock avs2 800. Dual plane intake manifold, edelbrock performer. 2.5 inch collector long tube header with 1 5/8 main pipes, mated to 2.5 inch free flow muffler exhaust.

Dart 200cc SHP Heads

Cam Info (Howard 110245-12)

LSA 112

Intake Centerline 108

Duration at 050 inch Lift:

225 int./231 exh.

Valve Lift: .500 int/.510 exhaust

1.6 Roller Rockers (to get that lift up, it needs to be at 550 for my heads ideally but there is no cam that combines everything I want perfectly)

2800 Stall Converter

12cc dished SpeedPro pistons.

Decked so pistons are .005 in the hole, with a thick gasket to get me the ideal quench for aluminum heads at around 10.2 compression.

This is the kit I am ordering with upgraded 6 inch rods (scat 7/16" stroker clearanced rods ). Internal balance crank plus they balance the rest of the assembly. ARP bolts on everything. Northern is really good about customizing and getting you exactly what you want. With my various upgrades the total will be closer to $1,900. Pistons are the weakest point in the build so I'm going to ask about forged options there, but I really like the 12cc dish size.

Auto Parts Catalog - Northern Auto Parts

Discover Northern Auto Parts' catalog for a wide range of car parts, including engine rebuild kits. Request your free catalog by mail or browse online.

www.northernautoparts.com

www.northernautoparts.com

The only thing I haven't picked is my oil pan, oil pump, and water pump because I haven't researched those things yet. I know I'll be beating my oil pan with a hammer for stroker clearance.

Last edited: